Professional Documents

Culture Documents

Exhaust Gas Pressure Drop in Duct

Uploaded by

Myungkwan HaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exhaust Gas Pressure Drop in Duct

Uploaded by

Myungkwan HaCopyright:

Available Formats

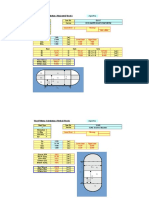

ID450-500

Design Criteria for Exhasut gas duct & Stack Line

Elv Edv Eq = = = 85 mbar 866.8 mmAq 30 mbar 305.9 mmAq 5.4 m3/s 19440 m3/hr E 0 T0 T P0 P = = = = = = 0 x (T0/T) x (P/P0) = 0.50 kg/m3 1.293 kg/m3 0 Deg. C 273.15 K 480 Deg. C 753.15 K 10330 mmAq 10635.9 mmAq Standard barometric pressure Edv + P0 Exhuast gas density at Exhaust gas density at 480 deg. C 0 deg. C Limit value for exhaust gas back pressure Design value for exhaust gas back pressure

( Horizontal straight pipe line) EXH. GAS. FUILD TEMP. DEG. 480 EXH. GAS

FLOW RATE m3/hr 19,440

OD 550 (treble pipe)

ID m 0.45

DENSITY KG/m3 0.50

VISCOSITY m2/s 0.00007391

mm 0.15

AREA m2 0.159043

VELOCITY m/s 33.9530819

RE. NO. 206,722.9

/D 0.00033

( Vertical straight pipe line) EXH. GAS. FUILD TEMP. DEG. 480 EXH. GAS

FLOW RATE m3/hr 19,440

OD 550 (double pipe)

ID m 0.5

DENSITY KG/m3 0.50

VISCOSITY m2/s 0.00007391

mm 0.15

AREA m2 0.19635

VELOCITY m/s 27.5019099

RE. NO. 186,050.0

/D 0.00030

1) Friction loss for Straight run of Pipe a) LstrH f1 P1 b) LstrV f2 P2 = =0.0055 x [ 1 +(20000 x /D + 10^6/Re)^1/3] = f1 x L/D x (V^2 x E / 2g) = =0.0055 x [ 1 +(20000 x /D + 10^6/Re)^1/3] = f2 x L/D x (V^2 x E / 2g) = = = = 12 m 0.027 20.8 mmAq 61.7 m 0.026 62.7 mmAq Vertical Straight pipe length Friction loss Coefficient for straight pipe run Horizontal Straight pipe length Friction loss Coefficient for straight pipe run

2) Friction loss for Fittings (Elbow, Y elbow, etc.) c) Y type elbow f3 No. P3 d) Z type elbow f4 No. P4 = = = f3 x (V^2 x E / 2g) = = = 0.56 1 ea 16.5 mmAq Friction loss Coefficient for elbow The Number of elbow

= = = f4 x (V^2 x E / 2g)

= = =

0.16 1 ea 4.7 mmAq

Friction loss Coefficient for elbow The Number of elbow

ID450-500

e) 45 deg elbow f5 No. P4 = = = f5 x (V^2 x E / 2g) = = = 0.5 1 ea 14.7 mmAq Friction loss Coefficient for elbow The Number of elbow

3) Friction loss for sudden expansion (500A-> 600A) f) f6 No. P4 = = = f3 x (V^2 x E / 2g) = = = 0.03 1 ea 0.9 mmAq Friction loss Coefficient for elbow The Number of elbow

4) Outlet loss at stack g) P5 =(V^2 x E / 2g) 5) Exhaust gas silencer h) P6 6) Up-draught in vertical pipe(stack) Alti= Atom= Sheight = 0 T0 Texh t air = = 19.3 mmAq 200 mmAq

150 m 995.4 mbar 10150.5 mmAq

Site altitude Atmospheric presssure

= = =

= 0 x (273.15/(273.15+texh)*(1013/Atom)

61.7 m 1.293 kg/m3 0 Deg. C 273.15 K 40 Deg. C = 313.15 K 1.1477 kg/m3

Exhaust gas density at

0 deg. C

0 T0 Texh t exh

= = =

= 0 x (273.15/(273.15+texh)*(1013/Atom)

1.293 kg/m3 0 Deg. C 273.15 K 360 Deg. C = 633.15 K 0.5677 kg/m3

Exhaust gas density at

0 deg. C

Hdraft =

Sheight x

(t air - t exh)

35.79 mmAq

Total Pressure drop : P1+P2 +P3+P4+P5 +P6 - Hdraft

303.81

<

305.9 mmAq O.K

Design value for exhaust gas back pressure recommended by MTU.

We have designed/arranged the exhuast gas duct/stack line size in compliance with the building and structural drawings provided with NAM-KWANG, considering the admissilbe back pressure (305.9 mmAq) recommemded by Engine Manufacturer. As shown above calculation, the present exhasut gas line design seems to be no problem in exhaust gas system for engine normal operation.

Exh. Gas duct (3)

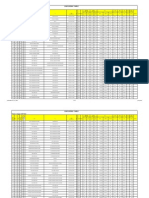

CASE I : Initial design (ID 350)

Elv Edv Eq = = = 85 mbar 866.8 mmAq 30 mbar 305.9 mmAq 5.4 m3/s 19440 m3/hr E 0 T0 T P0 P = = = = = = 0 x (T0/T) x (P/P0) = 0.50 kg/m3 1.293 kg/m3 0 Deg. C 273.15 K 480 Deg. C 753.15 K 10330 mmAq 10635.9 mmAq Standard barometric pressure Edv + P0 Exhuast gas density at Exhaust gas density at 480 deg. C 0 deg. C Limit value for exhaust gas back pressure Design value for exhaust gas back pressure

( Horizontal straight pipe line) EXH. GAS. FUILD TEMP. DEG. 480 EXH. GAS

FLOW RATE m3/hr 19,440

OD A 450

ID m 0.35

DENSITY KG/m3 0.50

VISCOSITY m2/s 0.00007391

mm 0.15

AREA m2 0.096211

VELOCITY m/s 56.1266383

RE. NO. 265,787.1

/D 0.00043

( Vertical straight pipe line) EXH. GAS. FUILD TEMP. DEG. 480 EXH. GAS

FLOW RATE m3/hr 19,440

OD A 450

ID m 0.35

DENSITY KG/m3 0.50

VISCOSITY m2/s 0.00007391

mm 0.15

AREA m2 0.096211

VELOCITY m/s 56.1266383

RE. NO. 265,787.1

/D 0.00043

1) Friction loss for Straight run of Pipe a) LstrH f1 P1 b) LstrV f2 P2 = =0.0055 x [ 1 +(20000 x /D + 10^6/Re)^1/3] = f1 x L/D x (V^2 x E / 2g) = =0.0055 x [ 1 +(20000 x /D + 10^6/Re)^1/3] = f2 x L/D x (V^2 x E / 2g) = = = = 12 m 0.028 77.4 mmAq 61.7 m 0.028 397.8 mmAq Vertical Straight pipe length Friction loss Coefficient for straight pipe run Horizontal Straight pipe length Friction loss Coefficient for straight pipe run

2) Friction loss for Fittings (Elbow, Y elbow, etc.) c) Y type elbow f3 No. P3 d) Z type elbow f4 No. P4 = = = f3 x (V^2 x E / 2g) = = = 0.56 1 ea 45 mmAq Friction loss Coefficient for elbow The Number of elbow

= = = f4 x (V^2 x E / 2g)

= = =

0.16 1 ea 12.8 mmAq

Friction loss Coefficient for elbow The Number of elbow

Exh. Gas duct (3)

e) 45 deg elbow f5 No. P4 = = = f5 x (V^2 x E / 2g) = = = 0.5 1 ea 40.1 mmAq Friction loss Coefficient for elbow The Number of elbow

3) Friction loss for sudden expansion (500A-> 600A) f) f6 No. P4 = = = f3 x (V^2 x E / 2g) = = = 0.03 1 ea 2.4 mmAq Friction loss Coefficient for elbow The Number of elbow

4) Outlet loss at stack g) P5 =(V^2 x E / 2g) 5) Exhaust gas silencer h) P6 6) Up-draught in vertical pipe(stack) Alti= Atom= Sheight = 0 T0 Texh t air = = 80.3 mmAq 200 mmAq

150 m 995.4 mbar 10150.5 mmAq

Site altitude Atmospheric presssure

= = =

= 0 x (273.15/(273.15+texh)*(1013/Atom)

61.7 m 1.293 kg/m3 0 Deg. C 273.15 K 40 Deg. C = 313.15 K 1.1477 kg/m3

Exhaust gas density at

0 deg. C

0 T0 Texh t exh

= = =

= 0 x (273.15/(273.15+texh)*(1013/Atom)

1.293 kg/m3 0 Deg. C 273.15 K 360 Deg. C = 633.15 K 0.5677 kg/m3

Exhaust gas density at

0 deg. C

Hdraft =

Sheight x

(t air - t exh)

35.79 mmAq

Total Pressure drop : P1+P2 +P3+P4+P5 +P6 - Hdraft

820.01

> Not Acceptable

305.9 mmAq

Design value for exhaust gas back pressure recommended by MTU.

As shown above calculation, firiction loss of the exhasut gas line with ID 350 exceeds the admissible back pressure value 305.9 mmAq.

Exh. Gas duct (3)

Design Criteria for Exhasut gas duct & Stack Line

CASE II : Current Design (ID 500)

Elv Edv Eq = = = 85 mbar 866.8 mmAq 30 mbar 305.9 mmAq 5.4 m3/s 19440 m3/hr E 0 T0 T P0 P = = = = = = 0 x (T0/T) x (P/P0) = 0.50 kg/m3 1.293 kg/m3 0 Deg. C 273.15 K 480 Deg. C 753.15 K 10330 mmAq 10635.9 mmAq Standard barometric pressure Edv + P0 Exhuast gas density at Exhaust gas density at 480 deg. C 0 deg. C Limit value for exhaust gas back pressure Design value for exhaust gas back pressure

( Horizontal straight pipe line) EXH. GAS. FUILD TEMP. DEG. 480 EXH. GAS

FLOW RATE m3/hr 19,440

OD 550

ID m 0.5

DENSITY KG/m3 0.50

VISCOSITY m2/s 0.00007391

mm 0.15

AREA m2 0.19635

VELOCITY m/s 27.5019099

RE. NO. 186,050.0

/D 0.00030

( Vertical straight pipe line) EXH. GAS. FUILD TEMP. DEG. 480 EXH. GAS

FLOW RATE m3/hr 19,440

OD 550

ID m 0.5

DENSITY KG/m3 0.50

VISCOSITY m2/s 0.00007391

mm 0.15

AREA m2 0.19635

VELOCITY m/s 27.5019099

RE. NO. 186,050.0

/D 0.00030

1) Friction loss for Straight run of Pipe a) LstrH f1 P1 b) LstrV f2 P2 = =0.0055 x [ 1 +(20000 x /D + 10^6/Re)^1/3] = f1 x L/D x (V^2 x E / 2g) = =0.0055 x [ 1 +(20000 x /D + 10^6/Re)^1/3] = f2 x L/D x (V^2 x E / 2g) = = = = 12 m 0.026 12.2 mmAq 61.7 m 0.026 62.7 mmAq Vertical Straight pipe length Friction loss Coefficient for straight pipe run Horizontal Straight pipe length Friction loss Coefficient for straight pipe run

2) Friction loss for Fittings (Elbow, Y elbow, etc.) c) Y type elbow f3 No. P3 d) Z type elbow f4 No. P4 = = = f3 x (V^2 x E / 2g) = = = 0.56 1 ea 10.8 mmAq Friction loss Coefficient for elbow The Number of elbow

= = = f4 x (V^2 x E / 2g)

= = =

0.16 1 ea 3.1 mmAq

Friction loss Coefficient for elbow The Number of elbow

Exh. Gas duct (3)

e) 45 deg elbow f5 No. P4 = = = f5 x (V^2 x E / 2g) = = = 0.5 1 ea 9.6 mmAq Friction loss Coefficient for elbow The Number of elbow

3) Friction loss for sudden expansion (500A-> 600A) f) f6 No. P4 = = = f3 x (V^2 x E / 2g) = = = 0.03 1 ea 0.6 mmAq Friction loss Coefficient for elbow The Number of elbow

4) Outlet loss at stack g) P5 =(V^2 x E / 2g) 5) Exhaust gas silencer h) P6 6) Up-draught in vertical pipe(stack) Alti= Atom= Sheight = 0 T0 Texh t air = = 19.3 mmAq 200 mmAq

150 m 995.4 mbar 10150.5 mmAq

Site altitude Atmospheric presssure

= = =

= 0 x (273.15/(273.15+texh)*(1013/Atom)

61.7 m 1.293 kg/m3 0 Deg. C 273.15 K 40 Deg. C = 313.15 K 1.1477 kg/m3

Exhaust gas density at

0 deg. C

0 T0 Texh t exh

= = =

= 0 x (273.15/(273.15+texh)*(1013/Atom)

1.293 kg/m3 0 Deg. C 273.15 K 360 Deg. C = 633.15 K 0.5677 kg/m3

Exhaust gas density at

0 deg. C

Hdraft =

Sheight x

(t air - t exh)

35.79 mmAq

Total Pressure drop : P1+P2 +P3+P4+P5 +P6 - Hdraft

282.51

<

305.9 mmAq O.K

Design value for exhaust gas back pressure recommended by MTU.

We have designed/arranged the exhuast gas duct/stack line size in compliance with the building and structural drawings provided with NAM-KWANG, considering the admissilbe back pressure (305.9 mmAq) recommemded by Engine Manufacturer. As shown above calculation, the present exhasut gas line with ID 500 seems to be no problem in exhaust gas system for engine normal operation.

You might also like

- Air Pressure Loss in Piping and DuctsDocument5 pagesAir Pressure Loss in Piping and DuctsPhyu Mar Thein KyawNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- Restriction Orifice SizingDocument5 pagesRestriction Orifice SizingjoeNo ratings yet

- Venturi Scrubber Theory & ExperimentDocument6 pagesVenturi Scrubber Theory & ExperimentTian Fung Wang100% (1)

- Air Receiver Sizing CalculationDocument1 pageAir Receiver Sizing CalculationAziz HaqueNo ratings yet

- Burner CalculationDocument9 pagesBurner CalculationAbul QasimNo ratings yet

- Steam Calculation 2008 0326Document53 pagesSteam Calculation 2008 0326Myungkwan HaNo ratings yet

- Gas Pipe SizingDocument3 pagesGas Pipe SizingthecodekingNo ratings yet

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- Evaporator heat transfer and surface area calculationDocument4 pagesEvaporator heat transfer and surface area calculationDaniyal HashmiNo ratings yet

- Control Valve Sizing - EnggcyclopediaDocument4 pagesControl Valve Sizing - EnggcyclopediaazitaggNo ratings yet

- Calculation of Scrubber DiameterDocument44 pagesCalculation of Scrubber DiameterRamakrishna SomuNo ratings yet

- Thermal InsulationDocument27 pagesThermal Insulationmkchy12No ratings yet

- Pressure Drop in BendDocument5 pagesPressure Drop in BendfitratulqadriNo ratings yet

- Heat Exchanger Design 1Document9 pagesHeat Exchanger Design 1Rajeev SaxenaNo ratings yet

- Sizing Stack HeightDocument1 pageSizing Stack Heightashwini_kumar19840% (1)

- Orifice Sizing PrinciplesDocument12 pagesOrifice Sizing Principlesjlcheefei9258100% (1)

- Design of AgitatorDocument3 pagesDesign of Agitatorkaps12No ratings yet

- Combustion CalcsDocument8 pagesCombustion Calcs31331311313No ratings yet

- FLUE GAS ANALYSIS AND HEAT EXCHANGER SIZINGDocument3 pagesFLUE GAS ANALYSIS AND HEAT EXCHANGER SIZINGRajendraNo ratings yet

- Ist Stage Cooler Process and Mechanical DetailsDocument2 pagesIst Stage Cooler Process and Mechanical DetailsjnmanivannanNo ratings yet

- Sizing For Vaporiser/Flash Vessel: InputsDocument3 pagesSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranNo ratings yet

- Process Calculation - Purge Gas CalculationDocument1 pageProcess Calculation - Purge Gas CalculationmakamahamisuNo ratings yet

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Heat Transfer in Jacketed VesselDocument2 pagesHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Control valve Cv calculationDocument3 pagesControl valve Cv calculationN. S. PanditNo ratings yet

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićNo ratings yet

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocument2 pagesDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658No ratings yet

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarNo ratings yet

- Technical Design Principles for Liquid Ring Vacuum PumpsDocument18 pagesTechnical Design Principles for Liquid Ring Vacuum PumpsAgung SiswahyuNo ratings yet

- Boilers Chimney Draft and Breeching CalculationDocument15 pagesBoilers Chimney Draft and Breeching Calculationjoabjim8392No ratings yet

- Steam Pipe SizingDocument16 pagesSteam Pipe SizingsamvendanNo ratings yet

- HCL Scrubber DesignDocument5 pagesHCL Scrubber DesignManish0301198375% (4)

- Project No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasDocument11 pagesProject No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasrajachemNo ratings yet

- Shell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsDocument6 pagesShell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsrajachemNo ratings yet

- Steam CalculationDocument27 pagesSteam CalculationRAVI KUMAR CarpenterNo ratings yet

- Pressuredrop Calculations by Kern Method SRRDocument18 pagesPressuredrop Calculations by Kern Method SRRrajeev50588No ratings yet

- PACKED COLUMN DESIGN FOR HCL SCRUBBERDocument11 pagesPACKED COLUMN DESIGN FOR HCL SCRUBBERsoreksatuNo ratings yet

- EXHAUST BACK PRESSURE CALCULATION FOR UNIVERSITY OF SHARJAH HOSPITAL GENSETDocument1 pageEXHAUST BACK PRESSURE CALCULATION FOR UNIVERSITY OF SHARJAH HOSPITAL GENSETRoshan ShanmughanNo ratings yet

- Spreadsheet Heat Loss from a PipeDocument1 pageSpreadsheet Heat Loss from a PipeJogender DhayalNo ratings yet

- C3CYCLVDocument13 pagesC3CYCLVUok RitchieNo ratings yet

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Is 14164 2008Document45 pagesIs 14164 2008Pukhraj DagaNo ratings yet

- Flares CalculationsDocument14 pagesFlares CalculationsAnonymous oVRvsdWzfBNo ratings yet

- Flowrate Calculation For An Orifice FlowmeterDocument3 pagesFlowrate Calculation For An Orifice FlowmetervbiroliniNo ratings yet

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignMakhdoom Ibad HashmiNo ratings yet

- Exhaust ChimneyDocument4 pagesExhaust ChimneyDesigner ForeverNo ratings yet

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 pagesWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document16 pagesVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanNo ratings yet

- Pneumatic Conveying Design CalculationsDocument4 pagesPneumatic Conveying Design CalculationsfunloverjhaNo ratings yet

- Vessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumDocument4 pagesVessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumDongwon ShinNo ratings yet

- Half Pipe CalculationDocument3 pagesHalf Pipe CalculationCaptainTonies0% (1)

- Design Calculation TankDocument28 pagesDesign Calculation Tankibiceng100% (4)

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous nwByj9L100% (2)

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous 9iK0i8h0dPNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsIbrahim El SharNo ratings yet

- Atasehir Gardens Podium OF: Member: LocationDocument7 pagesAtasehir Gardens Podium OF: Member: LocationklynchelleNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design Sheetsashuswara84% (25)

- Burner CalculationDocument6 pagesBurner CalculationAnonymous 3ESYcrKP100% (4)

- Water quality parameters and their measurementDocument19 pagesWater quality parameters and their measurementMyungkwan Ha100% (1)

- WaterlossDocument40 pagesWaterlossMyungkwan HaNo ratings yet

- Line SizingDocument3 pagesLine SizingMyungkwan HaNo ratings yet

- HRSG Basics PDFDocument14 pagesHRSG Basics PDFNimeshNo ratings yet

- Engine Derating ReviewDocument7 pagesEngine Derating ReviewMyungkwan HaNo ratings yet

- Applicable Raw Water Quality (Supplied by Owner) : Well No. 238 Is Not TestedDocument2 pagesApplicable Raw Water Quality (Supplied by Owner) : Well No. 238 Is Not TestedMyungkwan HaNo ratings yet

- Exhaust Gas Line Desing CriteriaDocument4 pagesExhaust Gas Line Desing CriteriaMyungkwan HaNo ratings yet

- Steam Calculation 2008 0326Document53 pagesSteam Calculation 2008 0326Myungkwan HaNo ratings yet

- SA Engineering College Statistics and Numerical Methods NotesDocument8 pagesSA Engineering College Statistics and Numerical Methods NotesRaja Nirmal KumarNo ratings yet

- Material Balance On A 2 Unit DistillationsDocument6 pagesMaterial Balance On A 2 Unit Distillationsnhalieza1067No ratings yet

- IEEE Paper For Image ProcessingDocument32 pagesIEEE Paper For Image Processingsaravanan_dijucsNo ratings yet

- Calcul Evaltn-Embankments Reinforced With geocells-FEM-2015Document14 pagesCalcul Evaltn-Embankments Reinforced With geocells-FEM-2015Rakesh KapoorNo ratings yet

- Mijlocul Cerului in SinastrieDocument2 pagesMijlocul Cerului in SinastrieKali KaliNo ratings yet

- (Architecture Ebook) Alvar Aalto, Alvar Aalto and The Bio-ArchitectureDocument5 pages(Architecture Ebook) Alvar Aalto, Alvar Aalto and The Bio-Architecturepooh86poohNo ratings yet

- CASD 2017. Robust H-Infinity Backstepping Control Design of A Wheeled Inverted Pendulum SystemDocument5 pagesCASD 2017. Robust H-Infinity Backstepping Control Design of A Wheeled Inverted Pendulum SystemNam Hoang ThanhNo ratings yet

- Particulate Matter Sampling PDFDocument62 pagesParticulate Matter Sampling PDFAshitNo ratings yet

- Lightweight SUV Frame Design DevelopmentDocument50 pagesLightweight SUV Frame Design DevelopmentAltairEnlightenNo ratings yet

- Mec 424 - Laboratory Report: Free Vibration Experiment - Natural Frequency of Spring Mass System Without DampingDocument24 pagesMec 424 - Laboratory Report: Free Vibration Experiment - Natural Frequency of Spring Mass System Without DampingWan AimanNo ratings yet

- POLYMERIZATION PROCESSESDocument0 pagesPOLYMERIZATION PROCESSESmajesticdharma1985No ratings yet

- Expt 01Document10 pagesExpt 01Kathleen De Vera BarrilNo ratings yet

- Autocad 2d Module 23 PDFDocument0 pagesAutocad 2d Module 23 PDFRam LamaNo ratings yet

- G.D.GOENKA PUBLIC SCHOOL CLASS 10 CHEMISTRY CHAPTER 2 ACIDS BASES SALTS ASSIGNMENTDocument3 pagesG.D.GOENKA PUBLIC SCHOOL CLASS 10 CHEMISTRY CHAPTER 2 ACIDS BASES SALTS ASSIGNMENTvikas aggarwal100% (1)

- Especificacion SHY73MC4 UDocument3 pagesEspecificacion SHY73MC4 UYgor Salgado100% (3)

- Math at Grade 4Document9 pagesMath at Grade 4api-239942675No ratings yet

- Ising ModelDocument5 pagesIsing Modeldecerto252No ratings yet

- Fortran (For NACA)Document7 pagesFortran (For NACA)hdslmnNo ratings yet

- SosthenesDocument396 pagesSosthenesAthiesh KumarNo ratings yet

- 16.323 Principles of Optimal Control: Mit OpencoursewareDocument26 pages16.323 Principles of Optimal Control: Mit Opencoursewaremousa bagherpourjahromiNo ratings yet

- Lucia 1995 Rock-FabricPetrophysical Classification of Carbonate Pore SpaceDocument26 pagesLucia 1995 Rock-FabricPetrophysical Classification of Carbonate Pore SpaceMarcos Antonio Romero Arteaga100% (1)

- AADE Review of Lost Circulation Materials and Treatments With An Updated ClassificationDocument9 pagesAADE Review of Lost Circulation Materials and Treatments With An Updated ClassificationMuhamad IrfanNo ratings yet

- Dual Nature of LightDocument15 pagesDual Nature of LightUriahs Victor75% (4)

- Xxii Paper 51Document9 pagesXxii Paper 51kjyeom_258083906No ratings yet

- Numerical Solution of Seepage Problem of Groundwater FlowDocument5 pagesNumerical Solution of Seepage Problem of Groundwater FlowIOSRjournalNo ratings yet

- CGR 16050 2019 2020 1Document1 pageCGR 16050 2019 2020 1Chandan Prasad KushwahaNo ratings yet

- Gear Motors: Achieving The Perfect Motor & Gearbox MatchDocument16 pagesGear Motors: Achieving The Perfect Motor & Gearbox MatchJohn LeeNo ratings yet

- Working of Steam Turbines and Its AuxillariesDocument48 pagesWorking of Steam Turbines and Its AuxillariesbalajigandhirajanNo ratings yet

- Laser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsDocument6 pagesLaser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsK. JayarajanNo ratings yet

- Normal Distribution Giuded SolutionsDocument5 pagesNormal Distribution Giuded SolutionsleeshanghaoNo ratings yet