Professional Documents

Culture Documents

Painting Procedures

Uploaded by

marx0506Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Painting Procedures

Uploaded by

marx0506Copyright:

Available Formats

GENERAL PROCEDURES IN THE APPLICATION OF PAINT

90

FOR CONCRETE SURFACE APPLICATION

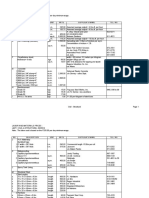

Application On : Interior and Exterior stucco, masonry, bricks and other concrete surfaces. NEW SURFACES 1.) 2.) 3.) Scrape off loose cement, sand, chalk, dust and other surface deposits and contaminants. Mix 1 part by volume SPHERO CONCRETE NEUTRALIZER to 16 parts by volume water. Using a brush or roller, generously apply the mixture onto the surface, ensure that surface is completely wet. Apply uniformly by starting from the top downwards. Let dry overnight before painting. To test if the surface is properly neutralized, test with red litmus or pH paper. If litmus paper turns blue then a second neutralization is necessary, if not, proceed to the next step. If on the other hand a pH paper is used and the color that it changes to corresponds to 6 and below in the standard, this means the acid level is higher than acceptable level, therefore wash the surface thoroughly with water until it reaches a pH of 7 or 8 and let dry before proceeding to the next step. If the change in color corresponds to the values of 9 and above in the standard, this means the surface has high alkalinity level thus a second neutralization is needed and should be left to dry before proceeding to the next step. If the change on the other hand falls in the standard color level, between 7 and 8, this means that the levels are with acceptable standards, let dry thoroughly then proceed to the next step in the Painting system. 4.) 5.) 6.) 7.) 8.) However if treated surface is left exposed for days or is washed down by rain, the effect of the concrete neutralizer may be nullified. In such cases, test with red litmus or pH paper. Generally concrete surfaces take about 28 days or a month to cure, if painting is urgent, a SPHERO ACRYLIC CONCRETE SEALER may be applied. Let dry for 4 hours before applying succeeding coats. Apply SPHERO FLAT LATEX as primer. Dry for 2-4 hours. Repair minor imperfections with SPHERO LATEX CONCRETE PUTTY. Touch dry in 30 mins. to 1 hour then sand. Apply 2 coats of either SPHERO FLAT, SEMI-GLOSS or SPHERO GLOSS LATEX. Tint with SPHERO LATEX ACRY-COLOR to desired color.

FOR OLD OR PREVIOUSLY PAINTED SURFACES 1.) 2.) 3.) Scrape off loose, scaling and peeling old paints. Sand whole surface including those where old paint still adhere to surface. For areas with extreme chalking problems, steel brush, blow air from a compressor or wipe with a clean rag pre-wetted with water. Let dry, then apply 1 coat SPHERO ACRYLIC CONCRETE SEALER. Dry for at least 4 hours before applying subsequent coats. For areas affected by molds and mildews, wipe the whole area with a clean rag with a Chlorox solution. Scrub using a stiff nylon brush then rinse with water. Leave overnight. For areas with mapping problems, properly prepare the surface then apply 1 full coat of SPHERO ACRYLIC CONCRETE SEALER. Dry for at least 4 hours 4.) 5.) 6.) Apply SPHERO FLAT LATEX as primer. Dry for 2-4 hours. Repair minor imperfections with SPHERO LATEX CONCRETE PUTTY. Touch dry in 30 mins. to 1 hour then sand. Apply 2 coats of either SPHERO FLAT, SEMI-GLOSS or SPHERO GLOSS LATEX. Tint with SPHERO LATEX ACRY-COLOR to desired color.

91

FOR WOOD SURFACE APPLICATION

NEW SURFACES 1.) 2.) 3.) 4.) 5.) Surfaces to be painted must be free of oil, dust, grease, wax and old loosely adhering finish, cracking and scaling paint. Sand surface until wood is smooth to the touch and no slivers or roughness remain. Dust off and wipe using a clean rag then apply one coat of SPHERO FLATWALL ENAMEL. Using a putty knife apply SPHERO GLAZING & SPOT PUTTY on wood surface imperfections such as open wood grains, nail heads, dents, scratches, shallow dents, etc. Apply two coats of SPHERO QUICK DRYING ENAMEL PAINT. PREVIOUSLY PAINTED SURFACES 1.) 2.) 3.) 4.) 5.) 6.) 7.) Surfaces to be painted must be free of oil, dust, grease, wax and old loosely adhering finish, cracking and scaling paint or other contaminants. For areas affected by molds and mildews, wipe the whole area with a clean rag with a Chlorox solution. If existing paint is still in good condition, wash the surface with water or with a mild detergent solution to remove surface contaminants. Let dry. Apply 1 or 2 coats of SPHERO QDE. If existing paint condition is poor, strip to bare substrate by sanding or wire-brushing. Then apply 1 coat of SPHERO FLATWALL ENAMEL. Using a putty knife apply SPHERO GLAZING & SPOT PUTTY on wood surface imperfections such as open wood grains, nail heads, dents, scratches, shallow dents, etc. Apply two coats of SPHERO QUICK DRYING ENAMEL PAINT.

FOR METAL SURFACE APPLICATION

NEW SURFACES 1.) Surfaces to be painted must be thoroughly cleaned and free of oil, dust, grease, wax, old loosely adhering finish, cracking and scaling paint by wiping, scraping, sanding, and / or by wire brushing. Ensure removal of grease and oil by use of solvent. Treat surface with SPHERO RUST CONVERTER. Let stand overnight, then wipe off with clean rag soaked in lacquer thinner white residue. Apply with either brush, spray, one (1) or (2) coats of the SPHERO METAL PRIMERS. RED OXIDE, RED LEAD, ZINC CHROMATE or SPHERO PREPA-COAT, ENAMEL PRIMER SURFACER. Apply two coats of SPHERO QUICK DRYING ENAMEL PAINT. PREVIOUSLY PAINTED SURFACES 1.) 2.) 3.) 4.) 5.) 6.) Surfaces to be painted must be thoroughly cleaned and free of oil, dust, grease, wax, old loosely adhering finish, cracking and scaling paint or other contaminants by wiping, scraping, sanding, and / or by wire brushing. Ensure removal of grease and oil by use of solvent. If the existing paint is sound and shows normal chalking, sand lightly and wipe surface dust free. If existing paint shows cracking, alligatoring, peeling or is in generally poor condition, remove by scraping, wire-brushing or sanding. Treat surface with SPHERO RUST CONVERTER. Let stand overnight, then wipe off with clean rag soaked in lacquer thinner white residue. Apply with either brush, spray, one (1) or 2 coats of the SPHERO METAL PRIMERS : RED OXIDE, RED LEAD, ZINC CHROMATE or SPHERO PREPA-COAT ENAMEL PRIMER SURFACER. Apply two coats of SPHERO QUICK DRYING ENAMEL PAINT.

2.) 3.) 4.)

92

PROCEDURES IN THE APPLICATION OF SPECIAL TYPES OF PAINT

93

SPHERO SPHERTEX SOLVENT TEXTURED PAINT

1.) 2.) 3.) PREPARATION Surfaces to be painted must be free of oil, dust grease, wax and old loosely adhering finish, cracking and scaling paint. All cracks and open joints should be sealed. On new concrete surfaces apply SPHERO CONCRETE NEUTRALIZER while wood must be scuff sanded prior to paint application.

APPLICATION For Concrete or Wood, 1.) Apply one (1) coat of SPHERO SPHERTEX PRIMER WHITE. Allow to dry for 4 hours. 2.) For a Textured Finish, use a mortar or splatter gun, apply SPHERO SPHERCAST. Reduce to spraying consistency with SPHERO SPHERTEX REDUCER. Let dry for 5-10 minutes before flattening the rough texture with a metal roller pre-wetted with water. Different textures are achieved depending on nozzle diameter opening and air pressure, the higher the air pressure, the smaller the texture size. For a bigger texture effect, lower the air pressure. 3.) 4.) For a Plain Finish, omit all application procedure for a Textured Finish and proceed to Topcoat Application. Apply the topcoat, using a brush, roller or spray gun, apply 2 coats of white or colored SPHERO SPHERTEX GLOSS or SEMI-GLOSS.

SPHERO V-TEX WATER-BASED TEXTURED PAINT

1.) 2.) 3.) PREPARATION Surfaces to be painted must be free of oil, dust grease, wax and old loosely adhering finish, cracking and scaling paint. All cracks and open joints should be sealed. On new concrete surfaces apply SPHERO CONCRETE NEUTRALIZER while wood must be scuff sanded prior to paint application. APPLICATION For Concrete Surfaces, apply one (1) coat of SPHERO FLAT LATEX WHITE or SPHERTEX PRIMER WHITE. For Wood, apply SPHERO FLATWALL ENAMEL or SPHERO SPHERTEX PRIMER WHITE. Using a standard roller spread SPHERO V-TEX TEXTURED PAINT at even thickness. Using a pattern roller of choice, roll on lightly in one direction with uniform pressure to impress desired texture effect. As topcoat, apply one (1) coat SPHERO FLAT or SEMI-GLOSS or GLOSS LATEX WHITE or colored.

1.) 2.) 3.) 4.) 5.)

SPHERO LACQUER ENAMEL

1.) 2.) 3.) PREPARATION Surfaces to be painted must be thoroughly cleaned and free of oil, dust, and grease, and wax, old loosely adhering finish, cracking and scaling paint by wiping, scraping, and / or by sanding. Ensure removal of grease and oil by use of solvent. Surface must be thoroughly dry prior to primer application. APPLICATION Apply by spray SPHERO LACQUER PRIMER enough to achieve a dry film thickness of 11.5 mils/coat. Sand properly primed surface to rid of surface roughness. Remove sand dust and other loose particles. Apply SPHERO LACQUER GLAZING & SPOT PUTTY on wood surface imperfections such as open wood grains, nail heads, dents, scratches, shallow dents, etc. Touch dry in 15 minutes, sand in 1 hour. If necessary, recoat in 1 hour. If putty becomes stiff due to solvent evaporation, add small amount of SPHERO LACQUER THINNER until ease of application is attained again.

1.) 2.) 3.)

94

4.) 5.)

Apply by spray SPHERO LACQUER ENAMEL. Touch dry in 10 minutes. Recoat in 1 hour to achieve dry film thickness of 1-1.5 mils/coat.

SPHERO LACQUER ENAMEL & AUTOMOTIVE LACQUER

1.) 2.) 3.)

PREPARATION Surfaces to be painted must be thoroughly cleaned and free of oil, dust, and grease, and wax, old loosely adhering finish, cracking and scaling paint by wiping, scraping, and / or by sanding. Ensure removal of grease and oil by use of solvent. Surface must be thoroughly dry prior to primer application. APPLICATION Reduce 1 part SPHERO LACQUER PRIMER to 1 part SPHERO LACQUER THINNER. SPRAY SPHERO LACQUER PRIMER enough to achieve a dry film thickness of 1-1.5 mils/coat. Sand properly primed surface to rid of surface roughness. Remove sand dust and other loose particles. Using a putty knife apply SPHERO LACQUER GLAZING & SPOT PUTTY on wood surface imperfections such as open wood grains, nail heads, dents, scratches, shallow dents, etc. Touch dry in 15 minutes, sand in 1 hour. If necessary, recoat in 1 hour. If putty becomes stiff due to solvent evaporation, add small amount of SPHERO LACQUER THINNER until ease of application is attained again. Apply by spray SPHERO AUTOMOTIVE LACQUER. Touch dry in 10 minutes. Recoat in 1 hour to achieve dry film thickness of 1-1.5 mils/coat.

1.) 2.) 3.) 4.)

5.) 6.)

SPHERO EPOXY PRODUCTS

PREPARATION Surfaces to be painted must be thoroughly cleaned and free of oil, dust, and grease, and wax, old loosely adhering finish, cracking and scaling paint by wiping, scraping, and / or by sanding. Ensure removal of grease and oil by use of solvent. Surface must be thoroughly dry prior to primer application.

1.) 2.) 3.)

APPLICATION SPHERO EPOXY PRIMER / ENAMEL 1.) 2.) With brush, roller, or spray, apply 1 or 2 coats of SPHERO EPOXY PRIMER. If needed recoat after 6 hours. As topcoat, apply 2 coats of SPHERO EPOXY ENAMEL, Chlorinated Rubber, Acrylic, or Lacquer paints. Touch dry in 1-2 hours, recoat in 4-6 hours. Hard Dry in 24 hours. Full cure 7 days.

SPHERO EPOXY FLOOR COATING 1.) 2.) With brush, roller, or spray, apply 1 or 2 coats of SPHERO EPOXY FC SEALER. As topcoat, apply 2 coats of SPHERO EPOXY FLOOR COATING. Recoat after 4-6 hours. Hard Dry in 24 hours. Full cure in 7 days.

SPHERO EPOXY SOLVENTLESS SL FINISH 1.) 2.) With brush or roller, apply 1 or 2 coats of SPHERO EPOXY HD SEALER, for a Plain Floor Coat System. As topcoat, apply 2 coats of SPHERO EPOXY SOLVENTLESS SL FINISH. Allow overnight intercoating interval. Hard Dry for light human traffic in 72 hours. Full Cure in 7 days.

95

TROUBLE SHOOTING TIPS FOR COMMON PAINT FAILURES

96

Understanding the primary causes of paint failures will help you prevent future paint problems. The primary causes of paint failures are moisture, inadequate surface prep, the improper application of paints, the Sun, and weathering. You should be aware that most paint failures are related to moisture and inadequate surface preparation. Some of the more common paint failures are listed below in alphabetical order with recommendations for their prevention. ALLIGATORING is cracked paint that resembles alligator skin, and is generally found on wood surfaces. Alligatoring occurs when paint can not adhere to a glossy surface, when a second coat of paint is applied over an inadequately dried first coat of paint, weather aging, excessive coats of paint, or when the finish coat expands and contracts at a greater extent that any underlying coats. Paint must be completely removed when alligatoring has occurred to ensure an even and uniform finish. Wood surfaces should be primed with a top quality alkyd primer and acrylic latex finish. BLEEDING is an unsightly surface discolouration commonly found on exterior wood surfaces and hardboard siding, ceilings, repainted wallpaper, or when light coloured paint is applied over dark coloured paint. The causes of bleeding are moisture and water soluble dyes located within wood surfaces and wallpaper, and inadequate priming of surfaces. Bleeding on hardboard siding is caused by wax. The removal of any excessive water source is essential before any surface preparation can be completed. Exterior wood surfaces should be primed with top quality alkyd based primers and finished with top quality acrylic latex paints. Interior surfaces should be primed with either a top quality alkyd based or acrylic latex based stain blocking primer, and finished with a top quality acrylic latex finish paint. BLISTERING Fresh paint applied in direct sunlight, and moisture, causes paint to blister. Surfaces that are heated by the Sun and become hot can prematurely dry new paint, causing blistering. This is more common with dark or dramatic colours because they, in addition to surfaces, absorb heat. Heat blistering will have a layer of paint under the blister if the surface is being repainted. Trapped moisture in walls or behind surfaces will eventually try to escape through painted surfaces, also causing blistering. Moisture blistering will reveal a bare surface under the blister. Blistering surfaces should be scraped and sanded smooth, primed with a top quality alkyd or acrylic latex primer, and finished with a top quality acrylic latex finish paint. If moisture blistering occurs on a repainted surface, spot priming of bare spots will be necessary to ensure a uniform and even finish before the final priming and painting is completed. CHALKING is the weathered powder found on exterior painted surfaces and is a normal way for paint to weather away. However, premature chalking can be caused by inadequate priming or thin paint. Homeowners should be aware that chalking on siding located above masonry will run during rainy weather causing the masonry to stain. Once a chalked surfaced is pressured washed clean and prepared for painting, one coat of a top quality alkyd primer and one coat of a top quality acrylic latex finish paint is highly recommended for the prevention of future excess chalking. CHECKING AND CRACKING Checking is an early form of cracking and occurs when paint begins to loose elasticity, forming narrow breaks on the painted surface. These breaks later swell and become cracks. Checking and cracking are found on wood surfaces with multiple layers of paint, or plywood. Checked or cracked paint should be completely removed from surfaces before repainting. Properly prepared wood surfaces should be primed with a top quality alkyd primer and finished with a top quality acrylic latex finish paint. EFFLORESCENCE is a white salty substance that forms on masonry and plaster due to moisture migrating through the surface. If left untreated for long periods of time, it will become hard and crusty. Any source of excessive moisture must be eliminated and the surface must be cleaned by scraping or wire brushing, and surfaces must be repaired where applicable before priming and painting. Surfaces can be painted with top quality alkyd or acrylic latex based primers and paints that are alkaline resistant.

97

FADING is caused by the natural weathering due to the ultraviolet rays of the Sun. Chalking pigment, alkali from masonry, and tint intended for interior based paints but used on exterior surfaces, will cause paint to fade prematurely. HATBANDING is caused by the over cutting in of interior walls, ceilings , and trim corners, and the use of excessively long roller naps. It occurs when wet paint is applied over dry paint. Hatbanding is very noticeable with dark and dramatic interior colours and sheens. Using small nap rollers and applying a thin brush coat of paint will help eliminate hatbanding. LAP MARKS are due to the inadequate application of coatings. They are mostly seen on exterior surfaces. If a homeowner or contractor is brush painting siding, the paint must be applied horizontally from one end to the other without stopping. If the homeowner or contractor stops in the middle or the paint dries to fast, when the application of the paint to the surface is continued, a lap mark forms where the paint overlapped. This is a major reason why coatings should never be applied in direct sunlight. Coatings should be applied in shady area's in warm months and homeowners and contractors should stay ahead of the Sun in cooler months. Staying ahead of the Sun will allow it to come around and dry the area most recently painted. MILDEW is a fungus that grows best in a warm humid climate and is often found in shaded area's, but not limited to shaded area's. Mildew can appear in a variety of colours and prefers painted surfaces because of the nutrients that paints provide. These same nutrients float through the air and land on painted surfaces and become food. Mildew grows faster on flat surfaces than on glossy surfaces, and is attracted to linseed oil based products that contain no mildewcide. Most paints and stains come already made with mildewcide included. However, mildewcide can be added to paints and stains that do not contain one. Mildew can be effectively cleaned with a 3 to 1 ratio of water to bleach. A much stronger solution maybe necessary in extreme cases of neglect. Proper surface preparation and cleaning are crucial for mildew prevention, in addition to using a top quality primer and acrylic latex finish paint. Acrylic latex finish paints are the most mildew resistant. Painting contractors who perform quality surface preparation and painting are a homeowners best ally in preventing the growth of mildew. PEELING occurs on a variety of surfaces and is directly linked to moisture and inadequate surface preparation. Understanding different surfaces and how they react to moisture and coatings will greatly reduce the risk of this common paint problem. RUSTING occurs when metal is exposed to moisture and oxygen. Any metal surfaces should be completely sealed with a rust inhibited primer. If rust appears through painted surfaces, it should be wire brushed to bare metal, or treated with a coating that will harden it. Two coats of a top quality rust inhibited alkyd or acrylic latex primer should be applied to metal surfaces once the rust is treated or wire brushed away. Rusty nails that bleed through surfaces should be reset, coated with a top quality rust inhibited primer, caulked, primed, and painted with top quality coatings. SAGGING AND RUNNING can occur when paint is applied over glossy surfaces, excessive thinning, too much paint, or paint being applied to a dirty surface. Proper application of paints and surface preparation will eliminate sags and runs. WRINKLING is caused when thick paint is not brushed out and the under part remains wet, but the surface layer dries. Avoid covering surfaces with one thick coat when two are required.

98

PAINTING SAFETY TIPS

Although most paints are generally safe to work with, you should take extra precaution to ensure there are no unnecessary accidents. Here are some general safety tips to follow when painting. 1. Make sure to properly ventilate the area. Try to keep all doors and windows open. Also, try and setup some exhaust fans and keep all pets out of the area. If you are unable to properly ventilate the area, make sure to wear a respiratory mask and take frequent fresh air breaks. If your painting requires you to do some sanding, make sure to wear a dusk mask and safety goggles. Cover the floor of your work area. Use a canvas drop cloth. These work better than plastic because they are not as slippery. Wet paint can become dangerous at high temperatures. Don't paint or store your paints near a source of heat or fire and do not smoke while painting! If your project requires you to use a ladder, make sure to properly inspect it before use. It's important to make sure all legs of the ladder stand squarely on the ground to ensure sturdiness. Also make sure that the cross bars are locked into place. When using the ladder, never step on the top step and never lean away from the ladder. It's much safer to get off the ladder and move it, then try to reach and risk falling. Once you're done with your painting project, make sure to dispose of your supplies the right way. Many paints and supplies are toxic and need to be disposed of at a toxic-waste dump. Make sure to check the label and follow all manufacturer's instructions.

2. 3. 4. 5.

6. 7.

99

GLOSSARY OF TERMS

100

The following glossary contains terms used commonly in the paint and coatings industry to describe the characteristics, usage and components of paints and coatings. ABATEMENT Involves either removal of the painted surface, covering the painted surface with an impermeable surface, or covering surface with heavy-duty coating (encapsulant). ACRYLIC A synthetic resin used in high-performance water-based coatings. A coating in which the binder contains acrylic resins. ADHESION The ability of dry paint to attach to and remain fixed on the surface without blistering, flaking, cracking or being removed by tape. AEROSOL A product that uses compressed gas to spray the coating from its container. AIR CURE One method by which liquid coatings cure to a dry film. Oxygen from the air enters the film and cross-links the resin molecules. Also called "Air Dry" and "Oxidizing." ALKYD Synthetic resin modified with oil. Coating that contains alkyd resins in the binder. AMIDE A functional group which can act as an epoxy resin curing agent. ANTI-FOULING PAINT Paints formulated especially for boat hulls, docks and other below-waterline surfaces and structures to prevent the growth of barnacles and other organisms on ships' bottoms. BINDER Solid ingredients in a coating that hold the pigment particles in suspension and attach them to the substrate. Consists of resins (e.g., oils, alkyd, latex). The nature and amount of binder determine many of the paint's performance properties--washability, toughness, adhesion, color retention, etc. BLISTERING Formation of dome-shaped projections in paints or varnish films resulting from local loss of adhesion and lifting of the film from the underlying surface. BODY The thickness or viscosity of a fluid. BOILED OIL Linseed (sometimes soya) oil that was formerly heated for faster drying. Today, chemical agents are added to speed up the drying process. BUTADIENE A gas which is chemically combined with styrene to create a resin used in latex binders, styrene-butadiene. CATALYST Substance whose presence increases the rate of a chemical reaction, e.g., acid catalyst added to an epoxy resin system to accelerate drying time. CHALKING Formation of a powder on the surface of a paint film caused by disintegration of the binder during weathering. Can be affected by the choice of pigment or binder. CHROMA A measurement of color. The degree of saturation of a hue. A color at its full intensity has maximum chroma. CLEAR COATING A transparent protective and/or decorative film; generally the final coat of sealer applied to automotive finishes. COALESCENT AID The small amount of solvent contained in latex coatings. Not a true solvent since it does not actually dissolve the latex resins, the coalescent aid helps the latex resins flow together, aiding in film formation.

101

COATING A paint, varnish, lacquer or other finish used to create a protective and/or decorative layer. Generally used to refer to paints and coatings applied in an industrial setting as part of the original equipment manufacturer's (OEM) process. COHESION A bonding together of a single substance to itself. Internal adhesion. COLORANT Concentrated color (dyes or pigments) that can be added to paints to make specific colors. COLORFAST Non-fading in prolonged exposure to light. COLOR RETENTION The ability of paint to keep its original color. Major threats to color retention are exposure to ultraviolet radiation and abrasion by weather or repeated cleaning. CORROSION INHIBITIVE A type of metal paint or primer that prevents rust by preventing moisture from reaching the metal. Zinc phosphate, barium metaborate and strontium chromate (all pigments) are common ingredients in corrosion-inhibitive coatings. These pigments absorb any moisture that enters the paint film. CREOSOTE A liquid coating made from coal tar once used as a wood preservative. It has been banned for consumer use because of potential health risks. CURE, CURING The process whereby a liquid coating becomes a hard film. DEAD FLAT No gloss or sheen. DILUENT A liquid used in coatings to reduce the consistency and make a coating flow more easily. The water in latex coatings is a diluent. A diluent may also be called a "Reducer," "Thinner," "Reducing Agent" or "Reducing Solvent." DRIERS Various compounds added to coatings to speed the drying. DRY COLORS Powder-type colors to be mixed with water, alcohol or mineral spirits and resin to form a paint or stain. DRYING OIL An oil that when exposed to air will dry to a solid through chemical reaction with air: linseed oil, tung oil, perilla, fish oil, soybean oil. EARTH PIGMENTS Those pigments that are obtained from the earth, including barytes, ochre, chalk and graphite. EGGSHELL Gloss lying between semigloss and flat. EMULSION A mixture of solids suspended in a liquid. EMULSION PAINT Coating in which resins are suspended in water, then flow together with the aid of an emulsifier. Example: latex paint. ENAMEL Broad classification of paints that dry to a hard, usually glossy finish. Most equipmentcoating enamels require baking. Enamels for walls do not. EPOXY Extremely tough and durable synthetic resin used in some coatings. Epoxy coatings are extremely tough, durable and highly resistant to chemicals, abrasion, moisture and alcohol.

102

EXTENDER Ingredients added to paint to increase coverage, reduce cost, achieve durability, alter appearance, control rheology and influence other desirable properties. Less expensive than prime hiding pigments such as titanium dioxide. Examples: barium sulphate, calcium carbonate, clay, gypsum, silica, talc. May also improve coating performance. FILM BUILD Amount of thickness produced in an application. Millimeters (mils) of dry film per mils of applied wet film. FILM THICKNESS Depth or thickness of the dry coating in millimeters. FIRE RESISTANCE The ability of a coating to withstand fire or to protect the substrate to which it is applied from fire damage. FIRE RETARDANT A coating which will (1) reduce flame spread, (2) resist ignition when exposed to high temperature or (3) insulate the substrate and delay damage to the substrate. FLAT A surface that scatters or absorbs the light falling on it so as to be substantially free from gloss or sheen (0-15 gloss on a 60-degree gloss meter). FORCED DRY Baking the paint between room temperature and 150 F to speed the drying process. GALVANIZING Process in which a thin coating of zinc is applied to iron or steel to prevent rust. GLOSS The luster or shininess of paints and coatings. Different types of gloss are frequently arbitrarily differentiated, such as sheen, distinctness-of-image gloss, etc. Trade practice recognizes the following gloss levels, in increasing order of gloss: flat (or matte)-- practically free from sheen, even when viewed from oblique angles (usually less than 15 on 60-degree meter); eggshell-- usually 20-35 on 60-degree meter; semi-gloss--usually 35-70 on 60-degree meter; fullgloss--smooth and almost mirror-like surface when viewed from all angles, usually above 70 on 60degree meter. GLOSS METER A device for measuring the light reflectance of coatings. Different brands with the same description (such as semi-gloss or flat) may have quite different ratings on the gloss meter. HARDENER Curing agent for epoxies or fiberglass. INERT A material that will not react chemically with other ingredients. LACQUER A fast-drying usually clear coating that is highly flammable and dries by solvent evaporation only. Can be reconstituted after drying by adding solvent. LATEX-BASED PAINT General term used for water-based emulsion paints made with synthetic binders such as 100% acrylic, vinyl acrylic, terpolymer or styrene acrylic. A stable emulsion of polymers and pigment in water. LEAD A metal, previously used as a pigment in paints. Discontinued in the early 1950s by industry consensus standard, and banned by the Consumer Products Safety Commission in 1978 because of its toxicity. LINSEED OIL Drying oil made from the flax seed. Used as a solvent in many oil- based paints. "Boiled" linseed oil can be used to protect wood from water damage. Sometimes used as a furniture polish. LIQUID DRIERS Solution of soluble driers in organic solvents.

103

MARINE PAINT Coating specially designed for immersion in water and exposure to marine atmosphere. MATERIAL SAFETY DATA SHEET (MSDS) Information sheet that lists any hazardous substance that comprises one percent or more of the product's total volume. Also lists procedures to follow in the event of fire, explosion, leak or exposure to hazardous substance by inhalation, ingestion or contact with skin or eyes. Coatings manufacturers are required to provide retailers with an MSDS for every product they sell to the retailer. Sales clerks should make MSDSs available to retail customers. MINERAL SPIRITS Paint thinner. Solvent distilled from petroleum. MONOMER Substance composed of low molecular weight molecules capable of reacting with like or unlike molecules to form a polymer. NAPHTHA A petroleum distillate used mostly by professionals (as opposed to do-it- yourself painters) for cleanup and to thin solvent-based coatings. A volatile organic compound (see VOC). NATURAL RESINS Resins from trees, plants, fish and insects. Examples: damars, copals. NONVOLATILE The portion of a coating left after the solvent evaporates; sometimes called the solids content. OIL PAINT A paint that contains drying oil, oil varnish or oil-modified resin as the film-forming ingredient. The term is commonly and incorrectly used to refer to any paint soluble by organic solvents. OLEORESIN A natural plant product that contains oil and resins. Turpentine is an example. OXIDATION Chemical reaction upon exposure to oxygen. Some coatings cure by oxidation, when oxygen enters the liquid coating and cross-links the resin molecules. This film-forming method is also called "Air Cure" and "Air Dry." (Oxidation also causes rust on bare metals.) PAINT A coating including resin, a solvent, additives, pigments and, in some products, a diluent. Paints are generally opaque, and commonly represent the portion of the industry known as "architectural coatings." PAINT REMOVER A chemical that softens old paint or varnish and permits it to be easily scraped off. Also called "stripper." PENETRATING FINISH A finish that sinks into the substrate, as opposed to settling on the surface. PIGMENT Insoluble, finely ground materials that give paint its properties of color and hide. Titanium dioxide is the most important pigment used to provide hiding in paint. Other pigments include anatase titanium, barium metaborate, barium sulphate, burnt sienna, burnt umber, carbon black, China clay, chromium oxide, iron oxide, lead carbonate, strontium chromate, Tuscan red, zinc oxide, zinc phosphate and zinc sulfide. POLYMER Substance, the molecules of which consist of one or more structural units repeated any number of times; vinyl resins are examples of true polymers. POLYMERIZATION The interlocking of molecules by chemical reaction to produce very large molecules. The process of making plastics and plastic-based resins. POLYVINYL CHLORIDE A synthetic resin used in the binders of coatings. Tends to discolor under exposure to ultraviolet radiation. Commonly called "vinyl."

104

PRIMER First complete coat of paint of a painting system applied to a surface. Such paints are designed to provide adequate adhesion to new surfaces or are formulated to meet the special requirements of the surfaces. PROPELLANT The gas used to expel materials from aerosol containers. RESIN Synthetic or natural material used as the binder in coatings. Can be translucent or transparent, solid or semi-solid. Examples: acrylic, alkyd, copal ester, epoxy, polyurethane, polyvinyl chloride, silicone. SEMI-GLOSS FINISH Finish that has a low luster sheen. Semi-gloss paints are formulated to give this result (usually 35-70 degrees on a 60-degree meter). SILICONE A resin used in the binders of coatings. Also used as an additive to provide specific properties, e.g., defoamer. Paints containing silicone are very slick and resist dirt, graffiti and bacterial growth, and are stable in high heat. SOLIDS The part of the coating that remains on a surface after the vehicle has evaporated. The dried paint film. Also called Nonvolatile. SOLVENT Any liquid which can dissolve a resin. Generally refers to the liquid portion of paints and coatings that evaporates as the coating dries. SPECULAR GLOSS Mirror-like finish (usually 60 degrees on a 60-degree meter). Substrate: Any surface to which a coating is applied. TITANIUM DIOXIDE White pigment in virtually all white paints. Prime hiding pigment in most paints. TURPENTINE Distilled pine oil, used as a cleaner, solvent or thinner for oil-based and alkyd coatings. URETHANE An important resin in the coatings industry. A true urethane coating is a twocomponent product that cures when an isocyanate (the catalyst) prompts a chemical reaction that unites the components. VEHICLE Portion of a coating that includes all liquids and the binder. The vehicle and the pigment are the two basic components of paint. VISCOSITY The property of a fluid whereby it tends to resist relative motion within itself. VOC See Volatile Organic Compound VOLATILITY The defining quality of a liquid that evaporates quickly when exposed to air. Volatile Organic Compound: Organic chemicals and petrochemicals that emit vapors while evaporating. In paints, VOC generally refers to the solvent portion of the paint which, when it evaporates, results in the formation of paint film on the substrate to which it was applied. VOLUME SOLIDS Solid ingredients as a percentage of total ingredients. The volume of pigment plus binder divided by the total volume, expressed as a percent. High-volume solids mean a thicker dry film with improved durability. WATER-BASED Coatings in which the majority of the liquid content is water. WHITE LEAD Lead carbonate

105

You might also like

- PAINTSDocument42 pagesPAINTSKib-anne Miguel PasikanNo ratings yet

- Asian Paints Tractor EmulsionDocument2 pagesAsian Paints Tractor EmulsionAsian PaintsNo ratings yet

- Section 1500: Fig. 1400-D-48 Fig. 1400-D-49Document26 pagesSection 1500: Fig. 1400-D-48 Fig. 1400-D-49Anthony Thaddeus AntonioNo ratings yet

- Paint Defects and RemediesDocument27 pagesPaint Defects and RemediesDanna Faye ValoisNo ratings yet

- Thermal Spray Coating For Steel ProcessingDocument5 pagesThermal Spray Coating For Steel ProcessingRamkiyengarNo ratings yet

- HP TouchSmart Elite 7320 All-in-One PC Product Specifications - HP® Customer SupportDocument11 pagesHP TouchSmart Elite 7320 All-in-One PC Product Specifications - HP® Customer Supportrca ieftinNo ratings yet

- Car Paint InvoiceDocument1 pageCar Paint InvoiceKaushal GangradeNo ratings yet

- Paint Products and Finish ProductsDocument17 pagesPaint Products and Finish ProductsSheree LabeNo ratings yet

- TDS Epoxy Zinc Phosphate Primer HB 50 GreyDocument3 pagesTDS Epoxy Zinc Phosphate Primer HB 50 GreySAlman Khan50% (2)

- Construction PaintingDocument21 pagesConstruction Paintingjack.simpson.changNo ratings yet

- Air Gun SprayingDocument5 pagesAir Gun SprayingJohn BrittoNo ratings yet

- Epoxy Resin Kit User Guide2Document17 pagesEpoxy Resin Kit User Guide2Goparking SpofreetinfoNo ratings yet

- Geometry Area ProjectDocument6 pagesGeometry Area Projectapi-219147077No ratings yet

- Stucco Italiano - Venetian PlastersDocument37 pagesStucco Italiano - Venetian PlastersClara PolistenaNo ratings yet

- Car PaintingDocument16 pagesCar PaintingAnonymous pC9nprsSFaNo ratings yet

- Caliber SOP Guidelines - 3M & Akzo - Final PDFDocument43 pagesCaliber SOP Guidelines - 3M & Akzo - Final PDFAnonymous ZNIVWABX1No ratings yet

- Car Paint MaterialDocument1 pageCar Paint MaterialAbriel HaqqaniNo ratings yet

- 5 Things Surface Prep 1Document40 pages5 Things Surface Prep 1Jesus De la RosaNo ratings yet

- Thermal Spray Procedures For OHT Cage - Bearing PDFDocument12 pagesThermal Spray Procedures For OHT Cage - Bearing PDFalan gonzalezNo ratings yet

- Deck Manual PDFDocument27 pagesDeck Manual PDFly piseth100% (1)

- STANDARD AUDIO TESTS: POWER OUTPUT AND DISTORTION MEASUREMENTSDocument23 pagesSTANDARD AUDIO TESTS: POWER OUTPUT AND DISTORTION MEASUREMENTSbiotekyNo ratings yet

- Crate FXT 65 FXT 120 07S194 SchematicsDocument2 pagesCrate FXT 65 FXT 120 07S194 SchematicsYayan JosephNo ratings yet

- Reference Manual: ENGLISH (1 - 55)Document60 pagesReference Manual: ENGLISH (1 - 55)Anonymous stoudVe3rNNo ratings yet

- Manual de Partes Honda EliteDocument117 pagesManual de Partes Honda EliteJohan MariñoNo ratings yet

- Alpha One Gen2 InstallationDocument1 pageAlpha One Gen2 InstallationNeo ZaoNo ratings yet

- Estimating How Much Paint To BuyDocument7 pagesEstimating How Much Paint To BuyZhardei Alyson NaranjoNo ratings yet

- Marshall JMP-1 mods from French articleDocument8 pagesMarshall JMP-1 mods from French articlecesarin1968No ratings yet

- How To Paint MDF To A Mirror Finish Worklog - Shoryuken PDFDocument28 pagesHow To Paint MDF To A Mirror Finish Worklog - Shoryuken PDFB100% (1)

- 2005 Scion SMGDocument32 pages2005 Scion SMGAaron Hedlund50% (2)

- Intro To Casting!Document12 pagesIntro To Casting!api-443709779No ratings yet

- ViktorDocument140 pagesViktorDani Sherlock100% (1)

- Zinc Nickel Electroplating Guide ZyliteDocument9 pagesZinc Nickel Electroplating Guide ZyliteBryan DixNo ratings yet

- Typical Phase Inverter/Driver Circuit With Post Master Volume ControlDocument1 pageTypical Phase Inverter/Driver Circuit With Post Master Volume ControlFrank L. BaumNo ratings yet

- Modern Painting Processes at Our Poznań PlantDocument4 pagesModern Painting Processes at Our Poznań PlantlingayasNo ratings yet

- Types of PaintsDocument2 pagesTypes of PaintsmariyaNo ratings yet

- A Mod For The Fender Blues JR.: First ImpressionsDocument2 pagesA Mod For The Fender Blues JR.: First ImpressionsErika PetersonNo ratings yet

- Reflections Coating GuideDocument3 pagesReflections Coating GuideZaheer AhamedNo ratings yet

- DIY Active Subwoofer Build With Integrated AmplifiDocument18 pagesDIY Active Subwoofer Build With Integrated AmplifiDavid HernandezNo ratings yet

- Carbon Fibre Skinning Starter KitDocument8 pagesCarbon Fibre Skinning Starter KitcraigbonnymanNo ratings yet

- D C B A F E Distortion Channel: ©2007 LOUD Technologies Inc. All Rights Re Served PWA Guitar Amplifi Er PCB SchematicsDocument3 pagesD C B A F E Distortion Channel: ©2007 LOUD Technologies Inc. All Rights Re Served PWA Guitar Amplifi Er PCB Schematicsgearhead1No ratings yet

- NATIONAL Brake Disc Catalogue Jul2011Document214 pagesNATIONAL Brake Disc Catalogue Jul2011virziNo ratings yet

- CMTDocument37 pagesCMTVennela VasupilliNo ratings yet

- Label Welding DefectsDocument54 pagesLabel Welding DefectsMuthuKumarNo ratings yet

- Avhp 2300 DVDDocument172 pagesAvhp 2300 DVDduver barreraNo ratings yet

- Carbomastic 15: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbomastic 15: Selection & Specification Data Substrates & Surface PreparationMarcos MacaiaNo ratings yet

- SSPC Pa1 PDFDocument14 pagesSSPC Pa1 PDFAnonymous zia5og7psNo ratings yet

- Types of PlastersDocument21 pagesTypes of PlastersShivam RavalNo ratings yet

- Hitachi Washing MachineDocument2 pagesHitachi Washing MachineAromaro AmarNo ratings yet

- Acura DA Seat Foam Repair1Document6 pagesAcura DA Seat Foam Repair1ocdank19806116No ratings yet

- Wood Finishing - Wikipedia PDFDocument62 pagesWood Finishing - Wikipedia PDFJitendra MoreNo ratings yet

- Troubleshooting Refinish ProblemsDocument64 pagesTroubleshooting Refinish ProblemsJosé CalçãoNo ratings yet

- Paint Defect Troubleshooting Guide PDFDocument16 pagesPaint Defect Troubleshooting Guide PDFRavi KhoseNo ratings yet

- Comparison of Water and Oil PaintsDocument16 pagesComparison of Water and Oil PaintsMg H100% (1)

- How To Polish MetalDocument9 pagesHow To Polish Metaldecio ventura rodrigues miraNo ratings yet

- 03 Surfaces PreparationDocument7 pages03 Surfaces PreparationjuliopanNo ratings yet

- Epifanes System Guide - WebDocument60 pagesEpifanes System Guide - WebpagliasoNo ratings yet

- French Wash Specification v7Document7 pagesFrench Wash Specification v7Filip MNo ratings yet

- Asian Paints Royale Play MetallicsDocument2 pagesAsian Paints Royale Play MetallicsAsian Paints100% (1)

- Interior Wall Finishes Emulsion GuideDocument2 pagesInterior Wall Finishes Emulsion GuideArunNo ratings yet

- Zinsser BrouchureDocument2 pagesZinsser Brouchureislandboy33333No ratings yet

- Payments on disputed sums risks minimizedDocument3 pagesPayments on disputed sums risks minimizedmarx0506No ratings yet

- Cost Consultant - Designing Buildings WikiDocument4 pagesCost Consultant - Designing Buildings Wikimarx0506No ratings yet

- Building Fire Safety SAMFSDocument2 pagesBuilding Fire Safety SAMFSmarx0506No ratings yet

- Tender Analysis and RecommendationsDocument18 pagesTender Analysis and Recommendationsmarx0506No ratings yet

- Additional PreliminariesDocument2 pagesAdditional Preliminariesmarx0506No ratings yet

- Priced Bill of Quantities - Designing Buildings WikiDocument4 pagesPriced Bill of Quantities - Designing Buildings Wikimarx0506No ratings yet

- Priced Bill of Quantities - Designing Buildings WikiDocument4 pagesPriced Bill of Quantities - Designing Buildings Wikimarx0506No ratings yet

- Piotr Nowaczyk FIDICDocument32 pagesPiotr Nowaczyk FIDICmarx0506No ratings yet

- Change Order For Construction Contracts - Designing Buildings WikiDocument4 pagesChange Order For Construction Contracts - Designing Buildings Wikimarx0506100% (1)

- Earned Value Management TopicsDocument10 pagesEarned Value Management Topicsmarx0506No ratings yet

- Final Certificate For Construction Contracts - Designing Buildings WikiDocument4 pagesFinal Certificate For Construction Contracts - Designing Buildings Wikimarx0506No ratings yet

- Understanding Liquidated Damages ClausesDocument4 pagesUnderstanding Liquidated Damages Clausesmarx0506100% (1)

- Architect's Instruction - Designing Buildings WikiDocument4 pagesArchitect's Instruction - Designing Buildings Wikimarx0506100% (1)

- Procurement PDFDocument8 pagesProcurement PDFmarx0506No ratings yet

- Construction Contract - Designing Buildings WikiDocument4 pagesConstruction Contract - Designing Buildings Wikimarx0506No ratings yet

- E Procurement PDFDocument3 pagesE Procurement PDFmarx0506No ratings yet

- Provisional Sum - Designing Buildings WikiDocument4 pagesProvisional Sum - Designing Buildings Wikimarx0506No ratings yet

- Provisional Sum EOT ClaimsDocument5 pagesProvisional Sum EOT Claimsmarx0506No ratings yet

- Latent DefectDocument2 pagesLatent Defectmarx0506No ratings yet

- Understanding Liquidated Damages ClausesDocument4 pagesUnderstanding Liquidated Damages Clausesmarx0506100% (1)

- Construction Contracts Checklist enDocument15 pagesConstruction Contracts Checklist enmarx0506No ratings yet

- Understanding Liquidated Damages ClausesDocument4 pagesUnderstanding Liquidated Damages Clausesmarx0506100% (1)

- Latent DefectDocument2 pagesLatent Defectmarx0506No ratings yet

- New FIDIC - Checklist & GuidelinesDocument45 pagesNew FIDIC - Checklist & Guidelinesb16579% (14)

- FIDICDocument2 pagesFIDICmarx0506No ratings yet

- Extension of Time and Liquidated DamagesDocument19 pagesExtension of Time and Liquidated DamagesWan Hakim Wan YaacobNo ratings yet

- BCCD Fact Sheet2014Document2 pagesBCCD Fact Sheet2014marx05060% (1)

- SCSI Guide To Life Cycle CostingDocument23 pagesSCSI Guide To Life Cycle Costingmarx0506100% (1)

- Paint PDFDocument293 pagesPaint PDFmohanNo ratings yet

- Gee13d T Midterm Art Critism Bamuya Charles T Bscesep3bDocument3 pagesGee13d T Midterm Art Critism Bamuya Charles T Bscesep3bRowena SolomonNo ratings yet

- Architectural Thought The Design Process and and The Expectant Eye - Compressed (2) (083-100)Document18 pagesArchitectural Thought The Design Process and and The Expectant Eye - Compressed (2) (083-100)Nuraliya PurbaNo ratings yet

- Stan Brakhage's Rejection of Language in FilmDocument5 pagesStan Brakhage's Rejection of Language in FilmKHÁNH NGUYỄN VĂNNo ratings yet

- 'Sensitive Plates' and 'Sentimental Keepsakes' The Social Life of Reverse Glass Painting - From Canton To LeidenDocument17 pages'Sensitive Plates' and 'Sentimental Keepsakes' The Social Life of Reverse Glass Painting - From Canton To LeidenFKG AbuduresitiNo ratings yet

- Sở Giáo Dục Và Đạo Tạo Tỉnh Đắk Lắk Trường Ptdtnt Tây NguyênDocument13 pagesSở Giáo Dục Và Đạo Tạo Tỉnh Đắk Lắk Trường Ptdtnt Tây NguyênMila Tran LeNo ratings yet

- Group 4Document26 pagesGroup 4Blee TecsonNo ratings yet

- Portrait Painting From Photograph - Colorful WatercolorDocument3 pagesPortrait Painting From Photograph - Colorful WatercolorAlejandro ZozorangaNo ratings yet

- Paint Color Mixing GuideDocument1 pagePaint Color Mixing GuideAbhay AswalNo ratings yet

- ARTS10 - q1 - Mod1 - Principles of Design and Elements of Arts - v2Document29 pagesARTS10 - q1 - Mod1 - Principles of Design and Elements of Arts - v2Lovely MejascoNo ratings yet

- Leisure Painter July 2017 FreeMags - CCDocument73 pagesLeisure Painter July 2017 FreeMags - CCJuanRodriguez100% (2)

- WECANWEdIntroReader PDFDocument284 pagesWECANWEdIntroReader PDFIreneIrene100% (1)

- Art - Appreciation - Unit - 2 For StudentsDocument37 pagesArt - Appreciation - Unit - 2 For StudentsJomar Catacutan100% (1)

- Us GamesDocument76 pagesUs GamesRana100% (2)

- Realist ManifestoDocument7 pagesRealist ManifestoEmNo ratings yet

- Total Tattoo-June 2021Document114 pagesTotal Tattoo-June 2021Comicgek100% (2)

- KIAN SANTANG - REVISI Vinilon PipaDocument2 pagesKIAN SANTANG - REVISI Vinilon PipaWahyu Ardi AntaNo ratings yet

- Materials & Labor PricesDocument18 pagesMaterials & Labor PricesFranklyn GenoveNo ratings yet

- Art AppreciationDocument4 pagesArt Appreciationmikee jane sabilloNo ratings yet

- SSDSSDSSSDocument3 pagesSSDSSDSSSMARIA NADINE DELOS REYESNo ratings yet

- Our Lady of Fatima University: Sunflower MonsteraDocument2 pagesOur Lady of Fatima University: Sunflower MonsteraChrisha DangilanNo ratings yet

- Detailed Lesson Plan in MAPEH GRADE 9 I. ObjectivesDocument6 pagesDetailed Lesson Plan in MAPEH GRADE 9 I. ObjectivesAnonymous Q6BSqaNo ratings yet

- Figure Drawing Fundamentals for ArtistsDocument321 pagesFigure Drawing Fundamentals for ArtistsDayal Zalke100% (2)

- Tool ProficienciesDocument8 pagesTool Proficiencieslmt-12No ratings yet

- Mantegna or Pollaiuolo?Document5 pagesMantegna or Pollaiuolo?Lubava ChistovaNo ratings yet

- Sandro Botticelli: Famous Renaissance PainterDocument15 pagesSandro Botticelli: Famous Renaissance PainterDavid BriceñoNo ratings yet

- Mixed Exercises 27Document13 pagesMixed Exercises 27Trần LộcNo ratings yet

- Telangana Folk Art Scroll Paintings CheriyalDocument37 pagesTelangana Folk Art Scroll Paintings Cheriyalraish alamNo ratings yet

- Lesson 1 - PrintmakingDocument28 pagesLesson 1 - PrintmakingMr WenceslaoNo ratings yet

- Humanities Culture Continuity and Change Volume II 3rd Edition Sayre Test BankDocument9 pagesHumanities Culture Continuity and Change Volume II 3rd Edition Sayre Test BankLeroyBrauncokfe100% (18)