Professional Documents

Culture Documents

Meo Oral Fn-4

Uploaded by

Anonymous 4ylE57C6Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Meo Oral Fn-4

Uploaded by

Anonymous 4ylE57C6Copyright:

Available Formats

Mot-Gnl Fn-4.txt ?08.10.12 Mr BISWAS ,Subimal chakraborthy fn 4 1.type of avr u worked on,advantage of avr 2.

expansion valve diagram, function of thermostat, equalizer line conn use , and all about expansion valve, use of electrical operated solon valve before exp valve. 3. new ship cane from yard, how to avoid hunting keeping in mind all thing are perfect Q> Disadvantages of Co2 as a refrigerant? ans: 1. High operating pressures. 2. Heavy equipment and piping. 3. Non miscible in oil. 4. leak detection difficult. 5. critical temp of CO2 31 deg.C. Q> Ship building steel? ans: Steel wth C-0.15 to 0.23%. properties: 1) Reasonable cost. 2. Good weldablity. 3. Ductility and homogeniety. 4. Yield pt high proportio of UTS. 5. Flame cutting easy. 6. resistanceto corrosion. Graded from A to E as per classification society. Q> What are Variable-geometry turbochargers? ans: Also check pounders. Variable-geometry turbochargers (VGTs) are a family of turbochargers, usually designed to allow the effective aspect ratio (sometimes called A/R Ratio) of the turbo to be altered as conditions change. This is done because optimum aspect ratio at low engine speeds is very different from that at high engine speeds. If the aspect ratio is too large, the turbo will fail to create boost at low speeds; if the aspect ratio is too small, the turbo will choke the engine at high speeds, leading to high exhaust manifold pressures, high pumping losses, and ultimately lower power output. By altering the geometry of the turbine housing as the engine accelerates, the turbo's aspect ratio can be maintained at its optimum. Because of this, VGTs have a minimal amount of lag, have a low boost threshold, and are very efficient at higher engine speeds. VGTs do not require a wastegate. VGTs tend to be much more common on diesel engines as the lower exhaust temperatures mean they are less prone to failure.The vanes are controlled by a membrane vacuum actuator, electric servo actuation, hydraulic actuator or air actuator using air-brake system pressure. Q> Diff.between MC ans MCC? ans: 1. more compact. 2. masses reduced and complete balancing achieved. 3. high top land piston in mcc and not in mc. 4. height of bed plate reduced In 1996 and onward the MC-C versions of the small and medium bore engines were added to the programme. In this case the -C stands for "compact", as the engines were intended to be lighter, cheaper and yet more powerful. They feature an integrated camshaft housing, simplified cross-head and a variety of other smaller changes to facilitate the "compact" concept. In exchange the fuel injection system was simplified and the VIT system was made an option. The small and medium bore MC-C engines are thus best suited to vessels operating for prolonged periods at the power at which the engines are optimised. Q> why supercharging is better in 4/s as compared to 2/s? Page 1

Mot-Gnl Fn-4.txt ans: This is bcoz of miller cycle.A traditional Otto cycle engine uses four "strokes", of which two can be considered "high power" the compression stroke (high power consumption) and power stroke (high power production). Much of the internal power loss of an engine is due to the energy needed to compress the charge during the compression stroke, so systems that reduce this power consumption can lead to greater efficiency. In the Miller cycle, the intake valve is left open longer than it would be in an Otto cycle engine. In effect, the compression stroke is two discrete cycles: the initial portion when the intake valve is open and final portion when the intake valve is closed. This two-stage intake stroke creates the so called "fifth" stroke that the Miller cycle introduces. As the piston initially moves upwards in what is traditionally the compression stroke, the charge is partially expelled back out the still-open intake valve. Typically this loss of charge air would result in a loss of power. However, in the Miller cycle, this is compensated for by the use of a supercharger.A key aspect of the Miller cycle is that the compression stroke actually starts only after the piston has pushed out this "extra" charge and the intake valve closes. This happens at around 20% to 30% into the compression stroke. In other words, the actual compression occurs in the latter 70% to 80% of the compression stroke. BISWAS SIR & BHOUMICK SIR 01/10/2012 Function: 4 all about injection timing type of compressor valve.why plate type? HOERBIGER type. low inertia rapid lifting. more surface area. material of compressor valve & spring explain draw card with crank angle position lubrication system of stern tube bearing.material of stern tube bearing function of hunting gear. explain telemotor system function of floating lever 03-10-12 mr sinha & battacharya fun 4 1)Why 3 injectors are used in MAN&W new engines-advantages? 2)Causes of short cycling of ref.compressor? 3)What is the function of antipolishing ring? 4)In sulzur engines why jackbolts are fitted? ?04 oct mukherjee alone all functions......... parametric rolling, post control of nox( other than scr ---- exh gas recircl) large angle of heel & its effect on M co2 bottles storage pressure, bursting disc pressure, and bursting disc materail why nox production in large slow speed engine is more. what is high calorific value and low calorific value of fuel. why the same fuel has two values. boundary lubrication materail of liner, max running hours upto which it can run, wear rate of liner, max allowable wear rate working principle of accelerometer describe large engine bedplate and crankshaft design construction and materials t/c rpm indicator working principle SAE 40W 20, what w indicates & astm, bis, ps, carb. working of echo sounder telephone why medium speed e/g t/c are more effective than high, slow speed e/g function of small motor on governor, what it do Page 2

Mot-Gnl Fn-4.txt bumping clearance taken for comp. its normal but after running it hits, what are all the reasons ?27/9/12 mr.biswas Fn-4 1.wt type of cam in starting air distributor in man&bmw ? Y not positive type reason? 2.while blr hydraulic pr testing wt checks u will do? 3.bearing defects? Explain each? Wt r d Babbitt metals?compsitions?tell any other bearing materials use on board 4.what is intr cooler and after coolers ?wt is d purpose explain by thermodynamic diagram? 5.wt is fuel pump lead? Wt it is controlling 6.wt is chain tightening? When u do values? How u do? fn4 1.stuffing box..in detail all clearences.overhaul in case of wear down. 2.thrust block lubrication. 3.what is pack method.pack method is one of d method of carbunization...cynaiding nd pack method r same thng.. 3.what all need to b done for prolong operation of m/e. 4.vit supervit in detail. 5.long stroke super long stroke in detail ?21.09.12 BISWAS AND SUBIMAL CHAKRAVARTY (EX PO) FN 4 1.HOW TO CALCULATE SFOC? 2.WHAT IS CRITICAL SPEED? ANS: LAMB chapter-Vibration 3.how to take boiler water sample?Where it is taken? Is there any cooling arrangement for the sample, before taking the sample?(Ans:Yes, a small condenser type is provided) What r the tests done?(Ans: CHLORIDE, ALKALINITY, PHOSPHATE) .How frequently it is done(Ans:preferably-Daily or once in 2 or 3 days). Describe the Phosphate test? 4. TELL THE LO PROPERTIES OF LO USED IN REFRIGERATION SYSTEM. ?27/09 Mr.Biswas & Mr. Sarkar Fn-4 1. Why long stroke. Max stroke -bore ratio available, why limited upto 4.2?compression pr. max. available.why limitations? 2. Liner inspection, after piston is out. defects & their probable reason 3. H & X moments? why r they created? 4.Main engine fuel pump timing check procedure. 5. Fuel pump lead & cam lead ? 6. In generator some big end have serrations & some not, reason for having serrations. 7. Tests for ductility, hardness,notch toughness. 8. Why tensile test carried out on boiler, hull mtrl? what all we get fm the test?define plasticity, elasticity,uts, yield point.... 9. Precautions for accurate boiler water test results 10.Types of defrosting? What is there in hot gas defrosting line, so that no liquid can go to compressor? ?24/09/2012 Biswas and BN Das fun4 1. VIT , Super VIT and one more VIT , What is the advantage of using vit 2. Diff between Load dependent lubricator and ALFA lubricator 3. Exhaust valve materials 4. Latest developments in steering gear safeties except electrical safeties ?24/09/2012.BISWAS SIR AND BN DAS Fn 4 & 6: 1.How air dist. give exact air for each cylinder during ME starting? what type of Cam is there? why -ve cam is used in it.? Page 3

Mot-Gnl Fn-4.txt 2.In F. O. what kind of addatives are present? why? 3.Working Principle of Alpha Lubricator? how shaft encodar sences and where it connected..? 4.If TBN of L.O.is high then what is the problem for using such oil.? 5.After chain tightning what things u will checks.? 6.BLR hyd pressure test and accumilation pressure test? Why they r required? 7.Rudder and propeller dorps how to measure? what r the values? 8.L.O cooler Pressure test? Draw cross section of double pass cooler? how to find out leaking tubes? Mr. biswas n Mr. chaukroborti 21/09/12 Fn 4. 1. what are checks in cyl liner inspection, avg wear rate, max allowable wear. 2. bedding of propeller, what is min contact area is required? 3. what all types of indicator cards. draw power dig and light spring diag. show in both if piston rings are leaking. ?24/09/2012.SINHA SIR AND BN DAS FUN4 1.VIT & SUPER VIT 2.AXIAL VIBRATION DAMPER ,PURPOSE,CONSTRUCTION DETAILS 3.GREY CI,NODULAR CI,AND OTER ONE I DONT KNOW.DETAILS AND USES 4.LOAD DEPENDENT LUBRICATION AND ALPHA LUBRICATION DETAILS ----------------------------------------------------------------------------PRIN T OUT TAKEN--------------------------------------------------------------------------18-9-12 MR BISWAS AND MR BHOWMICK fn 4 1. Why air bottel drain milky in colour? 2. Offset control for boiler water level cotroller? 3.Alfa level Alcap principle in detail? 4.Torsional vibration? how to deal with it in details? 5. Babbit material? 5th Sept 2012 Mr Biswas and external Function 4B: 1. What do u mean you mean by moment of inertia? Why do we need to calculate Moment of Inertia? Why do we prefer I section as load carrying members? Went deep into basics of bending moment, formulaes, etc. ans: 1. Moment of inertia is the resistance to bending moment of the body which is subjected to a load. I couldnt answer why I section is preferred and neither could I recall the formulaes 2. Explain reliquefaction cycle of LNG. How the temperature of Nitrogen in the cooling cycle is reduced to cryogenic levels? What arrangement is provided to attain cryogenic temperatures? ans:2. I started explaining the nitrogen cycle 3 stage compression, cold box, heat exchange with BOG, expansion on the expander, saturation temperature of nitrogen dropping due to reduction in pressure, thereby further reduction of temperature. however, external kept on asking me what special arrangement is provided which controls the drop of temperature of nitrogen to -165 degrees. I explained compression ratio of compressor stages and expansion ratio of the expander as well. Neither could I understand what he was getting at, nor was he satisfied with my answer :P 3. Explain radial and axial turbines. What type of turbine is incorporated in the Main Engine turbocharger? ans: 4. What type of oil mist detectors are used in Auxiliary generators? Can we replace main engine mist detector with that of aux engine? If not, why? ans: He specifically wanted to know what type of oil mist detectors are Page 4

Mot-Gnl Fn-4.txt fitted on auxiliary engines. He got irritated when I mentioned optical type, and was disgusted when I started explaining working principle. He just wanted a one word answer about what type of detector. I had no clue about difference in OMD for main engine and auxiliary engine. However I guessed that both can't be interchanged. He was pleased to hear my guess, but started asking me why we cant change. I kept silent! two types OMD , comparator type for low speed engines and level type for medium and high speed engines...comparator type is used where proper partitions are available n in level type no need of partitions as in generator.comparator used where engine size is large and normal crankcase atmosphere has very less oil mist. This type compares in turn,each individual crank space against avg value of all cranks also once per cycle,compares the avg. value against clean outside air. Now the level type, used where crank throws not well partitioned. rpm is high,size of engine is small, normal atmosphere in crank case has relatively higher oil mist density. In this type ref. tube is sealed off to contain clean air.the crank atmosphere is compared with respect to clean air at all times 5. How is the weight of the shaft and impeller of a vertical centrifugal pump supported? ans: I said the casing of the motor was welded to the frame housing of the coupling and the frame housing was stiffened to the tank top using frames. Since motor is coupled to pump shaft, the load thus gets distributed to the tanktop. However, he started laughing and said that rotor of the motor is also connected to shaft, so what is supporting the rotor then FN 4&6 BISWAS/BHOWMIK 1) Last ship's engine model & ship specifications. 2) Type of turbo charger,bearings,lubrication arrangement.(of the last ship mainengine) 3) vane type steering gear. 4) stern tube bearing arrangement. 5) bedding of main bearing. 6) fuel pump lead. 7) refer plant leak test,name the latest refer. under use? 8) reasons for purifier over flowing. 9) economiser tubes arrangement. 10) draw card. 11) crankcase inspection. 12) MAN B&W reversing. fn3&4(sinha& external)on 30/08/2012 fn4 1.what is crankshaft deflection, how to interpret values explain with diagram. 2.what are the difficulties in cross head bearing lubrication. 3.what is CAS 4.what are the advantages of electronic fuel injection, other than difference between conventional fuel injection & electronic injection ?31 AUG ,only external no internal !!!!(don't know his name ) questions not function wise all mixed up .(all function ) 1)which Eng u worked on ? why now MAN B&W preferred ??? 2)what u under stand by FLOORS in a ship? 3)what type of fuel large eng use? i told residual fuel .then he told tell me to tell the story frm oil field to bunkering ...COMPLETE? 4)how a solenoid v/v works ? 5)why fuse and a over load trip both provided in same circuit ? 6)tell the principle of gas cutting . 7)what u under stand by special area and emmision control area ?? why they are Page 5

Mot-Gnl Fn-4.txt different i.e y not only special area y require additional ECA? 8)do manual say the max Viscosity of fuel which can b used ? 9)u reach engine room ,boiler gauge glass empty what will be ur action . 10)what is meaning Regional Understanding ? !!) how metal hardening toughening and other 2 processes which i don't remember are done ?? 13)what tests are done on boiler water .range approx for various constituent . how much v should maintain phosphate content , what problem if too much phosphate content ? 14)dynamic balancing of vessel? 15) thermostatic expansion v/v ? F4 sinha and bnd on 29.08.12 1.diff b/w vit index and fuel index. 2.Qse and super vit. 3.zero setting. 4.three fuel injec pounders page 287. ans: MAN Diesel has addressed the potential for enhancing the reliability of combustion chamber components under increasing mean effective pressure conditions by rearranging the fuel valves in the cylinder cover. Originally, the 90-type large b ore engine was provided with three fuel valves per cylinder. A number of tests were made in the early 1980s using only two valves, which, with the contemporary mean effective pressures and maximum pressures, showed an advantage in the form of a slightly reduced sfc and only a minor increase in the heat load. A two-valve configuration was consequently introduced. Rising mean effective pressures in the 1990s, however, encouraged further testing with three fuel valves per cylinder, the measurements showing a reduced temperature level as well as a more uniform temperature distribution .In sulzer, during part load operation, engines having 3 fuel valve installations, and electronic actuation of injection improve combustion efficiency by injecting using a single valve. The valve used for injection are alternated with preset patterns fed into the injection control system. temperature distribution in the combustion chamber is optimum and deposits are much less compared to conventional part load operation. Q> What is sulzer Integrated Piston Wear Analysis? ans: piston ring circumference has a v shape groove filled with anti magnetic bronze material. as the ring passes a sensor it picks up signal from ring to nalyze: 1) average ring wear 2) segment ring wear( uniform wear on all sides) 3) circumferential ring wear (wear at a point over a period) 4) ring rotation ( is it rotating or not. Q> what are erosion plugs in jerk fuel pumps? ans: erosion plugs are fitted on the housing of jerk fuel pumps of port type only and not on valve type used on sulzer engines.the use is to prevent the pump body to get errode due to oil hitting the body of pump when spill ports get opened.bcs there is tremendous pressure in the pump while pumping,so when termination of injectionn occurs then the oil strikes the pump body with very high velocity. Q> .why compound gauge is fitted in refirigeration system? dont tell me tht it shows both -ve and +ve ans: It shows pressure and temperatures(two different physical quantity) for different refrigerants like R-12,R-22,R134 a etc. These pr. gauges are also provided with a seperate card to cross check whether they are working correctly for the refrigerant in use or not. Q> why there is olden days, why ans: the reason splashes..so it no safety ball provided in gauge glass used now a days? and in there was no ball used on steam side as in water side? y no ball used in stem side is .. steam evaporates whereas water stops water splashing so no injuries to personnel working around Page 6

Mot-Gnl Fn-4.txt it.. Q> what is engine dispalcement ?? ans: total swept volume of an engine( swept vol /cyl x no. of cyl).can be used to evaluate the requirements of a turbo charger while a new engine is being matched with a specific type of turbo. Q> why milky colour drain water coming from air bottle drain? ans: when pressurised water comes out of air bottle due sudden drop in pressure there would be vaporisation of dissolved gases in the emulsified mixture which causes foaming and consequently milky white appearance can be seen.Exactly what happens inside the c/case of refer compressor when it is started due to sudden drop in pressure dissolved refrigerant will cause foaming of lube oil Q> what is spcv ? ans: stagnation pressure control valve.it is fitted in sulzer fuel oil system between pump and hp pipe,in order to prevent late injection and after burning Spcv is stagnation pressure control valve used to suppress the after injection on RTA engines. If the SPCV is removed, the fuel pump is directly connected to the high pressure pipe allowing stagnation pressure to drop to a level where cavitation can occur Q> why sample water is taken from jcw p/p outlet,not from the expansion tank ans: bcoz sample has to be representative of what is going to the inlet of engine and it can best be taken at JCW p/p discharge as it is then going to ME cooling jacket..... also in the expansion tank if any solids present in water may settle down....hence sample is taken from JCW p/p discharge ?29 aug funt 4 1. Wat is fuel pump lead? ans:pump lead is the the movement of the plunger when the suction port is closed to the top position till whr the piston can move. the lead can change wen the suction port can be moved up by moving the pluger up and down via VIT. How is it related to fuel pump timing? 2.wat is vit index, fuel index & pressure index....difference. diagram of variation of each with load ans: vit index indicates the movement of barrel. fuel index indicates the fuel rack position and the presure index show the fuel quality setting. then he asked that if i can draw the variation of each index on % load. icud only draw vit index. graph for vit index and fuel index is 3.100% redunduncy in steering gear with diagram. 4.wat r alkaline and non-alkaline salts in boiler water??? ans: alkaline salt are the sodium salts. non-alkaline salts are the salts of calcium and magnesium. sodium salts are solible in watrr whr as calcium salts and magnesium salts are insoluble and are present in the boiler watrr in the form of precipitates. sodium salts doesnt form scales whr as calcium salts and magnesium salts form 5.he asked how does air compressor unloads....i said that thr is an electrical drain as well as pneumatic drain. he then asked wat all ways can be thr. i cudnt recollect thr, but its written in gulia. then he asked me to explain the whole... Bhoumic 4 & 6 1.Latest modification in super long stroke engine for cross head lubrication.--I said Xhd pin size increased..Lo pressure increased...he disagree..saying something related to stroke and power 2.How accom. AC temp is maintained 3.Bottom bearing bolt failed just after decarb..Everything tightened properly--reasons Page 7

Mot-Gnl Fn-4.txt 4.Main LO pump overhaulling 5.Air Bottle survey 6.Replacing a section of pipe with new one...how it will be carried out by welding...pipe very long and cant be taken in workshop 7.Reversing B & W in details M/E T/C running at low rpm, reasons??? fuel racks stuck, couple of units not firing, governor problem,fuel filters partially choked, aux blower not running deposits on turbine blades, turbine nozzles, compressor side loaded with oily dust.(turbine/blower washing shud improve the rpm if the reason are above mentioned). wrong fuel with excess sulfur/soot content.. economiser diff pressure too high causing restricted exhaust flow... Fun 4B 27/08/2012 Biswas Sir & Bhowmik Sir 1.What all engines u have worked,Tell me about its nomenclature both Sulzer & MAN B&W(as I had worked on both). 1.1Tell me what all actions will occur as the telegraph is put to astern.(Reversing of Sulzer Engine) 1.2 How lost motion servomotors work. 2 Alpha Lubrication system. 2.1 What all inputs it requires. 3.Crankshaft deflection curve how to plot. 3.1 How to interpret the values. 4.Material used for hull constrruction. 5.Ultrasonic testing of materials. 6.Function of three fuel injectors(Asked by Biswas Sir). when COMPRESSION PRESSURE OF MAIN ENGINE , is around 80 bar , THEN HOW CAN A STARTING AIR OF 30 BARS GIVE A KICK TO MAIN ENGINE for cranking it up to 20 revs , before injection of fuel ??? ans: the starting air of 30 bar acts throughout the stroke where as the combustion pressure only for a few degrees.......so when the work done in both processes is calculated, it comes out to be almost same ......hence 30 bar air can turn the engine...........when plotting on p-v diagram....the curve will be a horizontal line in case of starting air, where volume on the x-axis and for combustion process it is well known ?22nd aug sinha n mr. bkrc fn.4 1.what z catalytic fins, name any two,how to get rid of cat fines, allowed qty in bunker. 2. basic principle of reverse osmosis, decribe the full system. 3. describe boiler 2 element control method 4. describe operation of windlass 5.case hardening method( he asked all de methods pack carburizing, flame hardening, niriding,induction hardening.), purpose n difference between each ?22 August 2012. Mr. Biswas sir and BKRC sir.. function appeared 4b and 6. fn 4. & 6 1. mps ..all about it ..all details and formulae .. full touch n pass i said.. Page 8

Mot-Gnl Fn-4.txt mps as in mean piston speed .. told him everythin related to it.. how it is derived ..its use in the power equation ..wat it means for the design engineer n ow it limits the power n the construction and how it decides the combustion .. everythin related to it.. 2.actions after low lo pr. alarm till stopping of engine.. all the funda of governor and actuating of puncture valve. 3.catfines ..alsi ..value ..the different sizes .. i told him 5 to 30 microns.. ways waof removing .. wat special procedures will be done.. and all that .. 4. conrod top survey .. 5.taking out of a liner..of me..dunt say jackin method .. 6.bottom end overhaul and replace of ae engine.. 7. reverse osmosis.. the whole funda :D .. 8.chain tightening is the place where i screwed up big time.. told sir everythin but couldnot draw the chain pattern rite ..got confused badly ..n hence d result.. Can anybody tell me the expansion of B&W 5L67GFCA...(M/E) The engine types prior to the introduction of the MC-engines were designated e.g. EF, FF, GF, GFCA, GB. The first letter was an indication of the mean pressure, while the subsequent letters were an indication of the application and turbo ch arger efficiency. This system was increasingly difficult to maintain as the engines were being developed and it had earlier been decided to reduce the designation to two letters. Some letters were already in use to designate stroke or used in 4-stroke designations. It was thus decided to name the new engine type MC, where M indicates the mean pressure (but not strictly according to the previous system) and the C indicated the turbo charger efficiency. This was at the same time the last engine designation according to the old system. func 4 sinha n bathachrya 21/08/12 diff between mk5 and mk6 engines wat is safety head in refer comp wat is diff between rmg45 n rmg 55 fuels stay tubes and plain tubes in boiler wats de difference wat is definition of ignition point and auto ignition point orals fn 4 & 6 sinha n bhattacharya 21/08/2012 1.sulzer has come out with reduced height scavenge port.what is the reason? 2.how axial thrust is accomodated in sleeve type bearing t/c? 3.cpr ring.what are the benifits?clearance etc. 4.why ref comp suction pipe is led to the c/case of the compressor? 5.principle of self locking nut.... 6.why colour of the gauge glass water se seen black. 7.overhauling of pr reducing valve. fn 4 & 6 diff b/w MC and MCC? How pulsation is handled in HP pipe after injection? Pulsation in the HP pipe after injection can become a cause of secondary injection so they need to be handled.In earlier designs delivery v/v on fuel p/p is provided with a coller which was acting as relief piston which enters the v/v seat bore to extract fuel from HP pipe before v/v is completely closed. Also these pulsations give rise to high pressure waves. So the length of HP has been reduced. Umbrella seal? umbrella seal is provided in man b&w fuel p/p on plunger, this seal has replaced o-rings used in past. to prevent the leakage of fuel oil to the camshaft area. Page 9

Mot-Gnl Fn-4.txt o rings use to get brittle, over a period of time and cause leakage of fuel oil to camshaft area hence mixing with l.o. umbrella seal is made of metal so not affected by high temperature of f.o. SPCV? fuel p/p zero setting? primary and secondary explosion in c/case?reasons,avoidance? Axial vibration damper? y 3 injectors? how to decide that piston rings need to change? Anchor and Anchor chain cable testings? fn 4b 1. what is the diff. b/w MC,MC-C,ME...(why separate camshaft p/p in mc engines n what is its discharge pr.) 2. moment compensator, what it does and how it works. 3.fuel p/p zero setting. 4.ehxhaust manifold pr. in main engine .and how a constant pr. t/c works. 5. abt. alpha luricator...inputs it requires..(.load,rpm,angle,sul?phur%,........?)-he wanted one more input and hinted at something like PHASE 6.DECIDER-how will u check thrust bearing clearance and clearance value? 1.Compression ratio of diesel engine 2.Accumulation pressure why on boiler. 3.Piston rings of compressor higher than 4 stroke engines. Fn. 4 1. How does MAN B&W SMC engine installation benefit the hull? 2. Main bearing inspection procedure. Maximum clearance value. 3. Bad weather, one unit web slip, how to detect and what is the effect on the effected units. How is the effect measured? Will the peak pressure increase or decrease? 4. Flammability diagram. Why is the UEL line inclined in the diagram? 30th july mr. biswas and external(white haired frenchie) mixed bag...as soon as i will remember i will edit the post 1.stern tube bearing arrangement , material , locking , chrome liner how it is fit, number of seals , why ? 2 floating boiler ? ( i might have heard wrong) 3 boiler tube expansion how is it accomodated ? 4 model testing of a ship ? what all we get ? 5 Full AVR circuit with functioning of SCR? 6 Difference b/w doubler and insert? 7 MIG / TIG welding. diffrence? 8 HIGH VOLTAGE Motor onboard. location of the circuit breaker and why is it placed there ? 9 what checks will you do on main engine after the vessel floats post grounding ? 10 how to calculate wetted surface area. in full detail. ans: given in reed's denny nd Taylor formula. he wanted to hear hw we calculate using Simpsons rule thru the tpc curve. 11 hot plate in galley ckt diagram. 12 MAN B&W k , l , s in nomenclature. full engine name specification. 13 co2 system 5 yearly , 10 yearly , 15 yearly ? 14 NOX control....working of SCR... AMMONIA SLIP....RATE SHAPING? 15 when does a battery switches over from trickle charging to full charging ? why 11 hot plate in galley ckt diagram. 12 MAN B&W k , l , s in nomenclature. full engine name specification. 13 co2 system 5 yearly , 10 yearly , 15 yearly ? 14 NOX control....working of SCR... AMMONIA SLIP....RATE SHAPING? 15 when does a battery switches over from trickle charging to full charging ? why Page 10

Mot-Gnl Fn-4.txt ?27th July Mr. Sinha and Mr. Mukherjee Func 4 and 5 F 4 : 1. what will be the course of action if the piston is found to be stuck. 2. what engine have u worked on. explain the l.o cooling arrangement. 3. what was the tube arrangement in the aux blr. explain. 4. what is short cycling. indication and reasons. 5. what arrangement is provided to check any moisture content entering the engine unit. 6. Common Rail, Rt flex working, Advantages. 7. Foaming, Prinming, Carry over 8. Affects of catalytic fines and sodium vanadium in fuel. Fn:4 1.) assuming tht the piston is removed..how wud u overhaul the piston and wat is the name of the bolt connecting piston rod to piston.( basically hows the piston is connected to piston nd name of the bolts being used....huh i started scratching my head..hahah) 2.) wat is pinching swrew and nd no of pinching swrew used in one tie rod?..and how to avoide loosening of pinching screw..and at wat torque it is tightned to?.. (..well its a screw used in tie rod to avoide vibration..they r three in nos and set 120 deg apart..secured with locking wire .(.tightening torque nd the some locking arrangement ..really dont have idea.) 3.) wat is munz, monel meta?..wat is invar material.( u'll find this in touch and pass) (mr. behra is very much specific abt his own ans so when u say invar materl..u have to and aluminum 4.)how the bed plate is mounted and wat material its made up of?.( i made too much mess in my ans) 5.)m/e turbo charger vibration sensing probe working principle and hows the signal get transformed. nd also how the temperature converted in electronic signal and come to control room 23/07/2012 Mr.bhowmick function 4 criteria for hydrodynamic lubrication. reversing of man b&w capacity of s.w pump of your last ship.how it relate with engine power? what specification is given on pump body? ?25th orals Mr.Biswas and Mr. B.N Das Fn4: 1: type of vit on your last ship (super vit), explain super vit, break point range, control air pressure, how super vit works, how it is achevied? 2: diff betwn alpha lubrication and lcd type in B&W 3: P Alkalinity and T alkalinity, why take both, wat is the significance of P Alkalinity 4: what are temporary and permanent hardness salts 5: 50% redundancy in steering system 6: Stern tube lube oil safeties and pressures ans: ?1: super vit he wants about the break point, double threading in barrel linked to the vit rack superimposed with fqs, actuated by the position servo air pressure which is varied as per the load and signal from the governor and regulating shaft. 2:mainly abt the spray pattern in both types nd how often it is injected 3:i told P alkalinity for hydroxides and half carbonates only, these result from the addition of dosing chemicals, he was satisfied 4: he jus wanted the names of the salts, temporary hardness are bicarbonates of Page 11

Mot-Gnl Fn-4.txt calicium and magnesium, permanent are sulphates, carbonates, nitrates, chlorides and silicates of calcium and magnesium 5: i passed the question 6: pressure in my last ship was 1.2 bar, safties are the lo low level alarm, lo non flow alarm 27 july 2012..... (Biswas sir and bhatachargi sir) Fn4: 1) Safety head in refrigeration system. 2) tightening torque of tie rods. 3) checks done in con-rod bolts, why done only in A/E. 4) umbrella sealing... he told its in B&W fuel p/p. 5) Alpha lubricator... what inputs it collects? ?25th orals Mr.Biswas and Mr. B.N Das Fn4: 1: type of vit on your last ship (super vit), explain super vit, break point range, control air pressure, how super vit works, how it is achevied? 2: diff betwn alpha lubrication and lcd type in B&W 3: P Alkalinity and T alkalinity, why take both, wat is the significance of P Alkalinity 4: what are temporary and permanent hardness salts 5: 50% redundancy in steering system 6: Stern tube lube oil safeties and pressures ? 23/07/2012 Mr.bhowmick function 4 criteria for hydrodynamic lubrication. reversing of man b&w capacity of s.w pump of your last ship.how it relate with engine power? what specification is given on pump body ?25.07.12 mr. Biswas & mr. B N Das 5th attempt fn 4 1.difference between vit and super vit. which was installed in ur last ship. 2.starting air line diagram. fn of start air pilot v/v.automatic v/v & types. 3.why recirculation of f/o is required. 4.vibration, whatever u know. how axial vibration is created. 5.blr high lift safety v/v features & accumulation pr. 6.one more i dont remember. ?26/07/12 Mr Biswas & mukarjee Fun4 1,only by looking how to differentiate 2s & 4s engine 2,what determines power of an engine 3,by not opening the journal how to find hydrodynamic lub is effective. 4,why inlet valve is bigger than outlet valve Fn. 4 1. How does MAN B&W SMC engine installation benefit the hull? 2. Main bearing inspection procedure. Maximum clearance value. 3. Bad weather, one unit web slip, how to detect and what is the effect on the effected units. How is the effect measured? Will the peak pressure increase or decrease? 4. Flammability diagram. Why is the UEL line inclined in the diagram? mr. sinha n mukharji 20/7 /12 1. diff betn sulzer RTA,RD,RND 2. Camshaft arrangement in RTA 3. Axial damper purpose, working? why provided ? 4. Piston ring develpoments n their positions. all clearances? 5. how many safety v/vs r provided in blr n why? 6.why n how accumulation pr. test carried out? Page 12

Mot-Gnl Fn-4.txt ?18/07/2012 EXTERNAL: PAUL INTERNL: BISWAS FN 4, 1) HOW THE CAPACITY OF AC IS CONTROLLED.HOW WILL YOU FIND WHICH UNITS ARE UNLOADED BY LOOKING AT THE AC COMPRESSOR. 2) EXPLAIN THE WORKING OF SERVO MOTOR IN ENGINE.(EVERTHING) 3) EXPLAIN THE OPERATION OF AUTOMATIC AIR START VALVE. 4) HOW TO CLCULATE MEAN EFFECTIVE PRESSURE. WHAT IS SPRING CONSTANT. GIVE VALUE OF UR LAST SHIP ETC 5) HOW IS THE PURRIFIER BOWL SEALED. EASY QUESTIONS BUT WAS NOT HAPPY WITH ANY ANSWER AND SOMEWHERE WANTED PRACTICAL ASPECT AND SOMEWHERE HIGH FUNDA THEORY. fn4 mean piston speed define net refrigerating affect .. show in graph wherre is it .. in any process p*v to the power n .. wat is value of n range of n how is thrust in sleeve type turbocharger taken 9th july orals...cochin MOTOR... wat type of engine u sailed wat type of fuel p/p draw c/s of the p/p wat is VIT? more deep into VIT ME safety trips...how you are testing each safety trips explain in detail.... thrust brg clearance in t/c piston removal..piston clr....checks to be done on piston... wat is hydrophor...how p/p start stop on auto...how to adjust diff pressure switch... draw purifier shaft arrangement...about threads on spindle.... types of lubrications...wat type of lubrication for X hd ..why..where we have hydro dynamic lubrication in ME...some more questions... GENERAL... draw rudder carrier brg explain why it is given...some more questions related to that i dont remember.. refrigeration cycle more question on expansion v/v.. you are gng for dry dock...you find hull plate near bilge p/p is cracked wat specification u will give so that repair can be done on that plate...from which plans available in ship you will come to know the location of the plate... wat are plans available in ship latest improvement in stern tube oil seal....more questionz related to stern tube seal... p/p room ventilation...draw ........wat type motor used...wat safeties we have....more questionz...on that how sea chest gratings secured types of protection used for hull corrosion wat is ICCP...explain n drwa de circuit.... wat is MGPS...explain in details...

?04/07/2012 Sinha !!!!!!! . What is stability of Governor ?? 8. hydrostatic balancing of pfr ?? 9. directional interlock of M/E starting ?? 10. how to adjust K value of T/C ?? n how to measure K value ?? 11. ascertain efficiency of stuffing box while engine running ?? 12. how to arrest transverse vibration of M/E ?? 13. moment of inertia defn ?? and how is it significant with respect to ships hull ?? ?28th oral Biswas and mukhopadhya fn 4 Ship moving at full speed , bridge ask to reduce or stop engine immediately Page 13

Mot-Gnl Fn-4.txt what precautions you ill take as engineer. explain vit what is the pr. in exh. manifold and scav. manfold, how is it that exh.pr. is less which drives turbine and scav. pr is more that exh. pr. ? what inspection you carry out on tie rod, what in pinching screws and where ar of ce they positioned. what type of coupling is used between alternator and diesel eng what are the maintenances ?03.06.12 sinha n mukharjee fn-4 how to diff b/w 2-stroke n 4-stroke if both r of similar size n construction what is turbo compounding exhaust valve shouding n effects what conditions affects maximum pressure in cylinder M.r. Biswas and external Fn41. What is diff bw main brg holding bolts of man and sulzer engine, details of both designs. 2. t/c washing dry n water both, wt precautions to take, also for blower side, wt precautions to be taken. 3. Annealing, normalizing details, wt is critical temp, wt is structural change(grain structure) after annealing. 4. Co 2 used as ref, wt r drawbacks, wt is critical temp of co2 n wt happens at that temp. 5. liner cooling arrangements, bore cooling funda n some other small questions on this. Desider ques- bedding of main bearing by mr. biswas Mr. Biswas and mr. Mukherjee 29 june Funct 4 1. Wat is variable geomerty turbocharger? 2. Why supercharging is more beneficial for medium why tspeed engine than slow speed or high speed supercharging? 3. If tbn is less in clylinder oil used....wat will happen? He wants to listen clover leafing....wat does 70 tbn means??? 4. Wat is critical speet how it effects our engine??? ? 28th oral biswas n mukhopadhya fun 4 1. REVERSING OF B & W, AS WELL AS SULZER. 2.DISCRIPTION OF YOUR SHIP( MEANS:- 6S50MC 3.CONSTRUCTION OF CROSS HEAD BEARING 4.AT WHAT LUBRICATION OF LINER IS DEPENDENT. 5. BEARING CLEARANCES 22.6.12 Biswas and bhowmick fun 4 1) fuel pump zero admission check 2) advantages of 3fuel injectors 3)feed water regulation pid c0ntroller 4)advantages of plate type of valves in air compressor 5)screw p/p working 22.06.12 biswas sir and bhoumik fn. 4 1. indicator diagrams. -4 types. asked in detail about draw card and light spring diagram.- given various scenarious and asked to show them in draw card and light spring diagram. 2. rotary vane system-construction and working. direction valve. working presssure. Page 14

Mot-Gnl Fn-4.txt 3. boiler water test p, t alk., chloride, phosphate, ph and hydraine. requirement for phosphate reserve. 4. supercharging. turbocharger system - constant/pulse type. construction detail. material with composition. 5. what is air conditioning. psychometric chart. how temperature and humidity is maintained during summer and winter time. mr biswas and mr sarkar p, m, t alkalinity what signifies fatigue, example, endurance limit work hardening how to adjust fuel p/p timing limit switch of crane reason for ex v/v burning in main engine, remea 19th Mr. Biswas and Mr. Sarkar fn 3, 4b, 6 1. what are the advantages of intelligent engine f.o system 2.what are the test done on boiler materials 3.why some 4s engine con rod has serration and some dont have 4.what is surging why happened, 5.what is on off proportional and resst control how used on boiler, what adv and disadv. 6. how to check thickness of t/c casing 7.how to measure stern tube wear down 8. a/e after 50% load red hot what to check 9.why hath coaming fitted, how. 10.condition of drydocking, why trimmed by stern 11.hermonization of survey what are the survey harmonized 12.special survey 13 gwp odp recent hcfc oral on 18.06.12 biswas and ex po fun 4 1.what engine u did. 2.what is compression ratio.why different engine have diff. c.r. why life boat engine have high c.r. what is the c.r. ratio of two stroke,four stroke, and life boat engine 3.all type of boiler water test on board. why two test for alkalinity how to take boiler water sample 4.tempering why it is done. Fun 4B & 6,18th June Biswas sir & Chakraborty sir. Fun 4B 1.Use of viscosity & density of Fuel oil regarding combustion purpose only. 2.Oilyness of lube oil. 3.Compression ratio,clearance volume,why more & less for different engines. 4.How to carry out boiler water test,differnt types,why phospate test is done. Fun 4B & 6,18th June Biswas sir & Chakraborty sir. Fun 4B 1.Use of viscosity & density of Fuel oil regarding combustion purpose only. 2.Oilyness of lube oil. 3.Compression ratio,clearance volume,why more & less for different engines. 4.How to carry out boiler water test,differnt types,why phospate test is done. Fun 6 1.What is annealing,How to anneal copper why its different for different metals,why it is done. 2.OMD alarm is sounded in your watch how will you proceed your actions,what is LEL. 3.Surging of T/C,when surging what happens to turbine side. 4.Material for piston in 2 stroke & 4 stroke,why different,reasons on 01/05/12 Biswas & Behera Fn - 4b all questions were from lamb's behera's patent questions other questions are Page 15

Mot-Gnl Fn-4.txt why valve lift is D/4 why not D/3 or D/5 what will happen if if you put D/3 or D/5 instead of D/4? about D/4 he has asked abt bilge line the answeri told him was D/4 permits same flow rate as it is in pipe to which it is attached.if its D/3 opening it will be more but of no use and it will also increase the valve size as well as attached pipe's size & if D/5 opening will be less and it will create back pressure in the line. what are the contaminants of lube oil and why?give the percentage you will allow for solid partilcles in lube oils as 2nd engineer. for water the allowable % is 0.2 and for solid particles it is 1%. contaminants in lube oils as i told were 1. water(from any leakage or from purifier), 2.vanadium(fuel oil) 3. iron (liners,crankshaft,timing gears,camshaft etc) 4.crhromium (piston rings),5.sodium (sea water ingress,residual fuel) 6.silicon (dirt ingress)7.white metal if thick shell bearing and last one bore cooled piston and why which engine ? 02/05,mr biswas and mukopadhaya fn 4&fn 6 1. y three injector. 4 PROPER ATOMISATION ,REDUCE NOX ,"AND MEP IMPROVEMENT 2.advantage of high land piston 3wat r da new development in mc engine piston CPR PISTON RING,6 GROOVE ON PITON RING GROOVE ,DOUBLE LAP SEAL JOINT,TOP PISTON RING CERAMIC AND CHROMIUM COATING, PISTON RING GROOVES TICK CHROMIUM COATING ,4ANS FW AND LO BUTNOT IN STEAM ,CANNOT USED IN STEAM BCOZ OF DIFFERENTIAL PR B/W THE PLATES,TITANIUM PLATE,WITH NITRILE RUBBER 4 in e/r where ,plate cooler r used and y? 5 accumulation of pressure test, how to do ? 6 in b&w engine y distance between the cylinder cover and cylinder liner is reduced? TO REDUCE THE STRESS ON THE LINER ,4 PROPER LUBRICATION,TO REDUCE LINER WEAR . 7 draw &explain the pressure reducing v/v 8 how the slide v/v works and draw it and explain 9 charging of refrigerant orals on 30th.biswas n bhaumik f-4 1.rt flex to be fully explained with common rail in detail 2.reversing in rt flex 3.vit n super vit 4.in aircon how to maintain humidity 5.centrigugal pump in detail orals on 01/05/12 behra & sinha func4 1.comp. of brass. bronze and steel? 2.what is mundz metal/ 3. sketch & explain ovrspeed trip? 4. what is there 2 prevent bending of bending exh v/v seat due 2 high temp & press? 5. why in some engine inlet v/v is bigger than exh v/v 25th April with Mr sinha fn-4 what is the advantage of jack bolt in RND engine. what is the advantage of variable pressure injector. what is difference between stay tube and plain tube in Alborg-Aq-3 boiler. what all the parameter is needed for drawing the psychometri chart ? 27th April,Mr Biswas nd Mr Mukopadhyay... Fn-4, 1)which type of engine hav u worked on?? wat is the meaning of S, M, C in 6S 42 MC engine? the new engine series of MAN B&W,difference b/w MC nd MC-C engine??wat all modification hav been made in new B&W engines??? Page 16

Mot-Gnl Fn-4.txt 2)Modifications in crosshead nd crosshead bearings of MAN B&W with respect to older MAN B&W Engines??wat r the advantages?? 3) crank pin brng,main brng nd crosshd brng clerances?? 4) Scavange air manifold nd exhaust manifold pressure??which one is less??how is it possible that low pressure exhaust gas giving high pressure scavange air??? 5) wat is Nodular cast iron?? April 20th.....mr. Berra and mr. Sinha.fn 4,fn5,fn6 Fn4. & fn 6 were more or less intermixed. Around 15 questions were asked with a lot of cross questioning....remember only 10. 1.heering bone gear. We're is it used in e.r .......aux engine. 2. UCV & LCV i.e upper calorific and lower calorific value of fuel. 3. Statchin temperature in boiler.......don't know the answer......may be has got something to do with pinch point. 4. Difference between 2s 4s engine. How will u make it out from the outside. I told that 2s will have a more oily funnel....he was satisfied but then he asked why......don't know. 5. Full forms...ASTM(American Society for Testing and Materials), BIS, SAE( society of automotive engineers), PS.......bis is buero of Indian standards....spell check. P.s is the German abbreviation of horse power....pfer Strachen spell check again. 6.sae 20W40 7.1 parameter that will immediately tell about the engine power........told a lot of answer but wasn't satisfied......laughed on ma face.....it might be turbocharger air flow. Please check. 8. 1 check that will immediately tell if the bond ing of white metal on thin shell bearing is gone......did not know.......later some nice guy outside told me that we tap the white metal with a cooper coin and it should give a clear or crisp sound. 9.why double volute casing........got asked this question second time in a row....first by mr. Bis was. I told mr. Biswas radial thrust balancing......he said wrong.. he wanted to hear about the increase in area for converting all the kinetic energy in pressure......for high speed pumps....I told Behra first about more area requirement.......he said wrong ....then I told about radial thrust balancing...he said correct......strange.....bette?r tell both... 10. Rate shaping 11. Thin shell bearing.......what. Why .. What is nip....how much in mm. What if more ....what if less..... oral on 24.04.12 by mr. sinha and rk paul Fn. 4 1) wat is capacity control? how do v do capacity control in AC cmpsr? 2) why do we need to take the bottom end bearing clearance? 3) what is distillate fuel and residual fuel difference? wat is the basic difference? 4) during decarb, you are taking up the piston? suddenly piston started slipping down? why and what will be ur first action Mr A.K Biswas and the external whom i dont know Fn 4b & ^ What is a moment compensator?where is it?what is the purpose of it?it is stationery or rotating? What r the different vibrations in engine and counter measures? Diff betw thin shell n thick shell bearings?what r the advan of thin shell bearing over thick shell brg? Cross section view of gear p/p?where we use it in E/R? What r tests done on piston(after chaging the piston crown)? how r different temperature maintained in refer rooms?what is the temperature of handling room?the working of automatic refer system. how do u prepare the main bearing for survey? Page 17

Mot-Gnl Fn-4.txt accumulation test of boiler,why is it done?what all u check if the pressure is raising in the boiler while testing? what is surface hardening?what the diff type of process in it?explain about nitrading?name the components of main engine which r surface hardened by nitrading? Mr Sinha and Mr. Bhattcharya(from MMA).23/4/12 1.explain subcooling and superheating. 2.what is the purpose of de-superheater. 3.what is oros piston.explain. 4.what is the arrangemet is provided for expansion of piston rod inside crown. 5.what is float free arrangement and where do find this in engine room Mr.Biswas&Bhowmik 10th April 2012 Function-4B 1. All about Alpha lube? System Description, naming different part and how they work? 2. Cylinder oil properties? 3. Constructional Details of Meat room Evaporator with all parts, their function and materials. 4. How to chose a metal plate for ship building, what are the different characteristic features you will look for and why? 5. UTS? How to test? Name of testing machine? 6. 4-Ram Steering Gear system. Explain everything from the moment helm is given from bridge to when ship is steered in required direction? 7. What are the different types of forces acting on engine? Counter measures? Deciding Questions by Mr.Biswas 1. Engine I last worked on? 6 S 60 MC ok, what do you mean by zero setting of Engine? 2. What are the different types of vibrations on Main Engine? 3. What is Torsional Vibration and how it comes in play in an Engine? 4. Explain Torsional Vibration Damper with constructional details and how it works? MR.SINHA & MR.BHOWMIC 23.04.12 fn 4B 1. radial bores in liner, fn? why now used? draw a sectional view. 2. what arrangement is made for taking up blr tube expansion? 3. thrust bearing type and lubrication arrangement? 4. telegraph system, from brom bridge to the rudder. A.Biswas & External(dont know name) FN: 4 Biswas: what eng u hv worked? Ans: man b&w 6SMC60 Biswas: what is MC? ( as in manual it is written that M is some series and C also hv some significance which I was not sure some didnt answer) Then Biswas gave the answer,it is Moment Compensator Biswas: how a moment compensator work? Biswas:what r the properties of cyl l.o.? what is TBN70? Why alkalinity required?why less alkalinity oil used in crankcase? If cyl oil is used in crankcase what is the problem?? Detergency- why it is required? Where r the unburnt particles adhere to, in the cylinder?? External: what is labyrinth seal??how it is fitted? How it works? How it looks like FN 4 Q A)=WHAT ALL WE REQUIRE IN AN ENGINE FOR COMPLETE COMBUTION >>>1)SCAVANGE AIR AND THAT IN EXCESS OF AROUND 2 TIMES (XQ)DON'T YOU THINK EXCESS AIR WILL CARRY AWAY HEAT AND CAUSE FORMATION OF NOx.>>>EXPLAINED ALL I KNEW RELATED TO AIR. 2)COMPRESSION RATIO OF AROUND 12:1 FOR TEMPREATURE REQUIRED FOR FUEL TO AUTOINGNTE. Page 18

Mot-Gnl Fn-4.txt 3)FUEL TEMPREATURE OF AROUND 120C FOR PROPER ATOMIOSATION. (XQ)IS TEMP IRRESPECTIVE OF FUEL>>>NO SIR FOR HFO. (XQ)WHAT IS VISCOSITY OF FUEL AT INJECTION>>>13 TO 16 CST 4)PROPER ATOMIZATIONS (XQ)HOW IT IS ACHIEVED>>>NOZZLE HOLES AND PRESSURE FROM PUMP. (XQ)IF THE NOZZLE HOLES ARE CHOCKED HOW WILL U CHECK>>>BY NEEDLE SUPPLIED WHOSE DIA IS LESS THAN HOLE (XQ)THE NEDDLE IS LOST ON MOST OF THE SHIPS SO NEXT>>>BY SPRAY PATTERN (XQ)U WILL B UNABLE TO FIND BY THIS, ANY OTHRER METHOD>>>SORRY SIR (XQ)WHAT IS OPENING PRESSURE OF INJECTOR>>>250-300BAR. 5)PENETRATION ,FOR THIS THE LENGTH OF THE HOLE IS 3-4 TIMES DIA OF HOLE (XQ)UP TO WHERE IN CYLINDER SHOULD A FUEL MOLECULE TRAVEL FOR PROPER PENETRATION>>> JUST B4 PISTON CROWN(SHOULD NOT IMPINGE ON IT) 6)TURBULANCE FOR PROPER AIR FUEL MIXING (XQ)WHAT CAUSES SWIRL>>>SCAVANGE PORT PROFILE, PISTON CROWN SQUASH, INJECTOR PLACING. Q B) SO THIS WAS THEORY WHAT ALL YOU DO PRACTICALLY ON BOARD A SHIP TO GET COMPLETE COMBUSTION. >>>REPETED SAME AGAIN WITH SOME MORE POINTS> Q C) WHAT JCW TREATMENT IS DONE ON BOARD AND WHY? >>> NITRATES TREATMENT (XQ)TELL ME THE FULL CHEMICAL NAME>>>SODIUM NITRATE(WAS NOT VERY SURE) IT REACTS WITH THE METAL IN THE SYSTEM AND MAKES A PASSIVE FILM THERE BY PREVENTING FURTHER CORROSION> (XQ)WHAT DOES PASSIVE LAYER MEANS>>>IT COMBINES WITH THE METAL AND STAYS DOES NOT LEAVE THE SURFACE THERE BY EXPOSING IT TO FRESH CORROSION> (XQ)DOES NOT THIS LAYER INTERFERE WITH THE HEAT TRANSFER>>>NO(I KEPT QUIET) ALKALINITY RESERVE TO AVOID CORROSION (XQ)EXPLAIN ME THE CHEMISTRY>>>EXPLAINED ALL DAT CAME TO MIND. Q D)HOW IS WATER LEVEL MAINTAINED IN A BOILER >>>GAVE LOTS OF CONTROL FUNDA.(XQ)SO THE PUMP DO NOT RUN CONTINEOUSLY>>>NO (XQ)WHERE DO THE SIGNAL FROM SENSOR GO TO>>>PUMP CONTROLLER. Q E)WHAT IS SWELLING AND SHRINKAGE IN BOILER>>>TOLD WHAT EVER I KNEW. (XQ)SO WHAT ARE THEIR OPERATIONAL PROBLEMS.>>>SAID FEW WORD THEN KEPT QUIET. Q F)WHAT ARE THE DESIRABLE PROPERTIES OF CYL LUBE OIL OF MAIN ENGINE. >>>ALKALINITY TBN IS 70 (XQ)WHAT IS FULL FORM OF TBN? WHAT IS 70?WHY ALKALINITY. >>>DETERGENCY (XQ)WHY >>>DISPERSENCY (XQ)WHAT DISPERSES AND WHERE >>>LOW POUR POINT >>>HIGH VISCOSITY INDEX >>>OILINESS>>>WHAT IS IT AND WHEN IS ITS USE. >>>HISH VISCOSITY INDEX HE SUDDENLY SWITCHED TO NEXT FUNCTION FUNCTION 4: 1. WHAT IS MEAN PISTON SPEED 2. HOW CYLINDER LUBRICATION IS DONE DUE TO LOAD DEPENDED 3. HOW SERVICE AIR PRESSURE IS MAINTAIN DUE TO LOAD CHANGES 4. WHY AUX . ENGG BOTTOM END BOLT IS RENEWED AFTER RUNNING HOURS REACHED , WHY NOT DOING IN MAIN ENGINE 5. WHAT IS ACCUMULATION PRESSURE TEST, TESTING PROCEDUR fn 4 1. sterntube lo property? 2.Coefn of performance?capacity control? 3.ductility,malleability,name a metal which is ductile but not malleable?and vice versa and name a metal which is ductile and malleable too? 4.basic operating principle of intelligent engine?asked by biswas WHY CENTRIFUGAL PUMPS ARE PREFFERED INSTEAD OF SCREW PUMPS FOR SUPPLYING LUBE OIL TO MAIN ENGINE ? THE FIGURE SHOWS THE COMPARISON OF HEAD VS DISCHARGE OF TWO PUMPS.. IN THE CASE OF CENTRIFUGAL PUMP: Page 19

Mot-Gnl Fn-4.txt AS THE MAIN ENGINE SPEEDS UP THE OIL DEMAND FOR COOLING ALSO INCREASES, THE HEAT IS GENERATED MORE THE OIL BECOMES THINNER.. THIS REDUCES HEAD ON THE PUMP.. MORE OIL IS SUPPLIED THUS HELPING THE ENGINE TO MAINTAIN ITS PARAMETERS AT HIGHER RANGE OF SPEED IN THE CASE OF SCREW PUMP: AS THE HEAD VARIES DUE TO DEMAND THE FLOW RATE REMAINS ALMOST SAME FOR ITS ENTIRE RANGE.. ONLY OPTION LEFT IS TO INCREASE THE RPM OF THE PUMP TO INCREASE THE SUPPLY RATE. Why is the bottom end bearing clearance taken only at bdc... any other answer other than convinence and mentioned in manual It could be because at bdc, the crank pin is having even and least contact force with the lower bearing. the bearings wont be acted upon by the crank pin . at all other postions the bottom shell will be squeezed by Pin in someway or the other resulting in clearance being non uniform Fn-4 1)Degree of interference b/w web nd journal in semi built crank shaft. 2)Wat shud be the size of relief holes in crankcase relief door?? 3)How liner is selected for an engine of given output power??wat shud b the criteria?? 4)How pinching screw fitted on tie rods are locked to prevent it from getting loose due to vibration??

Page 20

You might also like

- ANSYS Fluent Teory Guide 21R1Document1,072 pagesANSYS Fluent Teory Guide 21R1John Stone0% (3)

- Five Methods of Putting a Single Cylinder Out of OperationDocument4 pagesFive Methods of Putting a Single Cylinder Out of OperationAnakin SkywalkerNo ratings yet

- Class 4 Frequent Asked Qs Shashwat000Document168 pagesClass 4 Frequent Asked Qs Shashwat000Lovy Singh100% (1)

- MEO CLASS IV OralsDocument25 pagesMEO CLASS IV OralsAnoop Vijayakumar0% (1)

- Mca Applied Heat 2017Document16 pagesMca Applied Heat 2017Anonymous 4ylE57C6No ratings yet

- Metamanual DG ShippingDocument6 pagesMetamanual DG ShippingAnonymous 4ylE57C60% (1)

- Mca Applied Heat 2017Document16 pagesMca Applied Heat 2017Anonymous 4ylE57C6No ratings yet

- Adhesives: Standard Terminology ofDocument12 pagesAdhesives: Standard Terminology ofJOHN MARTINNo ratings yet

- Meo cl2 MMDDocument38 pagesMeo cl2 MMDAurvin SinghNo ratings yet

- Mugilrajan B6 M3Document15 pagesMugilrajan B6 M3Mugilrajan Devarajan100% (2)

- Xtra 1st Class PDFDocument12 pagesXtra 1st Class PDFnishantNo ratings yet

- Mam II, Answers To Question Bank, 20-4-11Document57 pagesMam II, Answers To Question Bank, 20-4-11Giri VenkatesanNo ratings yet

- MAM - I, Question BankDocument8 pagesMAM - I, Question BankBharatiyulamNo ratings yet

- Assorted QuestionsDocument17 pagesAssorted QuestionsRohit MishraNo ratings yet

- IMP Main Engine and Aux EngineDocument37 pagesIMP Main Engine and Aux EngineLOKINo ratings yet

- Butterfly Valve Handles Locking ArrangementDocument55 pagesButterfly Valve Handles Locking Arrangementadam shaneNo ratings yet

- Stability Notes BN BeraDocument26 pagesStability Notes BN BeranishantNo ratings yet

- TRASSIDocument7 pagesTRASSIRohit Mishra50% (2)

- Explain The Fundamentals of Steering TheoryDocument33 pagesExplain The Fundamentals of Steering TheoryKazmi AshfaqNo ratings yet

- Ekm Motor Class 2Document84 pagesEkm Motor Class 2Anonymous 4ylE57C6100% (1)

- Marine Boilers 25Document99 pagesMarine Boilers 25Anjaana PrashantNo ratings yet

- Oral GeneralDocument8 pagesOral GeneralPrakhyati RautNo ratings yet

- Oily Water SeparatorDocument5 pagesOily Water SeparatorFe Capricho100% (1)

- Fuel Change Over Procedure-1Document4 pagesFuel Change Over Procedure-1Radu IchimNo ratings yet

- MEO Class 4B Examinations Oral Question Bank For Electro Technology and Control EngineeringDocument8 pagesMEO Class 4B Examinations Oral Question Bank For Electro Technology and Control EngineeringShriram AryanNo ratings yet

- Fun 3 & 6 Q & A UpdatedDocument173 pagesFun 3 & 6 Q & A Updatedrajesh kumarNo ratings yet

- MEO Class IV Exam Guide on Steering Gear SystemsDocument8 pagesMEO Class IV Exam Guide on Steering Gear Systemsnarendra rathoreNo ratings yet

- Commercial QnA 1 YearDocument27 pagesCommercial QnA 1 YearMariyath Muraleedharan KiranNo ratings yet

- MEO Class 4 Safety Questions SpecialDocument23 pagesMEO Class 4 Safety Questions SpecialBhalchandra ChandakkarNo ratings yet

- Safety Meo Class 4Document18 pagesSafety Meo Class 4Bhargav Krsna GayanNo ratings yet

- Some Test About RuddersDocument2 pagesSome Test About RuddersVaibhav DesaiNo ratings yet

- Class 4 2018 Kolkata MMD QuestionsDocument155 pagesClass 4 2018 Kolkata MMD QuestionsAbhinandan ChandraNo ratings yet

- Marine Engines NSKDocument31 pagesMarine Engines NSKJohn SnowNo ratings yet

- CoC Oral Exam Preparation (Part - 16) - CO2 Flooding System - Marine StudyDocument6 pagesCoC Oral Exam Preparation (Part - 16) - CO2 Flooding System - Marine StudyShaip Sankar100% (1)

- April 2021 Oral Questions - Chennai MMD: Motor SafetyDocument21 pagesApril 2021 Oral Questions - Chennai MMD: Motor SafetyAbdul MazithNo ratings yet

- Epariksha MEPDocument8 pagesEpariksha MEPPrateek Khanna100% (1)

- Fire Safety Handbook for Offshore TraineesDocument43 pagesFire Safety Handbook for Offshore TraineesDrawde AinogrobNo ratings yet

- MEO Class 2 Orals FN 3 6 Q ADocument15 pagesMEO Class 2 Orals FN 3 6 Q AAnkit BatraNo ratings yet

- ClassNK PSC ReportDocument62 pagesClassNK PSC ReportNguyen Huu TriNo ratings yet

- Latest Oral Questions MEO Class 4 Mumbai MMDDocument23 pagesLatest Oral Questions MEO Class 4 Mumbai MMDanon_322442463No ratings yet

- Development of Ballast Free ShipsDocument3 pagesDevelopment of Ballast Free ShipsVishva RagunathanNo ratings yet

- Met Class 4 Electrical WrittenDocument83 pagesMet Class 4 Electrical WrittenAjeet Jha86% (7)

- Irregularities in Indicator Diagram - Marine Engineering Study MaterialsDocument6 pagesIrregularities in Indicator Diagram - Marine Engineering Study MaterialsRavi Viknesh100% (1)

- Slow SteamingDocument3 pagesSlow SteamingArun SNo ratings yet

- EKM Class II QBankDocument26 pagesEKM Class II QBankRutvikNo ratings yet

- SM-212 Marine Diesel Engines II PDFDocument146 pagesSM-212 Marine Diesel Engines II PDFGeorge BusuricNo ratings yet

- MEO Class 4 Oral QuestionsDocument15 pagesMEO Class 4 Oral QuestionsVijay PrakashNo ratings yet

- NavalDocument18 pagesNavalRahul Ved0% (1)

- MEO Class 4 Oral and Written Questions Part 4Document43 pagesMEO Class 4 Oral and Written Questions Part 4amitt.rulezz80% (5)

- MEO Class I OralsDocument2 pagesMEO Class I OralsGurvindarNo ratings yet

- Class 4 Quick Reference For MEP - Motor and General Er Shashwat - 1Document227 pagesClass 4 Quick Reference For MEP - Motor and General Er Shashwat - 1Lovy Singh100% (2)

- MEO Class 2 QuestionDocument2 pagesMEO Class 2 Questionsumitsinha8950% (2)

- Enhanced Survey ProgrammeDocument3 pagesEnhanced Survey Programmevirendra302No ratings yet

- Procedure for Overhaul of A/E GeneratorDocument20 pagesProcedure for Overhaul of A/E GeneratorKapil Verma100% (1)

- BK Biswas SM MukherjeeDocument11 pagesBK Biswas SM MukherjeesinthustonNo ratings yet

- Class 4 Safety Oral Lsa File PDFDocument39 pagesClass 4 Safety Oral Lsa File PDFKarthikNair100% (21)

- Biswas 6Document4 pagesBiswas 6abhinav sinhaNo ratings yet

- Func 4B&6Document58 pagesFunc 4B&6Aswin MohanNo ratings yet

- Meoclass Ii MMD Oral QuestionsDocument5 pagesMeoclass Ii MMD Oral QuestionsSuresh JagadeesanNo ratings yet

- Scavenging & Supercharging Actions for Engine Room FiresDocument8 pagesScavenging & Supercharging Actions for Engine Room Fireskh al aminNo ratings yet

- Kochi MMD Questions 1Document13 pagesKochi MMD Questions 1Keshav AarjuNo ratings yet

- Mechanical Interview Questions and AnswersDocument7 pagesMechanical Interview Questions and AnswersAkesh KakarlaNo ratings yet

- Dec 2019Document8 pagesDec 2019Anonymous 4ylE57C6No ratings yet

- Dec 2019Document7 pagesDec 2019Anonymous 4ylE57C6No ratings yet

- 01 Master Responsibilities PDFDocument1 page01 Master Responsibilities PDFAnonymous 4ylE57C6No ratings yet

- Sample CVDocument1 pageSample CVAnonymous 4ylE57C6No ratings yet

- Mepc 10749Document35 pagesMepc 10749Anonymous 4ylE57C6No ratings yet

- July 2020Document7 pagesJuly 2020Anonymous 4ylE57C6No ratings yet

- MCERTIFI HEATDocument6 pagesMCERTIFI HEATAnonymous 4ylE57C6No ratings yet

- Vacuum System Upgrade ProjectDocument2 pagesVacuum System Upgrade ProjectAnonymous 4ylE57C6No ratings yet

- CLS 1 MotorDocument34 pagesCLS 1 MotorAnonymous 4ylE57C6No ratings yet

- Sample CVDocument1 pageSample CVAnonymous 4ylE57C6No ratings yet

- Sample CVDocument1 pageSample CVAnonymous 4ylE57C6No ratings yet

- SEABOURN PRIDE Power Restoration SequenceDocument2 pagesSEABOURN PRIDE Power Restoration SequenceAnonymous 4ylE57C6No ratings yet

- Replace Alarm Printers with Prilog Alarm LoggerDocument2 pagesReplace Alarm Printers with Prilog Alarm LoggerAnonymous 4ylE57C6No ratings yet

- SESCON feedwater & steam pressure regulator limitsDocument1 pageSESCON feedwater & steam pressure regulator limitsAnonymous 4ylE57C6No ratings yet

- Answering DGSA Exam QuestionsDocument3 pagesAnswering DGSA Exam QuestionsPedroTorres88No ratings yet

- How To - Aux Engine HFO To DO Change and BackDocument2 pagesHow To - Aux Engine HFO To DO Change and BackAnonymous 4ylE57C6No ratings yet

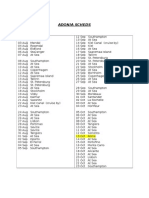

- Adonia SchedsDocument1 pageAdonia SchedsAnonymous 4ylE57C6No ratings yet

- Marine ShelfDocument20 pagesMarine ShelfAnonymous 4ylE57C6No ratings yet

- Top shipping companies contact detailsDocument6 pagesTop shipping companies contact detailsprasadcshettyNo ratings yet

- Fuel Pump - Marine EngineerDocument5 pagesFuel Pump - Marine EngineerAnonymous 4ylE57C6No ratings yet

- Marine Officer Exam Notes Oral Questions E-booksDocument4 pagesMarine Officer Exam Notes Oral Questions E-booksAnonymous 4ylE57C6100% (1)

- Marine Reciprocating CompressorsDocument3 pagesMarine Reciprocating CompressorsAnonymous 4ylE57C6No ratings yet

- Checklliistfor ISMDocument2 pagesChecklliistfor ISMAnonymous 4ylE57C6No ratings yet

- Maritime SchoolsDocument172 pagesMaritime SchoolsAnonymous 4ylE57C6100% (1)

- Induction Cooker Manual TCL 1821Document4 pagesInduction Cooker Manual TCL 1821prakashinaibsNo ratings yet

- Guide Atmospheric Testing Confined SpacesDocument0 pagesGuide Atmospheric Testing Confined SpacesAnonymous 4ylE57C6No ratings yet

- Class 1 Sea TimeDocument2 pagesClass 1 Sea TimeAnonymous 4ylE57C6No ratings yet

- Hooke's Law Verified in Spring ExperimentDocument11 pagesHooke's Law Verified in Spring ExperimentAbu Huzaifah100% (1)

- Plasmid Curing in BacteriaDocument3 pagesPlasmid Curing in BacteriaPayel BoseNo ratings yet

- Experiment 6Document6 pagesExperiment 6Sobana Kanthi33% (3)

- Point and Line SourceDocument41 pagesPoint and Line SourceNomanNo ratings yet

- Manual ATN-1100 Automatic Kjeldahl Nitrogen Determination ApparatusDocument35 pagesManual ATN-1100 Automatic Kjeldahl Nitrogen Determination Apparatuschristopher lee mercadoNo ratings yet

- Solubility - WikipediaDocument14 pagesSolubility - Wikipediatsvmpm1765No ratings yet

- Sintering Effect On The Performance of Tungsten-Copper Powder LinerDocument2 pagesSintering Effect On The Performance of Tungsten-Copper Powder LinermahsaNo ratings yet

- (Re) Coating of Pylons With ZINGAENDocument5 pages(Re) Coating of Pylons With ZINGAENMarco Antonio MoncerrateNo ratings yet

- Air PollutionDocument2 pagesAir PollutionBarani KingNo ratings yet

- Qe 22 A PDFDocument10 pagesQe 22 A PDF孙俊磊No ratings yet

- Nail Care 7 HandoutsDocument2 pagesNail Care 7 HandoutsChristine Joy ValenciaNo ratings yet

- Stereoisomers Part 1Document14 pagesStereoisomers Part 1Mabelle DucusinNo ratings yet

- What's New - PV Elite 2018Document28 pagesWhat's New - PV Elite 2018SathiyaseelanNo ratings yet

- Us03cicv21 Unit3Document28 pagesUs03cicv21 Unit3ashokNo ratings yet

- CHE211 Problem Set 5Document3 pagesCHE211 Problem Set 5AlexNo ratings yet

- Welding Defects and PreventionDocument2 pagesWelding Defects and PreventionVicky SinghNo ratings yet

- Recycling of Pad-Batch Washing Textile Wastewater Through Advanced Oxidation Processes and Its Reusability Assessment For Turkish Textile IndustDocument7 pagesRecycling of Pad-Batch Washing Textile Wastewater Through Advanced Oxidation Processes and Its Reusability Assessment For Turkish Textile IndustGizem D.No ratings yet

- Chemistry, Mathematics & Physics: All India Internal Test SeriesDocument15 pagesChemistry, Mathematics & Physics: All India Internal Test Seriesmadhav aggarwalNo ratings yet

- Ganoderma laccase optimizationDocument9 pagesGanoderma laccase optimizationRajeshKumarNo ratings yet

- Sloss Industries 1062235 M2234300 EX351 V 2Document1 pageSloss Industries 1062235 M2234300 EX351 V 2DanielDeFrancescoNo ratings yet

- Heavy Metal Contamination: An Alarming Threat To Environment and Human HealthDocument23 pagesHeavy Metal Contamination: An Alarming Threat To Environment and Human HealthMalik HopeNo ratings yet

- Monsal Enzymic Hydrolysis New Developments and Lessons LearntDocument23 pagesMonsal Enzymic Hydrolysis New Developments and Lessons LearntAnonymous MVHQ97KEoPNo ratings yet

- LS DYNA Aerospace Working Group Modeling Guidelines Document Version 19 1 Dated June 28, 2019 PDFDocument252 pagesLS DYNA Aerospace Working Group Modeling Guidelines Document Version 19 1 Dated June 28, 2019 PDFЮрий НовожиловNo ratings yet

- E2 Series RO SystemsDocument2 pagesE2 Series RO SystemsDiego ArguetaNo ratings yet

- Unit OperationsDocument4 pagesUnit OperationsCeazar Justine Fulugan100% (1)

- Jazeera Deco Primer-MsdsDocument5 pagesJazeera Deco Primer-MsdsMahmoud FlefilNo ratings yet

- Bioplastic ProjectDocument15 pagesBioplastic ProjectSarthak Verma100% (1)

- Entner Duodroff PathwayDocument2 pagesEntner Duodroff PathwayDr. SHIVA AITHALNo ratings yet