Professional Documents

Culture Documents

Otis Engineering Center Gien Field Component Manual

Uploaded by

nr1wolf_co_69529906Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Otis Engineering Center Gien Field Component Manual

Uploaded by

nr1wolf_co_69529906Copyright:

Available Formats

file.

doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11

Otis

A United Technologies Company

Page: 1/13

INTRODUCTION

The maintenance-free drive unit consists of a DC motor with a non-self-locking gear and is operated with speed control. The transmission is performed using a toothed belt. The toothed belt is guided across a deflection pulley. No limit switches are required for the operation of the door drive. The door widths as well as the positions "OPEN" and "CLOSE" are automatically determined after self learn run.

1 2

3

1 Transformer - 2 Control Board - 3 Belt - 4 Motor - 5 Coupling

WARNING

Only qualified staff should work on this device or in its vicinity. The staff must thoroughly be informed about all warnings and maintenance measures according to these operating. To ensure the correct and safe operation of this device, proper transport, storage, erection and assembly as well as careful operation and maintenance are required.

file.doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11

Otis

A United Technologies Company

Page: 2/13

TECHNICAL DATA

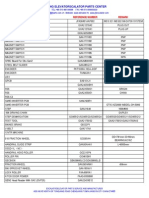

CONTROL BOARD

Detail marking on control board

DC GEAR MOTOR (OVERALL DOOR MASS 120kg)

Rated voltage Speed Protection Transmission Encoder Rated current 24V max DC 0.5m/s max IP20 15:1 Incremental encoder (100 increments/revolution) 1.8A

file.doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11

Otis

A United Technologies Company

Page: 3/13

TRANSFORMER (OVERALL DOOR MASS 120kg)

Main voltage Temperature Protection Rated output voltage Secondary current Main Filter 230/400V AC15%, 50/60Htz 0 to 50C IP54 30.5V DC 3.6A max Built-in

CONTROL DEVICE ATXX (OVERALL DOOR MASS 120kg)

Voltage Fuse Protection Input Door width (OP) Storing temperature Operating temperature Humidity stress 30.5V DC 5X20 T2.0A Top IP20, front IP43 24V 5% 700 to 900mm -20 to +80C 0 to +50C (no direct insulation) No thawing

TEST

EMC EN 12015 & EN 12016 TV (MOT) Type tested CE Certified

FUNCTION SETTING

Sword route "OPEN" Creeping-route "OPEN" Sword route "CLOSE" Creeping-route "CLOSE" Acceleration ramp "OPEN" Brake ramp "OPEN" Acceleration ramp "CLOSE" Brake ramp "CLOSE" Reversing-clamp "OPEN-CLOSE" Reversing-clamp "CLOSE-OPEN" Min opening speed (sword route) Min opening speed Min closing speed (sword route) Min closing speed Max opening speed Max closing speed Nudging speed Opening force Closing force Closing force (sword route) Continuous momentum "CLOSE" Continuous momentum "OPEN" Pressure momentum "CLOSE" Nudging force Pre-setting 5cm 5cm 5cm 5cm 2 50cm/s 2 50cm/s 2 50cm/s 2 50cm/s 2 50cm/s 2 50cm/s 6cm/s 6cm/s 6cm/s 6cm/s 40cm/s 25cm/s 15cm/s Max motor value 115N 115N Current 0.5A Current 0.5A Current 2.0A 115N Setting range 0 to 0.10m 0 to 0.10m 0 to 0.10m 0 to 0.10m 2 30 to 80cm/s 2 30 to 80cm/s 2 30 to 80cm/s 2 30 to 80cm/s 2 30 to 80cm/s 2 30 to 80cm/s 3 to 9cm/s 3 to 9cm/s 3 to 9cm/s 3 to 9cm/s 10 to 50cm/s 10 to 50cm/s 5 to 25cm/s 80N Max motor value 80 to 150N 80 to 150N Current 0 to 1.0A Current 0 to 1.0A Current 0 to 2.0A 80 to 150N

file.doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11

Otis

A United Technologies Company

Page: 4/13

OVERVIEW OF SERVICE TOOL MENU (SVT)

Welcom to APAX Press Button = 3

Monitor = 1 Status = 1 Input = 2 Output = 3

Test = 2 Even = 1 Actual = 1 Delete = 9 Main = 2 Part = 3 Interfchk = 4 SysCfg = 5

Setup = 3 Install = 1 Conf = 1 SetDef = 9 Field = 3 Eng = 4

Press SHIFT + 7 to get SETUP Menu

Tools = 4 Single = 1 Cont. = 2

AUTO-SET PARAMETERS (OP 700/750/800/850/900mm)

Start Opn Dist Open Crp Dist Close Crp Dist Start Cls Dist Accel Open Decel Open Accel Close Decel Close Reversal Open Reversal Close Start Open Speed Open Crp Speed Close Crp Speed Start Close Speed Max Open Speed Max Close Speed Nudging Speed Open Torque Close Torque Close Creep Torque Close Idle Torque Open Idle Torque Close Push Torque Nudging Torque Stop Torque main parameters Lateral opening 50 10 70 20 40 40 40 40 40 40 69 46 20 30 62 38 47 100 50 50 50 50 100 50 255 Central opening 50 20 50 20 40 40 40 40 40 40 69 46 20 30 54 41 47 100 50 50 50 50 100 50 255

file.doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11

Otis

A United Technologies Company

Page: 5/13

MECHANICAL ADJUSTMENT

The mechanical adjustment here after should be done before the electrical. Door panels adjustment & installation - At first, fit the slow speed door panel. - Fix the door panel on the hanger with 3 screws (A). - Align the door panel with the entrance column in opened position. - Fit the fast speed door panel. In order to fit it, you must dismantle the coupling of the hanger - Fix the door panel on the hanger with 3 screws (B).

- Align the door panel with the entrance column in opened position. - Align the two door panels with the entrance column in the opened door position.

file.doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11

Otis

A United Technologies Company

Page: 6/13

- Block the roping between the 2 hangers with the nut (C). - Adjust the stop bumper (D) when the door is in this position.

- The stop bumper (E) must be in contact with the hanger with the door in closed position. - Counterdrill (F) the hangers on jobsite and fit the rivets after panels adjustment.

file.doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11

Otis

A United Technologies Company

Page: 7/13

- With the coupling in opened position, adjust the stop bumper (A) to have the pawl axis (B) correctly positioned

Good

Bad

Bad

With coupling in closed position, adjust the stop bumper (B) to have the pawl vertical (A).

file.doc

ENGINEERING CENTER GIEN

H. Fanielle DETERRENT DEVICE

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11

Otis

A United Technologies Company

Page: 8/13

This safety device maintains the car door closed when the car is outside the door zone. Deterrent device adjustment With the door in closed position, adjust the stop bumper (A) which is in contact with the roller (B) to get (C) (dimension between the deterrent device and the cam at 52,5 mm).

file.doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11

Otis

A United Technologies Company

Page: 9/13

Lock adjustment When the cam is in the opened position, measure (A) dimension. This dimension should be about 46 mm. Lock roller adjustment (A ) dimension below is used to adjust the dimension between the lock rollers in order to obtain (C) = (A)

One of the two rollers is fitted on an eccentric axis to enable this adjustment Check : - (E) = 2 to 2,5 mm - (D) = 2 mm minimum is required It is adjustable by taking out shims (F) between the lintel and the roller The electric contact must close when B = 7 mm min. In the fully locked position, the latch must rest on the rubber stop In this condition B = 11 to 13 mm min.

Lock adjustment Position the lock in order to obtain the clearances as follow : when the cam passes between the rollers in the locking position, 5 mm is the optimal value with a 7mm maximum. If the gap > 7mm, the lock will make noise at the end of closing and begining of opening. G : Bend after adjustment.

file.doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11

Otis

A United Technologies Company

Page: 10/13

ELECTRICAL ADJUSTMENT

After mechanical adjustment between car and landing doors (gap of locking, coupling..) electrical adjustment could be done. CHECK LIST BEFORE SWITCH POWER ON: 1. Motor and encoder connected on ST306. 2. I/O and 24 VDCon P5. 3. Power supply from the transformer to the connector ST1. 4. Power supply from the transformer into the junction box on the connector. 5. OTIS Service Tool connected to the connector SVT. INITIATE THE LEARN RUN PARAMETER The door controller is an intelligent device which is able to find the end position and door width by itself, after an learn and test run was initiated through an maintenance person. The possibilities to initiate a parameter learn run are via "learn run" push button (see Control Board tag) and via OTIS Service Tool. 1. Push door into position "Open" 2. The Control Board needs a TC I-STOP command on the I/O interface (ST301). 3. a) Push the "learn run" button for more at least three seconds. b) After power on there is an internal testing time during approximately 20 seconds. While this time the Control Board doesn't accept any command. Then the Startup Procedure as listed here after has to be executed step by step. STARTUP PROCEDURE 1. Put the car on INSPECTION mode in front of one of landing door. 2. From the top of car, open handly the door and position it in opened position. 3. Switch on the operator power (wait 30/40 seconds for the click sound in the control box). 4. Push the "learn run" button for more at least three seconds. The door does one or two opening and closing cycles. 5. To open and close door with the OTIS Service Tool following procedure here after.

Press"Module"

Welcom to APAX Atxx = 3

Press "3"

Monitor = 1 Test = 2 Tools = 4

Press "4"

Single Run = 1 Cont Run = 2

Press "1"

Open = 1 Stop = 3 Close = 2 Revels = 4

Press "1" to open Press "2" to close

file.doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11 Connect the Service Tool

Otis

A United Technologies Company

Page: 11/13

SELF TEST IN PROGRESS

Disconnect the OTIS service Tool

SELF TEST IN OK-MECS-MODE

SELF TEST IN OK-MP2/3-MODE

Press "Module"

Welcom to APAX Atxx = 3

Press "3"

Monitor = 1 Test = 2 Tools = 4

Press "SHIFT 7"

Monitor = 1 Setup = 3 Test = 2 Tools = 4

Press "3"

Install = 1 Field = 3 ENG = 4 If the learning has already been made, modify directly the parameters If the learning has not been made with the button on the control board make the following operation

Press "3"

Config = 1 SetDef = 9

Press "1"

Start learn run Press "ENTER"

From the top of car, open the door handly and position it in opened position

Press "Enter"

Start "ENTER"

file.doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11 Press "1"

Init Run = 1 Door Para Run = 2

Otis

A United Technologies Company

Page: 12/13

Learning: Press "1" with default parameters Press "2" with customized parameters Monitor =is running = 2 Door 1 Test Stoop Door=run = 3 Tools 4

The door opens and closes in small speed by steps of 10cm and stops with closing

Para run finish Press "Funtkey"

The door is in closing position

Para run failed Run again "SET"

If there has been a mistake during learning put handly the door in opening position

Press "SET" Press "1"

Restart the learning operation

If the learning operation finished not correctly, it is possible to modify later the parameters

Press "3"

Install = 1 Field = 3 ENG = 4

The adjustment parameters appear, check the values with the Auto-Set Parameters Table from Technical Data here enclosed

file.doc

ENGINEERING CENTER GIEN

H. Fanielle

FIELD COMPONENT MANUAL PAX CAR DOOR, LATERAL OPENING

FAA24460P - Date: 2003-02-11

Otis

A United Technologies Company

Page: 13/13

To modify parameters the door must be in closing position. To test the door after each modification follow procedure here after.

Press "SET"

Install = 1 Field = 3 ENG = 4

Press "4"

Monitor = 1 Setup = 3 Test = 2 Tools = 4

Press "1"

Single Run = 1 Cont Run = 2

Open = 1 Stop = 3

Close = 2 Revels = 4

Press "1" to open Press "2" to close

After having checked door operation, access to adjustment parameters menu by pressing "SET+Function+3".

You might also like

- Service ToolDocument92 pagesService ToolIvcha50% (4)

- Gba26800bbi Fc1 Service Pandel Board-2Document22 pagesGba26800bbi Fc1 Service Pandel Board-2Ivcha94% (16)

- Escalera Otis 2.compressedDocument11 pagesEscalera Otis 2.compressedatom2013xd75% (4)

- GeN2 Regen UpgradeDocument22 pagesGeN2 Regen UpgradeLliego Jara50% (2)

- SVT GreskeDocument17 pagesSVT GreskeIvcha100% (6)

- 02 MUSE ACD3 T&C WiringDocument15 pages02 MUSE ACD3 T&C WiringMoises PerelloNo ratings yet

- 506NCE DAA26200R - SUI - 090713 - Start-UpDocument8 pages506NCE DAA26200R - SUI - 090713 - Start-UpPolinho Donacimento0% (1)

- OTIS Elevator Fault Code: LCB-2, TCBC and GECB Board Faults - Elevatorvip - Com - 1627641777743Document5 pagesOTIS Elevator Fault Code: LCB-2, TCBC and GECB Board Faults - Elevatorvip - Com - 1627641777743Aluko Damilare MosesNo ratings yet

- ICT Bill Acceptor Test Tool Diagnostic SoftwareDocument7 pagesICT Bill Acceptor Test Tool Diagnostic SoftwareismifaizulNo ratings yet

- Jufeng Elevator and Escalator Parts Center Product CatalogDocument48 pagesJufeng Elevator and Escalator Parts Center Product CatalogMelina Labor92% (13)

- Otis Elevator Parts ListDocument27 pagesOtis Elevator Parts Listcobain mei100% (1)

- 506 NCE Escalator QRDocument4 pages506 NCE Escalator QRwaclaw jazombekNo ratings yet

- OTIS LINK Escalator - Installation Manual - ENG - 200606Document56 pagesOTIS LINK Escalator - Installation Manual - ENG - 200606Vlad Shkrebty50% (2)

- MCS 220Document1 pageMCS 220Taha Alkibsi100% (3)

- Otis Pulse FCTSH 040805 PDFDocument2 pagesOtis Pulse FCTSH 040805 PDFangela1590No ratings yet

- FSD GAA30782GAA Feature and Set Up Description - 2014-05-23 - PDFDocument183 pagesFSD GAA30782GAA Feature and Set Up Description - 2014-05-23 - PDFQuang Pham Duy100% (1)

- Otis TCB Guide LinesDocument38 pagesOtis TCB Guide LinesAnonymous EstxH750% (2)

- GCS 222 MRL Start Up For E-I-PanelDocument17 pagesGCS 222 MRL Start Up For E-I-Paneldjidjelli nassir100% (4)

- List of Installation Parameters: Software Basic Data Mcs - LCB - IiDocument43 pagesList of Installation Parameters: Software Basic Data Mcs - LCB - IiBartz SantosNo ratings yet

- Gen2 ( Ø° ×° ÷ÊÔ) ×ÊÁÏDocument157 pagesGen2 ( Ø° ×° ÷ÊÔ) ×ÊÁÏungak201296% (23)

- SIGMA iAstar-S8 Integrated ControllerDocument143 pagesSIGMA iAstar-S8 Integrated ControllerJaydi Zambrano100% (3)

- Otis Software Basic DataDocument23 pagesOtis Software Basic Datanr1wolf_co_6952990682% (17)

- Mcs - LCB Ii: Feature Setup DescriptionDocument33 pagesMcs - LCB Ii: Feature Setup DescriptionElputoAmo XD100% (2)

- BD User Guide AP331400DAA - 2014-04-10Document167 pagesBD User Guide AP331400DAA - 2014-04-10diabNo ratings yet

- KDL16 Parameter List 972483D01: The Document Id of This Sheet Must Match With The Id Reported by UI Menu 6 - 0Document3 pagesKDL16 Parameter List 972483D01: The Document Id of This Sheet Must Match With The Id Reported by UI Menu 6 - 0Александр ЕгоровNo ratings yet

- 11 1 ControlDocument166 pages11 1 ControlFabian Virgili67% (3)

- Error Esc Movingwalk GECB Otis PDFDocument3 pagesError Esc Movingwalk GECB Otis PDFAnonymous llSP0xVy100% (11)

- Stvf7 Troubleshooting Manuel EnglishDocument32 pagesStvf7 Troubleshooting Manuel EnglishResul ŞenayNo ratings yet

- Replace Ovf20-Crc PDFDocument7 pagesReplace Ovf20-Crc PDFRawad Jaber50% (4)

- Fermator vf5Document28 pagesFermator vf5jay100% (2)

- Otis Door Drive User ManualDocument34 pagesOtis Door Drive User ManualRoyal Akash100% (8)

- 799all (GECB) (001-173) PDFDocument173 pages799all (GECB) (001-173) PDFtu_negro_luis100% (5)

- Xaa610bb GL enDocument24 pagesXaa610bb GL enchalogdNo ratings yet

- MCS LCB II List of ParametersDocument26 pagesMCS LCB II List of ParametersMalik AsifNo ratings yet

- SPMDCBDocument24 pagesSPMDCBSyed iliyas100% (3)

- Mcs - LCB Ii: RSL: List of Inputs and OutputsDocument28 pagesMcs - LCB Ii: RSL: List of Inputs and OutputsMelissa Knight80% (5)

- Otis Mcs 220c Gen2Document96 pagesOtis Mcs 220c Gen2krp85734982% (49)

- Basic Data Lbii Basic Data LB Ii - 1997!02!17Document29 pagesBasic Data Lbii Basic Data LB Ii - 1997!02!17Polinho Donacimento67% (3)

- Drawing 300 VF PDFDocument51 pagesDrawing 300 VF PDFAnonymous EstxH7100% (1)

- Mitsubishi GPSDocument3 pagesMitsubishi GPSaliakhterattariNo ratings yet

- UT ID 22.17.1 3 Otis Glide A Electrical Setup and Startup ManualDocument68 pagesUT ID 22.17.1 3 Otis Glide A Electrical Setup and Startup ManualFahadNo ratings yet

- Sigma Elevator Manual PDFDocument3 pagesSigma Elevator Manual PDFNadeem KhanNo ratings yet

- Escalator: Field Method ManualDocument83 pagesEscalator: Field Method ManualOsman Elmaradny50% (2)

- Permanent-magnetism Frequency-conversion Door Operator User's GuideDocument38 pagesPermanent-magnetism Frequency-conversion Door Operator User's GuideAN NhiênNo ratings yet

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Elevator Mechanic's Helper: Passbooks Study GuideFrom EverandElevator Mechanic's Helper: Passbooks Study GuideNo ratings yet

- QKS16-VF Hxdoor2Document24 pagesQKS16-VF Hxdoor2Curt NeilsonNo ratings yet

- IAA007AUS Unislide Install Manual (8!3!04)Document62 pagesIAA007AUS Unislide Install Manual (8!3!04)mrsaproNo ratings yet

- Challenger AC9000 Series Garage Door OperatorDocument24 pagesChallenger AC9000 Series Garage Door Operatorjackanddiane1No ratings yet

- Peugeot 206 Owners Manual 2007Document109 pagesPeugeot 206 Owners Manual 2007Henk Veen0% (1)

- 8808 FittingDocument10 pages8808 FittingSirLotusNo ratings yet

- DP189 Condense Shipping GuideDocument13 pagesDP189 Condense Shipping GuidewdataqwestNo ratings yet

- DFA127Document20 pagesDFA127info2378No ratings yet

- GAA 24350 AW11 IVb PDFDocument11 pagesGAA 24350 AW11 IVb PDFEvgeniyNo ratings yet

- E1 - E1A - E1Box - E1FDocument14 pagesE1 - E1A - E1Box - E1FDarek SlonskiNo ratings yet

- SimpleSwing Spec SheetDocument4 pagesSimpleSwing Spec SheetpdinhNo ratings yet

- Test Report NEMKO Theo Iec 60335-2-103Document12 pagesTest Report NEMKO Theo Iec 60335-2-103Phùng TuấnNo ratings yet

- Combined Coil Cut Off and Extraction-short-SFSDocument5 pagesCombined Coil Cut Off and Extraction-short-SFSAysmar EsthelaNo ratings yet

- S.No Questions Part A Level CompetenceDocument5 pagesS.No Questions Part A Level CompetenceNIKASH maniNo ratings yet

- Module - 1: Course Outline-Automotive Engineering Mec4209Document2 pagesModule - 1: Course Outline-Automotive Engineering Mec4209Twesiime MauriceNo ratings yet

- Activity Sheet SampleDocument5 pagesActivity Sheet SampleDhan GregorioNo ratings yet

- TP 6783Document60 pagesTP 6783FredNo ratings yet

- Farval Dr45 & Dr460a Reversing ValvesDocument8 pagesFarval Dr45 & Dr460a Reversing ValvesRobinson MarinNo ratings yet

- Alfa Laval MAB 103-24 Spare Parts Manual SPCDocument58 pagesAlfa Laval MAB 103-24 Spare Parts Manual SPCcmason2811100% (1)

- Heat Pump& Calorifiers Sch.Document1 pageHeat Pump& Calorifiers Sch.rashidNo ratings yet

- Tractor Case Series JX PDFDocument85 pagesTractor Case Series JX PDFLeonardo MedinaNo ratings yet

- What Is Hydraulic Technology? in The Hydraulic Technology WeDocument7 pagesWhat Is Hydraulic Technology? in The Hydraulic Technology Weömer111No ratings yet

- ABS System PresentationDocument16 pagesABS System PresentationPRINCE KUMARNo ratings yet

- List of Exhibitors at Garage Equipment PavilionDocument4 pagesList of Exhibitors at Garage Equipment PavilionDevasyrucNo ratings yet

- Understanding Pneumatics in AutomationDocument116 pagesUnderstanding Pneumatics in AutomationMady Deka Apriliya100% (4)

- 12-Volt Intimidator® - Agm - Valve Regulated: Effective July 1, 2020Document4 pages12-Volt Intimidator® - Agm - Valve Regulated: Effective July 1, 2020ragachemi ragaNo ratings yet

- Types of Lathe MachineDocument5 pagesTypes of Lathe MachineMD Mahmudul Hasan MasudNo ratings yet

- TK GWL GB 2016 WebDocument244 pagesTK GWL GB 2016 WebEdsonNo ratings yet

- 2025-ISB/ISC/ISL CM2150 Control SystemDocument7 pages2025-ISB/ISC/ISL CM2150 Control Systemralph arisNo ratings yet

- Dme-22 6 15Document8 pagesDme-22 6 15VIGNESH L RNo ratings yet

- SKF HydraulicsDocument117 pagesSKF HydraulicsJose luis Consuegra100% (1)

- DMC Compressor Manual - Pack SeriesDocument34 pagesDMC Compressor Manual - Pack SeriesDaniel LopezNo ratings yet

- Ingersoll 2135qxpaDocument2 pagesIngersoll 2135qxpatzuvela99No ratings yet

- Lightnin 70 Series MixerDocument4 pagesLightnin 70 Series MixerPhillip PhiriNo ratings yet

- 500-801 ManualDocument2 pages500-801 ManualmecambNo ratings yet

- Ajuste y Test Presiones Iniciales PDFDocument8 pagesAjuste y Test Presiones Iniciales PDFHugo Rivas ViedmanNo ratings yet

- Honda McvaDocument3 pagesHonda McvaAllen LiewNo ratings yet

- 3000 PDocument72 pages3000 PJoeNo ratings yet

- 986K Wheel Loader Electrical System (Cab) 486-0964 Chassis and Engine (486-0965)Document6 pages986K Wheel Loader Electrical System (Cab) 486-0964 Chassis and Engine (486-0965)abduallah muhammadNo ratings yet

- Snow Beast Owner's Manual 19nov2010Document27 pagesSnow Beast Owner's Manual 19nov2010MartyNo ratings yet

- Clarkson C-Valve Iom ManualDocument102 pagesClarkson C-Valve Iom Manualpca9750% (2)

- Service Manual: Sewing Machine Model 385, 15358Document32 pagesService Manual: Sewing Machine Model 385, 15358nikyryan8145No ratings yet