Professional Documents

Culture Documents

Pipe Size For Cooling Water System

Uploaded by

nagu108Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Size For Cooling Water System

Uploaded by

nagu108Copyright:

Available Formats

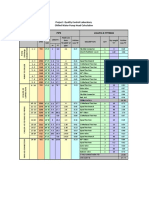

CLIENT : DHARANI SUGARS CHEMICALS LTD.

PROJECT : DISTILLERY IBR/NIBR PIPING

DATE : 31.07.2010

REV : 01

BENDING TOLERANCE OR MARGIN

32000

SA 106 Gr.B

0.08837

168.3 7.11

150

40

40-50 42.127 13.5

949.14 1.5

4.85

6.22

28.27

P01

Main Steam line to Turbine(3MW)

32TPH Boiler

3MW Turbine

380

390

32

44

32000

32000

SA 106 Gr.B

0.08837

219.1 8.18

200

40

40-50 24.332 13.5

949.14 1.5

6.49

7.16

10.35

P01

Main Steam line to Turbine(3MW)

32TPH Boiler

3MW Turbine

380

390

32

44

32000

32000

SA 106 Gr.B

0.08837

168.3 7.11

150

40

40-50 42.127 13.5

949.14 1.5

5.33

6.22

16.72

P01

Main Steam line to Turbine(3MW)

32TPH Boiler

3MW Turbine

380

390

32

44

32000

32000

SA 106 Gr.B

0.08837

33.4

3.68

25

40

40-50 1474.9 13.5

949.14 1.5

2.26

3.22

42.47

P01

Main Steam line to Turbine(3MW)

32TPH Boiler

3MW Turbine

380

390

32

44

32000

32000

SA 106 Gr.B

0.08837

21.3

2.77

15

40

40-50 4026.6 13.5

949.14 1.5

1.98

2.42

22.12

P01A

Main steam line to Atmosphere(Start

up vent).

Tapping from Main

Steam Line

Atmosphere

380

390

10

12

515

515

SA 106 Gr.B

0.29306

60.3

5.54

50

80

20-30 22.034 13.5

949.14 1.5

1.88

4.85

157.95

P01A

Main steam line to Atmosphere(Start

up vent).

Tapping from Main

Steam Line

Atmosphere

380

390

32

44

515

515

SA 106 Gr.B

0.08837

60.3

5.54

50

80

20-30 6.6439 13.5

949.14 1.5

2.87

4.85

68.77

Silencer

380

390

10.8

10667

10667

SA 106 Gr.B

0.297

219.9 6.35

200

20

20-30 26.099 13.5

949.14 1.5

2.75

5.56

102.38

PRDS-3

380

390

32

38.4

32000

32000

SA 106 Gr.B

0.08837

168.3 7.11

150

40

40-50 42.127 13.5

949.14 1.5

4.85

6.22

28.27

5.0ATA Header.

160

170

4.2

5.04

32000

32000

SA 106 Gr.B

0.37841

406.4 7.92

400

20

20-30 28.077 15

1054.6 1.5

2.47

6.93

180.65

PRDS-1

317

327

15

18

16000

16000

SA 106 Gr.B

0.16197

168.3 7.11

150

40

30-40 38.607 15

1054.6 1.5

2.93

6.22

112.58

PRDS-1

317

327

15

18

16000

16000

SA 106 Gr.B

0.16197

33.4

3.38

25

40

30-40 1291.5 15

1054.6 1.5

1.78

2.96

65.86

PRDS-1

317

327

15

18

16000

16000

SA 106 Gr.B

0.16197

21.3

2.77

15

80

30-40 3690.2 15

1054.6 1.5

1.68

2.42

44.22

5.0ATA Header.

160

170

4.2

5.04

17243

17243

SA 106 Gr.B

0.37841

323.9 6.35

300

20

20-30 23.837 15

1054.6 1.5

2.27

5.56

144.51

5.0ATA Header.

160

170

4.2

5.04

17243

17243

IS 3589

0.37841

323.9 5.6

300

5.6Thk. 20-30 23.609 12.8

899.93 1.5

2.40

4.90

103.76

Main Steam from Control valve to

PCV

Silencer(Start up vent).

By-Pass from Main steam line to PRDS- Tapping from Main

3.

Steam Line

Steam from PRDS-3 to 5.0ATA

PRDS-3

header.

22MW 2nd

22MW 2nd Extraction line to PRDS-1.

Extraction

22MW 2nd

22MW 2nd Extraction line to PRDS-1.

Extraction

22MW 2nd

22MW 2nd Extraction line to PRDS-1.

Extraction

Steam from PRDS-1 to 5.0ATA

PRDS-1

header.

Steam from PRDS-1 to 5.0ATA

PRDS-1

header.

3MW Turbine Extraction to DeTurbine Extraction

Superheater.

P01B

P01C

P01D

P02

P02

P02

P02A

P02A

P03

P03

3MW Turbine Extraction to DeSuperheater.

P03A

Steam from 5.0ATA header to Distillery

5.0ATA Header.

Analyser.

MATRIX SOLUTION

BANGALORE

Turbine Extraction

PIPE SIZE IN MM (OD)

DESIGNED

OPERATING

DESIGNED

OPERATING

TO

MINIMUM THICKNESS REQUIRED IN MM

32000

ALLOWABLE STRESS IN KG/CM2

38.4

ALLOWABLE STRESS IN KSI

32

ACTUAL VELOCITY

390

VELOCITY AS PER STANDARD

380

SCHEDULE

3MW Turbine

PIPE THICKNESS AVAILABLE IN MM

MINIMUM THICKNESS AVAILABLE IN MM

CORROSION ALLOWANCE CONSIDERED

PIPE SIZE NB CONSIDERED AS PER PROCESS

(NB)

SPECIFIC VOLUME IN M3/Kg AT OPERATING

CONDITION.

32TPH Boiler

MATERIAL SPECIFICATION

DESIGNED

Main Steam line to Turbine(3MW)

FLOW KG/hr

OPERATING

P01

FROM

LINE NO

SYSTEM DESCRIPTION

SL.NO

PRESSURE KG/Cm2 (g)

TEMPERATURE IN DEG C

PIPE LINE SIZE THICKNESS CALCULATION

De-Superheater.

195

205

4.2

5.04

19000

19000

SA 106 Gr.B

0.41432

355.6 7.92

350

20

20-30 24.119 15

1054.6 1.5

2.35

6.93

195.13

De-Superheater.

195

205

4.2

5.04

19000

19000

IS 3589

0.41432

355.6 8

350

8Thk.

20-30 24.142 12.8

899.93 1.5

2.49

7.00

180.73

Distillery Analyser.

160

170

4.2

5.04

19500

19500

SA 106 Gr.B

0.37841

355.6 7.92

350

20

20-30 22.608 15

1054.6 1.5

2.35

6.93

195.13

CLIENT : DHARANI SUGARS CHEMICALS LTD.

PROJECT : DISTILLERY IBR/NIBR PIPING

Steam from 5.0ATA header to Distillery

5.0ATA Header.

Analyser.

P03A

10

Steam from Down-stream of Turbine

P03B Extraction De-Super heater to 5.0ATA

header.

10

Steam from Down-stream of Turbine

P03B Extraction De-Super heater to 5.0ATA

header.

11

P04

11

DATE : 31.07.2010

REV : 01

PIPE LINE SIZE THICKNESS CALCULATION

Distillery Analyser.

160

170

4.2

5.04

19500

19500

IS 3589

0.37841

355.6 8

350

8Thk.

20-30 22.629 12.8

899.93 1.5

2.49

7.00

180.73

Down-Stream of

Turbine Extraction

De-superheater.

5.0 ATA header.

160

170

4.2

5.04

20500

20500

SA 106 Gr.B

0.37841

355.6 7.92

350

20

20-30 23.768 15

1054.6 1.5

2.35

6.93

195.13

Down-Stream of

Turbine Extraction

De-superheater.

5.0 ATA header.

160

170

4.2

5.04

20500

20500

IS 3589

0.37841

355.6 8

350

8Thk.

20-30 23.79

12.8

899.93 1.5

2.49

7.00

180.73

3mw Turbine Exhaust to DeSuperheater.

Turbine Exhaust.

De-Superheater.

153

163

1.6

1.92

13000

13000

SA 106 Gr.B

0.76006

406.4 7.92

400

20

20-30 22.91

15

1054.6 1.5

1.87

6.93

270.65

P04

3mw Turbine Exhaust to DeSuperheater.

Turbine Exhaust.

De-Superheater.

153

163

1.6

1.92

13000

13000

SA 106 Gr.B

0.76006

406.4 8.8

400

8.8Thk. 20-30 23.118 12.8

899.93 1.5

1.93

7.70

298.31

12

P04A

Steam from 2.5ATA Header to

Distillery Evaporator.

2.5ATA Header.

Distillery Evaporator

130

140

1.6

1.92

13500

13500

SA 106 Gr.B

0.71423

406.4 7.92

400

20

1054.6 1.5

1.87

6.93

270.65

12

P04A

Steam from 2.5ATA Header to

Distillery Evaporator.

2.5ATA Header.

Distillery Evaporator

130

140

1.6

1.92

13500

13500

SA 106 Gr.B

0.71423

406.4 8.8

400

8.8Thk. 20-30 22.559 12.8

899.93 1.5

1.93

7.70

298.31

13

P04B

Steam from turbine exhaust to

atmosphere.

Turbine Exhaust.

Valve

153

163

1.6

1.92

4333

4333

SA 106 Gr.B

0.76006

219.1 6.35

200

20

20-30 27.344 15

1054.6 1.5

1.70

5.56

226.97

14

P04C

Valve

Atmosphere

153

163

1.2

4333

4333

SA 106 Gr.B

1.278

219.1 6.35

200

20

20-30 45.974 15

1054.6 1.5

1.62

5.56

242.01

15

P04D

16

P04E

16

P04E

17

P04F

18

P04G

19

P04H

20

P04J

21

P04K

22

22

23

P04L

P04L

P04M

Steam from turbine exhaust to

atmosphere.

Steam From 5.0ATA Header to PRDS2.

Steam from PRDS-2 TO 2.5ATA

Header.

Steam from PRDS-2 TO 2.5ATA

Header.

Spray water to PRDS-1 De-Super

heater.

Spray water to PRDS-2 De-Super

heater.

Spray water to PRDS-3 De-Super

heater.

Spray water to Turbine Ext. De-Super

heater.

Spray water to Turbine EHS De-Super

heater.

Steam from Down-stream of Turbine

Exhaust De-Super heater to 2.5ATA

header.

20-30 22.357 15

5.0ATA Header.

PRDS-2

160

170

4.2

5.04

8243

8243

SA 106 Gr.B

0.37841

219.1 6.35

200

20

20-30 25.899 15

1054.6 1.5

2.02

5.56

174.72

PRDS-2

2.5ATA Header.

130

140

1.6

1.92

8500

8500

SA 106 Gr.B

0.71423

323.9 6.35

300

20

20-30 22.178 15

1054.6 1.5

1.79

5.56

209.61

PRDS-2

2.5ATA Header.

130

140

1.6

1.92

8500

8500

IS 3589

0.71423

323.9 5.6

300

5.6Thk. 20-30 21.966 12.8

899.93 1.5

1.85

4.90

165.56

Booster Pump

PRDS-1

80

90

18

21.6

2244

2244

SA 312TP304

0.001

48.26 2.77

40

10S

1.5-2

0.4349 17.86

1255.7 1

1.41

2.42

71.62

Booster Pump

PRDS-2

80

90

18

21.6

380

380

SA 312TP304

0.001

48.26 2.77

40

10S

1.5-2

0.0736 17.86

1255.7 1

1.41

2.42

71.62

BFP Discharge.

PRDS-3

150

160

32

38.4

6500

6500

SA 106 Gr.B

0.0011

48.26 5.08

40

80

1.5-3

1.7422 15

1054.6 2

2.87

4.45

55.09

80

90

18

21.6

2244

2244

SA 312TP304

0.001

48.26 2.77

40

10S

1.5-3

0.4349 17.86

1255.7 1

1.41

2.42

71.62

80

90

18

21.6

380

380

SA 312TP304

0.001

48.26 2.77

40

10S

1.5-3

0.0736 17.86

1255.7 1

1.41

2.42

71.62

20-30 22.357 15

1054.6 1.5

1.87

6.93

270.65

Booster Pump

Booster Pump

Turbine Ext. DeSuper heater.

Turbine EHS DeSuper heater.

Down-Stream of

Turbine Exhaust.

2.5ATA Header.

80

90

1.6

1.92

13500

13500

SA 106 Gr.B

0.71423

406.4 7.92

400

20

Steam from Down-stream of Turbine

Exhaust De-Super heater to 2.5ATA

header.

Down-Stream of

Turbine Exhaust.

2.5ATA Header.

130

140

1.6

1.92

13500

13500

SA 106 Gr.B

0.71423

406.4 8.8

400

8.8Thk. 20-30 22.559 12.8

899.93 1.5

1.93

7.70

298.31

3MW DM water storage tank to

Desuper heating spraying system.

3MW DM water

storage tank spray

water pump

discharge.

De-superheating

station.

80

90

18

21.6

8000

8000

SA 312TP304

0.001

60.3

50

10S

1255.7 1

1.52

2.42

59.97

MATRIX SOLUTION

BANGALORE

2.77

1-2

0.9436 17.86

PIPE LINE SIZE THICKNESS CALCULATION

REMARKS

CLIENT : DHARANI SUGARS CHEMICALS LTD.

PROJECT : DISTILLERY IBR/NIBR PIPING

OK. Pending till

stress analysis.

OK. Pending till

stress analysis.

OK. Pending till

stress analysis.

OK. Pending till

stress analysis.

OK. Pending till

stress analysis.

OK

OK

Deleted.

For Future

Provision.

For Future

Provision.

OK

OK

OK

OK

OK

OK

OK

OK, For 300Nb

26m/sec. as per

commitment 350

NB.

MATRIX SOLUTION

BANGALORE

DATE : 31.07.2010

REV : 01

CLIENT : DHARANI SUGARS CHEMICALS LTD.

PROJECT : DISTILLERY IBR/NIBR PIPING

PIPE LINE SIZE THICKNESS CALCULATION

OK, For 300Nb

26m/sec. as per

commitment 350

NB.

OK, For 300Nb

28m/sec. as per

commitment 350

NB.

OK, For 300Nb

28m/sec. as per

commitment 350

NB.

OK, For 350Nb

30m/sec. but as

per commitment

400 NB.

OK, For 350Nb

30m/sec. but as

per commitment

400 NB.

OK, For 350Nb

28m/sec. but as

per commitment

400 NB.

OK, For 350Nb

28m/sec. but as

per commitment

400 NB.

OK

OK, For 350NB vel

is 25m/sec.

OK

OK

OK

OK

OK

For Future

Provision.

OK

OK

OK

OK

OK

MATRIX SOLUTION

BANGALORE

DATE : 31.07.2010

REV : 01

OPERATING

DESIGNED

OPERATING

DESIGNED

MATERIAL SPECIFICATION

SPECIFIC VOLUME IN M3/Kg AT

OPERATING CONDITION

PIPE SIZE IN MM (OD)

PIPE THICKNESS AVAILABLE IN

MM

THICKNESS

VELOCITY AS PER STANDARD

ACTUAL VELOCITY

ALLOWABLE STRESS IN KSI

ALLOWABLE STRESS IN KG/CM2

AS PER IBR ASME B 31.1.

CORROSION ALLOWANCE

CONSIDERED

MINIMUM THICKNESS REQUIRED

IN MM

MINIMUM THICKNESS AVAILABLE

IN MM

BENDING TOLERANCE OR MARGIN

REMARKS

31

41

1.2

2700000

2700000

SA 53 Gr.B

0.00100472

914

7.92

900

SCH 10

<1

1.2

15.0

1054.6

2.52

7.13

182.88

VELOCITY IS MORE

P02

MAIN CW PUMP DISCHARGE

31

41

2.4

2700000

2700000

SA 53 Gr.B

0.00100472

762

7.92

750

SCH 10

1.5-2.0

1.7

15.0

1054.6

2.87

7.13

148.69

OK

P03

CW MAIN SUPPLY HEADER

31

41

2.4

2700000

2700000

SA 53 Gr.B

0.00100472

762

7.92

750

SCH 10

1.5-2.0

1.7

15.0

1054.6

2.87

7.13

148.69

OK

P04

CONDENSER INLET

31

41

2.4

1475000

1475000

SA 53 Gr.B

0.00100472

457

6.35

450

SCH 10

1.5-2.0

2.7

15.0

1054.6

2.52

5.72

126.83

MORE

P05

CONDENSER OUTLET

41

51

1.5

1.8

1475000

1475000

SA 53 Gr.B

0.00100828

457

6.35

450

SCH 10

1.5-2.0

2.7

15.0

1054.6

2.39

5.72

139.15

MORE

P06

CW RETURN HEADER

41

51

1.5

1.8

3075000

3075000

SA 53 Gr.B

0.00100828

813

7.92

650

SCH 10

1.5-2.0

1.7

15.0

1054.6

2.69

7.13

164.65

MORE

P07

CW RETURN HEADER-1

41

51

1.5

1.8

1350000

1350000

SA 53 Gr.B

0.00100828

559

6.35

200

SCH 20

1.5-2.0

1.6

15.0

1054.6

2.48

5.72

130.75

OK

P08

CT INLET

41

51

1.5

1.8

225000

225000

SA 53 Gr.B

0.00100828

219.1

6.35

200

SCH 20

1.5-2.0

1.9

15.0

1054.6

2.19

5.72

161.33

OK

P09

AUX. CW PUMP SUCTION.

31

41

1.2

125000

125000

SA 53 Gr.B

0.00100472

219.1

6.35

200

SCH 10

<1

1.0

15.0

1054.6

2.12

5.72

168.99

VELOCITY IS MORE

10

P10

AUX. CW PUMP DISCHARGE

31

41

6.5

7.8

125000

125000

SA 53 Gr.B

0.00100472

168.3

7.11

150

SCH 40

1.5-2.0

1.9

15.0

1054.6

2.62

6.40

144.19

OK

11

P11

AUX. CW SUPPLY HEADER

31

41

6.5

7.8

125000

125000

SA 53 Gr.B

0.00100472

168.3

7.11

150

SCH 40

1.5-2.0

1.9

15.0

1054.6

2.62

6.40

144.19

OK

12

P12

ALTERNATER INLET

31

41

6.5

7.8

68400

68400

SA 53 Gr.B

0.00100472

168.3

7.11

150

SCH 40

1.0-1.5

1.0

15.0

1054.6

2.62

6.40

144.19

OK

13

P13

OIL COOLER INLET

31

41

6.5

7.8

35000

35000

SA 53 Gr.B

0.00100472

114.3

6.02

100

SCH 40

1.0-1.5

1.2

15.0

1054.6

2.42

5.42

123.75

OK

14

P14

SAMPLE COOLER INLET

31

41

6.5

7.8

10000

10000

SA 53 Gr.B

0.00100472

60.3

3.91

40

SCH 40

1.0-1.5

1.3

15.0

1054.6

2.22

3.52

58.35

OK

15

P15

BOILER INLET

31

41

6.5

7.8

11600

11600

SA 53 Gr.B

0.00100472

60.3

3.91

40

SCH 40

1.2-2.0

1.5

15.0

1054.6

2.22

3.52

58.35

OK

16

P16

ALTERNATER OUTLET

31

41

6.5

7.8

68400

68400

SA 53 Gr.B

0.00100472

168.3

7.11

150

SCH 40

1.0-1.5

1.0

15.0

1054.6

2.62

6.40

144.19

OK

17

P17

OIL COOLER OUTLET

31

41

6.5

7.8

35000

35000

SA 53 Gr.B

0.00100472

114.3

6.02

100

SCH 40

1.0-1.5

1.2

15.0

1054.6

2.42

5.42

123.75

OK

18

P18

SAMPLE COOLER OUTLET

31

41

6.5

7.8

10000

10000

SA 53 Gr.B

0.00100472

60.3

3.91

40

SCH 40

1.0-1.5

1.3

15.0

1054.6

2.22

3.52

58.35

OK

19

P19

BOILER OUTLET

41

51

1.5

1.8

11600

11600

SA 53 Gr.B

0.00100828

60.3

3.91

40

SCH 40

1.2-2.0

1.5

15.0

1054.6

2.05

3.52

71.54

OK

PRESSURE

KG/Cm2 (g)

PIPE SIZE NB CONSIDERED AS

PER PROCESS (NB)

DESIGNED

MAIN CW PUMP SUCTION

FLOW KG/hr

OPERATING

P01

TEMPERATURE

IN DEG C

LINE NO.

SYSTEM DESCRIPTION

SL.NO

PIPE LINE SIZE AND THICKNESS CALCULATIONS FOR COOLING WATER

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Steam Pipe SizingDocument16 pagesSteam Pipe SizingsamvendanNo ratings yet

- Air Receiver SizingDocument3 pagesAir Receiver Sizingmazumdar_satyajit100% (2)

- 3) Sme & Makeup Air CalculationDocument33 pages3) Sme & Makeup Air CalculationAshiq NishmaNo ratings yet

- Air Receiver SizingDocument3 pagesAir Receiver Sizinglutfi awnNo ratings yet

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraNo ratings yet

- Instrument Air Dryer Sizing CalculationDocument1 pageInstrument Air Dryer Sizing CalculationAravind Kannan100% (2)

- AHU Duct Connection Calculation SheetDocument14 pagesAHU Duct Connection Calculation SheetAdnan Attish100% (1)

- Fgas Refrigerant CalculatorDocument10 pagesFgas Refrigerant CalculatorKumar sssssNo ratings yet

- NFPA Pipe Sizing EXAMPLEDocument4 pagesNFPA Pipe Sizing EXAMPLEMatt AndersonNo ratings yet

- Hot Water System Sizing CalculationDocument1 pageHot Water System Sizing CalculationPhyu Mar Thein KyawNo ratings yet

- Hazen Williams EquationDocument1 pageHazen Williams EquationNur IzzaidahNo ratings yet

- Air Receiver SizingDocument4 pagesAir Receiver SizingAnonymous a4Jwz14WNo ratings yet

- Line SizingDocument2 pagesLine SizingHarryBouterNo ratings yet

- Chiller Size CalculatorDocument4 pagesChiller Size CalculatormpokeNo ratings yet

- Rosemount 1495 Orifice Plate, 1496 Flange Union, 1497 Meter SectionDocument24 pagesRosemount 1495 Orifice Plate, 1496 Flange Union, 1497 Meter SectionJames ThomasNo ratings yet

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Document1 pageTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456No ratings yet

- Pump and Line Calculation SheetDocument7 pagesPump and Line Calculation SheetNghiaNo ratings yet

- Fire Relief Dynamic StudyDocument2 pagesFire Relief Dynamic StudyImtinan MohsinNo ratings yet

- Calculation of Scrubber DiameterDocument44 pagesCalculation of Scrubber DiameterRamakrishna SomuNo ratings yet

- Heat Loss Insulated PipeDocument1 pageHeat Loss Insulated Pipeprateek_bhoirNo ratings yet

- Water Pressure Loss Calculator Colebrook WhiteDocument5 pagesWater Pressure Loss Calculator Colebrook Whitebahus911No ratings yet

- Control Valve SizingDocument3 pagesControl Valve SizingN. S. PanditNo ratings yet

- Expansion Tank Capacity Calculation SheetDocument5 pagesExpansion Tank Capacity Calculation SheetDEX TERRNo ratings yet

- Batch Time Calculation For Isothermal Cooling in Internal Coil Vessel With AgitationDocument2 pagesBatch Time Calculation For Isothermal Cooling in Internal Coil Vessel With Agitationdhavalesh1100% (1)

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- Insulation ThicknessDocument2 pagesInsulation ThicknessShashi Kant KumarNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingWade ColemanNo ratings yet

- Nozzle Line Vavle EstimatorDocument10 pagesNozzle Line Vavle EstimatorMichael HaiseNo ratings yet

- 325 - Sparger DesignDocument3 pages325 - Sparger DesignInggit Prillasari100% (1)

- Calculation For Restriction OrificeDocument4 pagesCalculation For Restriction OrificeAshish PawarNo ratings yet

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNo ratings yet

- Ducts Pressure Losses Board: Carpark Souq Waqif Ahu - A Basement-1Document2 pagesDucts Pressure Losses Board: Carpark Souq Waqif Ahu - A Basement-1Karthy GanesanNo ratings yet

- Orifice Plate CalculationDocument3 pagesOrifice Plate Calculationnixsol75No ratings yet

- Steam CalculationDocument27 pagesSteam CalculationRAVI KUMAR CarpenterNo ratings yet

- Chilled Water Pump Head CalculationDocument18 pagesChilled Water Pump Head CalculationPeshoMagdyNo ratings yet

- Heat Load EstimationDocument5 pagesHeat Load EstimationSultan FirassuddinNo ratings yet

- Technical Data Pressure Drop Calculations: Case 1 Case 2Document1 pageTechnical Data Pressure Drop Calculations: Case 1 Case 2AJNo ratings yet

- Shop Drawing: Welcome Air-Tech (M) SDN BHDDocument1 pageShop Drawing: Welcome Air-Tech (M) SDN BHDKarthi KeyanNo ratings yet

- Agitator SizingDocument4 pagesAgitator SizingArbee AquinoNo ratings yet

- Sizing Duct Work SheetDocument4 pagesSizing Duct Work SheetMaulana MaftuhiNo ratings yet

- Hydraulic Calculation For Pipeline PumpsDocument12 pagesHydraulic Calculation For Pipeline PumpsDEEPAK PAL100% (1)

- Air Receivers Volume CalculationDocument123 pagesAir Receivers Volume CalculationsdgthdtrtretNo ratings yet

- Equipment Selection & Design - 2Document5 pagesEquipment Selection & Design - 2Nabeel SiddiqueNo ratings yet

- Blow Off Pipe SizingDocument13 pagesBlow Off Pipe Sizinggopaltry100% (1)

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- Electrcial Room Ventilation System Calculation: X 1.005 X 5 Airflow (m3/hr)Document2 pagesElectrcial Room Ventilation System Calculation: X 1.005 X 5 Airflow (m3/hr)psjjoshiNo ratings yet

- Fgas Refrigerant CalculatorDocument12 pagesFgas Refrigerant CalculatorKhadija MirajNo ratings yet

- Duct SizingDocument2 pagesDuct SizingJoseagushNo ratings yet

- Calculation of Air Pipe SizeDocument6 pagesCalculation of Air Pipe SizePhyu Mar Thein Kyaw100% (1)

- Air Receiver Sizing Metric UnitsDocument4 pagesAir Receiver Sizing Metric UnitsAnonymous Od7nYs8No ratings yet

- Expansion Tank SizingDocument1 pageExpansion Tank Sizinghaysam0% (2)

- All Ventilation & Press.. CalculationDocument57 pagesAll Ventilation & Press.. CalculationRaju KsnNo ratings yet

- Air Receiver Sizing CalculationDocument1 pageAir Receiver Sizing CalculationAziz HaqueNo ratings yet

- Hot Water Circulation Pump Capacity CalculationDocument2 pagesHot Water Circulation Pump Capacity CalculationKarthy GanesanNo ratings yet

- Ligne O.D THK Quantity Ub Qty Groove Preheating Visual SpectrumDocument10 pagesLigne O.D THK Quantity Ub Qty Groove Preheating Visual SpectrumAsan IbrahimNo ratings yet

- Tarif Pieces Detachees 2017 Grundfos FranceDocument762 pagesTarif Pieces Detachees 2017 Grundfos FrancekiyogxNo ratings yet

- All in Spec EquipmentDocument78 pagesAll in Spec EquipmentJayus WibowoNo ratings yet

- Pipe Specification Doniambo: Max MaxDocument3 pagesPipe Specification Doniambo: Max MaxHMMSPNo ratings yet

- Process Flow DiagramDocument1 pageProcess Flow DiagramRobie RoqueNo ratings yet

- Villages of Block District Tikamgarh, M.P.': Prathvipur, For Ultimate Capacity of Bringing 15.70 HoursDocument4 pagesVillages of Block District Tikamgarh, M.P.': Prathvipur, For Ultimate Capacity of Bringing 15.70 HoursAditya SuranaNo ratings yet

- Thermowells in LNG Carrier Liquid LinesDocument4 pagesThermowells in LNG Carrier Liquid LinesFernando Igor AlvarezNo ratings yet

- PackoDocument30 pagesPackoikuzma_1No ratings yet

- Gravity Distribution Systems: A System Design and ConstructionDocument40 pagesGravity Distribution Systems: A System Design and ConstructionTooma DavidNo ratings yet

- Valve PDFDocument20 pagesValve PDFRamalingam Prabhakaran100% (1)

- Piping Class - GS70Document1 pagePiping Class - GS70Dmitriy RybakovNo ratings yet

- Service Manual Toshiba Estia 3rd GEN enDocument212 pagesService Manual Toshiba Estia 3rd GEN enALFONSO BARROETANo ratings yet

- NTRP - 4-04.2.3 Signed Oct 21Document280 pagesNTRP - 4-04.2.3 Signed Oct 21Aiden ShoreNo ratings yet

- Diamond Walraven Product Catalog PDFDocument218 pagesDiamond Walraven Product Catalog PDFKABIR CHOPRANo ratings yet

- Technical Specifications of Tubewell WorksDocument13 pagesTechnical Specifications of Tubewell WorksLeng Chai100% (1)

- Water Cooled ChillerDocument106 pagesWater Cooled ChillerErwin100% (4)

- P0050S MGPSDocument21 pagesP0050S MGPSDmytro 1No ratings yet

- Water Volume Calculations in SystemsDocument8 pagesWater Volume Calculations in SystemsSaahil KhaanNo ratings yet

- Lfgproducts Brochure WebDocument10 pagesLfgproducts Brochure WebAldo Germán Pavez MoraNo ratings yet

- 514Document8 pages514hubert_veltenNo ratings yet

- Applicable Codes and StandardsDocument48 pagesApplicable Codes and Standardskiki270977No ratings yet

- Aquion Prosystems POU ManualDocument12 pagesAquion Prosystems POU ManualGreg ReynekeNo ratings yet

- Piping Design CriteriaDocument15 pagesPiping Design CriteriaSubash Chandrabose0% (1)

- Catalogo, Embraco, LG, Samsung, Panasonic, Secop, Hitachi, GMCC, Bitzer, CopelandDocument56 pagesCatalogo, Embraco, LG, Samsung, Panasonic, Secop, Hitachi, GMCC, Bitzer, CopelandFran GarsosNo ratings yet

- Api 653 Report-Hydrolic Test PDFDocument12 pagesApi 653 Report-Hydrolic Test PDFnaoufel1706No ratings yet

- Painting Specification For Storage Tanks.Document27 pagesPainting Specification For Storage Tanks.Akshat Jain80% (5)

- AREMA Volume 1, Chapter 1, Part 4, Section 4.8 HDPE PDFDocument20 pagesAREMA Volume 1, Chapter 1, Part 4, Section 4.8 HDPE PDFpquiroga2100% (2)

- Project Standard Specification: Drainage and Vent Piping 15420 - Page 1/8Document8 pagesProject Standard Specification: Drainage and Vent Piping 15420 - Page 1/8adel rihanaNo ratings yet

- x80 Line Pipe For Large Diameter High Strength PipelineDocument15 pagesx80 Line Pipe For Large Diameter High Strength PipelineAnonymous AlhzFE9EVNNo ratings yet

- (-III) (-III) : Page 1 of 9Document9 pages(-III) (-III) : Page 1 of 9VINEET KUMARNo ratings yet

- REEDDocument8 pagesREEDWilliam EvansNo ratings yet

- Daftar Kebutuhan Material Untuk Pengeboran 77 SumurDocument6 pagesDaftar Kebutuhan Material Untuk Pengeboran 77 SumurPT. EbanNo ratings yet

- Varian GC 450 Pre Installation Requirements English PDFDocument14 pagesVarian GC 450 Pre Installation Requirements English PDFmardonioandrade0% (1)

- Gis 06-401Document14 pagesGis 06-401EslamSheblNo ratings yet

- Pipeline Tech JournalDocument72 pagesPipeline Tech JournalcindydianitaNo ratings yet