Professional Documents

Culture Documents

1 Control of Non Conforming Product Materials

Uploaded by

Falcon EgyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Control of Non Conforming Product Materials

Uploaded by

Falcon EgyCopyright:

Available Formats

This printed document is an UNCONTROLLED COPY - Check B.O.S.

to verify validity prior to use

Date printed: Saturday, July 12, 2008

SOP-0000 Control of Non-conforming Product & Materials

Start

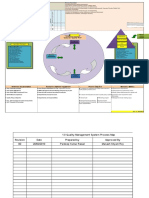

Incidents of known or suspected product or process non-conformances may arise or be identified during the implementation of any of the activities identified below (blue boxes). The respective controls, responsibilities, and authority are detailed in the applicable Work Instructions (red text) identified under each of the individual scenarios

5.2 Customer Focus 7.2.3 Customer Communication 7.4.3 Verification of Purchased Product 7.5.5 Preservation of Product 7.5.3 Identification & Traceability 8.3 Control of Non-conforming Product 8.3.1 Control of Non-conforming Product - Supplemental 8.3.3 Customer Information 4.2 Quality Requirements 4.6 Periodic Re-qualification 4.16 Customer Feedback

ISO 9001

Customerspecifics

Notification by Supplier of defective Shipped Parts

Receiving Inspection - Supplier Qualification

In-Process Handling / Production

Laboratory/Finished Product Testing

Process/ Customer / Health & Safety Audits, Materials Management & Housekeeping

External Returns

Quality Assurance Department upon notification from Supplier, initiates action to trace, identify & segregate suspect/nonconforming materials

WI-____ Processing of Defects

Receiver/Quality Assurance identify & segregate suspect or non-conforming materials during inspection of incoming material or supplier qualification

WI-7001 Receiving Inspection of Raw Materials WI-7000 Bulk Tanker Offloading WI-5011 Testing Version Density WI-5012 Testing Version Pot Life WI-5013 Testing Version Viscosity WI-5014 Testing Isocyanates WI-5015 Testing Version Resin WI-5018 Receiving Inspection of Fibreglass

Production and/or Quality Assurance Personnel identify & segregate known or suspected nonconformances

WI-3043 Isocyanate and Resing Handling WI-3039 Nitrogen Blanketing WI-3044 Resin Agitation Totes WI-5003 Cup Test WI-5006 Ratio Check WI-5016 Gel Time Test WI-5002 Process Inspection WI-3001 Cutting Modules to Length and Weighing WI-3009 Drilling Modules Standard Holes WI-5005 Physical and Dimensional Inspection WI-5004 Marking, Drill Hole, Slot Inspection WI-5007 Module Disposition WI-7003 Transfer of Modules WI-7004 Order Preparation WI-3010 Packaging and Shipping Poles WI-3045 Cutting Poles to Length & Top Caps WI-3042 Custom Drilling WI-3014 Preparing Module & Pole ID Tag WI-5027 Shipment Inspection

Quality Assurance Personnel identify & segregate known or suspected nonconformances

WI-3040 Preparing Test Specimens from Modules WI-5000 Flex Strength & Modules Test WI-5001 Interlaminar Shear Strength Testing of Tubular Composite Samples WI-5008 Density, Void Content and Glass Content Test

Unidentified, unlabelled or non-conforming materials or products found during Internal/External, Process or Customer Audits, health & safety audits, Materials Management or by housekeeping are segregated and identified as non-conforming

WI-______Process Audit WI-____ Health & Safety Audit WI-5021 Safe Handling of Chemicals WI-7002 Handling and Storage of Raw Materials

Customer returns nonconforming product or notifies The Company of Warranty issues resulting in known or suspect Nonconformances

Customer Communication Customer Corrective Action Request

Engineering Engineering Design change results in obsolete materials which must be identified and segregated SOP-0011 Change Control Product, Process, Sourcing

Annual Validation Testing Respective Test/ Audit results in identification of nonconforming product Per Quality Inspection and Test Plan (QITP) Floor Plan Hold Area, Quarantine Area, Scrap Area Outdoor Storage Plan

Identification & Segregation

As applicable, Supplier Quality Specialist or Quality Assurance Supervisor ensures suspect or known non-conforming materials are clearly identified & segregated or moved to designated HOLD/Quarantine area

Type 2 Nonconformance notification

See CSR...Type 1 and Type 2 4.2.4 Control of Records

Determine disposition Authority

Quality Lab Technician per applicable Work Instruction assesses suspected or identified nonconforming materials/products to determine the Disposition authority Type 1 Authority: The Company NonType 2 Authority: Customer conformance

Type

As applicable:

Inspection Labels

On Hold FAIL Tag (F-5004) NCR Quarantine Tag (F-5011) Customer Notification/Warranty Issue Customer-specific Requirements (Type 1 and Type 2 Nonnonconformance)

Customer communicates disposition status and required actions, as applicable

No

Customer to Disposition?

Customer communication

Yes

Processing Non-conformances

Quality Lab Technician per applicable Work Instruction

1) Implements Customer-defined dispositioning instructions or 2) Determines & assigns disposition of one of the following: - Return to Source - Scrap - 3rd Party Sort - Rework/reuse - Send to Lab for testing - Hold - Customer/Internal Waiver Nonconformance Monitoring Records 3) communicates disposition status as applicable to ensure that customers are promptly Customer Waiver Disposition Labels, as appropriate: informed of issues which might impact them (Supply Chain Coordinator notifies F-5015 Engineering Test Label customer of any actual or potential supplier issues, or potential supply or capacity issues F-5021 Lab Sample Label and Q.A. Manager notifies customer of any actual or potential non-conforming product F-5004 On HOLD/FAIL Tag which may have been shipped) F-5010 PASS Tag 4) maintains records of the nature of all nonconformities, F-5011 Do Not use/Hold/NCR (including suspected nonconformities which are F-5031 Interim PASS (Orange) subsequently approved, and any actions taken, including concessions/waivers obtained)

Go to

Patricia Ravanello - Management Systems

SOP-0012 Control of Non-Conforming Product and Materials, Revision: 0

Page: 1 of 3

This printed document is an UNCONTROLLED COPY - Check B.O.S. to verify validity prior to use

Date printed: Saturday, July 12, 2008

SOP-0000 Control of Non-conforming Product & Materials

As applicable: Nonconformance Report Customer Waiver Disposition Labels, as appropriate: F-5015 Engineering Test Label F-5021 Lab Sample Label F-5004 On HOLD/FAIL Tag F-5010 PASS Tag

A

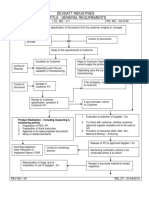

4.2.4 Control of Records 8.5.2 Corrective Action

Respective Responsible Party takes action to: eliminate the detected non-conformity authorize its use, release or acceptance, under concession by a relevant authority, and where applicable by the customer, or preclude its original intended use or application and initiates corrective action per SOP-0000 Corrective and Preventive Action and Continual Improvement and/or the applicable Work Instruction as identified below, ensuring that records of the results of action taken are maintained

- See respective output of processes (Work Instructions) identified below

7.1.4 Change Control 8.3.2 Control of Reworked Product 8.5.2 Rejected Product Test/Analysis

4.2.4 Control of Records 8.3.4 Customer Waiver

Repair/Rework

Scrap/Disposal

Return to Source

Design Change

Purge

Customer/Supplier/Internal Waiver Quality Assurance ensures that: Customer Interim Authorization is obtained prior to further processing whenever the product or process is different from that which is currently approved and that records are maintained of the expiration date and quantity authorized per

SOP-0011 Change Control WI-5____ Processing Engineering and Document Change Requests

Responsible party (per applicable W.I.) identifies instructions for re-work identifies re-inspection requirements to ensure effectiveness of corrective action ensures that the above is accessible and utilized by the appropriate personnel. WI-_____ Repair/Rework Management

WI-_____ Processing of Defects WI-______ Quarantine Area Management WI-5021 Safe Handling of Chemicals

WI-____ Processing of Defects WI-______ Quarantine Area Managemen t

SOP-0011 Change Control Product, Process, Source WI-7___ Management of Obsolete Material

WI-_____ Processing of Defects Purging of Raw Materials In process Finished Product

Go To B

Patricia Ravanello - Management Systems

SOP-0012 Control of Non-Conforming Product and Materials, Revision: 0

Page: 2 of 3

This printed document is an UNCONTROLLED COPY - Check B.O.S. to verify validity prior to use

Date printed: Saturday, July 12, 2008

SOP-0000 Control of Non-conforming Product & Materials

B

Metrics DASHBOARD Non-conformance Monitoring Records Rework Records Scrap Records Repair Records Spill Records Supplier PPM

Department Managers monitor and assess the nature and frequency of nonconformances per SOP-0000 Monitoring, Measurement and Analysis and report analysis and conclusions to Senior Management per SOP-0000 Business Planning and Management Review 1) to verify the suitability and effectiveness of the Business Operating System, 2) to monitor progress toward objectives 3) to assess the need for additional resources, and 4) to identify or evaluate opportunities for continual improvement

- Management Review Meeting Minutes (Actions/Responsibilities/Timing) - Resource Requirements - Opportunities or recommendations for continual improvement

End

Patricia Ravanello - Management Systems

SOP-0012 Control of Non-Conforming Product and Materials, Revision: 0

Page: 3 of 3

You might also like

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- 4.2 - Needs and Expectation With Risk AnalysisDocument3 pages4.2 - Needs and Expectation With Risk AnalysisSafety Dept50% (2)

- Sequence & Interaction Example PDFDocument1 pageSequence & Interaction Example PDFTAHIR MAHMOODNo ratings yet

- Audit MatrixDocument4 pagesAudit MatrixramschellamNo ratings yet

- How To Conduct Management ReviewDocument8 pagesHow To Conduct Management ReviewS Seetharaman100% (1)

- Internal Quality Management System Audit Checklist (ISO9001:2015)Document46 pagesInternal Quality Management System Audit Checklist (ISO9001:2015)Hector Nicacio Mendoza100% (1)

- Audit Report - Annex 1 - Action Catalogue Including Opportunities For Improvements and Positive AspectsDocument7 pagesAudit Report - Annex 1 - Action Catalogue Including Opportunities For Improvements and Positive AspectsMohamed HamedNo ratings yet

- Quality Manual: Qms Description MatrixDocument31 pagesQuality Manual: Qms Description MatrixmuthuselvanNo ratings yet

- Sta-P08-02 Non Conforming ProductDocument6 pagesSta-P08-02 Non Conforming ProductAnonymous B7pghhNo ratings yet

- Manufacturing Process AuditDocument1 pageManufacturing Process AuditSachin Kumbhar100% (1)

- Product Audit FormDocument2 pagesProduct Audit Formcong da0% (1)

- Form - Supplier Quality Survey - Rev 0Document3 pagesForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonNo ratings yet

- Context of Org, Expectation of Interested Parties, Risk and OpporDocument3 pagesContext of Org, Expectation of Interested Parties, Risk and OpporRAHUL SINGHNo ratings yet

- QP Nonconforming Product Sample 2014Document2 pagesQP Nonconforming Product Sample 2014Anna Maree100% (1)

- 8D & 7QC ToolsDocument117 pages8D & 7QC ToolsAshok Kumar100% (1)

- 9001 Audit Checklist-Monitoring Measurement and ImprovDocument7 pages9001 Audit Checklist-Monitoring Measurement and ImprovAmer RahmahNo ratings yet

- As9100d Inernal Audit ChecklistDocument90 pagesAs9100d Inernal Audit ChecklistPANDIYANNo ratings yet

- Suppliers Quality Assurance Manual (PDFDrive)Document135 pagesSuppliers Quality Assurance Manual (PDFDrive)umtNo ratings yet

- QP 83001 Rev 09 Non-Conforming Material Control ProcedureDocument6 pagesQP 83001 Rev 09 Non-Conforming Material Control ProcedureImam MansyurNo ratings yet

- HIRA 038 Cleaning of Cranes .Document4 pagesHIRA 038 Cleaning of Cranes .srinibas mohapatraNo ratings yet

- Qms Interaction ChartDocument1 pageQms Interaction Chartpnagarajj0% (1)

- SWOT ANALYSIS For ISO Context of The OrganizationDocument1 pageSWOT ANALYSIS For ISO Context of The OrganizationZach JavelonaNo ratings yet

- QSV 2 Product Release Procedure EN 01 PDFDocument6 pagesQSV 2 Product Release Procedure EN 01 PDFprashanthNo ratings yet

- Apqp Flow RevisedDocument2 pagesApqp Flow RevisedbajjhiNo ratings yet

- Procedure - Risk & OOpportunity ManagementDocument4 pagesProcedure - Risk & OOpportunity Managementchahi100% (2)

- QMS Inspection ProcedureDocument5 pagesQMS Inspection ProcedureReyhan MfNo ratings yet

- 1.0 QMS Process MapDocument3 pages1.0 QMS Process MapRohit SoniNo ratings yet

- Turtle Diagram - Management ReviewDocument1 pageTurtle Diagram - Management Reviewsyahir etNo ratings yet

- Process Flow Chart PDFDocument2 pagesProcess Flow Chart PDFSerkan CebeciogluNo ratings yet

- 6BWSHR Working With Machines A2 Poster EnglishDocument1 page6BWSHR Working With Machines A2 Poster EnglishKhuda BukshNo ratings yet

- A Standard Procedure For DeviationDocument2 pagesA Standard Procedure For DeviationGAURAV SHARMA100% (1)

- Quality ManualDocument45 pagesQuality Manualhmp90100% (1)

- Quality Objective PRSDocument1 pageQuality Objective PRSKurt ClaveriaNo ratings yet

- DCMAISO9001 AS9100 ChecklistDocument73 pagesDCMAISO9001 AS9100 ChecklistNestor Czerwacki0% (3)

- 7.4.1 Procedure Supplier Selection With FlowchartDocument3 pages7.4.1 Procedure Supplier Selection With FlowchartBharath50% (4)

- Supplier Audit Check SheetDocument33 pagesSupplier Audit Check SheetMotive PostNo ratings yet

- GMs Drill Deep Read Across MatrixDocument10 pagesGMs Drill Deep Read Across MatrixJohn Oo100% (1)

- Guidelines For Incoming InspectionDocument3 pagesGuidelines For Incoming InspectionAman KatiyarNo ratings yet

- Clause 9.2.2 - Internal Audit Report or NC ReportDocument2 pagesClause 9.2.2 - Internal Audit Report or NC Reportsudeesh kumarNo ratings yet

- Quality Assurance ProceduresDocument35 pagesQuality Assurance ProcedurestrikjohNo ratings yet

- 4 Context of The Organization 4.1 Understanding The Organization and Its ContextDocument5 pages4 Context of The Organization 4.1 Understanding The Organization and Its ContextkarthiksaadhanaNo ratings yet

- Turtle Diagram For PDCA AuditDocument4 pagesTurtle Diagram For PDCA AuditProf100% (18)

- Context of The Organization: Faraz H Laldin Faraz H Laldin JuniorDocument4 pagesContext of The Organization: Faraz H Laldin Faraz H Laldin JuniorFH LNo ratings yet

- Manufacturing Audit ChecklistDocument8 pagesManufacturing Audit Checklistgksp100% (1)

- 14 RCAT - Root Cause Analysis TechniquesDocument3 pages14 RCAT - Root Cause Analysis TechniquesDanny Durham100% (1)

- ISO 13485:2016 Quality Systems Manual: Document No. QMD-001Document11 pagesISO 13485:2016 Quality Systems Manual: Document No. QMD-001Roslan.Affandi2351100% (1)

- IATF Process Audit Check Sheet FormatDocument14 pagesIATF Process Audit Check Sheet Formatukavathekar71% (7)

- QMS of The Company As Per IsoDocument62 pagesQMS of The Company As Per IsogalavaNo ratings yet

- TMT Procedure - Management ReviewP1Document1 pageTMT Procedure - Management ReviewP1sumanNo ratings yet

- Part Submission Warrant: Supplier Information and DeclarationDocument32 pagesPart Submission Warrant: Supplier Information and DeclarationMadhavan Ram100% (1)

- Audit Check ListDocument7 pagesAudit Check Listtuan mai vanNo ratings yet

- 1635 - 03 Control of Non Conforming Products Rev. 01Document5 pages1635 - 03 Control of Non Conforming Products Rev. 01Senthilkumar NarayananNo ratings yet

- M09 Production and Service ProvisionDocument4 pagesM09 Production and Service ProvisionMay Ann DuronNo ratings yet

- Manufacturing Process Audit Checklist: Reference DocumentsDocument4 pagesManufacturing Process Audit Checklist: Reference DocumentsAri Rosyadi100% (1)

- Supplier APQP ProcedureDocument12 pagesSupplier APQP ProcedureNabeel Arya ZahranNo ratings yet

- 5M CHANGE ProcedureDocument8 pages5M CHANGE ProcedurePk Nimiwal100% (1)

- A Control of Nonconforming Material: Document Number Revision Title Rev DateDocument3 pagesA Control of Nonconforming Material: Document Number Revision Title Rev DateImam MansyurNo ratings yet

- Derivative StrategyDocument1 pageDerivative StrategyvadlapatisNo ratings yet

- 6.1 Definition of BenchmarkingDocument6 pages6.1 Definition of BenchmarkingvadlapatisNo ratings yet

- Starbucks Presentation - Case StudyDocument25 pagesStarbucks Presentation - Case Studyvadlapatis0% (1)

- Teles Voipbox Pri 17.1 ReferencemanualDocument214 pagesTeles Voipbox Pri 17.1 ReferencemanualvadlapatisNo ratings yet

- CH - "Communication Barriers": Language and Semantic BarriersDocument5 pagesCH - "Communication Barriers": Language and Semantic BarriersvadlapatisNo ratings yet

- Contemporary Theories of MotivationDocument17 pagesContemporary Theories of MotivationArsalan SattiNo ratings yet

- Cash Rules Learn and Manage The 7 Cash Flow Drivers For Your Company SuccessDocument218 pagesCash Rules Learn and Manage The 7 Cash Flow Drivers For Your Company SuccessmonicaescobarroaNo ratings yet

- Sadcas f401Document41 pagesSadcas f401EkopribadiNo ratings yet

- Root Cause AnalysisDocument2 pagesRoot Cause Analysisjjjj000No ratings yet

- Pro10-03 Ref of Lab Test Backup Plan SOPDocument13 pagesPro10-03 Ref of Lab Test Backup Plan SOPmahmouda100No ratings yet

- BJMQ 3113 Quality Management System FIRST SEMESTER 2020/2021 (A201) Individual Assignment Quality Management System Audit Group ADocument12 pagesBJMQ 3113 Quality Management System FIRST SEMESTER 2020/2021 (A201) Individual Assignment Quality Management System Audit Group AainaNo ratings yet

- Prasath Resume For Industrail & Process EngineerDocument3 pagesPrasath Resume For Industrail & Process EngineerPrasathNo ratings yet

- IMS (ISO 9001:2015, ISO 14001:2015 and OHSAS 45001:2018) Minutes of Management Review MeetingDocument12 pagesIMS (ISO 9001:2015, ISO 14001:2015 and OHSAS 45001:2018) Minutes of Management Review MeetingKishan Maurya75% (12)

- Quality Manual (Sefam PVT LTD) 344Document104 pagesQuality Manual (Sefam PVT LTD) 344ahmed100% (1)

- Advanced Cost AccountingDocument23 pagesAdvanced Cost Accountingabhishek_salunkhe8No ratings yet

- Paper RCFA - Root Cause Failure AnalysisDocument7 pagesPaper RCFA - Root Cause Failure AnalysisMiguelNo ratings yet

- Case Studies'Document71 pagesCase Studies'Harbaaz Singh100% (1)

- ISO 22000 Document Templates IndexDocument8 pagesISO 22000 Document Templates IndexHamada AhmedNo ratings yet

- IATF - International Automotive Task ForceDocument23 pagesIATF - International Automotive Task ForceKaran MalhiNo ratings yet

- RM QAFA Training DocumentDocument27 pagesRM QAFA Training Documentស្រី ស្រស់No ratings yet

- 6 ISO 9000 ImplementationDocument30 pages6 ISO 9000 ImplementationIgnou DelhiNo ratings yet

- Audit Report 2 - ClientDocument10 pagesAudit Report 2 - Clientmanil_5No ratings yet

- Hanson Blackwattle Bay Quality Management Plan: Prepared byDocument21 pagesHanson Blackwattle Bay Quality Management Plan: Prepared bysellitt ngNo ratings yet

- ISO 9001.2015 Presentation To Process OwnersDocument68 pagesISO 9001.2015 Presentation To Process OwnersArlene DacpanoNo ratings yet

- ISO 9001-2015 Process Audit ChecklistDocument18 pagesISO 9001-2015 Process Audit Checklistprincess cipriano100% (5)

- OCIMF SIRE Training SeminarDocument353 pagesOCIMF SIRE Training SeminarPanagiotis Ktenas100% (3)

- Corrective Action Report March 2013Document14 pagesCorrective Action Report March 2013Jaijeev Pali50% (2)

- Ac 21-43Document54 pagesAc 21-43Jayant GhawalkarNo ratings yet

- AIAG - CQI-9 - Heat Treatment System AssessmentDocument72 pagesAIAG - CQI-9 - Heat Treatment System Assessmentvenkateswaran100% (2)

- Nato Standard AQAP-2310 Nato Quality Assurance Requirements For Aviation, Space and Defence SuppliersDocument34 pagesNato Standard AQAP-2310 Nato Quality Assurance Requirements For Aviation, Space and Defence SuppliersNestor CzerwackiNo ratings yet

- Internal Quality Auditing ProcedureDocument7 pagesInternal Quality Auditing ProcedurePrime CapNo ratings yet

- Roles and Responsibilities of Contracting Parties Scope and ObjectivesDocument40 pagesRoles and Responsibilities of Contracting Parties Scope and ObjectivesSUBODH100% (1)

- Introduction To Control PlansDocument6 pagesIntroduction To Control Plansamarchavan894No ratings yet

- Master GM AuditDocument37 pagesMaster GM AuditMichael Hicks100% (1)

- 2 4 15 199Document10 pages2 4 15 199nsk79in@gmail.comNo ratings yet

- Advoco 2018 Current Practices Report PDFDocument17 pagesAdvoco 2018 Current Practices Report PDFAnonymous Bu00TMNo ratings yet

- Doc10-16 BHHRL Qual ManDocument28 pagesDoc10-16 BHHRL Qual Manghadeer shaikhnaNo ratings yet