Professional Documents

Culture Documents

Ad 036633 001

Uploaded by

narutothunderjet216Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ad 036633 001

Uploaded by

narutothunderjet216Copyright:

Available Formats

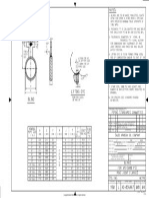

990

L

INDEX

DRAWING NUMBER

1/2 E

STAMP

ON BOTH

SIDES

R=25mm

D

1/2 D

22

STAMP

ON BOTH

SIDES

R=25mm

R=25mm

2. THICKNESS "T" IS CALCULATED PER ASME B31.3

PAR. 304.5.3 WITH P=3.1 MPa AND SE=223.4 MPA AT

T=38^C (100^F) TO OBTAIN THE MAXIMUM P/SE RATIO.

FLANGE MATERIAL IS ASME B16.5 MATERIAL GROUP NO. 1.2.

100

TYP.

150

10

32

25

V/2

V

150

STAMP

ON BOTH

SIDES

21

REV. NO.

SHEET NO.

10

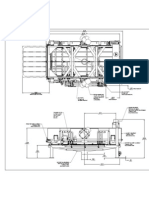

1. SPECTACLE PLATES, BLINDS AND SPACERS ARE

TO BE MADE FROM STEEL PLATE ASTM-A-36 OR

EQUAL WITH SPECIFIED MINIMUM YIELD STRENGTH OF

248.2 MPa.

PLANT NO.

001

AD-036633

1/2 E

NOTES:

A

B

B

A

NOMINAL

PIPE SIZE

LIFTING EYE

V+6

FOR PIPE SIZES

30" AND UP

SPECTACLE PLATE

BLIND

SPACER

V

3. TOLERANCES: DIAMETERS "A" & "B"- :+1.5mm

THICKNESS "T": +1.5mm, -0.25mm

4. LIFTING EYE IS TO BE FORMED FROM STEEL ROD OF

COMPOSITION SIMILAR TO THAT OF THE PLATE.

COMMERCIAL STANDARD EYEBOLTS MAY BE USED IF

THEY HAVE THE REQUIRED DIMENSIONS AND MATERIAL

COMPOSITION.

5. GASKET CONTACT SURFACES ( AREA BETWEEN DIAMETERS

"A" & "B" ) SHALL HAVE A SURFACE FINISH ROUGHNESS

IN THE RANGE BETWEEN 3.2 AND 6.4 um AARH ( SEE ANSI

B46.1 ) AS JUDGED BY VISUAL COMPARISON. FLANGE

SURFACES SHALL BE PARALLEL.

6. SPECTACLE PLATE MAY BE FABRICATED BY WELDING

TWO SECTIONS TOGETHER. WELDING SHALL BE 100%

PENETRATION BY A PROCEDURE APPROVED BEFORE

FABRICATION.

BLIND

MASS

SPACER

MASS

( kg. )

( kg. )

( kg. )

7. EDGES OF BLINDS TO BE FREE FROM ROUGH

BURN FINISH AND BURRS.

8. STAMP SIZE AND CLASS 150 IN 8mm LETTERS WHERE

INDICATED ON DRAWING, ON BOTH SIDES OF PLATE.

40

290

40

10

355

50

13

420

50

16

12

13

310

495

65

19

12

20

28

345

335

545

65

20

12

25

11

36

510

395

370

610

65

23

16

38

17

56

18"

545

440

385

650

65

26

16

48

18

66

20"

22"

600

490

420

710

65

29

16

67

23

90

655

545

445

760

65

32

20

84

27

111

24"

710

595

470

825

65

35

20

110

36

146

26"

28"

770

645

505

885

65

37

20

136

44

180

825

695

535

940

55

40

20

163

52

215

30"

32"

34"

875

745

560

1000

65

45

20

215

64

278

( mm )

( mm )

( mm )

( mm )

( mm )

( mm )

2"

100

55

120

165

40

3"

130

80

140

205

40

4"

170

105

160

240

6"

215

155

185

8"

275

205

230

10"

335

255

260

12"

14"

16"

405

310

445

( in. )

( mm )

SEE

NOTE-4

SPECTACLE

MASS

935

795

600

1075

65

45

24

244

71

314

985

850

625

1125

55

47

24

281

77

358

36"

1040

900

655

1180

65

51

24

345

91

435

38"

40"

1105

950

690

1250

65

54

24

412

114

526

1155

1000

715

1300

65

58

24

478

125

603

42"

1215

1050

745

1360

65

60

24

549

145

694

44"

1270

1100

775

1415

55

62

28

616

157

773

46"

1320

1150

800

1465

65

65

28

657

164

821

48"

1380

1205

825

1525

55

68

28

718

173

891

22

12-30-97

HRD

CHANGE DESIGN CONDITION

TO MAX. P/SE RATIO

21

07-24-96

WAS

REVISED NOTE 5

20

08-09-88

RLO

CONSOLIDATED SHTS.1 & 2 INTO SH. 1,

METRIC VERSION ONLY.

REV.

NO.

DATE

BY

DESCRIPTION

NGMM

DRAWN BY

DATE STARTED

DATE COMPLETED

OPRG DEPT.

NONE

SCALE

CHECKED BY

ENG DEPT.

APPD FOR CONSTR.

THIS DRAWING IS NOT TO BE USED FOR

CERTIFIED

CONSTRUCTION OR FOR ORDERING

MATERIAL UNTIL CERTIFIED AND DATED

DATE

SPECTACLE PLATES, BLINDS AND

SPACERS FOR CLASS 150

RAISE FACE FLANGES

STD. DWG.

METRIC

PLANT NO.

INDEX

990

DRAWING NUMBER

AD-036633

SHEET NO.

001

A-2636

CopyrightSaudi Aramco 2009. All rights reserved.

APPD

CHKD CERT.

REV. NO.

22

ENG.(03/87)

CADD

You might also like

- Orbital Tube Welding PDFDocument7 pagesOrbital Tube Welding PDFnarutothunderjet216100% (1)

- Welder Qualification (ALL CODES)Document3 pagesWelder Qualification (ALL CODES)narutothunderjet216No ratings yet

- Aa 036531 001Document1 pageAa 036531 001narutothunderjet2160% (1)

- Lifting Lug Design ThuwalDocument80 pagesLifting Lug Design Thuwalnarutothunderjet216No ratings yet

- Cables TheoryDocument15 pagesCables TheorytceterexNo ratings yet

- Design of Pile FoundationDocument17 pagesDesign of Pile FoundationNarnindi Venkata Ramananda SagarNo ratings yet

- Column Base Plate (Fixed Type)Document11 pagesColumn Base Plate (Fixed Type)Ernest Navarro100% (2)

- Beam Design Data and CalculationsDocument43 pagesBeam Design Data and CalculationsJessie Radaza TutorNo ratings yet

- Beam Design With RCCDocument24 pagesBeam Design With RCCOsarieme Osakue100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Report of Lifting Beam DesignDocument5 pagesReport of Lifting Beam Designnarutothunderjet216100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Better - Call - Saul - 4x10 WINNERDocument70 pagesBetter - Call - Saul - 4x10 WINNERMarcos Valdés GarridoNo ratings yet

- NBME 22 OfflineDocument200 pagesNBME 22 OfflineGautham Kanagala86% (14)

- API Drill Pipe Specs-1Document26 pagesAPI Drill Pipe Specs-1SACHIN H. DHAMAPURKARNo ratings yet

- Pharmaceutical Microbiology - B.pharmDocument383 pagesPharmaceutical Microbiology - B.pharmkeyurNo ratings yet

- A106 A672 A53 API5L ComparisonDocument4 pagesA106 A672 A53 API5L Comparisonkyashkumar100% (10)

- Espct - Tba Ensamble Total Monobore 3k Acording With Kom 3-1-8 3k Forging Anda Part NumberDocument1 pageEspct - Tba Ensamble Total Monobore 3k Acording With Kom 3-1-8 3k Forging Anda Part NumberJeaneth HerreraNo ratings yet

- Welder Qualification PDFDocument7 pagesWelder Qualification PDFnarutothunderjet216No ratings yet

- AWS Welding Performance Qualification StandardDocument12 pagesAWS Welding Performance Qualification Standardnarutothunderjet216No ratings yet

- Riser GuideDocument120 pagesRiser GuideAndrea ZuritaNo ratings yet

- OTC Drug ListDocument7 pagesOTC Drug ListHong Diem100% (1)

- Reinforced Concrete Column DesignDocument18 pagesReinforced Concrete Column DesignGeorge LazarNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Piping Class Summary - CM2Document1 pagePiping Class Summary - CM2narutothunderjet216100% (1)

- ALL Purspose Excel SheetDocument329 pagesALL Purspose Excel SheetRajput PratiksinghNo ratings yet

- RCC Design Based in Indian CodesDocument43 pagesRCC Design Based in Indian Codeschaos_atulNo ratings yet

- Lta StandardDocument178 pagesLta Standardkokuei100% (5)

- S275JRDocument1 pageS275JRShahzad QamarNo ratings yet

- Synovial Joints StructureDocument20 pagesSynovial Joints StructureJayricDepalobosNo ratings yet

- Rocket Motor Head-end Structural AnalysisDocument83 pagesRocket Motor Head-end Structural AnalysisRudra Sai SandeepNo ratings yet

- Piping Class Summary - OSBL PDFDocument2 pagesPiping Class Summary - OSBL PDFnarutothunderjet216100% (1)

- Pipe Reinforcing at SupportDocument12 pagesPipe Reinforcing at SupportSeungmin Paek100% (3)

- RCC41 Continuous Beams (A & D)Document28 pagesRCC41 Continuous Beams (A & D)aminjoles100% (1)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- D&D Main Beam Grids C To HDocument17 pagesD&D Main Beam Grids C To Hdicktracy11No ratings yet

- APDocument112 pagesAPAbhi 7No ratings yet

- TPG IiiDocument47 pagesTPG IiiLenny Lizzeth ParadaNo ratings yet

- Datasheet Capacitor YAGEODocument10 pagesDatasheet Capacitor YAGEOrafaelfernandes183No ratings yet

- Pages From Scn2110-2120 - Product ScreensDocument1 pagePages From Scn2110-2120 - Product ScreenssukuivaNo ratings yet

- Notes: P.T. Badak N.G.L. Bontang L.N.G. PlantDocument10 pagesNotes: P.T. Badak N.G.L. Bontang L.N.G. PlantAdidtya Budhi SaputraNo ratings yet

- Perimeter Fence System Components Index: Page Date Naams Codes DescriptionDocument39 pagesPerimeter Fence System Components Index: Page Date Naams Codes DescriptionjessicaNo ratings yet

- Lifting Eye Blind: NotesDocument1 pageLifting Eye Blind: Notesnarutothunderjet216No ratings yet

- Project: Client: Engineer: Remarks:: Your Company Name HereDocument5 pagesProject: Client: Engineer: Remarks:: Your Company Name HerevNo ratings yet

- J-Bolt Edge System For LHD TramsDocument8 pagesJ-Bolt Edge System For LHD TramsfernandojNo ratings yet

- Da 950068 002 PDFDocument1 pageDa 950068 002 PDFpremNo ratings yet

- Elect Manhole Handhole MetricDocument7 pagesElect Manhole Handhole MetricRom GuarenNo ratings yet

- Heatshrink Cable Terminations for Power UtilitiesDocument63 pagesHeatshrink Cable Terminations for Power UtilitiesBasman GeorgeNo ratings yet

- Procter&Gamble: Belt, Vacuum Conveyor 16 Inw X 75 Inp LDocument1 pageProcter&Gamble: Belt, Vacuum Conveyor 16 Inw X 75 Inp LthtrhzstrhzstrNo ratings yet

- Layout Solns 3Document12 pagesLayout Solns 3VIKRAM KUMARNo ratings yet

- 10 SEER air conditioner specsDocument4 pages10 SEER air conditioner specsOscar Sanchez Velasquez0% (1)

- Raccordi A Inserto Forgiato PDFDocument3 pagesRaccordi A Inserto Forgiato PDFpeppino di capriNo ratings yet

- RCC41Document23 pagesRCC41kibzeamNo ratings yet

- Section PropertiesDocument4 pagesSection PropertiesOng George SammyNo ratings yet

- RCC41 Continuous Beams (A & D)Document17 pagesRCC41 Continuous Beams (A & D)Zayyan RomjonNo ratings yet

- RCC41 Continuous Beams (A & D)Document18 pagesRCC41 Continuous Beams (A & D)Anonymous lEmizZaJ100% (1)

- Concrete Design - Comparison is-BSDocument10 pagesConcrete Design - Comparison is-BSStephen Rajkumar JayakumarNo ratings yet

- Using Flange Joint in Duct SiystemDocument23 pagesUsing Flange Joint in Duct Siystematamete100% (1)

- r1Document3 pagesr1naseema1No ratings yet

- Siemens NEMA Control 40 Cut Sheet1Document4 pagesSiemens NEMA Control 40 Cut Sheet1Josue Vieira OliveiraNo ratings yet

- D931 Fixed Orifice Double Regulating Valve (Fodrv) : PN25 Bronze Balancing Valve Χρυσαφι∆Ησ Α.ΕDocument8 pagesD931 Fixed Orifice Double Regulating Valve (Fodrv) : PN25 Bronze Balancing Valve Χρυσαφι∆Ησ Α.ΕMohamed AdelNo ratings yet

- Transformer BushingDocument11 pagesTransformer BushingNunna BaskarNo ratings yet

- 5 8kV 250A 500A Konnetor Teknik OzelliklerDocument14 pages5 8kV 250A 500A Konnetor Teknik OzelliklerFrancisco Campaña PerezNo ratings yet

- Bis Code of PracticeDocument23 pagesBis Code of PracticefaisalkalathilNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IIFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Advances in Ceramic Armor XFrom EverandAdvances in Ceramic Armor XJerry C. LaSalviaNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNo ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Anak 'Child',作者:Freddie Aguilar, 1978 ANAK (Original song & lyrics in Filipino)Document1 pageAnak 'Child',作者:Freddie Aguilar, 1978 ANAK (Original song & lyrics in Filipino)narutothunderjet216No ratings yet

- Short document ID codesDocument1 pageShort document ID codesnarutothunderjet216No ratings yet

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocument4 pagesSummary ISO TR 15608 Metallic Materials Grouping SystemV SwamiNo ratings yet

- Word 9Document1 pageWord 9narutothunderjet216No ratings yet

- Boxfile LabelDocument2 pagesBoxfile Labelnarutothunderjet216No ratings yet

- Bargarefg4re Gra H5 Gtve5t3 54g Eth W54 Hnt4 6 Twry45y2 46 U5 264 4Document1 pageBargarefg4re Gra H5 Gtve5t3 54g Eth W54 Hnt4 6 Twry45y2 46 U5 264 4narutothunderjet216No ratings yet

- BrochupdfDocument24 pagesBrochupdfnarutothunderjet216No ratings yet

- Welders, CWI Inspectors, Instructors Now You Can Design Your Inspection Tool KitDocument2 pagesWelders, CWI Inspectors, Instructors Now You Can Design Your Inspection Tool Kitcamelod555No ratings yet

- Aaadoc 1Document1 pageAaadoc 1narutothunderjet216No ratings yet

- How To Take A Weld Test (UAWT)Document4 pagesHow To Take A Weld Test (UAWT)narutothunderjet216No ratings yet

- Star Very GoodDocument8 pagesStar Very Goodnarutothunderjet216No ratings yet

- Echnical Ulletin: Cmnsi P S CrmoDocument1 pageEchnical Ulletin: Cmnsi P S Crmonarutothunderjet216No ratings yet

- Beam Design ThuwalDocument5 pagesBeam Design Thuwalnarutothunderjet216No ratings yet

- Welding Performance QualificationDocument5 pagesWelding Performance Qualificationnarutothunderjet216No ratings yet

- Insulation PDFDocument10 pagesInsulation PDFnarutothunderjet216100% (1)

- STEEL PIPE For Automatic Sprinkler SystemsDocument51 pagesSTEEL PIPE For Automatic Sprinkler Systemsnarutothunderjet216No ratings yet

- AWS WPQR WPS FormularioDocument1 pageAWS WPQR WPS FormularioAntonio RuscittoNo ratings yet

- EquationcscxDocument1 pageEquationcscxnarutothunderjet216No ratings yet

- Painting Specification - 11 11 16Document13 pagesPainting Specification - 11 11 16narutothunderjet216No ratings yet

- A Project Report: Maya Engineering WorksDocument2 pagesA Project Report: Maya Engineering WorksVishwendra SinghNo ratings yet

- Ic M423GDocument2 pagesIc M423GSerikhi AliNo ratings yet

- Polythionic Acid Stress Corrosion CrackingDocument2 pagesPolythionic Acid Stress Corrosion CrackingVajid MadathilNo ratings yet

- How Game-Based Teaching Strategy Affect The Student's Learning in MathematicsDocument13 pagesHow Game-Based Teaching Strategy Affect The Student's Learning in MathematicsAaron Jay BulataoNo ratings yet

- Chap 24 Econ 40Document4 pagesChap 24 Econ 40Racel DelacruzNo ratings yet

- Asia Pacific College of Advanced StudiesDocument4 pagesAsia Pacific College of Advanced StudiesRussel QuinonesNo ratings yet

- The Prevention of Women & Children Repression Act 2000: A Study of Implementation Process From 2003 To 2013Document9 pagesThe Prevention of Women & Children Repression Act 2000: A Study of Implementation Process From 2003 To 2013Md. Abdul KarimNo ratings yet

- Research PresentationDocument13 pagesResearch Presentationapi-252252011No ratings yet

- UM16000 Flame Detector Installation Guide EnglishDocument12 pagesUM16000 Flame Detector Installation Guide Englishmohamed.rescoNo ratings yet

- Cambridge BiologyDocument78 pagesCambridge BiologyBraweet SapkotaNo ratings yet

- Manoshe Street Takeaway MenuDocument9 pagesManoshe Street Takeaway MenuimaddakrNo ratings yet

- Pursuing a Career in CosmetologyDocument3 pagesPursuing a Career in CosmetologyMaria CeciliaNo ratings yet

- A4 RelationshipgridDocument32 pagesA4 RelationshipgridjamesNo ratings yet

- Laughter Yoga Benefits Workplace ProductivityDocument2 pagesLaughter Yoga Benefits Workplace ProductivityJose Manuel Araujo OrregoNo ratings yet

- Lubricants: Chapter - 5 Lubricants and LubricationDocument5 pagesLubricants: Chapter - 5 Lubricants and LubricationMalaika AzeemNo ratings yet

- 342Mass&HeatModule (3) Soln071118 OlefinPlantDocument12 pages342Mass&HeatModule (3) Soln071118 OlefinPlantmanuelNo ratings yet

- Yıldız Technical University - Program Information Form - Page 1/9Document9 pagesYıldız Technical University - Program Information Form - Page 1/9Elsaadawi MohamedNo ratings yet

- Aire Acondicionado Mazda 3 2006Document2 pagesAire Acondicionado Mazda 3 2006Jhon ConnorNo ratings yet

- Comparing Food with Comparative AdjectivesDocument4 pagesComparing Food with Comparative AdjectivesLuisito GonzalezNo ratings yet

- PMBOK - Chapter 9: Project Human Resource ManagementDocument16 pagesPMBOK - Chapter 9: Project Human Resource Management7565006No ratings yet

- REBA Employee Assessment Worksheet: A. Neck, Trunk and Leg AnalysisDocument1 pageREBA Employee Assessment Worksheet: A. Neck, Trunk and Leg AnalysisAgni JayantiNo ratings yet

- IRIS 2017 DOG Treatment Recommendations 09may18Document15 pagesIRIS 2017 DOG Treatment Recommendations 09may18crilala23No ratings yet

- Type 3730-1 Electropneumatic PositionerDocument112 pagesType 3730-1 Electropneumatic PositionerDaniel ReyNo ratings yet

- Pathology AIIMSDocument26 pagesPathology AIIMSvkNo ratings yet