Professional Documents

Culture Documents

2 High Strength Steel Sheets With Improved Formability For Automobile Structural Uses

Uploaded by

san moedanoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 High Strength Steel Sheets With Improved Formability For Automobile Structural Uses

Uploaded by

san moedanoCopyright:

Available Formats

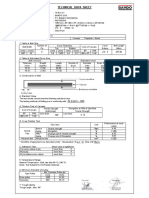

2 High Strength Steel Sheets with Improved Formability for Automobile Structural Uses

(1) JIS G3135

Tensile Test Symbol Of Class Tensile Strength N/mm2 340 min. 370 min. 390 min. 440 min. 490 min. 540 min. 590 min. 490 min. 540 min. 590 min. 780 min. 980 min. 340 min. Yield Proof Stress N/mm2 175 min. 205 min. 235 min. 265 min. 295 min. 325 min. 355 min. 225 min. 245 min. 265 min. 365 min. 490 min. 185 min. Elongation % t: Thickness

0.6mmt 1.0mm 1.0mmt 2.3mm

Coating Baking Hardened Amount N/mm2 30 min.

Bend Test Test Piece

Bend Angle

Radius of Inside surface

Tight lock Tight lock Tight lock Tight lock Tight lock

Test Piece

SPFC 340 SPFC 370 SPFC 390 SPFC 440 SPFC 490 SPFC 540 SPFC 590 SPFC 490Y SPFC 540Y SPFC 590Y SPFC 780Y SPFC 980Y SPFC 340H

34 min. 32 min. 30 min. 26 min. 23 min. 20 min. 17 min. 24 min. 21 min. 18 min. 13 min. 6 min. 34 min.

35 min. 33 min. 31 min. 27 min. 24 min. 21 min. 18 min. 25 min. 22 min. 19 min. 14 min. 7 min. 35 min.

NO.5 Perpendicular to rolling direction

Thickness 0.5

180O

NO.3

Thickness 1.0

Tight lock

Perpendicular to rolling direction

Thickness 0.5 Thickness 1.0 Thickness 3.0 Thickness 4.0

Tight lock

Remark: Concerning the applied thickness of the elongation value of SPFC780Y and SPFC980Y 0.6mm and over to under 1.0 mm and 1.0 mm a over to 2.3mm incl. shall be respectively shifted to 0.8mm and over to under 1.0 mm and 1.0 mm and over to 1.4mm incl.

(2) CSC

Tensile Test

Symbol Of Class Elongation %

Bend test Test Piece Bend Angle Radius of Inside surface Test Piece

Tensile Strength N/mm2 370 min.

Thicknesst mm Yield Proof Stress 0.55mm 1.0mm N/mm2 t1.0mm t2.0mm

CF 370R

205 min.

33 min.

34 min.

CF 390R

390 min.

235 min.

31 min.

32 min.

No.3 No.5 Perpendicular Perpendicular to 180O Tight lock to rolling rolling direction direction

Remark: For the coil of CF370R and CF390R, the bend test shall be carried out on request of the purchaser.

You might also like

- Saph 440Document1 pageSaph 440rinkumax2003No ratings yet

- Hot Rolled Products, Cold Rolled Products, Galvanised Products From Flats, Tata Steel, IndiaDocument4 pagesHot Rolled Products, Cold Rolled Products, Galvanised Products From Flats, Tata Steel, IndiaraajmrkNo ratings yet

- Aluminum MaterialDocument2 pagesAluminum Materialuseddille-864No ratings yet

- Kyocera Substrates) Electronic Fine CeramicsDocument17 pagesKyocera Substrates) Electronic Fine Ceramicsmanolo_superNo ratings yet

- Tyre flap specification AS:306:83:SEP:2016Document5 pagesTyre flap specification AS:306:83:SEP:2016Purchase and Stores Officer Contract Cell-IINo ratings yet

- TDS ZincTape EngDocument1 pageTDS ZincTape EngFahim MarwatNo ratings yet

- Pipeline Thickness CalculationDocument1 pagePipeline Thickness CalculationUmer KhanNo ratings yet

- Castilated Beam DesignDocument10 pagesCastilated Beam DesignAlphyl BalasabasNo ratings yet

- Tyre Flap Specification AS35083SEP2016Document5 pagesTyre Flap Specification AS35083SEP2016Purchase and Stores Officer Contract Cell-IINo ratings yet

- TR 47-180 Floor Deck Profile Data Sheet 9-12-14 PDFDocument3 pagesTR 47-180 Floor Deck Profile Data Sheet 9-12-14 PDFAkhil VNNo ratings yet

- TR 47-180 Floor Deck Profile Data Sheet 9-12-14 PDFDocument3 pagesTR 47-180 Floor Deck Profile Data Sheet 9-12-14 PDFAkhil VNNo ratings yet

- 3M Adhesive Transfer Tape 950Document6 pages3M Adhesive Transfer Tape 950Michael McQueenNo ratings yet

- Gmta 500Document1 pageGmta 500Victor MoralesNo ratings yet

- 3 - Flush End Plate Moment Conn To Beam WebDocument11 pages3 - Flush End Plate Moment Conn To Beam Webabdul khaderNo ratings yet

- REWINDING REPORT TITLEDocument14 pagesREWINDING REPORT TITLEzakir84md3639No ratings yet

- Mold DesigningDocument19 pagesMold Designingmitrofan.dragosNo ratings yet

- Lysaght Trimdek-Optima 2021Document12 pagesLysaght Trimdek-Optima 2021Fahmi YusoffNo ratings yet

- C1.1.0 Ajiya - 2018 - Roofing Catalogue Clip Lock ProfileDocument8 pagesC1.1.0 Ajiya - 2018 - Roofing Catalogue Clip Lock ProfileFahmi YusoffNo ratings yet

- Beam DesignDocument8 pagesBeam DesignSelva kumarNo ratings yet

- Thermally Conductive Adhesive Transfer Tapes: Technical Data April, 2002Document5 pagesThermally Conductive Adhesive Transfer Tapes: Technical Data April, 2002chayanunNo ratings yet

- Air Compressor Filter StagesDocument2 pagesAir Compressor Filter StagesBURAKNo ratings yet

- Light GaugeDocument2 pagesLight GaugeMomayKradookkradicNo ratings yet

- Technical Data Sheet: 1. Table of Belt SizeDocument1 pageTechnical Data Sheet: 1. Table of Belt SizeVicky ImmanuelNo ratings yet

- 20SQGD070 Spec SheetDocument5 pages20SQGD070 Spec Sheetsametb_1No ratings yet

- Technical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingDocument3 pagesTechnical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingNestramiNo ratings yet

- 3M Double Coated Tape 9731Document7 pages3M Double Coated Tape 9731Lucas HenriqueNo ratings yet

- FR4 4806Document2 pagesFR4 4806Trasma_Yunita_1885No ratings yet

- 3M92015 Double-Coated Tape PDFDocument6 pages3M92015 Double-Coated Tape PDFargh112No ratings yet

- Fisa Tehnica PVC Krystal Nou1Document3 pagesFisa Tehnica PVC Krystal Nou1Ioan CovaliovNo ratings yet

- Technical Data HPDE GeomembraneDocument1 pageTechnical Data HPDE Geomembranemariodiogo75No ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetNiko SwandanaNo ratings yet

- Equal angle steel profiles data sheetDocument2 pagesEqual angle steel profiles data sheetGalih PutraNo ratings yet

- Ajiya 2018 CATALOGUE-B2 Rev10-1Document4 pagesAjiya 2018 CATALOGUE-B2 Rev10-1manova enterpriseNo ratings yet

- ASTM A516 GR 70 N Pressure Vessel Plate: Sin Thai Special Steel Co., LTDDocument1 pageASTM A516 GR 70 N Pressure Vessel Plate: Sin Thai Special Steel Co., LTDHaidarHussainiNo ratings yet

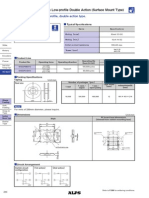

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- RF 35Document3 pagesRF 35Isra NazeerNo ratings yet

- HDPE Geomembrane Specification SheetDocument1 pageHDPE Geomembrane Specification SheetAzfar Aizat ZawawiNo ratings yet

- Tds Az Eci 3000 SeriesDocument11 pagesTds Az Eci 3000 SeriesIgor_uhuNo ratings yet

- C45Document2 pagesC45Marko DobrisavljevicNo ratings yet

- Elastomeric Bearing Pads SpecificationsDocument5 pagesElastomeric Bearing Pads SpecificationsMad WonderNo ratings yet

- 3m VHB Tape 5958frDocument9 pages3m VHB Tape 5958frDonald A HuntNo ratings yet

- Open channel lining design calculationsDocument4 pagesOpen channel lining design calculationsYunitan TeguhNo ratings yet

- Astm A153 PDFDocument1 pageAstm A153 PDFkhaledmiNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- TACT Switch GuideDocument3 pagesTACT Switch GuideshyhuNo ratings yet

- High Temperature Epoxy Tooling Board: Trelleborg Applied TechnologiesDocument3 pagesHigh Temperature Epoxy Tooling Board: Trelleborg Applied TechnologiesMert KıraçNo ratings yet

- Technical Data Sheet: 1. Table of Belt SizeDocument1 pageTechnical Data Sheet: 1. Table of Belt SizeVicky ImmanuelNo ratings yet

- Katalog TacoDocument30 pagesKatalog Tacosabry technoNo ratings yet

- Wet Film Thickness Gages: Comb Type GageDocument1 pageWet Film Thickness Gages: Comb Type GageNelson BarriosNo ratings yet

- Elix Ultra hh4115Document3 pagesElix Ultra hh4115DiegoTierradentroNo ratings yet

- Adhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Document4 pagesAdhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Reza AbdolahiNo ratings yet

- Elastomer testing guideDocument5 pagesElastomer testing guideEric FernandesNo ratings yet

- 45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignDocument3 pages45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignshyhuNo ratings yet

- Cork SheetDocument2 pagesCork Sheetsaurabh bondeNo ratings yet

- PVC SpecDocument2 pagesPVC SpecMuhammad Noor FizuanNo ratings yet

- 3M™ Scotch® Cellophane Film Tape 610: October, 2016Document3 pages3M™ Scotch® Cellophane Film Tape 610: October, 2016真幸运No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsNo ratings yet

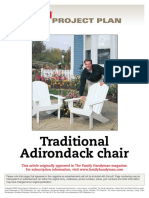

- Adirondack ChairDocument7 pagesAdirondack Chairsan moedanoNo ratings yet

- Diagrama Control DCDocument1 pageDiagrama Control DCsan moedanoNo ratings yet

- Ecg With PicDocument59 pagesEcg With Picsan moedano0% (2)

- TempleDocument17 pagesTemplesan moedanoNo ratings yet

- Casting Defects Trouble Shooting ChartDocument1 pageCasting Defects Trouble Shooting Chartsan moedanoNo ratings yet

- Part Inspection Standard (May 2013)Document9 pagesPart Inspection Standard (May 2013)san moedano100% (1)

- Broaches DesignDocument72 pagesBroaches Designsan moedanoNo ratings yet

- Thermal stress simulation integration optimizes die casting processDocument6 pagesThermal stress simulation integration optimizes die casting processsan moedanoNo ratings yet

- Access and OPC PDFDocument12 pagesAccess and OPC PDFsan moedanoNo ratings yet

- DOE Course - Parts 1-4oDocument116 pagesDOE Course - Parts 1-4osan moedanoNo ratings yet

- Ktan90026 VB and OpcDocument7 pagesKtan90026 VB and Opcregi1201No ratings yet

- Fmea ProcessPktNewRatingsDocument2 pagesFmea ProcessPktNewRatingsPrakash KumarNo ratings yet

- Surface Vehicle Standardsta Ndard: Rev. DEC83Document11 pagesSurface Vehicle Standardsta Ndard: Rev. DEC83san moedano100% (1)

- DMC-ZS15: Owner's Manual For Advanced FeaturesDocument0 pagesDMC-ZS15: Owner's Manual For Advanced Featuressan moedanoNo ratings yet

- MPLAB C32 LibrariesDocument150 pagesMPLAB C32 Librariessan moedanoNo ratings yet

- Surface Vehicle Recommended Practice: Rev. FEB2001Document10 pagesSurface Vehicle Recommended Practice: Rev. FEB2001san moedanoNo ratings yet

- 61132B PIC32ReferenceManualDocument1,138 pages61132B PIC32ReferenceManualphild2na2No ratings yet

- Ttha 115Document17 pagesTtha 115san moedanoNo ratings yet

- A Hand Book For The Mechanical Designer Ventilation Duct FanDocument107 pagesA Hand Book For The Mechanical Designer Ventilation Duct Fanrawneeh100% (6)

- Dodge Ram Fault CodesDocument42 pagesDodge Ram Fault Codesnaismith1100% (4)

- Abrasive Blasting Operation (Engineering Control and Work Practices Manual)Document78 pagesAbrasive Blasting Operation (Engineering Control and Work Practices Manual)kanakarao1100% (1)

- OBD-2 20codesDocument10 pagesOBD-2 20codessan moedano100% (1)

- Resistance Welding ManualDocument32 pagesResistance Welding Manualsan moedanoNo ratings yet

- DTC CodesDocument22 pagesDTC Codessan moedanoNo ratings yet

- WeldingDocument16 pagesWeldinghadeNo ratings yet

- 55 Watt Gas CO2 Laser TubeDocument66 pages55 Watt Gas CO2 Laser TubeFitzwalter100% (1)

- Dodge Ram Fault CodesDocument42 pagesDodge Ram Fault Codesnaismith1100% (4)

- Resist Spot Welding TipsDocument1 pageResist Spot Welding Tipssan moedanoNo ratings yet

- 21st - Century.manufacturing (Wright)Document449 pages21st - Century.manufacturing (Wright)san moedano100% (1)