Professional Documents

Culture Documents

Airlift Basic Calculation

Uploaded by

Stircu FlorianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Airlift Basic Calculation

Uploaded by

Stircu FlorianCopyright:

Available Formats

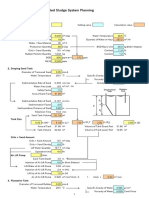

Enter data in green cells only Pumping rate Pipe diameter submergence lift % submergence cross-sectional area of pipe

Pipe volume Pipe volume/cu.ft. Vl (Flow rate) A (Pipe area) L (Lift) D (Pipe diameter) Lf (density of fluid) S (submergence) Lg (Gas density) Value of Ordinate Value of Abscissa

1,902,039 11.81 23.0 3.3 88%

0.760 17.46 7.48

gallon/day inch ft ft

300 30.00 7.0 1.0

ft2

mc/ora cm m m

ft3 gallon

1,320.86

0.760 3.28084 11.81103 100 22.97 0.0765 45,347 100<Y<10,225 10,225<Y<73,637 73,637<Y<117,690 117,690<Y<123.645 123,645<Y<128,308 128,308<Y<99,018 5.24

GPM

ft2 ft inch ft

4.53E+04 5.51 5.24 5.16 0.01 0.00 5.79

Graph reading Vg (Gas flow) Pressure

129.48 9.96

39.47

ft3/min psi

Calculations for an air lift assembly

Input data Results from left gal/day 1,902,039 gal/hr 79251.62 gal/min Calculate needed gals/day 500 gal/hr 12,000 gal/day

1320.86

total length submergence pipe diameter water flow

Calculation of maximum air lift pum 26.25 feet 88% % 11.81 inches 31.260 liter/min

optimal air flow range for these parameters 8% 28.94 liter/min 9% 28.68 liter/min Don't change anything pressure

0.10

PSI

There are two major sections to this spreadsheet. They fill two different niches. 1. on the left figu right will calculate the maximum capacity for a given scenario. There are a lot of variables that m It will not be grossly in error. My test demonstrated a flow of 30 gal/min and the calculator said

I have entered my basic pumping needs in the calculators.

The bottom, yellow cells show the CFM and the pressure needed to overcome the head. An air pu maximum, and therefore, limit that would make it prone to failure.

The convention I follow is to enter data in green cells and the formulas are completed in other co

Answer

If you enter a set of data where the air lift assembly will not work, there will be odd characters ap sizes or gallons to tweak your desired assembly. For instance, if a 2" pipe will not work, then try a

This spreadsheet is built off other persons' work . It must not be distributed for profit. It is for edu the right based on formulas found on an engineer ing site for air lift assemblies.

Please give proper attribution.

The calculator on the right is adapted from one found on http://www.airliftpump.com/ap_calc.h formulas from:

F.A. Zenz from "Explore the Potential of Air-lift Pumps and Multiphase", Chemical Engineering Pr

ate needed gals/day

ulation of maximum air lift pump capacity 800 cm feet of water 0.00875 feet of rise 30.00002 cm 8.259 gal/min 11,892.96

0.229659 26.01706

gal/day

ange for these parameters 1.02 cfm 1.01 cfm

ferent niches. 1. on the left figures from a known, desired gal/day number. 2. On the re are a lot of variables that might lower that maximum. This is a theoretical maximum. al/min and the calculator said it would be 33 gal/min

o overcome the head. An air pump would need to match this and not be at its

ulas are completed in other colored cells.

there will be odd characters appear within the calculations. If this occurs, change the " pipe will not work, then try a 3" and see if the formulas complete properly.

stributed for profit. It is for education and design purposes only. I built the calculator on t assemblies.

ww.airliftpump.com/ap_calc.htm by Dr. Sam Kondo, Ph.D. who is expressing the

hase", Chemical Engineering Progress, Aug., 1993

You might also like

- Tube Settler - CalculationDocument3 pagesTube Settler - CalculationJai Kumar88% (16)

- Airlift Basic CalculationDocument3 pagesAirlift Basic CalculationMohammed Eljammal100% (7)

- Airlift Basic CalculationDocument3 pagesAirlift Basic CalculationFadhilah Suroto100% (1)

- Water Treatment CalculatorDocument3 pagesWater Treatment CalculatorWael FawzyNo ratings yet

- Sequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsDocument37 pagesSequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsOn Gnios Ingeniería67% (6)

- Design and Calculation UASB Reactor For Sludge TreatmentDocument3 pagesDesign and Calculation UASB Reactor For Sludge TreatmentNguyễnThịBíchPhượngNo ratings yet

- Air BlowerDocument10 pagesAir Blowerewanz89100% (2)

- Inclined Plate Clarifier (Parallel Plate Clarifier, Lamella Clarifier) Basic Theory of OperationDocument2 pagesInclined Plate Clarifier (Parallel Plate Clarifier, Lamella Clarifier) Basic Theory of OperationThanneeru Naga Raju100% (2)

- Potential of Air Lift PumpsDocument6 pagesPotential of Air Lift Pumpsmiguelq_scribd100% (1)

- Principle of Air-Lift PumpDocument1 pagePrinciple of Air-Lift PumpPierre TNo ratings yet

- Airlift PumpDocument5 pagesAirlift PumpAnoop NimkandeNo ratings yet

- Airlift Basic CalculationDocument1 pageAirlift Basic Calculationcumpio425428No ratings yet

- WW ExcelDocument5 pagesWW Excelpartha6789No ratings yet

- Tech City-STP 100 KLD Price Comparison (03092016)Document10 pagesTech City-STP 100 KLD Price Comparison (03092016)Preston VargheseNo ratings yet

- Design Sheet STPDocument17 pagesDesign Sheet STPBhagyashree Rath0% (1)

- Spreadsheets For Secondary Clarifier DesignDocument3 pagesSpreadsheets For Secondary Clarifier DesignNiong David100% (1)

- Hopper Calulation For ClarifierDocument1 pageHopper Calulation For ClarifierHemantk8731100% (1)

- Cálculos Osmosis InversaDocument26 pagesCálculos Osmosis InversabetzabeNo ratings yet

- UASB Design Calculations - S.I Units: Workbook ContentsDocument12 pagesUASB Design Calculations - S.I Units: Workbook Contentsdiego100% (1)

- Tank Operating Manual Rev 3 PDFDocument54 pagesTank Operating Manual Rev 3 PDFCastoriadisNo ratings yet

- TM4112 - 12 History MatchingDocument87 pagesTM4112 - 12 History MatchingRay YudaNo ratings yet

- Pumping Rate Gallon/day Mc/ora Pipe Diameter Inch CM Submergence FT M Lift FT M % SubmergenceDocument5 pagesPumping Rate Gallon/day Mc/ora Pipe Diameter Inch CM Submergence FT M Lift FT M % SubmergenceTuan NguyenNo ratings yet

- Air Lift PumpDocument4 pagesAir Lift PumpFoxty67% (3)

- Air Lift PumpDocument9 pagesAir Lift PumpChukwuebuka AneneNo ratings yet

- Sand Filter Vs Disc FilterDocument1 pageSand Filter Vs Disc FilterKailash ThapliyalNo ratings yet

- Airlift PumpDocument5 pagesAirlift Pumpzarkima100% (1)

- Activated Sludge System PlanningDocument63 pagesActivated Sludge System PlanningSung Woong MoonNo ratings yet

- Design of Anaerobic Upflow ReactorDocument6 pagesDesign of Anaerobic Upflow ReactorKanishka WijesekaraNo ratings yet

- Softener CalculationDocument5 pagesSoftener CalculationAri WijayaNo ratings yet

- Process Design CalcDocument9 pagesProcess Design Calckiran raghukiranNo ratings yet

- Airlift Pump Article 1987Document14 pagesAirlift Pump Article 1987lychekNo ratings yet

- Proceess .FileDocument10 pagesProceess .Filekiran raghukiranNo ratings yet

- Design of Flocculator PaddlesDocument1 pageDesign of Flocculator Paddlessumitanurag100% (1)

- Chlorine RequirementDocument4 pagesChlorine RequirementPandiaraj MkNo ratings yet

- Clariflocculator TypesDocument7 pagesClariflocculator TypesdexterNo ratings yet

- STP Design (With MBBR)Document9 pagesSTP Design (With MBBR)Sagar Patel.100% (1)

- SBR - 6 MLDDocument38 pagesSBR - 6 MLDsharan kommi100% (1)

- Design of Secondary ClarifierDocument7 pagesDesign of Secondary Clarifierusmansherdin100% (1)

- Sewage Treatment WorksheetDocument18 pagesSewage Treatment WorksheetRemedanNo ratings yet

- De NitrificationDocument3 pagesDe Nitrificationkiran raghukiranNo ratings yet

- Annexure 16 - Tool For Design of Tube SettlerDocument1 pageAnnexure 16 - Tool For Design of Tube SettlerWikaz FiansyahNo ratings yet

- MBR DesignDocument5 pagesMBR DesignDavid LambertNo ratings yet

- SBR DesignDocument25 pagesSBR DesignConya Smathel100% (1)

- Clarifier DesignDocument12 pagesClarifier DesignAbinashNo ratings yet

- Price List For The equipments-STPDocument8 pagesPrice List For The equipments-STPEcologics IndiaNo ratings yet

- Screen and SBR v1.0Document3 pagesScreen and SBR v1.0Richard Magadia Jr0% (1)

- Saff Reactor: Design Flow 600 Incoming BOD To SAFF 300 % BOD Removal 94Document4 pagesSaff Reactor: Design Flow 600 Incoming BOD To SAFF 300 % BOD Removal 94Rakesh Verma100% (3)

- WTP Design 3.12 MLDDocument21 pagesWTP Design 3.12 MLDSandeep VaishnavNo ratings yet

- Tube Settler DesignDocument4 pagesTube Settler DesignKrishna Winx100% (1)

- Rapid Sand FilterDocument30 pagesRapid Sand Filtersachinambekar100% (1)

- Clariflocculator CalculationsDocument4 pagesClariflocculator Calculationssanu80% (5)

- Airlift PumpDocument18 pagesAirlift Pumptushar patelNo ratings yet

- Sps and Wetwell NTLDocument3 pagesSps and Wetwell NTLProject ManagerStructuresNo ratings yet

- Calculation Example of Extended AerationDocument30 pagesCalculation Example of Extended AerationHRK65100% (1)

- Uasb/egsb Applications For Industrial Wastewater TreatmentDocument10 pagesUasb/egsb Applications For Industrial Wastewater Treatmentalberto_03No ratings yet

- Demand 10 MLD Input Prompts Colour CodeDocument2 pagesDemand 10 MLD Input Prompts Colour CodeRyeanKRumano100% (1)

- ETP Design CalculationDocument6 pagesETP Design Calculationmanuel.hernandez100% (2)

- Process Design Calculation3 - NDDocument14 pagesProcess Design Calculation3 - NDabhishek5810No ratings yet

- Calculator GWR Contact Time Calculator v9Document16 pagesCalculator GWR Contact Time Calculator v9HeruNo ratings yet

- Calculating Pressure LossDocument2 pagesCalculating Pressure LossAhmed MoustafaNo ratings yet

- Turbo Calc SDocument11 pagesTurbo Calc SWembley CandidoNo ratings yet

- A New Approach For Sizing Finger-Type (Multiple-Pipe) Slug CatchersDocument9 pagesA New Approach For Sizing Finger-Type (Multiple-Pipe) Slug CatchersnicolasNo ratings yet

- DR RS Tutorial Sheet-Mechanical OperationsDocument8 pagesDR RS Tutorial Sheet-Mechanical OperationsNguyễn Hoàng QuânNo ratings yet

- AccuLoad Tank Proving GuideDocument20 pagesAccuLoad Tank Proving Guideابوالحروف العربي ابوالحروفNo ratings yet

- 3M VHB Tape Technical DataDocument10 pages3M VHB Tape Technical DataJheck AraulloNo ratings yet

- Preparation Guide: Orbit Sprinkler System DesignerDocument6 pagesPreparation Guide: Orbit Sprinkler System DesignerPera ZderaNo ratings yet

- Water Safety Flow Control & BFP ProductsDocument140 pagesWater Safety Flow Control & BFP ProductsLuis Gabriel BautistaNo ratings yet

- Glossary of Oil and Gas Terms PDFDocument8 pagesGlossary of Oil and Gas Terms PDFgarry_dirakNo ratings yet

- Problem Set 4 in FluidsDocument1 pageProblem Set 4 in Fluidsnaikin_1031No ratings yet

- Back Pressure ValveDocument3 pagesBack Pressure ValveAnkur SharmaNo ratings yet

- Jurnal Terapi Komprehensif HipertensiDocument4 pagesJurnal Terapi Komprehensif HipertensiismiNo ratings yet

- SMK Usj 13 Yearly Lesson Plan Physics Form 4 2015: Learning Area: 1. Introduction To PhysicsDocument17 pagesSMK Usj 13 Yearly Lesson Plan Physics Form 4 2015: Learning Area: 1. Introduction To PhysicsyuriNo ratings yet

- Friction Reducer For Coiled Tubing Milling OperationsDocument1 pageFriction Reducer For Coiled Tubing Milling Operationssuifengniliu0% (1)

- Pic 1 SL2 N/A Tc1A N2 Secondary Barrier: Tag #Revision #Document NºDocument2 pagesPic 1 SL2 N/A Tc1A N2 Secondary Barrier: Tag #Revision #Document NºRanchojiNo ratings yet

- Scroll Compressor Simulation Model: C. Schein R. RadermacherDocument9 pagesScroll Compressor Simulation Model: C. Schein R. Radermacherwidi_115No ratings yet

- Fly Better Book 1Document347 pagesFly Better Book 1Abhimanyu Tyagi100% (1)

- The Best Ways To Calculate Wind Load - WikiHowDocument5 pagesThe Best Ways To Calculate Wind Load - WikiHowsreedharNo ratings yet

- Petroleum Engineering Principles and PracticeDocument375 pagesPetroleum Engineering Principles and PracticeNabilaCL100% (3)

- Mud LoggingDocument16 pagesMud LoggingShamia EssamNo ratings yet

- Pressure Sensors OEM: Description FeaturesDocument4 pagesPressure Sensors OEM: Description FeaturesRolando Jara YoungNo ratings yet

- 4647 - EME2066 Tutorial 4, Trim.3,2014-15Document1 page4647 - EME2066 Tutorial 4, Trim.3,2014-15Ong Teck ChongNo ratings yet

- Eric Ed259126Document167 pagesEric Ed259126NguyenDinhLyNo ratings yet

- Cell Mechanics and Cellular EngineeringDocument570 pagesCell Mechanics and Cellular Engineeringlifejuice100% (1)

- 2223 Level L Chemistry Course QuestionsDocument56 pages2223 Level L Chemistry Course QuestionsZyteckNo ratings yet

- Boiling PointDocument5 pagesBoiling Pointimdad KURDINo ratings yet

- Leak TestingDocument27 pagesLeak TestingNurulAtirahNoroziNo ratings yet

- SoalDocument23 pagesSoalMiftah Rizkiawelly FitriNo ratings yet

- Piping Pressure TestingDocument22 pagesPiping Pressure TestingHadisupriadi100% (4)