Professional Documents

Culture Documents

Kirloskar Pump Family Curve

Uploaded by

Animesh SahaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kirloskar Pump Family Curve

Uploaded by

Animesh SahaCopyright:

Available Formats

KIRLOSKAR PROCESS PUMPS - TYPE KPD/KPD QF

Shaft :

Description

Range :

Delivery size up to 200 mm

Capacity up to 750 m3/hr

Heads up to 150 metres

Working Pressures 16-25 kg/cm2

Temperatures () 500C to + 3500C

Applications :

Chemical Process Industries, Petro Chemical,

Nuclear, Refinery, Paper and Power Plants etc.

Pumps suitable for handling Corrosive Acids,

Alkalies, Salt Solutions, Caustics, Hydro Carbons,

Oils, Thermic Fluids, Liquefied Gases, Condensates,

Viscous Liquids etc.

Constructional features :

Pumps are as per DIN 24256 and ISO 2858 and

generally conform to API 610 (7th Edition) The design

is of back pull out type. Large variety of models are

available to operate at 1450 rpm and 2900 rpm at

50Hz and 1750 rpm and 3500 rpm at 60 Hz.

Casing :

The casing has axial suction and top centre line

delivery. Smooth hydraulic passages ensure high

efficiency. Normal design is for foot mounted

pumps. Centre line mounting for special applications

are also available.

Impeller :

The impellers are of enclosed type and semi-open

impellers can also be supplied. Hydraulic balancing

of impellers is achieved either by back vanes or by

balancing holes. The impellers are statically and

dynamically balanced. Reliable fixing of the impeller

on shaft is achieved by using helicoil insert under

impeller nut. To improve NPSH performance,

inducer can be supplied.

Cut-sectional View

The shaft is supported by two antifriction bearings

to take residual axial thrust and prevent axial float or

radial run out. It is fully protected from the liquid

handled by means of a shaft sleeve and PTFE gaskets

between impeller nut, impeller hub and shaft sleeve.

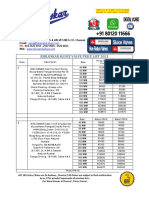

Performance Characteristics

Family Curve of KPD process pump at 1750 rpm-60Hz

Stuffing box :

The stuffing box is sealed by gland packing or by

mechanical seal. Conversion from gland packing to

mechanical seal is achieved by changing some

standardised parts. Re-machining of stuffing box is

not necessary. Stuffing box cooling is provided for

operating temperature 1050C for gland packed and

1400C for mechanical seal fitted pumps.

Bearings :

The bearings are oil lubricated. For high temperature

(above 180 0 ) application, bearing oil cooling

arrangement is provided. All pumps are provided

with reinforced bearing arrangement as standard

supply.

Direction of rotation :

Clockwise viewed from driving end.

Drive :

Pumps can be driven by electric motor or engine.

Flanges :

ANSI B 16.1, CL 125 Flat Face : for CI/BR

ANSI B 16.5, CL 150 Raised Face - for sp.metals

viz. st.steel, cast steel etc.

Drilling as per DIN, ASA, BS ect. (Optional)

Family Curve of KPD process pump at 3500 rpm-60Hz

Performance Characteristics

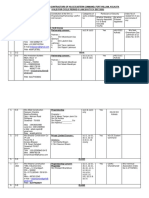

General Dimensions / Mounting Details (CLM) Pump.

Family Curve of KPD process pump at 1450 rpm-50Hz

Total Head in Metres

1450 R.P.M.

PUMP

DRG.

TYPE

UNIT SUC DEL

PUMP DIMENSIONS

a

h1

20/13QF

20/16QF

25

20

80

40

25 100

50

32

20/20QF

25/16QF

32/13

32/16

32/20

80

65

40

50 100

65/13

100

65

25/26A

50

25

32/26

65

s2

e1

23

18

SPR FIG.

t

80

50 125

170

155 155 187 187

165

155 145 187 177

140

125 125 157 157

160

155 145 187 177

170 165 202 197 285

1

14

40 20.5 6

135 125 167 157

2

24

50

27

100

15

72

88 190

170 165 202 197

14

15

180

200

2

1

252

257

1

1

2

225

1

89.5 110.5 230

200 64

100

65 100

72

225 64

125

80

100/20

125 100 125

65/32

65

100

80

89.5 110.5 230

260 230 305 275

88 190

210 175 242 207

89.5 110.5 230

260 230 305 275

240

18

14

285

18

18

100 150 300

310 295 355 340

23

25

15

92.5 107.5 230

260 230 305 275

18

15

315 315 90

140

125/26

365

42 110 45

530 315 365

150 125

125/40

12

310 295 355 340

18

100

300

400

1

23

25

355 315 400 360

200 150 160

150/40

365 450

125/26

11 150 125 140 670 315 365

200/38M

250 200 200

13

2

1

92.5 107.5

280 280

100

150/32

140

365 355

125

125/32

10

210 175 242 207

250 280

315 315

35

280

80/32

100/32

80

88 190

72

280

100/26

32

250

80/26

80/40

15 110

250 90

80/20

260 240 305 285 370

225

80/16

1

2

500 250 280 90

7

No.

130 130 162 162

220 220 252 252

65/26

Total Head in Metres

s1

250

65/20

150/52

SHAFT END

w

150

40

50/32

200/46

n4

125 125 157 157

225

40/32

50/26

Capacity in m3 /hr

n3

180

32

40/26

100/40

n2

140

160 64

80

50/20

65/16

n1

180

50/16

2900 R.P.M.

m1 m2 m3

160

50/13

Family Curve of KPD process pump at 2900 rpm - 50Hz

140

5

40/20

Capacity in m3 /hr

385 200 180

40/13

40/16

FOOT DIMENSIONS

h2

150

200 150 200 670 400 550

310 295 355 340 500

400 500 100

425 550

385 345 430 390

160

22

120

48 110 51.5 14

410 360 465 415 483.5

340

450 410 505 465

440 395 495 450

180

1

2

27

19 140 30

60 110 64.4 18

2

2

General Dimensions / Mounting Details (FM) Pump

Material of Construction

MOC CODE

ALL CI

(01)

Br. FITTED

(02)

ALL CAST

STEEL (10)

CF8M

(11)

ALL CF8M

(13)

ALL C AST STEEL

WITH Br. IMP. (12)

ALL ALLOY 20

(CN7M) (30)

PUMP CASING

CI

CI

Cast Steel

CI

CF8M

Cast Steel

CN7M

IMPELLER

CI

BR.

Cast Steel

CF8M

CF8M

BR.

CN7M

CASING RING

CI

CI

CA15H

CI

CF8M

BR.

CN7M

IMPELLER RING

CI

BR.

CA15H

CF8M

CF8M

BR.

CN7M

SHAFT

AISI 4140

AISI 4140

AISI 4140

AISI 4140

AISI 410

AISI 4140

SS410

31

SHAFT SLEEVE

SS410H

SS410H

SS410H

SS316

SS316

SS316

ALLOY 20

38

LANTERN RING

CI

CI

SS410

CI

SS316

SS410

CN7M

GLAND

CI

CI

Cast Steel

CI

CF8M

Cast Steel

CN7M

COMPONENT

PUMP

SIZE

DRIVING

UNIT

PUMP

DIMENSIONS

SUC DEL a

h1 h2 b

100 140

80 385 132 150 50

10

20/13 QF #

20/16 QF #

25

20

20/20 QF #

160 170

25/16 QF #

40

25/20 QF #

25 100

132

32/13

50

32

32/20

5

65

40

165

14

210 160

180

10

80 50 265 212

50/13

132 160

80

50 100

160

50/20

e1 d

t

20.5

6 100

43

36

11.5

44

38

40

240 190

50

14 100 70

240 190

265 212

39

285 14 15 110 24 50

27

8 100

240 190

180

42

48

42

46

265 212

200

53

65/13

100 65

160 180 65

125 95 280 212

69

25/26

50

25

180 225 65

125 95 320 250

90

32/26

50

32

65

40

80

50 125

40/26

40/32

50/26

50/32

65/16

65/20

65/26

100

180 225

320 250

125

200 250

345 280

100

7

180 225 65

500

100 65

80/16

80/20

80/26

320 250 370

225

250

225 280

65/32

100 65

225 280

80/40

100/32

100/40

14

80

16 160 120

125 100

140

150 125

125/40

530

35

10 140

85

345 280

86

400 315

18

116

360 280

106

146

181

134

400 315

15 110 42 110

45

12 140

157

280 355 100 18 200 150 500 400

23

250 355 80

18

158

200 150 500 400

23

212

285

280 355

315 400 100

16 160 120 400 315

18

370

164

179

150/32

200 150 160

315 400

150/40 $

200 150 160

315 450 100 18 200 150 550 450

22

23

65/40

125 65 150

280 340 80

18

18 160 120 435 355

Material Standards

Material

IS

BS

ASTM

Cast Iron (CI)

IS 210 (1978) Gr. FG 260

B.S. 2789 SNG 500/7

Austenitic

Iron (ACI)

Carbon Steel (CS)

CF8M

SS 316

IS 2749 Gr. AFG Ni 15

Cu 6 Cr 3

IS 1570 Gr. 40 C-8

IS 3444 Gr. 9

IS 1570 Gr. 05 Cr 18

Ni 11 Mo3

B.S. 3468 AUS 101 Gr.B

ASTM-A 536 60-40-18

& 65-45-12

ASTM-A 436 Type 1

B.S. 970 080 M 40

B.S. 1632 Gr. B

B.S. 970 316 S16

ASTM-A 107 Gr. 1040

ASTM-A 351 Gr. CF8M

ASTM-A 276 Type 316

B.S. 970 304 S 15

B.S. 3100 410 S 21

B.S. 1400 LG2C

B.S. 1504-101A

BS 97 ENIG

ASTM-A 276 Type 304

ASTM-A 276 Type 410

ASTM-B 62, B 145 Alloy 4A

ASTM-A 216 74 d Gr. WCB

ST.ST. ASTM A 217 GR CA 15

AISI 4140

140

16 160 120 435 355 370 18

250 315

79

96

400 315

225 280

125/26

125/32

320 250

14 125 95

280 355 80

77

15 110 32 80

18

65

90

120

16 160 120 360 280

250 315

100/26

14

280 212

200 280

125

14 125 95 320 250

180 225

125 100

125 80

103

160 200

100/20

80/32

90

345 280

180

125 80 125

90

225 280

200 250 80

Note : Other material of construction also available

H denotes hardened.

47

210 160

132 160

50/16

s2

WEIGHT

KG

190 140

112 140

160 180

s1

210 160 285 14 14 110 18 40

160 180

385

SHAFT END

100 70 240 190

132 160

80

40/13

40/20

m1 m2 n1 n2

80 50 190 140

112 140

32/16

40/16

FOOT DIMENSIONS

260

10

142

SS 410

Bronze (BR)

Cast Steel

CA 15

AISI 4140

IS 318 Gr. LTB2

IS 1570

Back Pull Out Arrangement

Working Temperature and Pressure

Using spacer type coupling, back-pullout

design enables the pump rotating unit to

be removed without disturbing the pipe

connections. The prime mover is also

undisturbed. This reduces servicing time,

resulting in lower maintenance costs and

reduction in production losses.

NOTE :

The pressure and temperature data holds

good only if flanges are suitable to a

particular operating pressure and

temperature.

General Outline Dimensions of KPD/KPDQF (FM) Pump

SIZE

UNIT

PUMP

DIMENSIONS

SUC DEL a

f h1

125/45 $

11A

150/43 $

11B

65/43 $

PUMP

Alternatives Available

Bearing Oil Cooling Arrangement

For high temperature applications above

1800C bearing oil cooling arrangement is

provided.

Centre line Mounting

For high temperature applications between

1800C to 3500C, pumps are offered with

centreline mounting.

PUMP

SIZE

DRIVING

125 150 160 670 350 450 100 20 180 120 70 550 450 500

23

19 140 48 110 51.4 14 180

290

150 200 160 685 350 475 100 20 180 120 90 550 450 514

23

19 140 48 110 51.4 14 180

300

65

18

15 110 42 110 45

195

100 160 530 280 365

80

m1

m2 m3 n1

DEL SUC a

h1

e1

d*

h2

m1 m2 n1

n2

s1

23

250 355 80

18

16 160 120 400 315

18

500 400

12 140

500

s2

e1

WEIGHT

KG

y

180

198

190

19 140 48 110 51.5 14

214

23

140

254

150/32 *

150 200 160

150/26A $

150 200 175 670 280 375 100 20 200 150 500 400 483.5 23

15 140 60 110 64.4 18 180

230

150 200 200 670 400 550 150 30 240 180 650 530 483 27

19 140 60 110 64.4 18 180

435

200 250 200 670 400 500 120 30 240 180 550 430 483.5 27

19 140 60 110 64.4 18 180

550

200 250 200 670 425 550 120 30 240 180 640 540 483.5 27

19 140 60 110 64.4 18 180

560

200/38M $

200/46 $

13

315 400

200 150

SHAFT END

280 355 100 18 200 150 500 400

315 400 100

150/52 $

22

Note :

Steam Jacket Arrangement

This special design can be offered for handling

liquids that cannot be pumped when cold.

Except for pump casing, casing cover and gland,

all parts are of standard design.

FOOT DIMENSIONS

125 150 140 670 280 355

125/40 *

n2

18 160 120 60 435 355 370

PUMP

DIMENSIONS

100 125

11

WEIGHT

KG

s2

125/26 *

125/32 *

h2

SHAFT END

s1

DRIVING

UNIT

100/40 *

FOOT DIMENSIONS

# These pumps can be provided with semi open impeller only.

$ These pumps cannot be supplied with semi open impeller.

* These pumps can be supplied in Unit-II under special requirment.

550 450

312

Cross Sectional View (KPD)

Cross Sectional View (KPD QF)

Typical Drawing

Interchangeability of Components

Pump Unit

11

11/A

11/B

13

Size

Casing

Impeller

32/13

40/13

50/13

65/13

32/16

32/16A

40/16

50/16

50/16A

32/20

32/20A

40/20

40/20A

50/20

65/16

80/16

65/20

80/20

100/20

25/26

32/26

40/26

50/26

65/26

65/26N

80/26

40/32

50/32

100/26

125/26

65/32

(1450 RPM)

65/32

(2900 RPM)

80/32

100/32

125/32

125/32M

150/32

150/32N

65/40

80/40

80/40N

100/40

125/40

125/40N

125/40M

150/40

65/43

125/26

(2900 RPM)

125/45

150/43

150/52

200/38M

200/46

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Casing

Cover

Bearing Housing

& Shaft

Pump Unit

6

7

9

10

11

12

20/13

20/16

20/20

32/13

40/13

50/13

65/13

25/16

32/16

40/16

10

10

50/16

11

11

32/20

12

12

40/20

13

13

50/20

14

14

65/16

15

15

80/16

16

16

65/20

17

17

80/20

18

18

100/20

19

19

12

32/26

20

20

13

Bearing Housing

& Shaft

8

9

10

11

22

22

65/26

23

23

80/26

24

24

15

40/32

25

25

16

50/32

26

26

100/26

27

27

125/26

28

28

65/32

29

29

20

49

50

45

46

47

52

53

48

49

50

25

26

21

22

23

6

7

16

17

18

24

50/26

15

14

33

41

Casing

Cover

21

44

39

40

Impeller

21

42

43

48

38

Casing

40/26

35

36

37

38

39

40

41

42

43

44

45

46

46

47

51

37

Size

13

34

30

31

32

36

Typical Drawing

33

29

Interchangeability of Components

14

17

80/32

30

30

100/32

31

31

125/32

32

32

150/32

33

33

80/40

34

34

20

100/40

35

35

21

125/40

36

36

22

18

19

Cross Sectional View (KPD)

Cross Sectional View (KPD QF)

Typical Drawing

Interchangeability of Components

Pump Unit

11

11/A

11/B

13

Size

Casing

Impeller

32/13

40/13

50/13

65/13

32/16

32/16A

40/16

50/16

50/16A

32/20

32/20A

40/20

40/20A

50/20

65/16

80/16

65/20

80/20

100/20

25/26

32/26

40/26

50/26

65/26

65/26N

80/26

40/32

50/32

100/26

125/26

65/32

(1450 RPM)

65/32

(2900 RPM)

80/32

100/32

125/32

125/32M

150/32

150/32N

65/40

80/40

80/40N

100/40

125/40

125/40N

125/40M

150/40

65/43

125/26

(2900 RPM)

125/45

150/43

150/52

200/38M

200/46

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Casing

Cover

Bearing Housing

& Shaft

Pump Unit

6

7

9

10

11

12

20/13

20/16

20/20

32/13

40/13

50/13

65/13

25/16

32/16

40/16

10

10

50/16

11

11

32/20

12

12

40/20

13

13

50/20

14

14

65/16

15

15

80/16

16

16

65/20

17

17

80/20

18

18

100/20

19

19

12

32/26

20

20

13

Bearing Housing

& Shaft

8

9

10

11

22

22

65/26

23

23

80/26

24

24

15

40/32

25

25

16

50/32

26

26

100/26

27

27

125/26

28

28

65/32

29

29

20

49

50

45

46

47

52

53

48

49

50

25

26

21

22

23

6

7

16

17

18

24

50/26

15

14

33

41

Casing

Cover

21

44

39

40

Impeller

21

42

43

48

38

Casing

40/26

35

36

37

38

39

40

41

42

43

44

45

46

46

47

51

37

Size

13

34

30

31

32

36

Typical Drawing

33

29

Interchangeability of Components

14

17

80/32

30

30

100/32

31

31

125/32

32

32

150/32

33

33

80/40

34

34

20

100/40

35

35

21

125/40

36

36

22

18

19

Back Pull Out Arrangement

Working Temperature and Pressure

Using spacer type coupling, back-pullout

design enables the pump rotating unit to

be removed without disturbing the pipe

connections. The prime mover is also

undisturbed. This reduces servicing time,

resulting in lower maintenance costs and

reduction in production losses.

NOTE :

The pressure and temperature data holds

good only if flanges are suitable to a

particular operating pressure and

temperature.

General Outline Dimensions of KPD/KPDQF (FM) Pump

SIZE

UNIT

PUMP

DIMENSIONS

SUC DEL a

f h1

125/45 $

11A

150/43 $

11B

65/43 $

PUMP

Alternatives Available

Bearing Oil Cooling Arrangement

For high temperature applications above

1800C bearing oil cooling arrangement is

provided.

Centre line Mounting

For high temperature applications between

1800C to 3500C, pumps are offered with

centreline mounting.

PUMP

SIZE

DRIVING

125 150 160 670 350 450 100 20 180 120 70 550 450 500

23

19 140 48 110 51.4 14 180

290

150 200 160 685 350 475 100 20 180 120 90 550 450 514

23

19 140 48 110 51.4 14 180

300

65

18

15 110 42 110 45

195

100 160 530 280 365

80

m1

m2 m3 n1

DEL SUC a

h1

e1

d*

h2

m1 m2 n1

n2

s1

23

250 355 80

18

16 160 120 400 315

18

500 400

12 140

500

s2

e1

WEIGHT

KG

y

180

198

190

19 140 48 110 51.5 14

214

23

140

254

150/32 *

150 200 160

150/26A $

150 200 175 670 280 375 100 20 200 150 500 400 483.5 23

15 140 60 110 64.4 18 180

230

150 200 200 670 400 550 150 30 240 180 650 530 483 27

19 140 60 110 64.4 18 180

435

200 250 200 670 400 500 120 30 240 180 550 430 483.5 27

19 140 60 110 64.4 18 180

550

200 250 200 670 425 550 120 30 240 180 640 540 483.5 27

19 140 60 110 64.4 18 180

560

200/38M $

200/46 $

13

315 400

200 150

SHAFT END

280 355 100 18 200 150 500 400

315 400 100

150/52 $

22

Note :

Steam Jacket Arrangement

This special design can be offered for handling

liquids that cannot be pumped when cold.

Except for pump casing, casing cover and gland,

all parts are of standard design.

FOOT DIMENSIONS

125 150 140 670 280 355

125/40 *

n2

18 160 120 60 435 355 370

PUMP

DIMENSIONS

100 125

11

WEIGHT

KG

s2

125/26 *

125/32 *

h2

SHAFT END

s1

DRIVING

UNIT

100/40 *

FOOT DIMENSIONS

# These pumps can be provided with semi open impeller only.

$ These pumps cannot be supplied with semi open impeller.

* These pumps can be supplied in Unit-II under special requirment.

550 450

312

General Dimensions / Mounting Details (FM) Pump

Material of Construction

MOC CODE

ALL CI

(01)

Br. FITTED

(02)

ALL CAST

STEEL (10)

CF8M

(11)

ALL CF8M

(13)

ALL C AST STEEL

WITH Br. IMP. (12)

ALL ALLOY 20

(CN7M) (30)

PUMP CASING

CI

CI

Cast Steel

CI

CF8M

Cast Steel

CN7M

IMPELLER

CI

BR.

Cast Steel

CF8M

CF8M

BR.

CN7M

CASING RING

CI

CI

CA15H

CI

CF8M

BR.

CN7M

IMPELLER RING

CI

BR.

CA15H

CF8M

CF8M

BR.

CN7M

SHAFT

AISI 4140

AISI 4140

AISI 4140

AISI 4140

AISI 410

AISI 4140

SS410

31

SHAFT SLEEVE

SS410H

SS410H

SS410H

SS316

SS316

SS316

ALLOY 20

38

LANTERN RING

CI

CI

SS410

CI

SS316

SS410

CN7M

GLAND

CI

CI

Cast Steel

CI

CF8M

Cast Steel

CN7M

COMPONENT

PUMP

SIZE

DRIVING

UNIT

PUMP

DIMENSIONS

SUC DEL a

h1 h2 b

100 140

80 385 132 150 50

10

20/13 QF #

20/16 QF #

25

20

20/20 QF #

160 170

25/16 QF #

40

25/20 QF #

25 100

132

32/13

50

32

32/20

5

65

40

165

14

210 160

180

10

80 50 265 212

50/13

132 160

80

50 100

160

50/20

e1 d

t

20.5

6 100

43

36

11.5

44

38

40

240 190

50

14 100 70

240 190

265 212

39

285 14 15 110 24 50

27

8 100

240 190

180

42

48

42

46

265 212

200

53

65/13

100 65

160 180 65

125 95 280 212

69

25/26

50

25

180 225 65

125 95 320 250

90

32/26

50

32

65

40

80

50 125

40/26

40/32

50/26

50/32

65/16

65/20

65/26

100

180 225

320 250

125

200 250

345 280

100

7

180 225 65

500

100 65

80/16

80/20

80/26

320 250 370

225

250

225 280

65/32

100 65

225 280

80/40

100/32

100/40

14

80

16 160 120

125 100

140

150 125

125/40

530

35

10 140

85

345 280

86

400 315

18

116

360 280

106

146

181

134

400 315

15 110 42 110

45

12 140

157

280 355 100 18 200 150 500 400

23

250 355 80

18

158

200 150 500 400

23

212

285

280 355

315 400 100

16 160 120 400 315

18

370

164

179

150/32

200 150 160

315 400

150/40 $

200 150 160

315 450 100 18 200 150 550 450

22

23

65/40

125 65 150

280 340 80

18

18 160 120 435 355

Material Standards

Material

IS

BS

ASTM

Cast Iron (CI)

IS 210 (1978) Gr. FG 260

B.S. 2789 SNG 500/7

Austenitic

Iron (ACI)

Carbon Steel (CS)

CF8M

SS 316

IS 2749 Gr. AFG Ni 15

Cu 6 Cr 3

IS 1570 Gr. 40 C-8

IS 3444 Gr. 9

IS 1570 Gr. 05 Cr 18

Ni 11 Mo3

B.S. 3468 AUS 101 Gr.B

ASTM-A 536 60-40-18

& 65-45-12

ASTM-A 436 Type 1

B.S. 970 080 M 40

B.S. 1632 Gr. B

B.S. 970 316 S16

ASTM-A 107 Gr. 1040

ASTM-A 351 Gr. CF8M

ASTM-A 276 Type 316

B.S. 970 304 S 15

B.S. 3100 410 S 21

B.S. 1400 LG2C

B.S. 1504-101A

BS 97 ENIG

ASTM-A 276 Type 304

ASTM-A 276 Type 410

ASTM-B 62, B 145 Alloy 4A

ASTM-A 216 74 d Gr. WCB

ST.ST. ASTM A 217 GR CA 15

AISI 4140

140

16 160 120 435 355 370 18

250 315

79

96

400 315

225 280

125/26

125/32

320 250

14 125 95

280 355 80

77

15 110 32 80

18

65

90

120

16 160 120 360 280

250 315

100/26

14

280 212

200 280

125

14 125 95 320 250

180 225

125 100

125 80

103

160 200

100/20

80/32

90

345 280

180

125 80 125

90

225 280

200 250 80

Note : Other material of construction also available

H denotes hardened.

47

210 160

132 160

50/16

s2

WEIGHT

KG

190 140

112 140

160 180

s1

210 160 285 14 14 110 18 40

160 180

385

SHAFT END

100 70 240 190

132 160

80

40/13

40/20

m1 m2 n1 n2

80 50 190 140

112 140

32/16

40/16

FOOT DIMENSIONS

260

10

142

SS 410

Bronze (BR)

Cast Steel

CA 15

AISI 4140

IS 318 Gr. LTB2

IS 1570

Performance Characteristics

General Dimensions / Mounting Details (CLM) Pump.

Family Curve of KPD process pump at 1450 rpm-50Hz

Total Head in Metres

1450 R.P.M.

PUMP

DRG.

TYPE

UNIT SUC DEL

PUMP DIMENSIONS

a

h1

20/13QF

20/16QF

25

20

80

40

25 100

50

32

20/20QF

25/16QF

32/13

32/16

32/20

80

65

40

50 100

65/13

100

65

25/26A

50

25

32/26

65

s2

e1

23

18

SPR FIG.

t

80

50 125

170

155 155 187 187

165

155 145 187 177

140

125 125 157 157

160

155 145 187 177

170 165 202 197 285

1

14

40 20.5 6

135 125 167 157

2

24

50

27

100

15

72

88 190

170 165 202 197

14

15

180

200

2

1

252

257

1

1

2

225

1

89.5 110.5 230

200 64

100

65 100

72

225 64

125

80

100/20

125 100 125

65/32

65

100

80

89.5 110.5 230

260 230 305 275

88 190

210 175 242 207

89.5 110.5 230

260 230 305 275

240

18

14

285

18

18

100 150 300

310 295 355 340

23

25

15

92.5 107.5 230

260 230 305 275

18

15

315 315 90

140

125/26

365

42 110 45

530 315 365

150 125

125/40

12

310 295 355 340

18

100

300

400

1

23

25

355 315 400 360

200 150 160

150/40

365 450

125/26

11 150 125 140 670 315 365

200/38M

250 200 200

13

2

1

92.5 107.5

280 280

100

150/32

140

365 355

125

125/32

10

210 175 242 207

250 280

315 315

35

280

80/32

100/32

80

88 190

72

280

100/26

32

250

80/26

80/40

15 110

250 90

80/20

260 240 305 285 370

225

80/16

1

2

500 250 280 90

7

No.

130 130 162 162

220 220 252 252

65/26

Total Head in Metres

s1

250

65/20

150/52

SHAFT END

w

150

40

50/32

200/46

n4

125 125 157 157

225

40/32

50/26

Capacity in m3 /hr

n3

180

32

40/26

100/40

n2

140

160 64

80

50/20

65/16

n1

180

50/16

2900 R.P.M.

m1 m2 m3

160

50/13

Family Curve of KPD process pump at 2900 rpm - 50Hz

140

5

40/20

Capacity in m3 /hr

385 200 180

40/13

40/16

FOOT DIMENSIONS

h2

150

200 150 200 670 400 550

310 295 355 340 500

400 500 100

425 550

385 345 430 390

160

22

120

48 110 51.5 14

410 360 465 415 483.5

340

450 410 505 465

440 395 495 450

180

1

2

27

19 140 30

60 110 64.4 18

2

2

KIRLOSKAR PROCESS PUMPS - TYPE KPD/KPD QF

Shaft :

Description

Range :

Delivery size up to 200 mm

Capacity up to 750 m3/hr

Heads up to 150 metres

Working Pressures 16-25 kg/cm2

Temperatures () 500C to + 3500C

Applications :

Chemical Process Industries, Petro Chemical,

Nuclear, Refinery, Paper and Power Plants etc.

Pumps suitable for handling Corrosive Acids,

Alkalies, Salt Solutions, Caustics, Hydro Carbons,

Oils, Thermic Fluids, Liquefied Gases, Condensates,

Viscous Liquids etc.

Constructional features :

Pumps are as per DIN 24256 and ISO 2858 and

generally conform to API 610 (7th Edition) The design

is of back pull out type. Large variety of models are

available to operate at 1450 rpm and 2900 rpm at

50Hz and 1750 rpm and 3500 rpm at 60 Hz.

Casing :

The casing has axial suction and top centre line

delivery. Smooth hydraulic passages ensure high

efficiency. Normal design is for foot mounted

pumps. Centre line mounting for special applications

are also available.

Impeller :

The impellers are of enclosed type and semi-open

impellers can also be supplied. Hydraulic balancing

of impellers is achieved either by back vanes or by

balancing holes. The impellers are statically and

dynamically balanced. Reliable fixing of the impeller

on shaft is achieved by using helicoil insert under

impeller nut. To improve NPSH performance,

inducer can be supplied.

Cut-sectional View

The shaft is supported by two antifriction bearings

to take residual axial thrust and prevent axial float or

radial run out. It is fully protected from the liquid

handled by means of a shaft sleeve and PTFE gaskets

between impeller nut, impeller hub and shaft sleeve.

Performance Characteristics

Family Curve of KPD process pump at 1750 rpm-60Hz

Stuffing box :

The stuffing box is sealed by gland packing or by

mechanical seal. Conversion from gland packing to

mechanical seal is achieved by changing some

standardised parts. Re-machining of stuffing box is

not necessary. Stuffing box cooling is provided for

operating temperature 1050C for gland packed and

1400C for mechanical seal fitted pumps.

Bearings :

The bearings are oil lubricated. For high temperature

(above 180 0 ) application, bearing oil cooling

arrangement is provided. All pumps are provided

with reinforced bearing arrangement as standard

supply.

Direction of rotation :

Clockwise viewed from driving end.

Drive :

Pumps can be driven by electric motor or engine.

Flanges :

ANSI B 16.1, CL 125 Flat Face : for CI/BR

ANSI B 16.5, CL 150 Raised Face - for sp.metals

viz. st.steel, cast steel etc.

Drilling as per DIN, ASA, BS ect. (Optional)

Family Curve of KPD process pump at 3500 rpm-60Hz

Family Curve of KPD-QF process pump at

1450 rpm-50Hz

Family Curve of KPD-QF process pump at

2900 rpm - 50 Hz

Family Curve of KPD-QF process pump at

1750 rpm - 60 Hz

As we are constantly endeavouring to improve the performance of our products/equipment, we reserve the right to make alterations from time to time and as such our

products/equipment may differ from that detailed in this publication. For latest information you may get in touch with our Regional Sales Offices.

CORPORATE OFFICE :

UDYOG BHAVAN, TILAK ROAD,

PUNE - 411 002 (INDIA)

PHONE : (020) 444 4444

FAX : (020) 4444198, 4440156

Email : kblin@kbl.co.in

Web Site : http://www.kirloskars.com

WORKS : KIRLOSKARVADI 416 308.

DIST. SANGLI

PHONE : (02346) 22301-5 FAX : (02346) 22311

Enquiries may be directed to the nearest Regional Sales Office.

Regional Sales Offices : Ahmedabad, Bangalore, Baroda, Bhubaneswar, Calcutta,

Chennai, Jaipur, Kochi, Lucknow, Mumbai, Nagpur, New Delhi, Pune, Ranchi,

Secunderabad.

KPD 112100

KIRLOSKAR BROTHERS LIMITED

PRINTING DIVISION, PUNE 411 038.

KIRLOSKAR

BROTHERS

LIMITED

You might also like

- Morse, Ingard - Theoretical Acoustics (1968)Document951 pagesMorse, Ingard - Theoretical Acoustics (1968)Yojik83% (6)

- Mark 3 ASME Pumps PDFDocument94 pagesMark 3 ASME Pumps PDFInf IngNo ratings yet

- Sro 19e Annexure 4Document83 pagesSro 19e Annexure 4Animesh SahaNo ratings yet

- Iafw 2249Document33 pagesIafw 2249Animesh Saha67% (3)

- Welded Joint, Welded ConnectionsDocument45 pagesWelded Joint, Welded ConnectionsRaju Sharma67% (12)

- 01 MF New Pages PDFDocument22 pages01 MF New Pages PDFSlobodan AnticNo ratings yet

- DB Pump CurvesDocument70 pagesDB Pump CurvesMusheer Basha75% (12)

- Technical Manual CPHMDocument36 pagesTechnical Manual CPHMRentu Philipose67% (3)

- Research - Kirloskar Fire Fighting Pumps PDFDocument8 pagesResearch - Kirloskar Fire Fighting Pumps PDFYogeshNo ratings yet

- KBL Pump Test HouseDocument8 pagesKBL Pump Test Housegautamten1110No ratings yet

- Kirloskar Sluice Valve Price List 2021: Valid From 10-12-2021 Till 31-04-2022 (Subject To Confirmation Thereafter)Document3 pagesKirloskar Sluice Valve Price List 2021: Valid From 10-12-2021 Till 31-04-2022 (Subject To Confirmation Thereafter)jhony Mud100% (1)

- Kirloskar PumpDocument24 pagesKirloskar PumpAmit Patel0% (1)

- Low Temp Refrigeration by VoltasDocument31 pagesLow Temp Refrigeration by Voltaskamal_muralikumar100% (1)

- Technical Manual DBDocument27 pagesTechnical Manual DBRentu Philipose100% (2)

- Brosur Etanorm SYTDocument24 pagesBrosur Etanorm SYTNovarNo ratings yet

- Split Case PDFDocument8 pagesSplit Case PDFnitin lageju100% (1)

- Pricelist-Tubes & ValvesDocument39 pagesPricelist-Tubes & ValvesHKRajesh100% (1)

- CpkoDocument24 pagesCpkoDeepak SparkleNo ratings yet

- Chapter 3 PelletizationDocument60 pagesChapter 3 PelletizationMohammadNouman KabutarwalaNo ratings yet

- Is 14846Document24 pagesIs 14846rinabiswas100% (1)

- Technical Data Sheet - IBG-1423-27 I VT-52-66Document8 pagesTechnical Data Sheet - IBG-1423-27 I VT-52-66Dinesh BhardwajNo ratings yet

- List of Indian Standards On PumpsDocument8 pagesList of Indian Standards On Pumpskiki270977No ratings yet

- Data Sheet PDFDocument36 pagesData Sheet PDFRaktima MisraNo ratings yet

- Vacuumpump TroubleshootingDocument5 pagesVacuumpump TroubleshootingKelly RobertsNo ratings yet

- Tube Mill PatraDocument30 pagesTube Mill PatraRitz HindustanNo ratings yet

- Submersible+Borehole+Pumps 60+HzDocument114 pagesSubmersible+Borehole+Pumps 60+HzNong Noc100% (1)

- Multi Wing Product Overview 2013Document12 pagesMulti Wing Product Overview 2013dharmeswarNo ratings yet

- Mechanical Energy Based ProcessDocument27 pagesMechanical Energy Based ProcessRameshkumar KandaswamyNo ratings yet

- Documents - Pub Knife Gate ValveDocument67 pagesDocuments - Pub Knife Gate ValveMahendra PatilNo ratings yet

- Kirloskar Brothers Limited, SanandDocument25 pagesKirloskar Brothers Limited, SanandjaydeepsinhNo ratings yet

- Pumps: Pacifico Ortaliza Pme 828Document32 pagesPumps: Pacifico Ortaliza Pme 828Angel Silva VicenteNo ratings yet

- Kirloskar Brothers LimitedDocument36 pagesKirloskar Brothers Limitedgopalakrishnannrm1202No ratings yet

- Design of Centrifugal Pump - ImpellerDocument18 pagesDesign of Centrifugal Pump - ImpellerRajib MandalNo ratings yet

- Practical Study of Borewell PumpDocument6 pagesPractical Study of Borewell PumpGray FullbusterNo ratings yet

- Microfinish Pump DataDocument2 pagesMicrofinish Pump DataPraveen PrajapatiNo ratings yet

- A Case Study of Bhogdoi River BasinDocument59 pagesA Case Study of Bhogdoi River Basinbimalgogoi100% (3)

- Material EquivalentDocument2 pagesMaterial EquivalentdilipNo ratings yet

- EFP 1250 GPM@110 MDocument1 pageEFP 1250 GPM@110 MAde WawanNo ratings yet

- SPMManualPDF PDFDocument22 pagesSPMManualPDF PDFAbhinav SaiNo ratings yet

- Hydraulic Powerpack DesignDocument18 pagesHydraulic Powerpack DesignChandrahas ReddyNo ratings yet

- Ifms Intelligent Fluid Management System: Solution OutlineDocument8 pagesIfms Intelligent Fluid Management System: Solution OutlineArmstrong Fluid TechnologyNo ratings yet

- GB5310 2008 Pipe SpecificationDocument5 pagesGB5310 2008 Pipe SpecificationRio EstikaNo ratings yet

- Technical Data Sheet 150mm & 300mmDocument2 pagesTechnical Data Sheet 150mm & 300mmManas Kumar SamalNo ratings yet

- Membrane Pre TreatmentDocument10 pagesMembrane Pre Treatmentadalcayde2514No ratings yet

- Multistage Pump - Kirloskar PDFDocument63 pagesMultistage Pump - Kirloskar PDFpsuvarnasNo ratings yet

- Slurry Pumps Ar1 PDFDocument40 pagesSlurry Pumps Ar1 PDFsanjayagrawal70-1No ratings yet

- DM Water CostingDocument1 pageDM Water CostingRaja ManiNo ratings yet

- Profile KSB-PADocument82 pagesProfile KSB-PAjaseel kNo ratings yet

- Gear Pump Datasheets 2Document12 pagesGear Pump Datasheets 2MauliNo ratings yet

- Pump in PlantDocument14 pagesPump in PlantGanesh MarkadNo ratings yet

- HPTM Machine DetailsDocument7 pagesHPTM Machine DetailsK Srinivasa Sagar100% (1)

- Apco Air Release Valves Arv Arv Air Release Valves Sales 600Document4 pagesApco Air Release Valves Arv Arv Air Release Valves Sales 600RashedNo ratings yet

- Kirloskar Pump Manual Maintainance PDFDocument105 pagesKirloskar Pump Manual Maintainance PDFakshay deepak raut100% (1)

- Iom Vertical Turbine PumpDocument33 pagesIom Vertical Turbine PumpSanto ENo ratings yet

- Is 6595 2 1993Document10 pagesIs 6595 2 1993mishraenggNo ratings yet

- 3 PumpingSystems Performance PDFDocument23 pages3 PumpingSystems Performance PDFEngHazem AlsharifNo ratings yet

- Pipe and Tube Bursting PressuresDocument2 pagesPipe and Tube Bursting PressuresRaymond MetselaarNo ratings yet

- Calculating Aeration Flow and Pressure RequirementsDocument34 pagesCalculating Aeration Flow and Pressure RequirementsFelipe BrainNo ratings yet

- Cast Iron Flanged Pipes IS7181 IS1537 Weight ChartDocument1 pageCast Iron Flanged Pipes IS7181 IS1537 Weight ChartSukanta chakrabortyNo ratings yet

- Horizontal Split Casing Pumps: Kirloskar Brothers LimitedDocument23 pagesHorizontal Split Casing Pumps: Kirloskar Brothers LimitedChaitanya DattaNo ratings yet

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- Series PGP, PGM 620 CharacteristicsDocument13 pagesSeries PGP, PGM 620 CharacteristicsAnonymous OFKjccHONo ratings yet

- DSM PDFDocument8 pagesDSM PDFSlobodan AnticNo ratings yet

- Imo Ace PumpsDocument12 pagesImo Ace Pumpsrentz76No ratings yet

- Elmeasure Digital Meters Price ListDocument2 pagesElmeasure Digital Meters Price ListAnimesh SahaNo ratings yet

- Min Wage UttrakhandDocument8 pagesMin Wage UttrakhandAnimesh SahaNo ratings yet

- Castrol Price List Lubricants Pricelist 2018Document3 pagesCastrol Price List Lubricants Pricelist 2018Animesh SahaNo ratings yet

- Cgda Io - 06 - 08Document31 pagesCgda Io - 06 - 08Animesh SahaNo ratings yet

- 1180 1a2Document1 page1180 1a2Animesh SahaNo ratings yet

- Maintenance & Operation On Contract BasisDocument2 pagesMaintenance & Operation On Contract BasisAnimesh SahaNo ratings yet

- DEPRECIATION RATE FOR MES INSTALLATIONS AMENDMENT 20 Mar 17 PDFDocument4 pagesDEPRECIATION RATE FOR MES INSTALLATIONS AMENDMENT 20 Mar 17 PDFAnimesh SahaNo ratings yet

- Cg-Fan Price ListDocument3 pagesCg-Fan Price ListAnimesh SahaNo ratings yet

- Appd List of Contractros of CEEC - Aug 18Document173 pagesAppd List of Contractros of CEEC - Aug 18Animesh SahaNo ratings yet

- Service Tax PolicyDocument2 pagesService Tax PolicyAnimesh SahaNo ratings yet

- Amendment Table B RMES 2015Document14 pagesAmendment Table B RMES 2015Animesh Saha100% (1)

- Compact Sub Station BrochureDocument8 pagesCompact Sub Station BrochureAnimesh SahaNo ratings yet

- Sewage Treatment PlantDocument41 pagesSewage Treatment PlantPradeepBansal50% (2)

- Exemption of Sales Tax and Electricity Duty On Electricity Consumed by Central GoovrnmentDocument2 pagesExemption of Sales Tax and Electricity Duty On Electricity Consumed by Central GoovrnmentAnimesh SahaNo ratings yet

- School Notes SJS KolkataDocument1 pageSchool Notes SJS KolkataAnimesh SahaNo ratings yet

- CG Monoblock Pump MB MRP DT 01-07-2012Document1 pageCG Monoblock Pump MB MRP DT 01-07-2012Animesh SahaNo ratings yet

- National Commission For Protection of Child Rights Act 2005Document11 pagesNational Commission For Protection of Child Rights Act 2005Animesh SahaNo ratings yet

- CESC - Tariff Order 12-13Document29 pagesCESC - Tariff Order 12-13Animesh SahaNo ratings yet

- Bharat Bijlee Price List 21 Mar 2011Document11 pagesBharat Bijlee Price List 21 Mar 2011Animesh SahaNo ratings yet

- Whirlpool AMC ACDocument1 pageWhirlpool AMC ACAnimesh SahaNo ratings yet

- ReinforcedConcreteDesign PDFDocument1 pageReinforcedConcreteDesign PDFMohd parvezNo ratings yet

- ASD Vs LRFD ComparisonDocument107 pagesASD Vs LRFD Comparisonpandiangv0% (1)

- Astm e 1252 PDFDocument13 pagesAstm e 1252 PDFMonalisa RodriguesNo ratings yet

- Markflow Grout 2 PDFDocument3 pagesMarkflow Grout 2 PDFBharat PaintsNo ratings yet

- High Field MRIDocument66 pagesHigh Field MRIMilena RakinNo ratings yet

- Conductive Polymer Based On Polyaniline-Eggshell Powder (PANI-ESP) CompositesDocument17 pagesConductive Polymer Based On Polyaniline-Eggshell Powder (PANI-ESP) CompositesSergioNo ratings yet

- Groundwater Flow and Solute Transport: Solved With Comsol Multiphysics 3.5ADocument9 pagesGroundwater Flow and Solute Transport: Solved With Comsol Multiphysics 3.5AmacryneNo ratings yet

- Gas DynamicsDocument10 pagesGas Dynamics130423No ratings yet

- NumericalsDocument6 pagesNumericalsaditya dhapodkarNo ratings yet

- Ddev Plastiks Industries Limited - SurangiDocument3 pagesDdev Plastiks Industries Limited - SurangiDebasis MallickNo ratings yet

- 538-310 ManualDocument17 pages538-310 ManualJavier PalaciosNo ratings yet

- EXPERIMENT 4: NMR Analysis of A Constitutional IsomerDocument18 pagesEXPERIMENT 4: NMR Analysis of A Constitutional IsomerdjambulazizNo ratings yet

- Sanicro 38 PDFDocument4 pagesSanicro 38 PDFJose Luis Gomez Ortiz100% (1)

- Ferroli Manual - Instalare - RLA IP - 200Document68 pagesFerroli Manual - Instalare - RLA IP - 200gereseNo ratings yet

- MCQ On MosDocument10 pagesMCQ On MosAkshayThakur0% (1)

- Wadada Hydel Techgeneral 2021Document36 pagesWadada Hydel Techgeneral 2021Hamza IzharNo ratings yet

- Concrete Masonry Design PDFDocument83 pagesConcrete Masonry Design PDFDipikaNo ratings yet

- An Overview of Orthodontic WiresDocument6 pagesAn Overview of Orthodontic WiresDr.kaviyarasuNo ratings yet

- Construction and Building Materials: L.C. HollawayDocument27 pagesConstruction and Building Materials: L.C. HollawayZain SaeedNo ratings yet

- Birefringe p5422 eDocument6 pagesBirefringe p5422 eGugunGunandarNo ratings yet

- Divergent Plate Boundaries: Main ArticleDocument2 pagesDivergent Plate Boundaries: Main ArticlemaluliNo ratings yet

- Drilling Fluids 2Document12 pagesDrilling Fluids 2محمد باسم محمد حسينNo ratings yet

- Smart Fibres Technology Introduction PDFDocument5 pagesSmart Fibres Technology Introduction PDFKavya ShivakumarNo ratings yet

- Why Ceramics Are BrittleDocument5 pagesWhy Ceramics Are Brittlehorizon9630% (1)

- Types of Cracks in Concrete and Typical Causes - GSADocument2 pagesTypes of Cracks in Concrete and Typical Causes - GSAdhan singhNo ratings yet

- Stress Analysis of Piston Using Pressure Load and Thermal LoadDocument8 pagesStress Analysis of Piston Using Pressure Load and Thermal LoadInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Reactor DesignDocument27 pagesReactor Designcheckmeout803100% (3)

- Question (Descriptive) Bank Unit - 1 and Unit-4Document19 pagesQuestion (Descriptive) Bank Unit - 1 and Unit-4Ziyaul AijazNo ratings yet