Professional Documents

Culture Documents

Limit State

Uploaded by

Subbarao KakumanuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Limit State

Uploaded by

Subbarao KakumanuCopyright:

Available Formats

NATIONAL HIGHWAYS AUTHORITY OF INDIA FOUR LANING OF TIRUPATI-TIRUTHANI -CHENNAI-SECTION OF NH-205 FROM Km 274+800 to Km 341+600 IN THE STATE OF ANDHRA

PRADESH & FROM Km 0+000 TO Km 59+600 IN THE STATE OF TAMIL NADU ON DESIGN,BUILD,FINANCE,OPERATE AND TRANSFER (DBFOT) TOLL BASIS

Structural Design Report DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION Note No:39/TTC/CUL-BOX/1X3X3/RO

Concessionaire TRANSTORY TIRUPATI-TIRUTHANI-CHENNAI TOLLWAYS PVT.LTD.

Document/File No.: Designed by: Approved by:

Venkatesh T R Reddy

No. of Pages: Checked by:

22 Praveen

R "O" Rev

12/13/2010 Date Remarks

DESIGN CONSULTANT Egis India Consulting Engineers Pvt. Ltd. 9-1-77/3, N0.31, Adjacent ITC Agri Building, S.D Road, Secunderabad. Tel: +91-40-40179495, Fax: +91-40-40179496

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 : DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION

Job Name : Design of Single Cell Box Culvert

DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION

1.0 1.1 Design Data Dimension Detail No of cells Clear Span Clear Height (at outer edge) Clear Height (at median location) Width of road at top Width of Box Ht of fill (W.C / P.C.C / pavement layers) over the top slab Thickness of top slab Thickness of bottom slab Thickness of external vertical wall Size of haunch Width of Crash barrier Distance of edge of crash barrier from edge of box Height of surcharge Safe Bearing Capacity of the soil Permissible Settlement 1.2 Material Properties Density of concrete Density of soil Density of wearing coat Density of Profile corrective course Coefficient of active earth pressure Angle of internal friction (in degree) 1.3 Design Parameters Grade of Concrete Clear Cover for earth face structural component Clear Cover for inside face structural component Clear Cover for bottom slab Permissible direct comp. strength of Concrete (scc) Permissible flexural comp. strength of Concrete (scb) Permissible tensile strength of Concrete ( sct ) Permissible tensile strength of Steel ( sst ) Design Costants: k j R Base Projection = = = = = = = = = = = = 0 mm M25 75 mm 50 mm 75 mm

2 6.25 N/mm

= = = = = = = = = = = = = = = =

1 3.00 3.00 3.000 12.00 12.00 0.065

m m m m m m NOT OK OK OK x 150

600 mm 600 mm 600 mm 150 0.500 m 0.500 m 1.20 m 2 120.00 KN/m 75.00 mm

= = = = = =

25.00 20.00 22.00 22.00 0.500 30.00

KN/m3 3 KN/m KN/m3 KN/m3 deg

8.33 N/mm 2 0.61 N/mm

2 240 N/mm

0.258 0.914

2 0.981 N/mm

Page # 2

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 : DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION

Job Name : Design of Single Cell Box Culvert

2.0 2.1

Load Calculations for the Box Structure Dead Load Self weight of the structure has been calculated directly in STAAD file by the comment "SELFWEIGHT -1".

2.2 2.2.1

Super Imposed Dead Load Top Slab Wearing coat thickness Ht of fill (Thickness of W.C / P.C.C / pavement layers) Load (UDL) on top slab = Wt of Crash barrier per meter Total UDL load due to S.I Dead Load Height of soil on projected portion of base slab Wt of soil on the projected portion of base slab 0.065*22

= = = = = = =

0.065 1.000 m 2.73 KN/m 0 KN/m 2.73 KN/m 0.00 m 0.00 KN/m

2.3

Earth Pressure Thickness of top slab Height of top haunch Clear height between top & bottom slab Height of bottom haunch Thickness of bottom slab Height from top (m) 1.300 1.300 + 0.300 1.600 + 0.150 1.750 + 0.900 2.650 + 0.900 3.550 + 0.900 4.450 + 0.150 4.600 + 0.300 4.900 Intensity of Earth pressure (KN/m2) 0.5 * 20 * 1.3 = 0.5 * 20 * 1.6 = 0.5 * 20 * 1.75 = 0.5 * 20 * 2.65 = 0.5 * 20 * 3.55 = 0.5 * 20 * 4.45 = 0.5 * 20 * 4.6 = 0.5 * 20 * 4.9 = = = = = = 0.600 0.15 3.00 0.15 0.60 m m m m m

13.00 16.00 17.50 26.50 35.50 44.50 46.00 49.00 75

2.4

Live Load Surcharge Equivalent height Uniform Intensity of loading = = = 1.20 m 2 12.00 KN/m

0.5 * 1.2 * 20

2.5

Braking Load Carriageway Live Load Width of the box Braking Load = 0.2 * 400 / 12 = = = 400 KN 12.00 m 6.67 KN

2.6

Additional pressure on edge 1m strip due to eccentricity of Live Load Live Load Width of culvert (parallel to traffic direction) Width of culvert (perpendicular to traffic direction) Distance of CG of load from outer edge of box culvert Transverse Moment Section Modulus of box in transverse direction Upward UDL on edge 1m strip = = = = = = = 400.00 KN 4.20 m 12.00 m 3.10 m 1162.00 KNm 100.80 m^3 11.53 KN/m

Page # 3

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION :

Job Name : Design of Single Cell Box Culvert

3.0

Effective width of tyres and load distribution for different vehicular loadings: Effective span Total Width of Box culvert Ht of fill (W.C / P.C.C / pavement layers) Thickness of deck slab lo b = = = = = = = = = = = 3.60 m 12.00 m 0.065 m 0.600 m 0.50 m 0.50 m 3.33

Width of Crash barrier / Kerb = Dist. of edge of crash barrier/guard stone from edge of box Span / Wdith ratio b / lo = 12 / 3.6

As per Cl. 305.16.2 of IRC:21, for continous slab For b / lo = 3.1 3.1.1 Class 70R vehicle: Axle - " l " : 5t 450 5t 1480

3.33

2.6

(Refer Appendix 1, IRC : 6-2000 )

5t 450

5t

20 t

20 t

410

40

410

1070 2790

410

40

410 1220

Transverse Total Load Impact factor = = = = = = = 410 (Refer Table of IRC:6-2000) 75 (Refer Table of IRC:6-2000) 5000 / 5.273 948.23 / 36 360 x 263 mm = = = = = = = =

Longitudinal 40.00 t 1.25 1.20 m 1.22 m 2.38 m 5.00 t 2 5.273 Kg/cm 360 mm

2 948.23 cm 26.3 cm

(Refer Cl.211.3 of IRC:6-1966)

Min. clear distance from C/B to the edge of the end wheel Distance between the axles in the direction of traffic C/C distance between end wheels in trans direction Load on one tyre Max. tyre pressure Contact width of tyre Contact area Breadth Contact area = = = = = =

360

Contact width of tyre in a direction perpendicular to the span Wheel dimension perpendicular to span Dist. from outer edge of kerb to = 0.5 + 1.2 + 0.41 / 2 c.g of wheel Effective width a b1 Effective width = = = = a a (1 - a / l o) + b1 (Refer Cl.305.16.2)

0.36 m 0.41 m 1.905 m

the distance of c.g of concentrated load from nearer support 3.6 / 2 - 1.22 / 2 = 1.190 m 0.36 + 2 * 0.065 = 0.49 m = > 2.56 m 1.48 m

= 2.6 x 1.19 x (1 - 1.19 / 3.6) + 0.49 (Dispersion width ends with in the deck slab) (Dispersion width of four wheels overlaps in trans direction)

Effective load in trans direction Effective width for design (In transverse direction) =

= =

20.00 t 4.942 m

Page # 4

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION :

Job Name : Design of Single Cell Box Culvert

1.905 Crash Barrier 0.50 1.20 0.41 0.04 0.41

2.380 1.07 0.41 0.04 0.41

Dispersion along span direction (Refer Cl.305.16.3 of IRC:21) Dispersion width for design (In longitudinal direction) Total load Dispersion area Load per unit area Load per unit area with I.F 3.1.2 Axle - " m ":

0.263 + 2 x (0.065 + 0.6)

= >

1.593 m 1.220

(IF(1.593>1.22,(1.593 + 1.22),1.593) = 2.813 m 40.0 t 2 13.90 m 2 2.88 t/m 3.60 t/m

2

= = = =

4.942 x 2.813 40 / 13.902 2.88 x 1.25

= = = =

(Refer Appendix 1, IRC : 6-2000 )

5t 795

5t 790

5t 795

5t

20 t

20 t

410

385

410

380 2790 Transverse

410

385

410 1220

Longitudinal = = = = = 410 = = = = = 40.00 t 1.25 1.20 m 1.22 m 2.38 m 5.00 t 2 5.273 Kg/cm 360 mm

2 948.23 cm 26.3 cm

Total Load Impact factor

= =

(Refer Cl.211.3 of IRC:6-1966)

Min. clear distance from C/B to the edge of the end wheel Distance between the axles in the dir. of traffic C/C distance between end wheels in trans direction Load on one tyre Max. tyre pressure Contact width of tyre Contact area Breadth Contact area = = = = = =

(Refer Table of IRC:6-2000) (Refer Table of IRC:6-2000) 5000 / 5.273 948.23 / 36 360 x 263 mm

360

Contact width of tyre in a direction perpendicular to the span Wheel dimension perp. to span Distance from outer edge of kerb to c.g of wheel Effective width a b1 Effective width = = = = a a (1 - a / l o) + b1 (Refer Cl.305.16.2)

= = =

0.36 m 0.41 m 1.905 m

the distance of c.g of concentrated load from nearer support 3.6 / 2 - 1.22 / 2 = 1.190 m 0.36 + 2 * 0.065 = 0.49 m = > 2.56 m 0.79 m

= 2.6 x 1.19 x (1 - 1.19 / 1.22) + 0.49 (Dispersion width ends with in the deck slab) (Dispersion width of four wheels overlaps in trans direction)

Effective load in trans direction Effective width for design (In transverse direction) =

= =

20.00 t 4.942 m

Page # 5

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION :

Job Name : Design of Single Cell Box Culvert

1.905 Crash Barrier 0.50 1.20 0.41 0.39 0.41

2.380 0.38 0.41 0.39 0.41

Dispersion along span direction (Refer Cl.305.16.3 of IRC:21) Dispersion width for design (In longitudinal direction) Total load Dispersion area Load per unit area Load per unit area with I.F

0.263 + 2 x (0.065 + 0.6)

= > =

1.593 m 1.220 2.813 m

(IF(1.593>1.22,(1.593 + 1.22),1.593)

= = = =

4.942 x 2.813 40 / 13.902 2.878 x 1.25

= = = =

40.0 t 2 13.902 m 2 2.88 t/m 3.60 t/m

2

3.1.3

Axle - " n ": 2.5 t 280

(Refer Appendix 1, IRC : 6-2000 ) 2.5 t 480 2.5 t 280 2.5 t 480 2.5 t 280 2.5 t 480 2.5 t 280 2.5 t 20 t 20 t

230 50

230 250

230 50

230

230 250 2790 Transverse

230 50 250

230 50

230 1220

Total Load Impact factor

= =

(Refer Cl.211.3 of IRC:6-1966)

= = = = = 230 = = = = =

40.00 t 1.25 1.20 m 1.22 m 2.56 m 2.50 t 2 5.273 Kg/cm 180 mm

2 474.12 cm 26.3 cm

Min. clear distance from C/B to the edge of the end wheel Distance between the axles in the dir. of traffic c/c distance between end wheels in trans direction Load on one tyre Max. tyre pressure Contact width of tyre Contact area Breadth Contact area = = = = = =

(Refer Table of IRC:6-2000) (Refer Table of IRC:6-2000) 2500 / 5.273 474.12 / 18 180 x 263 mm

180

Contact width of tyre in a direction perpendicular to the span Wheel dimension perp. to span Distance from outer edge of kerb to c.g of wheel Effective width a b1 Effective width = = = = a a (1 - a / l o) + b1 (Refer Cl.305.16.2)

= = =

0.18 m 0.23 m 1.815 m

the distance of c.g of concentrated load from nearer support 3.6 / 2 - 1.22 / 2 = 1.190 m 0.18 + 2 * 0.065 = 0.31 m = > 2.38 m 0.48 m

= 2.6 x 1.19 x (1 - 1.19 / 1.593) + 0.31 (Dispersion width ends with in the deck slab) (Dispersion width of wheels overlaps in trans direction)

Effective load in trans direction Effective width for design (In transverse direction) =

= =

20.00 t 4.942 m

Page # 6

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION :

Job Name : Design of Single Cell Box Culvert

1.815 Crash Barrier 0.50 1.20

0.280 0.23 0.05

0.480 0.23 0.25

0.280 0.23 0.05

0.480 0.23 0.25

0.280 0.23 0.05

0.480 0.23 0.25

0.280 0.23 0.23 0.05 0.23

Dispersion along span direction (Refer Cl.305.16.3 of IRC:21) Dispersion width for design (In longitudinal direction) Total load Dispersion area Load per unit area Load per unit area with I.F 3.2 3.2.1 Class -A vehicle: Single Lane Class A 5.7 t

0.263 + 2 x (0.065 + 0.6)

= > =

1.593 m 1.220 2.813 m

(IF(1.593>1.22,(1.593 + 1.22),1.593)

= = = =

4.942 x 2.813 40 / 13.902 2.878 x 1.25

= = = =

40.0 t 2 13.902 m 2 2.88 t/m

2 3.60 t/m

(Refer IRC : 6-2000,Cl. 207.1 )

5.7 t 1800

11.4 t

11.4 t

500

1300 2300 Transverse

500 1200

Longitudinal = = = = = = = 22.80 t 1.469 0.15 m 1.20 m 1.80 m 500 mm 25 cm

Total Load Impact factor

= =

(Refer Cl.211.3 of IRC:6-1966)

Min. clear distance from C/B to the edge of the end wheel Distance between the axles in the dir. of traffic c/c distance between end wheels in trans direction Contact width of tyre Contact breadth of tyre Contact area = = = 500 x 250 mm

Contact width of tyre in a direction perpendicular to the span Wheel dimension perpendicular to span Distance from outer edge of kerb to c.g of wheel Effective width a b1 Effective width = = = = a a (1 - a / l o) + b1 (Refer Cl.305.16.2)

= = =

0.50 m 0.50 m 0.90 m

the distance of c.g of concentrated load from nearer support 3.6 / 2 - 1.2 / 2 = 1.200 m 0.5 + 2 * 0.065 = 0.63 m = > 2.71 m 1.8 m

= 2.6 x 1.2 x (1 - 1.2 / 3.6) + 0.63 (Dispersion width crosses the deck slab) (Dispersion width of two wheels overlaps in trans direction)

Effective load in trans direction 0.90 Crash Barrier 0.50 0.15 0.50 1.800 1.30 0.50

11.40 t

Page # 7

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION :

Job Name : Design of Single Cell Box Culvert

Effective width for design (In transverse direction) Dispersion along span direction (Refer Cl.305.16.3 of IRC:21) Dispersion width for design (In longitudinal direction) Total load Dispersion area Load per unit area Load per unit area with I.F 3.2.2 Two Lane Class A 5.7 t 1800 5.7 t

4.055 m

0.25 + 2 x (0.065 + 0.6)

= > =

1.58 m 1.200 2.780 m

IF(1.58>1.2,(1.58 + 1.2),1.58)

= = = =

4.055 x 2.78 22.8 / 11.273 2.03 x 1.469

= = = =

22.8 t 2 11.27 m 2 2.03 t/m

2 2.98 t/m

5.7 t 1700 1800

5.7 t

22.8 t

22.8 t

500

1300

500

1200 5300

500

1300

500 1200

Transverse Total Load Impact factor = =

Longitudinal = = = = = = = 45.60 t 1.47 0.15 m 1.20 m 5.30 m 500 mm 25 cm

(Refer Cl.211.3 of IRC:6-1966)

Min. clear distance from C/B to the edge of the end wheel Distance between the axles in the direction of traffic c/c distance between end wheels in trans direction Contact width of tyre Contact breadth of tyre Contact area = = = 500 x 250 mm

Contact width of tyre in a direction perpendicular to the span Wheel dimension perpendicular to span Distance from outer edge of kerb to c.g of wheel Effective width a b1 Effective width = = = = a a (1 - a / l o) + b1 (Refer Cl.305.16.2)

= = =

0.50 m 0.50 m 0.90 m

the distance of c.g of concentrated load from nearer support 3.6 / 2 - 1.2 / 2 = 1.200 m 0.5 + 2 * 0.065 = 0.63 m = > 2.71 m 1.8 m

= 2.6 x 1.2 x (1 - 1.2 / ) + 0.63 (Dispersion width crosses the deck slab) (Dispersion width of four wheels overlaps in trans direction)

Effective load in transverse direction 0.90 Crash Barrier 0.50 0.15 0.50 1.800 1.30 0.50 1.700 1.20 0.50 1.800 1.30 0.50

22.80 t

Page # 8

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION :

Job Name : Design of Single Cell Box Culvert

Effective width for design (In transverse direction) Dispersion along span direction (Refer Cl.305.16.3 of IRC:21) Dispersion width for design (In longitudinal direction) Total load Dispersion area Load per unit area Load per unit area with I.F 3.3 70 R Tracked vehicle Total load Impact factor

7.555 m

0.25 + 2 x (0.065 + 0.6)

= > =

1.58 m 1.200 2.780 m

IF(1.58>1.2,(1.58 + 1.2),1.58)

= = = =

7.555 x 2.78 45.6 / 21.003 2.18 x 1.46875

= = = =

45.6 t 2 21.00 m 2 2.18 t/m

2 3.20 t/m

= =

(Refer Cl.211.3 of IRC:6-1966)

= = = = = = =

70.00 t 1.250 1.20 4.57 0.85 2.05 m m m m

Min. clear distance from C/B to the edge of the end wheel Length of vehicle in span direction Contact width of tyre in a direction perpendicular to the span C/C distance of wheels in a direction perpendicular to span Distance from outer edge of C/barrier to c.g of wheel Effective width a b1 Effective width = = = = a a (1 - a / l o) + b1 (Refer Cl.305.16.2)

2.125 m

the distance of c.g of concentrated load from nearer support 3.6 / 2 = 1.800 m 0.85 + 2 * 0.065 = 0.98 m = > 3.32 m 2.05 m

= 2.6 x 1.8 x (1 - 1.8 / 3.6) + 0.98 (Dispersion width ends with in the deck slab) (Dispersion width of wheels overlaps in trans direction)

Effective total load in transvrse direction 2.125 Crash Barrier 0.50 2.050 1.20 0.85 1.20 0.85

70.00 t

Effective width for design (In transverse direction) Dispersion along span direction (Refer Cl.305.16.3 of IRC:21) Dispersion width for design (In longitudinal direction) Total load Dispersion area Load per unit area Load per unit area with I.F

5.370 m

4.57 + 2 x (0.065 + 0.6)

5.90 m

5.900 m

= = = =

5.37 x 5.9 70 / 31.683 2.21 x 1.25

= = = =

70.0 t 2 31.68 m 2 2.21 t/m

2 2.763 t/m

3.4

Summary of Intensity of Loads: Loading 70R - Axle 'l' 70R - Axle 'm' 70R - Axle 'n' 1 Lane Class A 2 Lane Class A 70R-Track Design LL intensity for analysis Intensity of Load (t/m2) 3.600 3.598 3.598 2.982 3.202 2.763 =

2 3.600 t/m

Page # 9

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 : DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION

Job Name : Design of Single Cell Box Culvert

4.0

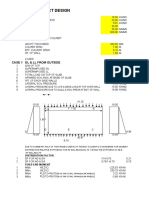

Design of Box Structure:

1 x 3 x 3 without Cushion

Theoretical curtailment point

C/L

25

26

26 18 17

27

27

28

28

29

29

30

18 17 16

16

15

15

14

14

13 12

13 1 2 3

6 5 6

Steel Bar mark ts1 ts2 ts3 ts4 ts5 ts6 w1 w2 w3 w4 w6 bs1 bs2 bs3 bs4 bs5 h1 h2 h3 h4

3.00 3.00 Dia Spacing 12 120 10 200 12 200 10 200 10 8 No. 12 200 12 120 12 200 10 200 10 8 No. 10 200 12 200 10 200 12 120 10 200 12 200 10 200 10 200 10 200 10 10 No.

L1 L2 L3

900 900 450

Depth of member (D) Width of the meber (b) Grade of Concrete Used Grade of steel Charactristic strength of concrete (f ck) Charactristic strength of steel (f y) Tensile strength of concrete (fctm) Design yield strength of shear reinforcement f ywd = 0.8*fyk/s Partial material safety factor for concrete (gm) Partial material safety factor for Steel (gs) Ultimate compressive strain in the concrete ( cu3) modulus of elasticity of reinforcing of steel (E s) modulus of elasticity of concrete (Ecm) modular ratio e (Es/Ecm) Ultimate tensile strain in the steel (s) = [{fy/(gs xEs)}+0.002] Coefficient to consider the influence of the concret strength (a) Factor (l ) Factor (h) fcd = (a*fck/gm) Factor Fav (hfcdl) Factor b = (l/2) Effective depth of member (d) M/(bd2Fav) = kav Limiting Neutral axis depth (x lim) = (d*ecu3)/(es+ecu3) Force in compression = Force in Tension from Fig. A2-4 - rectangular Tensile Strength fy*As gs As = hfcd * lx* b = Fav * x*b

= = = = = = = = = = = = = = = = = = = = = = =

210 1000 M30 Fe 500 30 500 2.5 348 1.5 1.15 0.0035 200000 31000 6.45 0.00417 0.67 0.8 1 13.400 10.720 0.400 544.0

mm mm

N/mm2 Table no:6.5 (IRC:112-2011) N/mm2 Table no:18.1 (IRC:112-2011) MPa MPa Basic Page 49: (IRC:112-2011) Basic Page 30: (IRC:112-2011) Up to fck 60Mpa no:6.5 (IRC:112-2011) Table N/mm2 Clause 6.2.2 (IRC:112-2011) MPa

Cube

A2.10 Page : 244 (IRC:112-2011)

0.8 Up to fck 60Mpa,Eq.A2-33 (IRC:112-2011); 0.8-((fck-60)/500) for 60<fck<110Mpa 1.0 Up to fck 60Mpa,Eq.A2-35 (IRC:112-2011); 1.0-((fck-60)/250) for 60<fck<110Mpa

Cylinder

0.003 248.113 mm

gs * Fav * x*b fy fy*As *(d-lx/2) gs fy*gs * Fav * x*b *(d-bx) g s * fy Fav * x*b *(d-bx) 0 d-sqrt(d2-4*b*M/Fav*b)/(2*b) 2 d*(1-sqrt(1-4*b*M/Fav*b*d ))/(2*b) d*(1-sqrt(1-4*b*kav))/(2*b) 544x(1-sqrt1-4x0.4x0.003))/(2x0.4) 1.37320392 mm < gs * Fav * x*b fy 1.15x10.72x1.373x1000/ 500 33.8577158 mm2 No's

2 628.32 mm

bx -dx + M/Fav*b x

= = = = = = = = = =

248.113

Safe

Required reinforcement As

Provide Provided reinforcemnt

2 =

20 > 33.86

Safe

Neutral axis depth (x)

fy*As * gm gs * hfck a * l* b 471240 1.15x1x30x0.67x0.8x1000 25.480 mm < 248.113

Safe

Page # 10

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 : DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION

Job Name : Design of Single Cell Box Culvert

Shear design

Longitudinal crushing of Shear Force byforce (NEd) compression struts (V Rd.max)

= =

cwbwz1fcd =

(cot+tan)

cwbwz1fcd

(2/sin2)

Shear Force by shear reinforcement (V Rd.s) Shear resistance of section without shear reinforcement (V Rd.c) Where K min cp 1

= = = = = = = = = =

Aswzfywdcot s [0.12K(801.fck) 1+ 0.031K3/2fck1/2 NEd/Ac Asl/bw.d <= <= 0.2fcd 0.02

0.33

+0.15cp]bw.d

<= 2 Where d is depth in mm

200 d

122.66 kN \ 261.26 kN 122.66 kN > 71.0 kN

Subject to a Minimum shear

VRd.c

Hence Shear reinforcement is not required If required VNS = V Rd.max = sin2 Cot = = = =

cwbwz1fcd

(cot+tan) VNS/cwbwz1fcd/2 0.034 0.99 58.04

cwbwz1fcd

(2/sin2)

<= 2.5

>= 1

Dia of bar used as shear

8 mm

2 legged

Shear Force by shear reinforcement

Aswzfywdcot s = VNS Spacing, s = Aswzfywdcot/VNS = 11234 mm Provide Shear reinforcement vertically 2 legged 8 mm dia @ 11225 mm C/C

Max Min

484 mm 194 mm

For Beams, minimum shear reinforcement ratio (min) Minimum spacing

= = =

0.072 fck/fyk 0.00078872 127.460827 mm

Page # 11

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 : DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION

Job Name : Design of Single Cell Box Culvert

4.1

Check for Flexure as per IRC:21: Main Reinforcement

Limiting depth (Xulim) Min Ast Reqd (mm2/m) MR with MR with respect to respect to concrete steel

Section

Face

Mdes (KN.m)

Xu

Effective depth provided

kav 0.0025 0.0183 0.0019 0.0199 0.0301 0.0038 0.0118 0.0097 0.0298 0.0055 0.0062 0.0239 0.0329 0.0048

Ast reqd. (mm2/m)

Bar Mark

Diameter

Spacing

Bar Mark

Diameter

Spacing

Ast provd. (mm2/m)

r (% steel)

Status

Status OK OK OK Not OK OK Not OK OK Not OK OK Not OK Not OK OK OK Not OK

29 & 30 27&28 16,17 15 13&14 2&3 4,5&6 4.2 Distribution Steel

Top Bottom Top Bottom Outside Inside Outside Inside Outside Inside Top Bottom Top Bottom

8 58 6 63 87 11 34 28 86 16 18 69 95 14

248.11 248.11 248.11 248.11 236.71 236.71 236.71 236.71 236.71 236.71 236.71 236.71 236.71 236.71

1.373 10.019 1.030 10.890 15.830 1.980 6.140 5.052 15.646 2.882 3.243 12.523 17.306 2.521

544.0 544.0 544.0 544.0 519.0 519.0 519.0 519.0 519.0 519.0 519.0 519.0 519.0 519.0

33.9 247.0 25.4 268.5 390.3 48.8 151.4 124.6 385.8 71.1 80.0 308.8 426.7 62.2

653 653 653 653 623 623 623 623 623 623 623 623 623 623

ts1 ts3 w1 ts3 w1 w2 w1 w2 w1 w2 bs1 w1 bs1 bs3

12 12 12 12 12 12 12 12 12 12 12 12 12 12

120 200 120 200 120 200 120 200 120 200 200 120 200 200

ts7 ts6 ts1 _ ts1 w5 _ w5 bs3 _ bs3 bs5 b6

0 12 12 0 12 0 0 0 12 0 0 12 12 0

120 200 120 200 120 200 120 200 200 200 200 120 200 200

942 1131 1885 565 1885.0 565.5 942.5 565.5 1508.0 565.5 565.5 1885.0 1131.0 565.5

2.78 3.34 5.57 1.67 0.36 0.11 0.18 0.11 0.29 0.11 0.11 0.36 0.22 0.11

6.4 46.4 4.8 50.4 69.6 8.8 27.2 22.4 68.8 12.8 14.4 55.2 76 11.2

222.7 265.5 445.5 132.7 420.2 127.4 211.7 127.1 336.2 127.3 127.3 421.2 251.8 127.4

unsafe unsafe unsafe unsafe unsafe unsafe unsafe unsafe unsafe unsafe unsafe unsafe unsafe unsafe

Section

Face

Mdes (KN.m)

Limiting depth (Xulim)

Xu

Effective depth provided

kav 0.001 0.005 0.008 0.002 0.008 0.006

Doverall provd. (m)

Deff provd. (m)

Ast reqd. (mm2/m)

Bar Mark

Diameter

Spacing

Ast provd. (mm2/m)

r (% steel)

Status OK OK OK OK OK OK

Top slab vertical wall Bottom slab 4.3

Top Bottom Outside Inside Top Bottom

2.0 15.8 21.8 7.0 23.8 17.3

248.113 248.113 248.113 248.113 248.113 248.113

0.343 2.7062 3.9211 1.2594 4.2829 3.1079

544.0 544.0 519.0 519.0 519.0 519.0

544 519 519

533 508 508

8 67 97 31 106 77

ts2 ts4 w3 w6 bs2 bs4

10 10 10 10 10 10

200 200 200 200 200 200

393 393 393 393 393 393

1.16 1.16 0.08 0.08 0.08 0.08

Check for Shear as per IRC:21

Section

Vdes (KN)

Deff provd. (m)

top slab Vertical wall Bottom slab

89.0 71.0 98.0

544 519 519

56.0 122.7 126.3

Subject to a Minimum shear resistance (Rd.c) 261.256 198.062 192.685

Shear Reqd Not reqd Not reqd Not reqd

Reinforcement Provided

Page # 12

Project Subject

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 : DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION

Job Name : Design of Single Cell Box Culvert

5.0 5.1

Check for Safe Bearing Capacity of Soil Summary of Support Reactions Support No. Max Vertical Reaction (DL + SIDL + EP on B/F + B.F + Surcharge EP + CWLL) (KN) 43.50 39.30 35.10 33.20 31.00 26.90 22.90 20.90 13.10 11.70 7.30 3.50 0.00 0.00 288.40 = = = 288.4/(4.200x1) = = = = = < Allowable Gross SBC of Soil =

2 120.0 KN/m Safe

[STAAD III Output]

1 2 3 4 5 6 7 8 9 10 11 12 35 36 Sum Total Load /m

288.40 KN 4.200 m

2 68.67 KN/m 2 11.53 KN/m 2 80.2 KN/m

Length of Box (along traffic direction) Base Pressure due to vertical loads

Additional pressure due to eccentricity of CWLL Total Base pressue =

Page # 13

Project

: Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205

Job Name : Design of Single Cell Box Culvert Subject DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION :

Serviceability Limit State(SLS) Stress Level Moment of Inertia of cracked section Stresses are calculated for Maximum bending moment Maximum compressive stress in concrete ( cc) = 95*10^6*17.31/2443469285 5.94 < 95*10^6*(544-17.31)/2443469285 61.43 < = 1000*0^3/3+1256.68*(544-0)^2*(200000/31000) 2443469285 mm4

14.4 MPa

Safe

Maximum tensile stress in steel ( sc) Crack width Maximum crack width where spacing of bonded reinforcement with in the tension zone

400 MPa

Safe

<= <= <=

5*(C+/2) 5*(50+16/2) 290 <= = =

mm 5*(C+/2) 0.8 for deformed bars 0.5 for bending

Case 1: Spacing of bonded reinforcement with in the tension zone 89.98 <= 290 Coefficient based on bond propoerties k1 Coefficient based on distribution of strain k2 . Maximum crack spacing Sr,max

= = = = = =

(3.4c+0.425k1k2)/p.eff (3.4*50+0.425*0.8*0.5*16)/0.0087 19853 mm As/Ac.eff 1256.68/(145*1000) 0.00867

rr.eff

Case2 :the spacing of bonded reinforcement or No bonded reinforcement with in the tension zone > 89.98 > Maximum crack spacing Sr,max case 3 : Defermed bar associated with pure bending Maximum crack spacing Sr,max = = Maximum of maximum cracking spacing Srmax = = =

5*(C+/2) 290 1.3 (d-XU) 638.3409264

mm mm

3.4c+0.17 p.eff 19929.01932 mm condition should be check

19852.87356 mm

Factor dependent on the duration of the load (kt) (esm-ecm) = = = >= =

0.5 >=0.6 ssc / Es 0.6*61.432/200000

(ssc - kt fct.eff/rr.eff (1+aerr.eff))/Es (61.432-0.5*2.5/0.0087*(1+6.45*0.0087))/200000 -0.000452 0.000184 >=0.6 sc / Es 0.000184

Wk

= = =

Sr,max (esm-ecm) 19852.9*0.00018 3.659 mm

< modify the section

0.3

severe

Project : Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 Job Name : Design of Single Cell Box Culvert Subject : DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION STAAD PLANE RCC BOX 1 x 3 x 3 without Cushion *ANALYSIS OF BOX CULVERT WITH SPRING CONSTANT INPUT WIDTH 79 UNIT METER KN JOINT COORDINATES 1000 2 0.3 0 0 3 0.45 0 0 4 0.836 0 0 5 1.222 0 0 6 1.608 0 0 7 1.993 0 0 8 2.379 0 0 9 2.765 0 0 10 3.15 0 0 11 3.3 0 0 12 3.6 0 0 13 0 0.3 0 14 0 0.45 0 15 0 1.35 0 16 0 2.25 0 17 0 3.15 0 18 0 3.3 0 19 3.6 0.3 0 20 3.6 0.45 0 21 3.6 1.35 0 22 3.6 2.25 0 23 3.6 3.15 0 24 3.6 3.3 0 25 0 3.6 0 26 0.3 3.6 0 27 0.45 3.6 0 28 1 3.6 0 29 1.534 3.6 0 30 2.067 3.6 0 31 2.6 3.6 0 32 3.15 3.6 0 33 3.3 3.6 0 34 3.6 3.6 0 35 3.601 0 0 36 -0.001 0 0 MEMBER INCIDENCES 1 1 2; 2 2 3; 3 3 4; 4 4 5; 5 5 6; 6 6 7; 7 7 8; 8 8 9; 9 9 10; 10 10 11;

11 11 12; 12 1 13; 13 13 14; 14 14 15; 15 15 16; 16 16 17; 17 17 18; 18 18 25; 19 12 19; 20 19 20; 21 20 21; 22 21 22; 23 22 23; 24 23 24; 25 24 34; 26 25 26; 27 26 27; 28 27 28; 29 28 29; 30 29 30; 31 30 31; 32 31 32; 33 32 33; 34 33 34; 35 36 1 36 12 35 MEMBER PROPERTIES INDIAN 1 11 PRIS YD 0.6 ZD 1 2 10 PRIS YD 0.6 ZD 1 3 TO 9 PRIS YD 0.6 ZD 1 12 TO 18 PRIS YD 0.6 ZD 1 19 TO 25 PRIS YD 0.6 ZD 1 26 TO 36 PRIS YD 0.6 ZD 1 CONSTANTS E 25000000 ALL POISSON 0.15 ALL DENSITY 25 ALL ALPHA 1.17e-005 ALL SUPPORTS 1 FIXED BUT FZ MX MY MZ KFY 240.001 12 FIXED BUT FX FZ MX MY MZ KFY 240.001 2 11 FIXED BUT FX FZ MX MY MZ KFY 360 3 10 FIXED BUT FX FZ MX MY MZ KFY 428.572 4 TO 9 FIXED BUT FX FZ MX MY MZ KFY 617.143 35 36 FIXED BUT FX FZ MX MY MZ KFY 0.001

LOAD 1 SELF WEIGHT SELFWEIGHT Y -1 LOAD 2 SIDL MEMBER LOAD 26 TO 34 UNI GY -2.73 LOAD 3 ACTIVE EARTH PR. (BOTH SIDES) MEMBER LOAD 12 TRAP GX 49 46 13 TRAP GX 46 44.5 14 TRAP GX 44.5 35.5 15 TRAP GX 35.5 26.5 16 TRAP GX 26.5 17.5 17 TRAP GX 17.5 16 18 TRAP GX 16 13 19 TRAP GX -49 -46 20 TRAP GX -46 -44.5 21 TRAP GX -44.5 -35.5 22 TRAP GX -35.5 -26.5 23 TRAP GX -26.5 -17.5 24 TRAP GX -17.5 -16 25 TRAP GX -16 -13 *WEIGHT OF EARTH ON PROEJCTED PORTION OF SLAB 35 36 UNI GY 0 LOAD 4 LIVE LOAD 1(70R TRACKED) MEMBER LOAD 26 TO 34 UNI GY -27.63 LOAD 5 LIVE LOAD 2 (40T BOGIE ) MEMBER LOAD 26 TO 34 UNI GY -36 LOAD 6 LIVE LOAD 3(CLASS A 2LANE) MEMBER LOAD 26 TO 34 UNI GY -32.02 LOAD 7 LL SURCHARGE (BOTH SIDES) MEMBER LOAD 12 TO 18 UNI GX 12 19 TO 25 UNI GX -12 LOAD 8 LL SURCHARGE (LEFT SIDE) MEMBER LOAD 12 TO 18 UNI GX 12 LOAD 9 LL SURCHARGE (RIGHT SIDE) MEMBER LOAD 19 TO 25 UNI GX -12 LOAD 10 BRAKING FORCE (LEFT SIDE) JOINT LOAD 25 FX 6.67

LOAD 11 BRAKING FORCE (RIGHT SIDE) JOINT LOAD 34 FX -6.67 LOAD COMBINATION 101 1 1.35 2 1.75 3 1.5 LOAD COMBINATION 102 1 1.35 2 1.75 3 1.5 4 1.5 LOAD COMBINATION 103 1 1.35 2 1.75 3 1.5 4 1.5 7 1.2 LOAD COMBINATION 104 1 1.35 2 1.75 3 1.5 4 1.5 8 1.2 10 1.5 LOAD COMBINATION 105 1 1.35 2 1.75 3 1.5 4 1.5 9 1.2 11 1.5 LOAD COMBINATION 106 1 1.35 2 1.75 3 1.5 5 1.5 LOAD COMBINATION 107 1 1.35 2 1.75 3 1.5 5 1.5 7 1.2 LOAD COMBINATION 108 1 1.35 2 1.75 3 1.5 5 1.5 8 1.2 10 1.5 LOAD COMBINATION 109 1 1.35 2 1.75 3 1.5 5 1.5 9 1.2 11 1.5 LOAD COMBINATION 110 1 1.35 2 1.75 3 1.5 6 1.5 LOAD COMBINATION 111 1 1.35 2 1.75 3 1.5 6 1.5 7 1.2 LOAD COMBINATION 112 1 1.35 2 1.75 3 1.5 6 1.5 8 1.2 10 1.5 LOAD COMBINATION 113 1 1.35 2 1.75 3 1.5 6 1.5 9 1.2 11 1.5 PERFORM ANALYSIS PRINT SUPPORT REACTION PRINT MAXFORCE ENVELOPE ALL FINISH

Table 6.5 Stress and Deformation Characteristics for Normal Concrete

Strenght classes for Concrete

fck (MPa) fcm(MPa) fctm(MPa) M15 M20 M25 M30 M35 M40 M45 M50 M55 M60 M65 M70 M75 M80 M85 M90 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 1.6 1.9 2.2 2.5 2.8 3.0 3.3 3.5 3.7 4.0 4.1 4.3 4.4 4.5 4.7 4.8 fctk,0.05( fctk,0.95( MPa) MPa) 1.1 2.0 1.3 2.5 1.5 2.9 1.7 3.2 1.9 3.6 2.1 3.9 2.3 4.3 2.5 4.6 2.6 4.9 2.8 5.2 2.9 5.4 3.0 5.6 3.1 5.7 3.2 5.9 3.3 6.1 3.3 6.2 Ecm (GPa) 27 29 30 31 32 33 34 35 36 37 38 38 39 40 40 41 e cl (0/00) e cul (0/00) e 2 (0/00) 1.8 1.9 2.0 2.0 2.1 2.2 2.3 2.3 2.4 2.4 2.5 2.5 2.6 2.6 2.7 2.7 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.4 3.2 3.0 2.9 2.9 2.8 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.1 2.2 2.3 2.3 2.4 2.4 e cu2 (0/00) 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.3 3.1 2.9 2.8 2.7 2.6 h 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 1.9 1.7 1.6 1.5 1.5 1.4 e 3 (0/00) 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.9 1.9 2.0 2.1 e cu3 (0/00) 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.3 3.1 2.9 2.8 2.7 2.6

1 Strength designation of concrete,(based on charactristic strength) and corresponding properties to be used in the design are given below. The strains are expressed in per thousand by 0/00 sign. 2 The tabulated values of Ecm are for quartzite/granite aggregate. For other aggregates, they should be multiplied by factors as given below Lime stone = 0.9 , Sand Stone = 0.7 ,basalt = 1.2

Table 6.1 Grades of Reinforced Steel

Type of Steel Mild Steel(MS) High yield strength deforme d steel (HYSD Steel) Grade/ Designati on Grade I Fe 415 Fe 415D Fe 500 Fe 500D Fe 550 Fe 550D Fe 600 415 415 500 500 550 550 600 Fy

Project : Four Laning of Tirupati-Tiruthani-Chennai Section of NH-205 Job Name : Design of Single Cell Box Culvert Subject : DESIGN OF BOX CULVERT 3M x 3M WITHOUT CUSHION STAAD PLANE RCC BOX 1 x 3 x 3 without Cushion *ANALYSIS OF BOX CULVERT WITH SPRING CONSTANT INPUT WIDTH 79 UNIT METER KN JOINT COORDINATES 1000 2 0.3 0 0 3 0.45 0 0 4 0.836 0 0 5 1.222 0 0 6 1.608 0 0 7 1.993 0 0 8 2.379 0 0 9 2.765 0 0 10 3.15 0 0 11 3.3 0 0 12 3.6 0 0 13 0 0.3 0 14 0 0.45 0 15 0 1.35 0 16 0 2.25 0 17 0 3.15 0 18 0 3.3 0 19 3.6 0.3 0 20 3.6 0.45 0 21 3.6 1.35 0 22 3.6 2.25 0 23 3.6 3.15 0 24 3.6 3.3 0 25 0 3.6 0 26 0.3 3.6 0 27 0.45 3.6 0 28 1 3.6 0 29 1.534 3.6 0 30 2.067 3.6 0 31 2.6 3.6 0 32 3.15 3.6 0 33 3.3 3.6 0 34 3.6 3.6 0 35 3.601 0 0 36 -0.001 0 0 MEMBER INCIDENCES 1 1 2; 2 2 3; 3 3 4; 4 4 5; 5 5 6; 6 6 7; 7 7 8; 8 8 9; 9 9 10; 10 10 11;

11 11 12; 12 1 13; 13 13 14; 14 14 15; 15 15 16; 16 16 17; 17 17 18; 18 18 25; 19 12 19; 20 19 20; 21 20 21; 22 21 22; 23 22 23; 24 23 24; 25 24 34; 26 25 26; 27 26 27; 28 27 28; 29 28 29; 30 29 30; 31 30 31; 32 31 32; 33 32 33; 34 33 34; 35 36 1 36 12 35 MEMBER PROPERTIES INDIAN 1 11 PRIS YD 0.6 ZD 1 2 10 PRIS YD 0.6 ZD 1 3 TO 9 PRIS YD 0.6 ZD 1 12 TO 18 PRIS YD 0.6 ZD 1 19 TO 25 PRIS YD 0.6 ZD 1 26 TO 36 PRIS YD 0.6 ZD 1 CONSTANTS E 25000000 ALL POISSON 0.15 ALL DENSITY 25 ALL ALPHA 1.17e-005 ALL SUPPORTS 1 FIXED BUT FZ MX MY MZ KFY 240.001 12 FIXED BUT FX FZ MX MY MZ KFY 240.001 2 11 FIXED BUT FX FZ MX MY MZ KFY 360 3 10 FIXED BUT FX FZ MX MY MZ KFY 428.572 4 TO 9 FIXED BUT FX FZ MX MY MZ KFY 617.143 35 36 FIXED BUT FX FZ MX MY MZ KFY 0.001

LOAD 1 SELF WEIGHT SELFWEIGHT Y -1 LOAD 2 SIDL MEMBER LOAD 26 TO 34 UNI GY -2.73 LOAD 3 ACTIVE EARTH PR. (BOTH SIDES) MEMBER LOAD 12 TRAP GX 49 46 13 TRAP GX 46 44.5 14 TRAP GX 44.5 35.5 15 TRAP GX 35.5 26.5 16 TRAP GX 26.5 17.5 17 TRAP GX 17.5 16 18 TRAP GX 16 13 19 TRAP GX -49 -46 20 TRAP GX -46 -44.5 21 TRAP GX -44.5 -35.5 22 TRAP GX -35.5 -26.5 23 TRAP GX -26.5 -17.5 24 TRAP GX -17.5 -16 25 TRAP GX -16 -13 *WEIGHT OF EARTH ON PROEJCTED PORTION OF SLAB 35 36 UNI GY 0 LOAD 4 LIVE LOAD 1(70R TRACKED) MEMBER LOAD 26 TO 34 UNI GY -27.63 LOAD 5 LIVE LOAD 2 (40T BOGIE ) MEMBER LOAD 26 TO 34 UNI GY -36 LOAD 6 LIVE LOAD 3(CLASS A 2LANE) MEMBER LOAD 26 TO 34 UNI GY -32.02 LOAD 7 LL SURCHARGE (BOTH SIDES) MEMBER LOAD 12 TO 18 UNI GX 12 19 TO 25 UNI GX -12 LOAD 8 LL SURCHARGE (LEFT SIDE) MEMBER LOAD 12 TO 18 UNI GX 12 LOAD 9 LL SURCHARGE (RIGHT SIDE) MEMBER LOAD 19 TO 25 UNI GX -12 LOAD 10 BRAKING FORCE (LEFT SIDE) JOINT LOAD 25 FX 6.67

LOAD 11 BRAKING FORCE (RIGHT SIDE) JOINT LOAD 34 FX -6.67 LOAD COMBINATION 101 112131 LOAD COMBINATION 102 11213141 LOAD COMBINATION 103 1121314171 LOAD COMBINATION 104 1 1 2 1 3 14 1 8 1 10 1 LOAD COMBINATION 105 1 1 2 1 3 1 4 1 9 1 11 1 LOAD COMBINATION 106 1 1 2 13 1 5 1 LOAD COMBINATION 107 1121315171 LOAD COMBINATION 108 1 1 2 1 3 1 5 1 8 1 10 1 LOAD COMBINATION 109 1 1 2 1 3 1 5 1 9 1 11 1 LOAD COMBINATION 110 11213161 LOAD COMBINATION 111 1121316171 LOAD COMBINATION 112 1 1 2 1 3 1 6 1 8 1 10 1 LOAD COMBINATION 113 1 1 2 1 3 1 6 1 9 1 11 1 PERFORM ANALYSIS PRINT SUPPORT REACTION PRINT MAXFORCE ENVELOPE ALL FINISH

You might also like

- Box Culvert Design: Case 1 DL & LL From OutsideDocument8 pagesBox Culvert Design: Case 1 DL & LL From OutsideselvakumarNo ratings yet

- Design of BOX (1 x 3.76m x 6.45m) at CHAINAGE 5+690Document66 pagesDesign of BOX (1 x 3.76m x 6.45m) at CHAINAGE 5+690Md Ghani HaiderNo ratings yet

- Introduction To SteelsDocument167 pagesIntroduction To Steelspaddiemaguire100% (1)

- CC Road Design PalasaDocument18 pagesCC Road Design PalasaManikantaNo ratings yet

- Analysis and Design of RCC Bridges and Box CulvertDocument114 pagesAnalysis and Design of RCC Bridges and Box CulvertAshraf Mohamed Yehia100% (1)

- Design 3.00 M Slab CulvertDocument60 pagesDesign 3.00 M Slab CulvertVallabhareddy Nageswara RaoNo ratings yet

- Design of RCC Bridge: Ds LsDocument9 pagesDesign of RCC Bridge: Ds LsHamidullah Totakhail0% (1)

- Aircraft Structures - 2 Basic FieldDocument42 pagesAircraft Structures - 2 Basic FieldVenkat Athmanathan100% (1)

- Design of RCC PierDocument10 pagesDesign of RCC Piervijayunity40% (5)

- Box Culvert Limit StateDocument52 pagesBox Culvert Limit StateMahadev Sastry88% (8)

- Construction of 6.00mts span culvert design and loading calculationsDocument63 pagesConstruction of 6.00mts span culvert design and loading calculationsJames Deepak100% (1)

- Causeway For Small SpanDocument73 pagesCauseway For Small SpanER Rajesh MauryaNo ratings yet

- Design Calculation of ROB On N F RailwayDocument40 pagesDesign Calculation of ROB On N F Railwayshashibhushan singhNo ratings yet

- Box Culvert Limit StateDocument45 pagesBox Culvert Limit StateMahadev Sastry0% (2)

- 2 8 16 - Caculation As Per IRC 112Document228 pages2 8 16 - Caculation As Per IRC 112snehar redkar100% (8)

- SLRB Design of 7.45m Clear Span For IRC Class A LoadingDocument15 pagesSLRB Design of 7.45m Clear Span For IRC Class A Loadingpaaji100% (9)

- FiRE 2: Fire Resistance of a Steel BeamDocument303 pagesFiRE 2: Fire Resistance of a Steel BeamvedranNo ratings yet

- Abutment Well: Bridge Over Nagraha Nala in Distt - Ambedkar NagarDocument56 pagesAbutment Well: Bridge Over Nagraha Nala in Distt - Ambedkar NagarRomark Pasia TorejaNo ratings yet

- Retainingwall BS8110Document8 pagesRetainingwall BS8110Obet NegoNo ratings yet

- Class A Loading (Two Lane) Deck SlabDocument8 pagesClass A Loading (Two Lane) Deck SlabSUPERINTENDING ENGINEERNo ratings yet

- Aqueduct Design Beam Slab ReinforcementDocument14 pagesAqueduct Design Beam Slab Reinforcementjeewan_sanima100% (3)

- Timber Design Lecture Notes Prelim PDFDocument4 pagesTimber Design Lecture Notes Prelim PDFSteve BariaNo ratings yet

- RCC PIER DESIGNDocument42 pagesRCC PIER DESIGNMd BIN HASAN100% (1)

- Irc Class Vehicle LoadDocument4 pagesIrc Class Vehicle LoadPrakash SIngh RawalNo ratings yet

- Slab CulvertDocument9 pagesSlab Culvertratnasai75% (4)

- Design of Super StructureDocument30 pagesDesign of Super StructureHemraj Raj100% (16)

- DESIGN OPTIMIZATIONDocument223 pagesDESIGN OPTIMIZATIOND.V.Srinivasa RaoNo ratings yet

- Box Culvert Design and Analysis CalculationsDocument11 pagesBox Culvert Design and Analysis CalculationscoreteamNo ratings yet

- Design of Gravity Abutment for Gagal BridgeDocument33 pagesDesign of Gravity Abutment for Gagal Bridgebkvs12340% (5)

- Design of Deck Slab BridgeDocument11 pagesDesign of Deck Slab BridgeSUPERINTENDING ENGINEER50% (2)

- Hydraulic design of box culverts for water diversion projectDocument26 pagesHydraulic design of box culverts for water diversion projectskumarsr100% (1)

- Design of Abutment-ROBDocument10 pagesDesign of Abutment-ROBNandeesha Ramesh100% (1)

- Calculation of Live Load Reaction For AbutmentsDocument4 pagesCalculation of Live Load Reaction For Abutmentsvasu7900No ratings yet

- 2 Cell Box CulvertDocument22 pages2 Cell Box Culvertabhijeet sahuNo ratings yet

- Abutment DesignDocument49 pagesAbutment Designhemantkle2u100% (1)

- Circular Pier With Circular Footing.Document25 pagesCircular Pier With Circular Footing.Balaji Rao Ch100% (5)

- Positioning of Irc Live LoadsDocument3 pagesPositioning of Irc Live Loadsvasu7900100% (1)

- Box Culvert at Chainage 83 10 M XLSX Depth 4 1 MDocument18 pagesBox Culvert at Chainage 83 10 M XLSX Depth 4 1 MMario Sajulga Dela Cuadra100% (1)

- Ba Culvertf TestDocument16 pagesBa Culvertf TestsanjuktaacharyyaNo ratings yet

- Cable stayed bridge analysis and designDocument80 pagesCable stayed bridge analysis and designamir100% (2)

- Design of Bridge PierDocument12 pagesDesign of Bridge PierSunita Chaurasia88% (8)

- Desig of Box Culvert For RailwayDocument341 pagesDesig of Box Culvert For RailwayYasika199080% (5)

- Trafo Found DesignDocument6 pagesTrafo Found DesignIrshad Khan100% (1)

- Scomposite-24.24Document87 pagesScomposite-24.24manish sharmaNo ratings yet

- Design of Abutment BridgeDocument51 pagesDesign of Abutment BridgePrakash Singh Rawal92% (13)

- BOX Culvert Load DetailsDocument7 pagesBOX Culvert Load Detailsragalwar100% (1)

- IRC Conc Bridge DesignDocument16 pagesIRC Conc Bridge DesignovikbasuNo ratings yet

- Box Culvert-Structural DesignDocument5 pagesBox Culvert-Structural DesignsivaNo ratings yet

- Weight&Lifting - To CheckDocument54 pagesWeight&Lifting - To ChecknamasralNo ratings yet

- Standard specifications for road bridge foundationsDocument110 pagesStandard specifications for road bridge foundationsopti123No ratings yet

- Design of AbutmentDocument47 pagesDesign of AbutmentRaju Ranjan SinghNo ratings yet

- Computation of Reaction Factors Using Courbon's MethodDocument2 pagesComputation of Reaction Factors Using Courbon's Methodvasu790075% (4)

- Abutment 45+705 110110Document106 pagesAbutment 45+705 110110AmbrishNo ratings yet

- Bridge Design (Shear Force and Bending Moment Calculation) : Irc Class Aa Tracked VehicleDocument16 pagesBridge Design (Shear Force and Bending Moment Calculation) : Irc Class Aa Tracked VehicleRohit Gupta33% (3)

- Design of RCC T - Girder Deck Using Morice & Little MethodDocument33 pagesDesign of RCC T - Girder Deck Using Morice & Little Methodvasu7900100% (4)

- Nhai RCC Slab BridgeDocument21 pagesNhai RCC Slab BridgeBilal A BarbhuiyaNo ratings yet

- Design of Backing Wall & Bed BlockDocument4 pagesDesign of Backing Wall & Bed BlocksantkabirNo ratings yet

- Design of 10m Span RCC Slab CulvertDocument105 pagesDesign of 10m Span RCC Slab CulvertD.V.Srinivasa Rao100% (4)

- B. Design of SubstructureDocument14 pagesB. Design of SubstructureDeepak Kr Gupta100% (4)

- SLRB Deck Slab DesignDocument8 pagesSLRB Deck Slab Designpaaji100% (1)

- Design of PCC Abutment - Open FoundationDocument21 pagesDesign of PCC Abutment - Open Foundationklynchelle89% (9)

- Heavy Plate TechDocument95 pagesHeavy Plate TechharshNo ratings yet

- Abutment DesignDocument112 pagesAbutment Designmasudulamin14No ratings yet

- Pile and Pile Cap ConnectionDocument13 pagesPile and Pile Cap ConnectionSubbarao Kakumanu100% (1)

- Calculation of Weights Allowable Stresses in 1967: If You'Ve Ever Asked Yourself "Why?"Document2 pagesCalculation of Weights Allowable Stresses in 1967: If You'Ve Ever Asked Yourself "Why?"aams_sNo ratings yet

- Basis of Design Case Study BuildingDocument49 pagesBasis of Design Case Study BuildingAnonymous AV90SAXa5V0% (1)

- Super Passage Trough Design-User ManualDocument13 pagesSuper Passage Trough Design-User Manualpaaji100% (1)

- Mechanical Engineering ReviewerDocument2 pagesMechanical Engineering Reviewertiburciomadlangtuta100% (2)

- Structural Culvert Design NigeriaDocument54 pagesStructural Culvert Design Nigeriasidiq7100% (2)

- Design of Abutment PDFDocument4 pagesDesign of Abutment PDFChManikumarNo ratings yet

- Design of BridgeDocument59 pagesDesign of BridgeMohd Aftab80% (5)

- RISA - Direct Analysis Method For AISC 13th Edition PDFDocument11 pagesRISA - Direct Analysis Method For AISC 13th Edition PDFYork ZengNo ratings yet

- Understanding Strength of Materials ConceptsDocument104 pagesUnderstanding Strength of Materials ConceptsbhargaviNo ratings yet

- Pilar JembatanDocument37 pagesPilar JembatanMAWAR08100% (4)

- Received With Thanks ' 39,751.00 Through Payment Gateway Over The Internet FromDocument1 pageReceived With Thanks ' 39,751.00 Through Payment Gateway Over The Internet FromSubbarao KakumanuNo ratings yet

- HPCL Visa11 PDFDocument1 pageHPCL Visa11 PDFEDS TeamNo ratings yet

- Box Culvert PaperDocument3 pagesBox Culvert Paperprasadnn2001No ratings yet

- March Daily Questions by Kakatiya Current AffairsDocument30 pagesMarch Daily Questions by Kakatiya Current AffairsSubbarao KakumanuNo ratings yet

- Comparing Internal & External Prestressing for Highway BridgesDocument6 pagesComparing Internal & External Prestressing for Highway BridgesSubbarao Kakumanu0% (1)

- Telangana Current Affairs 2017 by AffairsCloudDocument7 pagesTelangana Current Affairs 2017 by AffairsCloudSubbarao KakumanuNo ratings yet

- Mechanical 2010Document32 pagesMechanical 2010Anonymous KpVxNXsNo ratings yet

- BS 6562-Part 3-1990 - EN 10020-1988Document16 pagesBS 6562-Part 3-1990 - EN 10020-1988Subbarao KakumanuNo ratings yet

- Reference BooksDocument1 pageReference BooksSubbarao KakumanuNo ratings yet

- Assessment of Loss in Durability of Structures by NDT MethodsDocument5 pagesAssessment of Loss in Durability of Structures by NDT MethodsSubbarao KakumanuNo ratings yet

- Example Problems For Week 5Document4 pagesExample Problems For Week 5Ian VillaseñorNo ratings yet

- Heusler AlloysDocument71 pagesHeusler Alloyspeyman_qz_coNo ratings yet

- Donors and Acceptors in SemiconductorsDocument28 pagesDonors and Acceptors in SemiconductorsMohammad Gulam AhamadNo ratings yet

- Appbrief Porcine TracheaDocument2 pagesAppbrief Porcine TracheamgimohNo ratings yet

- Base Metal Alloys Used in Fixed and RemoveableDocument72 pagesBase Metal Alloys Used in Fixed and RemoveableKhushi DesaiNo ratings yet

- Recent Topics of Japanese Design Codes For Steel and Composite BridgesDocument6 pagesRecent Topics of Japanese Design Codes For Steel and Composite BridgesHuan VoNo ratings yet

- CH 8: Screws, Fasteners, and The Design of Non-Permanent JointsDocument15 pagesCH 8: Screws, Fasteners, and The Design of Non-Permanent JointsBhuwaneshwar DahalNo ratings yet

- Mechanical Analysis of Tubing String in Fracturing OperationDocument13 pagesMechanical Analysis of Tubing String in Fracturing OperationAlexandruVerdesNo ratings yet

- ChapterDocument44 pagesChapterMohamed MaherNo ratings yet

- Design of Haunched Composite Connections For Long-Span Beam ConstructionDocument10 pagesDesign of Haunched Composite Connections For Long-Span Beam ConstructioncasanovavnNo ratings yet

- 2.steps and Procedure of Tensile TestDocument2 pages2.steps and Procedure of Tensile TestMuhammad Faiz bin Ahmad ShafiNo ratings yet

- Connection Design: B19-CI: Units: Kip-In Story: Story1 Design Code: AISC 360-10Document6 pagesConnection Design: B19-CI: Units: Kip-In Story: Story1 Design Code: AISC 360-10surbanoj_79No ratings yet

- C5RA09312KDocument35 pagesC5RA09312KBurcu UzunoğluNo ratings yet

- NanomaterialsDocument5 pagesNanomaterialsakash ketkaleNo ratings yet

- Metallurgy, Properties, and Uses of FerrousDocument37 pagesMetallurgy, Properties, and Uses of FerrousAl DrinNo ratings yet

- Magneto CaloricDocument13 pagesMagneto CaloricMarcelo MartinsNo ratings yet

- Fatigue in CompositesDocument10 pagesFatigue in Compositestad0% (1)