Professional Documents

Culture Documents

Job Safety Analysis for Hydro-Testing

Uploaded by

Zeyad RezkOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis for Hydro-Testing

Uploaded by

Zeyad RezkCopyright:

Available Formats

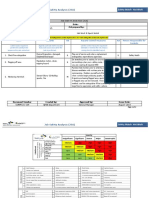

Job Safety Analysis Sheet

JOB DESCRIPTION: Hydro-testing of Pipe & Equipment JSA Ref. No. JSA 0044 Permit No. Date:

Facility:

Work Area / Equipment:

PERSONAL PROTECTIVE EQUIPMENT & TOOLS: Hard Hat, Safety Shoes, Safety Goggles, Hand Gloves, Coverall, hose, pump, pressure gauge, spade, gasket etc. SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS Yes / No Non compliance of KOC F & S Regulations and HSE MS Procedures PRECAUTIONS Refer HSEMS Procedures - Doc. No. LEAD/004 Permit to Work and Chapter - 2 Pressure Testing of Equipment, Systems & Pipelines of LEAD Regulations. Obtain a Cold Work Permit & other associated permits from Asset Owner. Conduct Tool Box Talk. Barricade the area where Hydro-test is to be carried out. Post warning notice. Ensure the equipment / tool to be used for hydro testing (such as hose, pump, coupling, pressure gauge, spade, gasket etc) are free from defect and suitable for the pressure rating of the system. Ensure the pressure relieving device is set at maximum allowable pressure for weakest portion of the segment to be hydro-tested. Keep away from the pressurized segment of the system being hydro-tested. Monitor the pressure gauge from a safe distance away from the potential source of high pressure jetting (Such as Flange Joint, Spade, and Coupling etc.) Ensure the workers are wearing required PPE. Never increase the hydro-test pressure more than the maximum allowable pressure for the weakest portion in the segment or pressure rating of the hose & coupling. Do not leave the pressurized hose or pump unattended when the hydro-test is going on. Isolate the equipment from all source of energy when not in use. Do not change (exceed / decrease) the duration of hydro-test without permission from Inspection Engineer.

Planning Unauthorized Personnel

Defective Tools / Equipment

Exceeding Maximum Allowable Pressure

Injury to Workers

Hydro-testing Damage to Equipment / System Un-attended Pressurized Tool / Equipment

Changing the Duration of Hydro-test

Unsafe Depressurization of Hydrotest Fluid

Ensure the safe depressurization of Hydro-test Fluid. Ensure proper wind up & housekeeping at worksite. The accessories (hoses & pump) not being used must be disconnected and stored separately. PSV (in case isolated) to be lined up after hydrotest completion.

Windup & Housekeeping

Scattered Material

Additional Hazards (Other than indicated above) Name: AHMAD ASSAD LEAD / ID. No. 014 Controlling Team: Signature: Designation: HSSE MANAGER Company: LEAD Contract No.(If Applicable): Date:

JSA Done By

You might also like

- JSA - Hydro-Testing of Pipe & EquipmentDocument1 pageJSA - Hydro-Testing of Pipe & EquipmentRajuNo ratings yet

- Hydro Testing On Piping System Utility and Plant Piping Jsa 2012Document4 pagesHydro Testing On Piping System Utility and Plant Piping Jsa 2012AldrinNo ratings yet

- Hydro Test JSADocument2 pagesHydro Test JSAEruse Okejero88% (17)

- Jsa Nitrogen PurgingDocument2 pagesJsa Nitrogen PurgingKanthimathinathan Krishnan100% (5)

- JSA for blowing air in underground pipingDocument4 pagesJSA for blowing air in underground pipingMohammed MinhajNo ratings yet

- JSA For Washing and Air BlowingDocument3 pagesJSA For Washing and Air BlowingMohammed MinhajNo ratings yet

- JSA Hydrant Pipe LineDocument7 pagesJSA Hydrant Pipe Lineakshay pradeepNo ratings yet

- JHA Pneumatic Test Using N2Document4 pagesJHA Pneumatic Test Using N2Luqman Osman89% (9)

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- Jsa n2 Purging PDF FreeDocument1 pageJsa n2 Purging PDF FreeSKH CultureNo ratings yet

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Jsa For Air Flushin & Mech. Cleaning of PipesDocument17 pagesJsa For Air Flushin & Mech. Cleaning of PipesKhuda Buksh100% (2)

- Catalyst Filling & SeggregationDocument3 pagesCatalyst Filling & SeggregationMohammed MinhajNo ratings yet

- JSA For Coating and Raping Activity in TankDocument7 pagesJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatNo ratings yet

- JSA For Painting Works-Hazards ControlDocument4 pagesJSA For Painting Works-Hazards Controlkaleem0% (2)

- Boring & Cone Penetration test-JSA-01Document3 pagesBoring & Cone Penetration test-JSA-01Akash Shukla67% (3)

- GRP PIPING INSTALLATION SWMSDocument13 pagesGRP PIPING INSTALLATION SWMSKhuda Buksh100% (1)

- JSA For Blower Cyclone and Duct Installation - Revision 004Document8 pagesJSA For Blower Cyclone and Duct Installation - Revision 004WilsonNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Copy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksDocument7 pagesCopy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksMohammed Minhaj80% (5)

- 4..pipe Spool Air Blowing & Cleaning JSA 04Document2 pages4..pipe Spool Air Blowing & Cleaning JSA 04Francis Vinoj100% (1)

- Blinding Deblinding Safety AnalysisDocument3 pagesBlinding Deblinding Safety Analysiskaremkoko33% (3)

- JSA for Holiday TestingDocument4 pagesJSA for Holiday TestingMohammed Minhaj67% (3)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Job Safety Analysis (JSA) - Rebar Installation/steel Fixing DateDocument1 pageJob Safety Analysis (JSA) - Rebar Installation/steel Fixing DatenabeelNo ratings yet

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- Safety checklist for hydro testDocument3 pagesSafety checklist for hydro testsaquib_jamadarNo ratings yet

- MANUAL LIFTING HAZARDSDocument9 pagesMANUAL LIFTING HAZARDSAhmad Siddiq100% (1)

- Alignment Check JSADocument5 pagesAlignment Check JSAHưởng Phạm100% (1)

- JSA For WrappingDocument6 pagesJSA For WrappingMohammed Minhaj100% (2)

- Flushing Pipe SafelyDocument5 pagesFlushing Pipe SafelyYosua SitumorangNo ratings yet

- Slip Form Construction Safety AnalysisDocument5 pagesSlip Form Construction Safety Analysisputrasejahtra50% (2)

- Civil Works Construction Confined Space JSADocument5 pagesCivil Works Construction Confined Space JSAkosoko100% (1)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument15 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda BukshNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- JHA - To Carry Out Reinstate of Interlock StonesDocument7 pagesJHA - To Carry Out Reinstate of Interlock Stoneslinga201450% (2)

- Jsa Non Destructive TestingDocument2 pagesJsa Non Destructive Testingghulammohyuddin100% (1)

- 008 JSA - Manual BoringDocument3 pages008 JSA - Manual BoringMohammed MinhajNo ratings yet

- Job Safety Analysis (Rolling For MS Plates)Document1 pageJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- Bolt Torquing Risk Assessment (Generic)Document5 pagesBolt Torquing Risk Assessment (Generic)kaleeswaran sNo ratings yet

- 6.chain Pulley BlockDocument2 pages6.chain Pulley BlockFrancis Vinoj100% (3)

- Radiography JSADocument2 pagesRadiography JSAVipul ShankarNo ratings yet

- Grounding System Jsa 2008Document4 pagesGrounding System Jsa 2008Aldrin100% (5)

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood0% (1)

- Pressure Test Work PermitDocument2 pagesPressure Test Work PermitMd Abdul Raja83% (6)

- Hot Work PermitDocument1 pageHot Work PermitManesh MNo ratings yet

- Jsa For Static Equipment ErectionDocument15 pagesJsa For Static Equipment ErectionKhuda Buksh100% (1)

- Jsa For Tie in of Fuel Gas LineDocument3 pagesJsa For Tie in of Fuel Gas LineMohammed Minhaj100% (1)

- Job Safety Analysis for Boiler WorkDocument8 pagesJob Safety Analysis for Boiler Worksanath adhikaryNo ratings yet

- Safe Work Guidelines for Contractors Using Pressurized Air (39Document3 pagesSafe Work Guidelines for Contractors Using Pressurized Air (39rahmatNo ratings yet

- Hydrostatic Pressure Test Safety ChecklistDocument3 pagesHydrostatic Pressure Test Safety ChecklistJerry Faria60% (5)

- Hydrostatic Pressure Test Safety CheckDocument3 pagesHydrostatic Pressure Test Safety CheckSreekumar K SNo ratings yet

- Hydrostatic Pressure Test Safety ChecklistDocument3 pagesHydrostatic Pressure Test Safety ChecklistKyaw Kyaw AungNo ratings yet

- Hydrostatic Pressure Testing Procedure1 PWLDocument6 pagesHydrostatic Pressure Testing Procedure1 PWLYavannaNo ratings yet

- Hydro Blasting Safety Program - ProgramDocument10 pagesHydro Blasting Safety Program - ProgramIsabella XavierNo ratings yet

- CP HS 12Document8 pagesCP HS 12aliNo ratings yet

- Method Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSDocument11 pagesMethod Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSPrem Preetham Dsouza100% (1)

- SOP For Hydro TestDocument2 pagesSOP For Hydro Testashfaque khanNo ratings yet

- JSA For Disconnect and Removal of Existing Chemical Injection Tank.Document6 pagesJSA For Disconnect and Removal of Existing Chemical Injection Tank.Nasrullah JanNo ratings yet

- Asp-Cspsolution ErgonomicsDocument2 pagesAsp-Cspsolution ErgonomicsZeyad RezkNo ratings yet

- Cihsolution NoiseDocument2 pagesCihsolution NoiseZeyad RezkNo ratings yet

- Asp-Cspsolution ToxicologyDocument2 pagesAsp-Cspsolution ToxicologyZeyad RezkNo ratings yet

- Asp-Cspsolution Workplace ViolenceDocument2 pagesAsp-Cspsolution Workplace ViolenceZeyad RezkNo ratings yet

- Asp-Cspsolution Work EnvironmentsDocument2 pagesAsp-Cspsolution Work EnvironmentsZeyad RezkNo ratings yet

- Asp-Cspsolution ToxicologyDocument2 pagesAsp-Cspsolution ToxicologyZeyad RezkNo ratings yet

- ASP-cspsolution Fire ProtectionDocument2 pagesASP-cspsolution Fire ProtectionZeyad RezkNo ratings yet

- Asp-Cspsolution Law and EthicsDocument2 pagesAsp-Cspsolution Law and EthicsZeyad RezkNo ratings yet

- Asp-Cspsolution Industrial HygieneDocument2 pagesAsp-Cspsolution Industrial HygieneZeyad RezkNo ratings yet

- ASP-CSP Question 12/24/2015 - ChemistryDocument2 pagesASP-CSP Question 12/24/2015 - ChemistryZeyad RezkNo ratings yet

- ASP-cspsolution Fire ProtectionDocument2 pagesASP-cspsolution Fire ProtectionZeyad RezkNo ratings yet

- ASP CertificationDocument44 pagesASP CertificationZeyad Rezk100% (1)

- ASP-cspsolution Fire ProtectionDocument2 pagesASP-cspsolution Fire ProtectionZeyad RezkNo ratings yet

- Asp-Cspsolution Industrial HygieneDocument2 pagesAsp-Cspsolution Industrial HygieneZeyad RezkNo ratings yet

- Asp-Cspsolution NoiseDocument2 pagesAsp-Cspsolution NoiseZeyad RezkNo ratings yet

- ASP-CSP Question 11/12/2015 - Ventilation: Professional Development For Health & Safety ExpertsDocument2 pagesASP-CSP Question 11/12/2015 - Ventilation: Professional Development For Health & Safety ExpertsZeyad RezkNo ratings yet

- Survey PDFDocument29 pagesSurvey PDFZeyad RezkNo ratings yet

- Asp-Cspsolution Management Rev 02Document2 pagesAsp-Cspsolution Management Rev 02Zeyad RezkNo ratings yet

- Survey PDFDocument29 pagesSurvey PDFZeyad RezkNo ratings yet

- Infrared Fuel SensorsDocument18 pagesInfrared Fuel SensorsAjish Rajan TNo ratings yet

- Issue 1499t2Document16 pagesIssue 1499t2Zeyad RezkNo ratings yet

- BeIN TV Guide AprilDocument9 pagesBeIN TV Guide AprilZeyad RezkNo ratings yet

- An Overview of Leading Software Tools For QRADocument5 pagesAn Overview of Leading Software Tools For QRAthawdarNo ratings yet

- Industrial Risk Management - Overview PDFDocument71 pagesIndustrial Risk Management - Overview PDFZeyad RezkNo ratings yet

- Fire Detection Technique Based On Photoacoustic PrincipleDocument6 pagesFire Detection Technique Based On Photoacoustic PrincipleZeyad RezkNo ratings yet

- Industrial Risk Management - Overview PDFDocument71 pagesIndustrial Risk Management - Overview PDFZeyad RezkNo ratings yet

- The Basics of Gas MonitorsDocument13 pagesThe Basics of Gas MonitorsRobVajko100% (1)

- Fire Detection Technique Based On Photoacoustic PrincipleDocument6 pagesFire Detection Technique Based On Photoacoustic PrincipleZeyad RezkNo ratings yet

- The Basics of Gas MonitorsDocument13 pagesThe Basics of Gas MonitorsRobVajko100% (1)

- Hydrotesting Failure Photos and Safety LessonsDocument3 pagesHydrotesting Failure Photos and Safety LessonsZeyad RezkNo ratings yet