Professional Documents

Culture Documents

NIC Components NSWC Series

Uploaded by

NICCompOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NIC Components NSWC Series

Uploaded by

NICCompCopyright:

Available Formats

Stacked Film Capacitor Chips NSWC Series

FEATURES

NSWC IS

• STACKED METALLIZED POLYETHYLENE NAPHTHALATE (PEN) FILM RECOMMENDED

• STANDARD EIA 1206, 1210, 1913, 2416, 2820, 3022 AND 3925 SIZES FOR NEW DESIGNS

• WIDE TEMPERATURE RANGE UP TO +105OC (16Vdc & 50Vdc)

• HIGH HEAT AND MOISTURE RESISTANT

• VERY STABLE TEMPERATURE, FREQUENCY, VOLTAGE, BIAS AND RoHS

nDIELECTRIC ABSORPTION CHARACTERISTICS Compliant

includes all homogeneous materials

• REFLOW SOLDERING ONLY

• TAPE AND REEL PACKAGING *See Part Number System for Details

Case Sizes

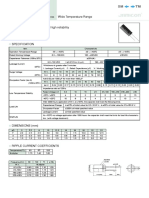

SPECIFICATIONS

1206 1210 1913 2416 2820 3022 3925

Capacitance Range 0.001 ~ 0.0047µF 0.00561 ~ 0.01µF 0.012 ~ 0.22µF 0.1 ~ 0.47µF 0.18 ~ 0.33µF 0.39 ~ 0.47µF 0.56 ~ 1.0µF

Votage Ratings 16Vdc, 50Vdc, 100Vdc

16V and 50V ±5% (J), 100V 0.001 ~ 0.01µF 5% (J) only,

Capacitance Tolerance

0.012 ~ 0.15µF 5% (J) or 10% (K), 0.18 ~ 1.0µF 10% (K) only

-55°C ~ +105°C (16Vdc, 50Vdc and 100V 0.012µF ~ 0.01µF)

Temperature Range

-55°C ~ +125°C (100Vdc, 0.012µF ~ 1.0µF with derating above +85°C)

Dissipation factor (20°C) 1.0% max. @ 1KHz

3 Gigohms or 1000Ω/F whichever is lower

Insulation resistance (20°C)

(16Vdc parts measured at 10Vdc)

Dielectric Withstanding 150% of Rated Voltage 60 Seconds

Voltage 175% of Rated Voltage for 5 Seconds (except 100Vdc parts)

Temperature Characteristic ±3% ∆C Maximum Over Temperature Range

Dielectric Absorption 0.05 ~ 0.10% Typical

ENVIRONMENTAL CHARACTERISTICS

Life Test At +105°C Capacitance Change Within +1%/-6% of Initial Value

1,000 Hours at 125% of Rated Voltage Dissipation Factor 1.1% Maximum

(125°C for 100Vdc, 0.012µF ~ 1.0µF) Insulation Resistance 1 Gigohm Minimum or 300Ω/F whichever is lower

Capacitance Change Within ±5% of Initial Value

Resistance to Soldering Heat:

Dissipation Factor 1.1% Maximum

+240°C Peak

Insulation Resistance 1 Gigohm Minimum or 300Ω/F whichever is lower

Capacitance Change (1) +8%/-5% (2) ±10% of Initial Value

Humidity Load Life (90% ~ 95% RH)

Dissipation Factor (1) 1.5% Max. (2) 2.0% Max.

(1) 1,000 Hours, +40°C

(500 Hours for 100Vdc, 0.012µF ~ 1.0µF) (1) 100 Megohm Min. or 30Ω/F

(2) 500 Hours, +60°C Insulation Resistance (2) 10 Megohm Min. or 3Ω/F

whichever is lower

Solderability with

90% Minimum Coverage After 2.5 Second Dip Into 245°C Solder Pot

25% Wt Rosin-Methanol Flux

RECOMMENDED LAND RECOMMENDED REFLOW PROFILE

PATTERN (mm)

300

EIA Size A B C Standard: +240 °C Peak Temperature

Temperature - Deg. C

1206 1.8 3.6 1.4 250 +250°C Special Order

1210 1.8 3.6 2.3 (see part numbering system)

200

1913 2.6 6.6 3.0

150

2416 3.8 7.8 3.8

Cool Down

2820 4.5 9.0 4.6 100

Time above 220°C

3022 5.1 9.7 5.0

60 sec. max.

3925 7.2 11.9 5.7 50

25 Pre-heat

Ramp-up 150°C ~ 180°C

25°C ~ 150°C 120 sec. max.

90 sec. max.

C

0

Time

PART NUMBER SYSTEM

A

B NSWC 104 J 50 TR D4 N F

RoHS Compliant

Optional High Temp. Reflow (+250°C)*

Size Code

Tape & Reel

Voltage

Tolerance Code: J=±5%

Capacitance in pF, 1st two digits are

® significant, 3rd digit is no. of zeros

Series *Special packaging and handling required.

NIC COMPONENTS CORP. www.niccomp.com www.lowESR.com www.RFpassives.com www.SMTmagnetics.com

49

Stacked Film Capacitor Chips NSWC Series

STANDARD PRODUCTS AND SIZE CODE DIMENSION (mm) AND CASE CODE

Working Voltage Case Length Width Height EIA

Cap. Code (Vdc) Fig. 1 16V & 50V, 100V D1~R8 P

Code L ±0.2 W H ±0.3 Code

16 50 100 Stacked Element Terminations: 95.5% Sn, 4% Ag and

0.5% Cu over phosphorus B2 1.1

0.001 102 B2 1.6 ± 0.2 0.65 1206

copper barrier over copper B3 1.5

0.0012 122 B2 base 3.2 ±0.3

C2 1.5 (Fig. 1) 1210

0.0015 152 B2 2.5 ± 0.2

C3 2.1

0.0018 182 B2 D1 1.4

0.0022 222 B2 H D2 2.0

0.0027 272 B2 4.8 3.3 ± 0.3 1913

D3 2.4

0.0033 332 B3 D4 2.8

0.0039 392 B3 E1 1.8

0.0047 472 B3 L2 W E2 2.0

p p 6.0 4.1 ± 0.3 2416

0.0056 562 C2 E3 2.4

0.0068 682 C2 L1

E4 2.8

0.0082 822 C3 G1 2.0 0.35

Fig. 2 (100V B2~C3) ±0.2

0.010 103 C3 G2 2.4

Stacked Element Terminations: 95.5% Sn, 4% Ag and 7.1 5.0 ± 0.4 (Fig. 2) 2820

0.012 123 D1 0.5% Cu over phenolic G3 2.9

0.015 153 D1 resin/Ag/Ni/Cu over

G5 3.5

copper base

0.018 183 D1 Q1 3.4

0.022 223 D1 7.7 5.5 ± 0.4 3022

Q2 4.0

0.027 273 D1 R1 3.0

0.033 333 D1 H R3 3.6

0.039 393 D1 9.8 6.3 ± 0.4 3925

R6 4.3

0.047 473 D2 R8 5.1

0.056 563 D2 D2

0.068 683 D2 D3 L2 W

p p

0.082 823 D3 D4

L1

0.1 104 D4 E1

0.12 124 D1 E1 E3

1.75 ±0.1

0.15 154 D2 E2 E4 EMBOSSED PLASTIC CARRIER

0.18 184 D2 E3 G1

0.22 224 D3 E4 G2 t 1.5 +0.1 4.0 ±0.1

0.27 274 E1 G3 -0

0.33 334 E2 G5

0.39 394 E3 Q1

F

0.47 474 E4 Q2

W

0.56 564 R1

B

0.68 684 R3

D∅

0.82 824 R6

1.0 105 R8 A P

C

TAPE DIMENSIONS (mm) 17.4

±1.0

Case Code A±0.1 B±0.1 C±0.2 t W±0.3 F P±0.1 D+0.2/-0 Qty/Reel

B2 1.5 3,000

1.9

B3 1.9 2,000

3.5 0.25 8.0 3.5 4.0 1.0

C2 1.9 2,000 2.0

2.8 ±0.5

C3 2.5 2,000 13

±0 .0

D1 2.0 3,000 .5

±2.0

±1.0

330

D2 3.8 5.1 2.6 1.5 3,000

80

D3, D4 3.4 0.3 5.5 2,000

12.0 8.0

E1, E2 2.7 ±0.05 ±0.05 3,000

4.6 6.3 .0

E3, E4 3.5 - 2,000 21 0.8

±

G1 ~ G5 5.5 7.4 4.7 1,500

Q1, Q2 6.91 8.43 5.685 0.343 7.5 1,000

16.0 12.0 1.5

R1 ~ R8 8.94 10.54 5.795 ±0.013 ±0.1 1,000

13.4

±1.0

NIC COMPONENTS CORP. www.niccomp.com www.lowESR.com www.RFpassives.com www.SMTmagnetics.com

50

NSWC Series

Stacked Film Capacitor Chips (High Voltage)

FEATURES NSWC IS

• STACKED METALLIZED POLYETHYLENE NAPHTHALATE (PEN) FILM RECOMMENDED

FOR NEW DESIGNS

• STANDARD EIA 1913, 2416 and 2420 SIZES

• HIGH HEAT AND MOISTURE RESISTANT

RoHS

• VERY STABLE TEMPERATURE, FREQUENCY, VOLTAGE, BIAS AND

nDIELECTRIC ABSORPTION CHARACTERISTICS Compliant

includes all homogeneous materials

• REFLOW SOLDERING ONLY

• TAPE AND REEL PACKAGING *See Part Number System for Details

Case Sizes

SPECIFICATIONS

1913 2416 2420

Capacitance Range 0.001 ~ 0.015µF 0.012 ~ 0.068µF 0.027 ~ 0.12µF

Voltage Ratings 250Vdc

Capacitance Tolerance ±5%(J)

Temperature Range -55°C ~ +85°C

Dissipation Factor 1.0% max. @ 1KHz

Insulation Resistance (20°C)

3 Gigohms @ 100Vdc

Through 2K Ohm Resistor

Dielectric Withstanding

150% of Rated Voltage

Voltage

Temperature Characteristic ±3% ∆C Maximum Over Temperature Range

Dielectric Absorption 0.05 ~ 0.10% Typical

ENVIRONMENTAL CHARACTERISTICS

Capacitance Change Within ±1%/-6% of Initial Value

Life Test At +85°C

Dissipation Factor 1.1% Maximum

1,000 Hours at 125% of Rated Voltage

Insulation Resistance 1 GigΩ Minimum

Capacitance Change Within ±5% of Initial Value

Resistance to Soldering Heat:

Dissipation Factor 1.1% Maximum

+240°C Peak

Insulation Resistance 1 GigΩ Minimum or 300Ω/F whichever is lower

Capacitance Change (1) +8%/-5%

Humidity Load Life (90 ~ 95% RH)

Dissipation Factor (1) ±1.5%

1,000 Hours, +40°C

Insulation Resistance (1) 100MegΩ

Capacitance Change Within ±5%

Resistance to Soldering Heat

Dissipation Factor Maximum 1.1%

240°C for 5 seconds

Insulation Resistance 1GigΩ

Solderability with

95% Minimum Coverage After 2.5 Second Dip into 245°C Solder Pot

25% Wt Rosin-Methanol Flux

RECOMMENDED LAND

RECOMMENDED REFLOW PROFILE PATTERN (mm)

300

Standard: +240 °C Peak Temperature EIA Size A B C

Temperature - Deg. C

250 +250°C Special Order 1913 2.6 6.6 3.0

(see part numbering system)

200 2416 3.8 7.8 3.8

150 2420 3.8 7.8 4.6

Cool Down

100

Time above 220°C

60 sec. max.

50

25 Pre-heat

Ramp-up 150°C ~ 180°C

25°C ~ 150°C 120 sec. max.

90 sec. max.

0

Time

PART NUMBER SYSTEM

NSWC 822 J 250 TR D1 N F

RoHS Compliant

Optional High Temp. Reflow (+250°C)*

Size Code

Tape & Reel

Voltage

Tolerance Code: J=±5%

Capacitance in pF, 1st two digits are

significant, 3rd digit is no. of zeros

® Series *Special packaging and handling required.

NIC COMPONENTS CORP. www.niccomp.com www.lowESR.com www.RFpassives.com www.SMTmagnetics.com

51

NSWC Series

Stacked Film Capacitor Chips High Voltage

STANDARD PRODUCTS AND SIZE CODE DIMENSION (mm) AND CASE CODE

Working Voltage Case Length Width Height EIA

p

Cap. Code (Vdc) Fig. 1 Code L±0.2 W H±0.3 Code

250 Stacked Element Terminations: 95.5% Sn, 4% Ag and D1 1.4

0.5% Cu over phosphorus

0.001 102 D1 copper barrier over copper

D2 2.0

4.8 3.3 ± 0.3 1913

0.0012 122 D1 base D3 2.4

0.0015 152 D1 D4 2.8

0.0022 222 D1 E2 2.0

0.0027 272 D1 E3 2.4

H 6.0 4.1±0.3 0.35 2416

0.0033 332 D1 E4 2.8

±0.2

0.0039 392 D1 E5 3.2

0.0047 472 D1 F1 3.0

0.0056 562 D1 L2 W F2 3.2

p p F3 6.0 5.0 ± 0.4 3.6 2420

0.0068 682 D1

0.0082 822 D1 L1 F4 3.8

0.010 103 D1 F5 4.5

0.012 123 D1

0.015 153 D1

0.018 183 D2

0.022 223 D2

0.027 273 D3

0.033 333 D4

0.039 393 E2

0.047 473 E3

0.056 563 E4

0.068 683 E5

0.082 823 F2

0.10 104 F4

0.12 124 F5

TAPE DIMENSIONS (mm)

Case Code A±0.1 B±0.1 C±0.2 t W±0.3 F P±0.1 D+0.2/-0 Qty/Reel

D1 2.0 3,000

D2 3.8 5.1 2.6 1.5 3,000

D3, D4 3.4 0.3 5.5 2,000

12.0 8.0

E1, E2 2.7 ±0.05 ±0.05 3,000

4.6 6.3

E3, E4 3.5 - 2,000

F1 ~ F5 5.5 6.3 4.7 1,500

17.4

±1.0

1.75 ±0.1

EMBOSSED PLASTIC CARRIER

2.0

1.5 +0.1 4.0 ±0.1 ±0.5

t

-0 13

±0 .0

.5

±2.0

±1.0

330

80

F

W

.0

21 0.8

B

±

D∅

A P

C 13.4

±1.0

NIC COMPONENTS CORP. www.niccomp.com www.lowESR.com www.RFpassives.com www.SMTmagnetics.com

52

You might also like

- Managerial EconomicsDocument3 pagesManagerial EconomicsGuruKPONo ratings yet

- Audio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionDocument29 pagesAudio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionLuc SchramNo ratings yet

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- GP Rating GSK Exit ExamDocument108 pagesGP Rating GSK Exit ExamMicle VM100% (4)

- NLP Business Practitioner Certification Course OutlineDocument11 pagesNLP Business Practitioner Certification Course OutlineabobeedoNo ratings yet

- NIC Components NSHC SeriesDocument2 pagesNIC Components NSHC SeriesNICCompNo ratings yet

- Resistencia de PrecisiónDocument4 pagesResistencia de PrecisiónLuis MartinNo ratings yet

- LVK Series: Four Terminal High Precision Current SenseDocument3 pagesLVK Series: Four Terminal High Precision Current SenseJUAN CHAMPACNo ratings yet

- NIC Components NSWC High Voltage SeriesDocument2 pagesNIC Components NSWC High Voltage SeriesNICCompNo ratings yet

- Res lvk-3082595Document4 pagesRes lvk-3082595f4bxwNo ratings yet

- NIC Components NSMX SeriesDocument3 pagesNIC Components NSMX SeriesNICCompNo ratings yet

- C3 Catalog CE Miniatura ElraDocument3 pagesC3 Catalog CE Miniatura ElraSneezy DwarfNo ratings yet

- NIC Components NRLR SeriesDocument11 pagesNIC Components NRLR SeriesNICCompNo ratings yet

- SL Series 85° SMD Ecap: FeaturesDocument6 pagesSL Series 85° SMD Ecap: FeaturesAlberto IsmaelNo ratings yet

- SL Series 85° SMD Ecap: FeaturesDocument6 pagesSL Series 85° SMD Ecap: FeaturesAlberto IsmaelNo ratings yet

- 01 EBG Series PCS 2019Document1 page01 EBG Series PCS 2019Islam El-saiedNo ratings yet

- CKH Cke-2944644Document4 pagesCKH Cke-2944644ChrisNo ratings yet

- Model L Series: Thick Film Low Profile SIP Conformal Coated Resistor NetworksDocument5 pagesModel L Series: Thick Film Low Profile SIP Conformal Coated Resistor NetworksKaren MkrtchyanNo ratings yet

- NIC Components NCF SeriesDocument3 pagesNIC Components NCF SeriesNICCompNo ratings yet

- NIC Components NSTLW SeriesDocument2 pagesNIC Components NSTLW SeriesNICCompNo ratings yet

- Technical: Single In-Line Conformal Series 770Document3 pagesTechnical: Single In-Line Conformal Series 770MiGuel RodasNo ratings yet

- Tta 2944741 PDFDocument4 pagesTta 2944741 PDFDhaval PatelNo ratings yet

- NIC Components NRLMW SeriesDocument5 pagesNIC Components NRLMW SeriesNICCompNo ratings yet

- Capacitor Selection Technical NoteDocument4 pagesCapacitor Selection Technical NoteSagarNo ratings yet

- Compact 100W Dual Output Power Supply with Universal AC InputDocument1 pageCompact 100W Dual Output Power Supply with Universal AC InputQooNo ratings yet

- SPS 100 PD2 PDFDocument1 pageSPS 100 PD2 PDFQooNo ratings yet

- NIC Components NTC-T SeriesDocument10 pagesNIC Components NTC-T SeriesNICCompNo ratings yet

- Resistor ArrayDocument5 pagesResistor ArrayJuampa ChruscielNo ratings yet

- AZ951/AZ952 Subminiature Power Relay SpecificationsDocument3 pagesAZ951/AZ952 Subminiature Power Relay SpecificationsvssabinNo ratings yet

- Datasheet 507446 Zettler Electronics Az9571 1c 3de PCB Relay 3 V DC 1 A 1 Change Over 1 PcsDocument2 pagesDatasheet 507446 Zettler Electronics Az9571 1c 3de PCB Relay 3 V DC 1 A 1 Change Over 1 PcsAitorNo ratings yet

- Cel47uf250v CDocument3 pagesCel47uf250v CJean Marc BEAUMONTNo ratings yet

- Rsen Series: Page - 1 - of 5Document5 pagesRsen Series: Page - 1 - of 5D FahlenNo ratings yet

- Long Life, Aluminum Electrolytic: Capacitance Range Capacitance Tolerance Rated Voltage Operating Temperature RangeDocument8 pagesLong Life, Aluminum Electrolytic: Capacitance Range Capacitance Tolerance Rated Voltage Operating Temperature RangeMohammed TarekNo ratings yet

- C606 C607 C752 753Document2 pagesC606 C607 C752 753Sol De GabrielNo ratings yet

- Chapter 6 Specifications: DC CharacteristicsDocument13 pagesChapter 6 Specifications: DC CharacteristicsGui GarciaNo ratings yet

- Samsung 0805 1uF 50V X7R MLCC SpecificationDocument2 pagesSamsung 0805 1uF 50V X7R MLCC Specificationelias rangelNo ratings yet

- Conductive Polymer AluminumDocument2 pagesConductive Polymer AluminumBaCresNo ratings yet

- NIC Components NSTL SeriesDocument2 pagesNIC Components NSTL SeriesNICCompNo ratings yet

- Capacitor PanasonicDocument6 pagesCapacitor PanasonicdenisharkNo ratings yet

- GH 1C 12LDocument2 pagesGH 1C 12LRoberto MendesNo ratings yet

- Film Resistors GuideDocument1 pageFilm Resistors GuideGeorge RibeiroNo ratings yet

- Aluminium Housed Wirewound Resistors: WH SeriesDocument4 pagesAluminium Housed Wirewound Resistors: WH SeriesLuis GarciaNo ratings yet

- NIC Components NPC SeriesDocument4 pagesNIC Components NPC SeriesNICCompNo ratings yet

- Acon (Radial Thru-Hole) GFW SeriesDocument3 pagesAcon (Radial Thru-Hole) GFW Seriesxyz99No ratings yet

- Mini gold capacitors for memory cards and mobile devicesDocument1 pageMini gold capacitors for memory cards and mobile devicesLaurentiu ApostolNo ratings yet

- NIC Components NTR-H SeriesDocument3 pagesNIC Components NTR-H SeriesNICCompNo ratings yet

- Specification: CL 21 F 223 Z B A N N N CDocument3 pagesSpecification: CL 21 F 223 Z B A N N N Csam2976No ratings yet

- NIC Components NRLFW SeriesDocument2 pagesNIC Components NRLFW SeriesNICCompNo ratings yet

- NIC Components NRLM SeriesDocument5 pagesNIC Components NRLM SeriesNICCompNo ratings yet

- Miniature Aluminum Electrolytic Capacitors: Wide Temperature Range SeriesDocument3 pagesMiniature Aluminum Electrolytic Capacitors: Wide Temperature Range Serieshemant kadlagNo ratings yet

- Capa Panasonic Low EsrDocument5 pagesCapa Panasonic Low EsrClovis APOVONo ratings yet

- 95 °C Long-Life, Screw Terminal, Aluminum ElectrolyticDocument12 pages95 °C Long-Life, Screw Terminal, Aluminum ElectrolyticSerhat TüysüzNo ratings yet

- Nominal Composition Standard Inventory SpecificationsDocument3 pagesNominal Composition Standard Inventory Specificationssafat parNo ratings yet

- A286 (Ficha Tecnica)Document3 pagesA286 (Ficha Tecnica)Alex Zambrana RodríguezNo ratings yet

- 12a DPST Miniature Power RelayDocument2 pages12a DPST Miniature Power RelaykarkeraNo ratings yet

- TE SeriesDocument8 pagesTE SeriesANIL ŞENNo ratings yet

- Datasheet PDFDocument2 pagesDatasheet PDFRodrigo Andres Ospino MercadoNo ratings yet

- 12V200AH GEL Battery SpecsDocument2 pages12V200AH GEL Battery SpecsEmmanuel santosNo ratings yet

- SPEC-2700K June2014Document4 pagesSPEC-2700K June2014termmmNo ratings yet

- TT - Electronics 898 3 R100K Datasheet PDFDocument4 pagesTT - Electronics 898 3 R100K Datasheet PDFelnegritoheberNo ratings yet

- Model 89: 3/4" Rectangular Multiturn Cermet Trimming PotentiometerDocument6 pagesModel 89: 3/4" Rectangular Multiturn Cermet Trimming PotentiometerManikanta Sai KumarNo ratings yet

- SERIES - Lead Terminal: FeaturesDocument4 pagesSERIES - Lead Terminal: FeaturesVenu Gopal Rao AggressNo ratings yet

- Codatron HTHighVoltage RegulatorsDocument9 pagesCodatron HTHighVoltage RegulatorsOil lessNo ratings yet

- BETAflam Solar 125 RV Flex 1500V DC - E - Voltagedrop Current LoadDocument4 pagesBETAflam Solar 125 RV Flex 1500V DC - E - Voltagedrop Current LoadMay OngNo ratings yet

- RoHS Makes Impact On Circuit DesignDocument3 pagesRoHS Makes Impact On Circuit DesignNICCompNo ratings yet

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 pagesSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompNo ratings yet

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 pagesSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompNo ratings yet

- NIC Components NCSP SeriesDocument2 pagesNIC Components NCSP SeriesNICCompNo ratings yet

- NIC Component Series NPIS - LSDocument11 pagesNIC Component Series NPIS - LSNICCompNo ratings yet

- NIC Components Corp.Document4 pagesNIC Components Corp.NICCompNo ratings yet

- NIC Component Series NACKADocument4 pagesNIC Component Series NACKANICCompNo ratings yet

- NIC Component Series NTIDocument4 pagesNIC Component Series NTINICCompNo ratings yet

- NIC Component Series NTC-R NTP-RDocument3 pagesNIC Component Series NTC-R NTP-RNICCompNo ratings yet

- NIC Components NRSNE SeriesDocument2 pagesNIC Components NRSNE SeriesNICCompNo ratings yet

- NIC Press Release NSPE x0210Document2 pagesNIC Press Release NSPE x0210NICCompNo ratings yet

- Technical Support: TPMG@Document1 pageTechnical Support: TPMG@NICCompNo ratings yet

- HTTP:WWW - Niccomp.com Technical Inquiries: TPMG@Document2 pagesHTTP:WWW - Niccomp.com Technical Inquiries: TPMG@NICCompNo ratings yet

- Web Exclusive: An Introduction To Low ESRDocument3 pagesWeb Exclusive: An Introduction To Low ESRNICCompNo ratings yet

- NIC Components NACH SeriesDocument3 pagesNIC Components NACH SeriesNICCompNo ratings yet

- NIC Components NCB-H SeriesDocument3 pagesNIC Components NCB-H SeriesNICCompNo ratings yet

- NIC Components NSPE-Y SeriesDocument2 pagesNIC Components NSPE-Y SeriesNICCompNo ratings yet

- NIC Components NSPE-S SeriesDocument3 pagesNIC Components NSPE-S SeriesNICCompNo ratings yet

- NIC Components NRE-HS SeriesDocument6 pagesNIC Components NRE-HS SeriesNICCompNo ratings yet

- NIC Components NACH SeriesDocument3 pagesNIC Components NACH SeriesNICCompNo ratings yet

- NIC Components Current Sensing Resistor GuideDocument1 pageNIC Components Current Sensing Resistor GuideNICCompNo ratings yet

- NIC Components NRE-WY SeriesDocument7 pagesNIC Components NRE-WY SeriesNICCompNo ratings yet

- NIC Components NSPE-H SeriesDocument3 pagesNIC Components NSPE-H SeriesNICCompNo ratings yet

- NIC Components NSPE-U SeriesDocument2 pagesNIC Components NSPE-U SeriesNICComp100% (2)

- NIC Components NMC-Q SeriesDocument7 pagesNIC Components NMC-Q SeriesNICCompNo ratings yet

- NIC Components NACEN SeriesDocument3 pagesNIC Components NACEN SeriesNICCompNo ratings yet

- NIC Components NSPE-T SeriesDocument3 pagesNIC Components NSPE-T SeriesNICComp100% (2)

- Guide To Hand SolderingDocument1 pageGuide To Hand SolderingNICComp100% (1)

- NIC Components NMC-H X2/Y3 SeriesDocument2 pagesNIC Components NMC-H X2/Y3 SeriesNICCompNo ratings yet

- NIC Components NPIM - C SeriesDocument6 pagesNIC Components NPIM - C SeriesNICCompNo ratings yet

- Production of Sodium Chlorite PDFDocument13 pagesProduction of Sodium Chlorite PDFangelofgloryNo ratings yet

- Assignment - Final TestDocument3 pagesAssignment - Final TestbahilashNo ratings yet

- WindSonic GPA Manual Issue 20Document31 pagesWindSonic GPA Manual Issue 20stuartNo ratings yet

- Damcos Mas2600 Installation UsermanualDocument26 pagesDamcos Mas2600 Installation Usermanualair1111No ratings yet

- Pfr140 User ManualDocument4 pagesPfr140 User ManualOanh NguyenNo ratings yet

- Paper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Document12 pagesPaper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Hisham AlEnaiziNo ratings yet

- Final Year Project (Product Recommendation)Document33 pagesFinal Year Project (Product Recommendation)Anurag ChakrabortyNo ratings yet

- Listening Exercise 1Document1 pageListening Exercise 1Ma. Luiggie Teresita PerezNo ratings yet

- Philippine Army BDU BidDocument2 pagesPhilippine Army BDU BidMaria TeresaNo ratings yet

- PEDs and InterferenceDocument28 pagesPEDs and Interferencezakool21No ratings yet

- Day 4 Quiz - Attempt ReviewDocument8 pagesDay 4 Quiz - Attempt ReviewĐỗ Đức AnhNo ratings yet

- CTR Ball JointDocument19 pagesCTR Ball JointTan JaiNo ratings yet

- Busbar sizing recommendations for Masterpact circuit breakersDocument1 pageBusbar sizing recommendations for Masterpact circuit breakersVikram SinghNo ratings yet

- SNC 2p1 Course Overview 2015Document2 pagesSNC 2p1 Course Overview 2015api-212901753No ratings yet

- Wheeled Loader L953F Specifications and DimensionsDocument1 pageWheeled Loader L953F Specifications and Dimensionssds khanhNo ratings yet

- eHMI tool download and install guideDocument19 pageseHMI tool download and install guideNam Vũ0% (1)

- Excel Solver Optimization ReportDocument9 pagesExcel Solver Optimization ReportMy Duyen NguyenNo ratings yet

- LEARNING ACTIVITY Sheet Math 7 q3 M 1Document4 pagesLEARNING ACTIVITY Sheet Math 7 q3 M 1Mariel PastoleroNo ratings yet

- Inventory ControlDocument26 pagesInventory ControlhajarawNo ratings yet

- Consumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaDocument16 pagesConsumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaSundaravel ElangovanNo ratings yet

- Oxygen Cost and Energy Expenditure of RunningDocument7 pagesOxygen Cost and Energy Expenditure of Runningnb22714No ratings yet

- IQ CommandDocument6 pagesIQ CommandkuoliusNo ratings yet

- Precision Machine Components: NSK Linear Guides Ball Screws MonocarriersDocument564 pagesPrecision Machine Components: NSK Linear Guides Ball Screws MonocarriersDorian Cristian VatavuNo ratings yet

- 7 Aleksandar VladimirovDocument6 pages7 Aleksandar VladimirovDante FilhoNo ratings yet

- White Box Testing Techniques: Ratna SanyalDocument23 pagesWhite Box Testing Techniques: Ratna SanyalYogesh MundhraNo ratings yet

- AD Chemicals - Freeze-Flash PointDocument4 pagesAD Chemicals - Freeze-Flash Pointyb3yonnayNo ratings yet