Professional Documents

Culture Documents

Calculation of CO2 Gas Requirement For Coal Bin Interisation

Uploaded by

vvijaybhan100%(1)100% found this document useful (1 vote)

314 views2 pagesCalculation of CO2 gas requirement for coal bin interisation

Original Title

Calculation of CO2 Gas Requirement for Coal Bin Interisation

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCalculation of CO2 gas requirement for coal bin interisation

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

314 views2 pagesCalculation of CO2 Gas Requirement For Coal Bin Interisation

Uploaded by

vvijaybhanCalculation of CO2 gas requirement for coal bin interisation

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

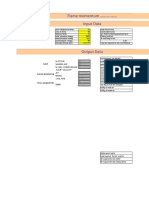

Calculation of CO2 gas requirement for coal bin interisation

1 2 3 4 5 6 7 8 9 10 11 12 13 no of fine coal silos vol of each fine coal silo extraction rate from fine coal silo aeration vol free vol above mat -20 m3 no of fine coal filters vol of each filters filter cleaning vol (m3/min ) vol of mill filter / ESP no of poldos sc vol of vessel density of co2 (kg/ m3 ) 2 160 13 3 20 4 45 0.17 1000 2 14 2 m3 tph m3/ min m3 m3/ min min m3

m3 kg/m3

Results

14 15 16 17 18 19 20 21 22 23 24

co2 for flooding free volume in silo

for flooding time 15 min (kg / 15 min ) flooding Rate (kg /hr )

co2 for flooding complete volume of silo

flooding time (hrs )

80 320 640 6.2 4430.8 6.2 502.2 6.2

m3 Hrs kg Hrs kgs Hrs

co2 for silo aeration

aeration time

co2 for bag filter cleaning

aeration time

co2 for flooding complete

volume of filters (kgs) 360

25 26 27 28

flooding of mill filter /ESP Flooding of poldos -sc vessel total co2 requirement Recommended margin on above

2000 56 8068.9 30%

kgs kgs kgs

admission rate in system

29 30 31 32 33 fine coal silo (kg /hr ) ,30 bar pr, +2 C bag filter (kg /hr ) .6- 8 bar pr.+2 C silo discharge cone (kg /hr ) 0.6 bar pr.+2 C mill filter /ESP (kg /hr ) ,20 bar pr,-10 C all poldos sc vessel (kg/hr ) ,30 bar pr ,+2 C 640 81.6 240 8000 336

You might also like

- Ball Mill CalculationsDocument12 pagesBall Mill Calculationsvvijaybhan80% (15)

- Project DesignDocument31 pagesProject DesignGunjan SolankiNo ratings yet

- 371hw06s (Rapid Mix Tank Design-Sample 1)Document5 pages371hw06s (Rapid Mix Tank Design-Sample 1)Yang Ching HianNo ratings yet

- Infinity for cement equipmentDocument8 pagesInfinity for cement equipmentfoxmancementNo ratings yet

- Clinker Plant Airflow and Fan Efficiency MeasurementDocument109 pagesClinker Plant Airflow and Fan Efficiency MeasurementSantanu PachhalNo ratings yet

- Raw Mix Design SoftwareDocument7 pagesRaw Mix Design Softwarevvijaybhan100% (9)

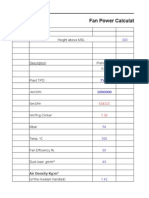

- Penta Engineering Corp. Fan Power CalculationDocument3 pagesPenta Engineering Corp. Fan Power CalculationManoj ThakurNo ratings yet

- Cement Mill Gearbox Input & Output RatiosDocument1 pageCement Mill Gearbox Input & Output RatiosvvijaybhanNo ratings yet

- Clinker CoolersDocument17 pagesClinker Coolersemad sabri0% (1)

- Alkali - Chlorine - Sulfur - Balance: Grate PreheaterDocument4 pagesAlkali - Chlorine - Sulfur - Balance: Grate PreheaterElwathig BakhietNo ratings yet

- Fuel Analysis CalculationDocument2 pagesFuel Analysis CalculationRamachandran Venkatesh100% (1)

- Fine Coal Conveying Velocity in Kiln Firing SystemDocument2 pagesFine Coal Conveying Velocity in Kiln Firing SystemVijay BhanNo ratings yet

- Line I Heat BalanceDocument60 pagesLine I Heat Balancehmaza shakeelNo ratings yet

- Typical Cement Mill Bag Filter Capital Cost CamparisonDocument1 pageTypical Cement Mill Bag Filter Capital Cost CamparisonKenny RuizNo ratings yet

- Flame Momentum CalculationDocument7 pagesFlame Momentum CalculationMohamed ZayedNo ratings yet

- Alk-SO3-Cl Balance - v2.1Document4 pagesAlk-SO3-Cl Balance - v2.1shani5573100% (4)

- Sulfur and Alkali Balance CalculationsDocument3 pagesSulfur and Alkali Balance CalculationsElwathig BakhietNo ratings yet

- Cooler BalanceDocument16 pagesCooler BalanceIrfan Ahmed100% (1)

- Ball Mill Degree of Filling CalculationDocument4 pagesBall Mill Degree of Filling Calculationvvijaybhan100% (1)

- Spreadsheet For Activated Sludge ProcessDocument31 pagesSpreadsheet For Activated Sludge ProcessHemantk8731100% (8)

- Heat CalcultionDocument4 pagesHeat CalcultionDgk RajuNo ratings yet

- Max ball size by feed size and mill diameterDocument3 pagesMax ball size by feed size and mill diametervvijaybhan100% (1)

- RPM Kiln Vs FDDocument2 pagesRPM Kiln Vs FDTIRIANTONo ratings yet

- Bestway Cement Limited heat balance and WHR analysisDocument4 pagesBestway Cement Limited heat balance and WHR analysisKiran Veerubhotla100% (1)

- Preheater Outlet gas flow calculationDocument7 pagesPreheater Outlet gas flow calculationAnoop TiwariNo ratings yet

- Roller Press Classifier Circulation FactorDocument9 pagesRoller Press Classifier Circulation Factorshahid2995100% (1)

- Pheater Heat BalanceDocument2 pagesPheater Heat BalanceRaji SuriNo ratings yet

- Cement Kiln Performance CalculationsDocument9 pagesCement Kiln Performance Calculationsvvijaybhan0% (2)

- K.F To Cl. FactorDocument1 pageK.F To Cl. FactorvvijaybhanNo ratings yet

- ALKALI-CHLORINE-SULFUR BALANCEDocument4 pagesALKALI-CHLORINE-SULFUR BALANCEBùi Hắc HảiNo ratings yet

- VRM Heat and Mass BalanceDocument1 pageVRM Heat and Mass BalanceRajeshRockNo ratings yet

- HT-2.2 RMR Heat Belance 5 Stage T17 M7,9Document1 pageHT-2.2 RMR Heat Belance 5 Stage T17 M7,9GiequatNo ratings yet

- Conversion Factor For NOx and SOx CalculationsDocument2 pagesConversion Factor For NOx and SOx CalculationsvvijaybhanNo ratings yet

- Bag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFDocument14 pagesBag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFRICARDOALEXBORGES100% (2)

- Overall Heat Balance - 11.08.2008Document8 pagesOverall Heat Balance - 11.08.2008Tamer FathyNo ratings yet

- Esp PresentationDocument19 pagesEsp PresentationRocky JonesNo ratings yet

- False air measurements at Ambuja Cements Rabriyawas plantDocument665 pagesFalse air measurements at Ambuja Cements Rabriyawas plantSantanu PachhalNo ratings yet

- Clinker Production Kiln Surface Heat Loss FactorsDocument2 pagesClinker Production Kiln Surface Heat Loss FactorsvvijaybhanNo ratings yet

- Clinker Production Kiln Surface Heat Loss FactorsDocument2 pagesClinker Production Kiln Surface Heat Loss FactorsvvijaybhanNo ratings yet

- Clinker Production Kiln Surface Heat Loss FactorsDocument2 pagesClinker Production Kiln Surface Heat Loss FactorsvvijaybhanNo ratings yet

- Solid Fuel PreperationDocument1 pageSolid Fuel PreperationvvijaybhanNo ratings yet

- Najran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportDocument2 pagesNajran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportIrfan AhmedNo ratings yet

- Clinker Production Caliculation ProgramDocument3 pagesClinker Production Caliculation Programvvijaybhan100% (1)

- FLOW MEASUREMENT ANALYSISDocument35 pagesFLOW MEASUREMENT ANALYSISSyeed SofieNo ratings yet

- Hardness of Clinker Due To Usage of Pet CokeDocument1 pageHardness of Clinker Due To Usage of Pet CokeVijay BhanNo ratings yet

- CoolerDocument10 pagesCoolerbudiNo ratings yet

- Tromp Curve CalculationDocument6 pagesTromp Curve Calculationvvijaybhan83% (6)

- Heat & Mass Equation For CementDocument99 pagesHeat & Mass Equation For Cementamit100% (1)

- Screw Conveyor CalculationDocument14 pagesScrew Conveyor Calculationvvijaybhan100% (2)

- Heat Balance DataDocument6 pagesHeat Balance DataOuaddani amineNo ratings yet

- Raw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesDocument3 pagesRaw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesRamachandrarao MaddaliNo ratings yet

- Grinding Media ConsumptionDocument9 pagesGrinding Media ConsumptionMuhammadNo ratings yet

- S. Description Symbol Unit No.: F.L. Smidth's ATOX Vertical Roller MillDocument2 pagesS. Description Symbol Unit No.: F.L. Smidth's ATOX Vertical Roller Millvvijaybhan0% (1)

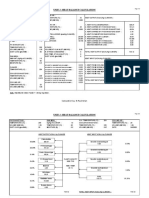

- Kiln Pre Heater Fan Power CalculationDocument4 pagesKiln Pre Heater Fan Power CalculationVijay Bhan67% (3)

- Fan Flow CalculationDocument1 pageFan Flow CalculationvvijaybhanNo ratings yet

- BALL MILL - Ball Charge Composition Piece Weight & Specific SurfaceDocument1 pageBALL MILL - Ball Charge Composition Piece Weight & Specific Surfacevvijaybhan100% (1)

- Flame MomentumDocument1 pageFlame Momentumayaskant751001No ratings yet

- Fuel Analysis: A H C N O S M QDocument10 pagesFuel Analysis: A H C N O S M QThaigroup CementNo ratings yet

- Heat Calculation by SG.Document26 pagesHeat Calculation by SG.TIRIANTO0% (2)

- 3500TPD Cement Plant Heat BalanceDocument2 pages3500TPD Cement Plant Heat BalanceIrshad HussainNo ratings yet

- Clinker Vs Kiln Feed FactorDocument3 pagesClinker Vs Kiln Feed FactorSSAC PVT.LTD.No ratings yet

- Compare kiln capacities and specificationsDocument1 pageCompare kiln capacities and specificationsgvrrNo ratings yet

- Blaine Apparatus CalibrationDocument1 pageBlaine Apparatus Calibrationvvijaybhan50% (2)

- Clinker Temperature Measurement BoxDocument3 pagesClinker Temperature Measurement BoxVijay BhanNo ratings yet

- Calculating primary fan momentum of coal transport barometerDocument5 pagesCalculating primary fan momentum of coal transport barometerTIRIANTONo ratings yet

- Ball Mill Grinding Media Max Ball Size CalculationDocument2 pagesBall Mill Grinding Media Max Ball Size Calculationvvijaybhan100% (1)

- Heat Balance Programme0Document18 pagesHeat Balance Programme0Mohamed SelimNo ratings yet

- Heat BalanceDocument3 pagesHeat Balanceayaskant751001No ratings yet

- Kiln Burner Flame Momentum CalculationDocument6 pagesKiln Burner Flame Momentum CalculationVijay BhanNo ratings yet

- Kiln Performance & Efficiency Formulas (Updated and Completed) - InFINITY For CEMENT EQUIPMENTDocument3 pagesKiln Performance & Efficiency Formulas (Updated and Completed) - InFINITY For CEMENT EQUIPMENTBùi Hắc HảiNo ratings yet

- Measurement DDocument37 pagesMeasurement Dgvrr1954100% (2)

- Burner CalculationDocument11 pagesBurner CalculationBùi Hắc HảiNo ratings yet

- Mass Balance of A ScrubberDocument3 pagesMass Balance of A ScrubberSubrata BanerjeeNo ratings yet

- Fuel and Combustion CalculationsDocument6 pagesFuel and Combustion Calculationsvvijaybhan100% (2)

- Coal Preparation: Chris HoltDocument24 pagesCoal Preparation: Chris HoltAhmed ElbehairyNo ratings yet

- Kiln Audit - Required Measurement ToolsDocument1 pageKiln Audit - Required Measurement ToolsVijay BhanNo ratings yet

- Preheater Cyclone Dsigns: Tube Dia X EntryDocument6 pagesPreheater Cyclone Dsigns: Tube Dia X EntrynileshNo ratings yet

- The Cement Grinding Office: Home About Us Services Mining AreaDocument3 pagesThe Cement Grinding Office: Home About Us Services Mining AreaVisnu SankarNo ratings yet

- CEMENT MILL NO 2 DATASHEETDocument2 pagesCEMENT MILL NO 2 DATASHEETThaigroup CementNo ratings yet

- (62. Viscose Filament Yarn: The Environment (Protection) Rules, 1986Document27 pages(62. Viscose Filament Yarn: The Environment (Protection) Rules, 1986Sarang BondeNo ratings yet

- Thermal Equivalents of Fuels in kcal and BtuDocument1 pageThermal Equivalents of Fuels in kcal and BtuvvijaybhanNo ratings yet

- Cement Kiln StartupDocument1 pageCement Kiln StartupvvijaybhanNo ratings yet

- Hammer Mill OperationDocument1 pageHammer Mill OperationvvijaybhanNo ratings yet

- Construction - Hammer MillDocument1 pageConstruction - Hammer MillvvijaybhanNo ratings yet

- Mill CIRCUIT SAMPLESDocument2 pagesMill CIRCUIT SAMPLESvvijaybhanNo ratings yet

- Gyratory Screen - LimestoneDocument1 pageGyratory Screen - LimestonevvijaybhanNo ratings yet

- Blaine Vs OutputDocument2 pagesBlaine Vs Outputvvijaybhan100% (1)

- Lime Stone Stock Pile CalculationDocument1 pageLime Stone Stock Pile CalculationvvijaybhanNo ratings yet

- Gera Box CalculationDocument1 pageGera Box CalculationvvijaybhanNo ratings yet

- Gera Box CalculationDocument1 pageGera Box CalculationvvijaybhanNo ratings yet