Professional Documents

Culture Documents

Connections I V2.0.6b Final

Uploaded by

Nick AndrewsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Connections I V2.0.6b Final

Uploaded by

Nick AndrewsCopyright:

Available Formats

This workbook comes "as is" with no implied warranties or express guarantees.

The user assumes all This workbook comes "as is" with no implied warranties or express guarantees. The user assumes al responsiblity for the use of this workbook, modifications and output. The User further agrees to verify th responsiblity for the use of this workbook, modifications and output. The User further agrees to verify accuracy of all output and to satisfy themselves that the results meet or exceed their expectation of acc accuracy of all output and to satisfy themselves that the results meet or exceed their expectation of ac and performance. and performance.

This workbook is not intended to be used by non-professionals. The user is expected to have the basic This workbook is not intended to be used by non-professionals. The user is expected to have the bas knowledge and skills necessary to verify the accuracy of the output and to interpret the codes and princ knowledge and skills necessary to verify the accuracy of the output and to interpret the codes and prin the science that the spreadsheets interpret. the science that the spreadsheets interpret.

This spreadsheet is based on interpretation of the design methodology. As much as the author has trie This spreadsheet is based on interpretation of the design methodology. As much as the author has tri achieve an accurate product, the codes rely upon interpretation as well as decisions drawn from engine achieve an accurate product, the codes rely upon interpretation as well as decisions drawn from engin judgment. There are no guarantees or express warranties implied in the use or output of these program judgment. There are no guarantees or express warranties implied in the use or output of these progra assures accuracy other than the efforts of the programers intent to achieve perfection. assures accuracy other than the efforts of the programers intent to achieve perfection.

The user agrees to hold harmless all persons and companies involved in the creation of the software a The user agrees to hold harmless all persons and companies involved in the creation of the software people involved in the distribution of any and all freeware and shareware available on this site or by link people involved in the distribution of any and all freeware and shareware available on this site or by li another site. THE DOWNLOAD AND/OR USE OF THE SOFTWARE IS AN IMPLIED ACCEPTANCE O another site. THE DOWNLOAD AND/OR USE OF THE SOFTWARE IS AN IMPLIED ACCEPTANCE THESE TERMS AND CONDITIONS. THESE TERMS AND CONDITIONS.

This spreadsheet is free software; you can redistribute it under the terms of the GNU General Public L This spreadsheet is free software; you can redistribute it under the terms of the GNU General Public as published by the Free Software Foundation; either version 2 of the License, or any later version. as published by the Free Software Foundation; either version 2 of the License, or any later version.

This program is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY; without This program is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY; withou implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the GNU implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the GN General Public License for more details. General Public License for more details.

You should have received a copy of the GNU General Public License along with this program; if not, w You should have received a copy of the GNU General Public License along with this program; if not, w the Free Software Foundation, Inc., 59 Temple Place, Suite 330, Boston, MA 02111-1307 USA the Free Software Foundation, Inc., 59 Temple Place, Suite 330, Boston, MA 02111-1307 USA

s. The user assumes all ees. The user assumes all further agrees to verify the er further agrees to verify the ed their expectation of accuracy eed their expectation of accuracy

xpected to have the basic expected to have the basic erpret the codes and principles of nterpret the codes and principles of

uch as the author has tried to much as the author has tried to cisions drawn from engineering ecisions drawn from engineering or output of these programs that or output of these programs that erfection. perfection.

creation of the software and all e creation of the software and all lable on this site or by link to ailable on this site or by link to MPLIED ACCEPTANCE OF MPLIED ACCEPTANCE OF

he GNU General Public License the GNU General Public License e, or any later version. se, or any later version.

NY WARRANTY; without even the ANY WARRANTY; without even the PURPOSE. See the GNU PURPOSE. See the GNU

with this program; if not, write to with this program; if not, write to 02111-1307 USA A 02111-1307 USA

This Workbook does not take the place of the AISC Manual of Steel Construct If you are going to use this workbook, BUY THE MANUAL. Every user of this workbook should use the latest Manual of Steel Construction examples to verify that the user understands the input and output of the spreadsheets.

This workbook requires proper installation of the file AISC_SEARCH.DLL available from the Americ This workbook requires proper installation of the file AISC_SEARCH.DLL available from the Amer Institute of Steel Construction. An automated installation program that copies and registers the nee Institute of Steel Construction. An automated installation program that copies and registers the ne dll's is available from AISC. dll's is available from AISC.

To use this workbook, open the Connections I.PDF file and determine the connection type to be ana To use this workbook, open the Connections I.PDF file and determine the connection type to be an Then click on the appropriate tab at the bottom of the screen that with the same tab noted in the Then click on the appropriate tab at the bottom of the screen that with the same tab noted in the Connections I.PDF. Enter data in the shaded cells in the format as noted. Each individual spreadshe Connections I.PDF. Enter data in the shaded cells in the format as noted. Each individual spreads determine if the connection is adequate for the applied load. For connections that are not adequate determine if the connection is adequate for the applied load. For connections that are not adequat error will be noted along with a brief explanation as to what needs to be changed. Other errors such error will be noted along with a brief explanation as to what needs to be changed. Other errors suc using the correct number of bolts are assumed to be intuitive (i.e., increase the number of bolts). using the correct number of bolts are assumed to be intuitive (i.e., increase the number of bolts).

Each spreadsheet is set to print the results to your default printer. Just click the print icon on the me Each spreadsheet is set to print the results to your default printer. Just click the print icon on the m

To report coding errors:

Bolt Lengths are calculated in accordance with the 1996 AISC Engineering Journal paper Specifyi Bolt Lengths are calculated in accordance with the 1996 AISC Engineering Journal paper Specify Length for High-Strength Bolts by Charlie Carter. All calculated lengths are rounded up to the next Length for High-Strength Bolts by Charlie Carter. All calculated lengths are rounded up to the nex highest 1/4 inch increment. highest 1/4 inch increment.

al of Steel Construction. HE MANUAL. Manual of Steel nderstands the ts.

available from the American L available from the American pies and registers the needed opies and registers the needed

connection type to be analyzed. e connection type to be analyzed. same tab noted in the e same tab noted in the Each individual spreadsheet will . Each individual spreadsheet will ons that are not adequate, some ions that are not adequate, some hanged. Other errors such as not changed. Other errors such as not e the number of bolts). se the number of bolts).

k the print icon on the menu bar. ick the print icon on the menu bar.

ng Journal paper Specifying Bolt ing Journal paper Specifying Bolt re rounded up to the next are rounded up to the next

AISC_SEARCH.DLL

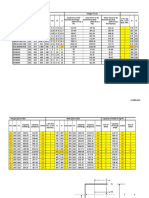

Enter Test Section H Type Beam Angle HSS AISC Std Nomenclature W18x35 L4x3-1/2x1/4 HSS8x8x1/4 EDI Nomenclature W18x35 L4x3-1/2x1/4 HSS8x8x.250

AISC V14.1 Shapes Database V14.1 Column Names EDI_STD_NOMENCLATURE AISC_MANUAL_LABEL Type T_F W A D ddet Ht h1 OD bf bfdet B b1 ID tw twdet twdet/2 tf tfdet t tnom tdes kdes kdet k1 x y eo xp yp bf/2tf B/t B\tdes h/tw Ht/tdes D/t Ix Zx Sx rx

Iy Zy Sy ry Iz rz Sz J Cw C Wno Sw1 Sw2 Sw3 Qf Qw ro H tab_alpha Qs Iw Za Zb Zc Wa Wb Wc Swa Swb Swc Sza Szb Szc rts ho Pa Pb

AISC_SEARCH.DLL Enter Test Section Here: HSS14x14x.500 In EDI form

ISC V14.1 Shapes Database Foxpro Table name EDI_STD #VALUE! AISC_MAN #VALUE! #VALUE! Type #VALUE! T_F #VALUE! W #VALUE! A #VALUE! D #VALUE! DDET #VALUE! HT #VALUE! H1 #VALUE! OD #VALUE! BF #VALUE! BFDET #VALUE! B #VALUE! B1 #VALUE! ID #VALUE! TW #VALUE! TWDET #VALUE! TWDET_2 #VALUE! TF #VALUE! TFDET #VALUE! T #VALUE! TNOM #VALUE! TDES #VALUE! KDES #VALUE! KDET #VALUE! K1 #VALUE! X #VALUE! Y #VALUE! EO #VALUE! XP #VALUE! YP #VALUE! BF_2TF #VALUE! B_T #VALUE! B_TDES #VALUE! H_TW #VALUE! HT_TDES #VALUE! D_T #VALUE! IX #VALUE! ZX #VALUE! SX #VALUE! RX

The The Foxpro Table Name must be used used for for the the section section lookup. lookup.

IY ZY SY RY IZ RZ SZ J CW C WNO SW1 SW2 SW3 QF QW RO H TAN_ALPHA QS IW ZA ZB ZC WA WB WC SWA SWB SWC SZA SZB SZC rts ho PA PB

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Design

ASD LRFD

WF

Bolts

3/4 7/8 1 1 1/8 1 1/4 STD SSLT 3/16 1/4 5/16 3/8 7/16 1/2 5/8

Holes

Plate

2 1/2 3 3 1/2 B C

BorC

ForW F W

Setback

1/4 3/8 1/2 5/8 3/4 7/8 1 0

Shelf

W44X335 W44X290 W44X262 W44X230 W40X593 W40X503 W40X431 W40X397 W40X372 W40X362 W40X324 W40X297 W40X277 W40X249 W40X215 W40X199 W40X392 W40X331 W40X327 W40X294 W40X278 W40X264 W40X235 W40X211 W40X183 W40X167 W40X149 W36X800 W36X652 W36X529 W36X487 W36X441 W36X395 W36X361 W36X330 W36X302 W36X282 W36X262 W36X247 W36X231 W36X256 W36X232 W36X210 W36X194 W36X182 W36X170 W36X160 W36X150

WT

WT22X167.5 WT22X145 WT22X131 WT22X115 WT20X296.5 WT20X251.5 WT20X215.5 WT20X198.5 WT20X186 WT20X181 WT20X162 WT20X148.5 WT20X138.5 WT20X124.5 WT20X107.5 WT20X99.5 WT20X196 WT20X165.5 WT20X163.5 WT20X147 WT20X139 WT20X132 WT20X117.5 WT20X105.5 WT20X91.5 WT20X83.5 WT20X74.5 WT18X400 WT18X326 WT18X264.5 WT18X243.5 WT18X220.5 WT18X197.5 WT18X180.5 WT18X165 WT18X151 WT18X141 WT18X131 WT18X123.5 WT18X115.5 WT18X128 WT18X116 WT18X105 WT18X97 WT18X91 WT18X85 WT18X80 WT18X75

HSS

HSS20X12X5/8 HSS20X12X1/2 HSS20X12X3/8 HSS20X12X5/16 HSS20X8X5/8 HSS20X8X1/2 HSS20X8X3/8 HSS20X8X5/16 HSS20X4X1/2 HSS20X4X3/8 HSS20X4X5/16 HSS20X4X1/4 HSS18X6X5/8 HSS18X6X1/2 HSS18X6X3/8 HSS18X6X5/16 HSS18X6X1/4 HSS16X16X5/8 HSS16X16X1/2 HSS16X16X3/8 HSS16X16X5/16 HSS16X12X5/8 HSS16X12X1/2 HSS16X12X3/8 HSS16X12X5/16 HSS16X8X5/8 HSS16X8X1/2 HSS16X8X3/8 HSS16X8X5/16 HSS16X8X1/4 HSS16X4X5/8 HSS16X4X1/2 HSS16X4X3/8 HSS16X4X5/16 HSS16X4X1/4 HSS16X4X3/16 HSS14X14X5/8 HSS14X14X1/2 HSS14X14X3/8 HSS14X14X5/16 HSS14X10X5/8 HSS14X10X1/2 HSS14X10X3/8 HSS14X10X5/16 HSS14X10X1/4 HSS14X6X5/8 HSS14X6X1/2 HSS14X6X3/8

1/4 3/8 1/2 5/8 3/4 7/8

No_Bolts

2 3 4 5 6 7 8 9 10 11 12 Unstiffened Stiffened 2 3

End

Boltsrow

ForB

B F 1 2

Boltcol

NorX

N X A325 A490 Yes No STD SSLT LSLT

Bolttype

YesorNo

Holes1

W36X135 W33X387 W33X354 W33X318 W33X291 W33X263 W33X241 W33X221 W33X201 W33X169 W33X152 W33X141 W33X130 W33X118 W30X391 W30X357 W30X326 W30X292 W30X261 W30X235 W30X211 W30X191 W30X173 W30X148 W30X132 W30X124 W30X116 W30X108 W30X99 W30X90 W27X539 W27X368 W27X336 W27X307 W27X281 W27X258 W27X235 W27X217 W27X194 W27X178 W27X161 W27X146 W27X129 W27X114 W27X102 W27X94 W27X84 W24X370 W24X335 W24X306

WT18X67.5 WT16.5X193.5 WT16.5X177 WT16.5X159 WT16.5X145.5 WT16.5X131.5 WT16.5X120.5 WT16.5X110.5 WT16.5X100.5 WT16.5X84.5 WT16.5X76 WT16.5X70.5 WT16.5X65 WT16.5X59 WT15X195.5 WT15X178.5 WT15X163 WT15X146 WT15X130.5 WT15X117.5 WT15X105.5 WT15X95.5 WT15X86.5 WT15X74 WT15X66 WT15X62 WT15X58 WT15X54 WT15X49.5 WT15X45 WT13.5X269.5 WT13.5X184 WT13.5X168 WT13.5X153.5 WT13.5X140.5 WT13.5X129 WT13.5X117.5 WT13.5X108.5 WT13.5X97 WT13.5X89 WT13.5X80.5 WT13.5X73 WT13.5X64.5 WT13.5X57 WT13.5X51 WT13.5X47 WT13.5X42 WT12X185 WT12X167.5 WT12X153

HSS14X6X5/16 HSS14X6X1/4 HSS14X6X3/16 HSS14X4X5/8 HSS14X4X1/2 HSS14X4X3/8 HSS14X4X5/16 HSS14X4X1/4 HSS14X4X3/16 HSS12X12X5/8 HSS12X12X1/2 HSS12X12X3/8 HSS12X12X5/16 HSS12X12X1/4 HSS12X12X3/16 HSS12X10X1/2 HSS12X10X3/8 HSS12X10X5/16 HSS12X10X1/4 HSS12X8X5/8 HSS12X8X1/2 HSS12X8X3/8 HSS12X8X5/16 HSS12X8X1/4 HSS12X8X3/16 HSS12X6X5/8 HSS12X6X1/2 HSS12X6X3/8 HSS12X6X5/16 HSS12X6X1/4 HSS12X6X3/16 HSS12X4X5/8 HSS12X4X1/2 HSS12X4X3/8 HSS12X4X5/16 HSS12X4X1/4 HSS12X4X3/16 HSS12X3-1/2X3/8 HSS12X3-1/2X5/16 HSS12X3X5/16 HSS12X3X1/4 HSS12X3X3/16 HSS12X2X5/16 HSS12X2X1/4 HSS12X2X3/16 HSS10X10X5/8 HSS10X10X1/2 HSS10X10X3/8 HSS10X10X5/16 HSS10X10X1/4

Welds

1/8 3/16 1/4 5/16 3/8 7/16 1/2 9/16 5/8 11/16 3/4 13/16 7/8 15/16 1

W24X279 W24X250 W24X229 W24X207 W24X192 W24X176 W24X162 W24X146 W24X131 W24X117 W24X104 W24X103 W24X94 W24X84 W24X76 W24X68 W24X62 W24X55 W21X201 W21X182 W21X166 W21X147 W21X132 W21X122 W21X111 W21X101 W21X93 W21X83 W21X73 W21X68 W21X62 W21X55 W21X48 W21X57 W21X50 W21X44 W18X311 W18X283 W18X258 W18X234 W18X211 W18X192 W18X175 W18X158 W18X143 W18X130 W18X119 W18X106 W18X97 W18X86

WT12X139.5 WT12X125 WT12X114.5 WT12X103.5 WT12X96 WT12X88 WT12X81 WT12X73 WT12X65.5 WT12X58.5 WT12X52 WT12X51.5 WT12X47 WT12X42 WT12X38 WT12X34 WT12X31 WT12X27.5 WT10.5X100.5 WT10.5X91 WT10.5X83 WT10.5X73.5 WT10.5X66 WT10.5X61 WT10.5X55.5 WT10.5X50.5 WT10.5X46.5 WT10.5X41.5 WT10.5X36.5 WT10.5X34 WT10.5X31 WT10.5X27.5 WT10.5X24 WT10.5X28.5 WT10.5X25 WT10.5X22 WT9X155.5 WT9X141.5 WT9X129 WT9X117 WT9X105.5 WT9X96 WT9X87.5 WT9X79 WT9X71.5 WT9X65 WT9X59.5 WT9X53 WT9X48.5 WT9X43

HSS10X10X3/16 HSS10X8X5/8 HSS10X8X1/2 HSS10X8X3/8 HSS10X8X5/16 HSS10X8X1/4 HSS10X8X3/16 HSS10X6X5/8 HSS10X6X1/2 HSS10X6X3/8 HSS10X6X5/16 HSS10X6X1/4 HSS10X6X3/16 HSS10X5X3/8 HSS10X5X5/16 HSS10X5X1/4 HSS10X5X3/16 HSS10X4X5/8 HSS10X4X1/2 HSS10X4X3/8 HSS10X4X5/16 HSS10X4X1/4 HSS10X4X3/16 HSS10X4X1/8 HSS10X3-1/2X1/2 HSS10X3-1/2X3/8 HSS10X3-1/2X5/16 HSS10X3-1/2X1/4 HSS10X3-1/2X3/16 HSS10X3-1/2X1/8 HSS10X3X3/8 HSS10X3X5/16 HSS10X3X1/4 HSS10X3X3/16 HSS10X3X1/8 HSS10X2X3/8 HSS10X2X5/16 HSS10X2X1/4 HSS10X2X3/16 HSS10X2X1/8 HSS9X9X5/8 HSS9X9X1/2 HSS9X9X3/8 HSS9X9X5/16 HSS9X9X1/4 HSS9X9X3/16 HSS9X9X1/8 HSS9X7X5/8 HSS9X7X1/2 HSS9X7X3/8

W18X76 W18X71 W18X65 W18X60 W18X55 W18X50 W18X46 W18X40 W18X35 W16X100 W16X89 W16X77 W16X67 W16X57 W16X50 W16X45 W16X40 W16X36 W16X31 W16X26 W14X730 W14X665 W14X605 W14X550 W14X500 W14X455 W14X426 W14X398 W14X370 W14X342 W14X311 W14X283 W14X257 W14X233 W14X211 W14X193 W14X176 W14X159 W14X145 W14X132 W14X120 W14X109 W14X99 W14X90 W14X82 W14X74 W14X68 W14X61 W14X53 W14X48

WT9X38 WT9X35.5 WT9X32.5 WT9X30 WT9X27.5 WT9X25 WT9X23 WT9X20 WT9X17.5 WT8X50 WT8X44.5 WT8X38.5 WT8X33.5 WT8X28.5 WT8X25 WT8X22.5 WT8X20 WT8X18 WT8X15.5 WT8X13 WT7X365 WT7X332.5 WT7X302.5 WT7X275 WT7X250 WT7X227.5 WT7X213 WT7X199 WT7X185 WT7X171 WT7X155.5 WT7X141.5 WT7X128.5 WT7X116.5 WT7X105.5 WT7X96.5 WT7X88 WT7X79.5 WT7X72.5 WT7X66 WT7X60 WT7X54.5 WT7X49.5 WT7X45 WT7X41 WT7X37 WT7X34 WT7X30.5 WT7X26.5 WT7X24

HSS9X7X5/16 HSS9X7X1/4 HSS9X7X3/16 HSS9X5X5/8 HSS9X5X1/2 HSS9X5X3/8 HSS9X5X5/16 HSS9X5X1/4 HSS9X5X3/16 HSS9X3X1/2 HSS9X3X3/8 HSS9X3X5/16 HSS9X3X1/4 HSS9X3X3/16 HSS8X8X5/8 HSS8X8X1/2 HSS8X8X3/8 HSS8X8X5/16 HSS8X8X1/4 HSS8X8X3/16 HSS8X8X1/8 HSS8X6X5/8 HSS8X6X1/2 HSS8X6X3/8 HSS8X6X5/16 HSS8X6X1/4 HSS8X6X3/16 HSS8X4X5/8 HSS8X4X1/2 HSS8X4X3/8 HSS8X4X5/16 HSS8X4X1/4 HSS8X4X3/16 HSS8X4X1/8 HSS8X3X1/2 HSS8X3X3/8 HSS8X3X5/16 HSS8X3X1/4 HSS8X3X3/16 HSS8X3X1/8 HSS8X2X3/8 HSS8X2X5/16 HSS8X2X1/4 HSS8X2X3/16 HSS8X2X1/8 HSS7X7X5/8 HSS7X7X1/2 HSS7X7X3/8 HSS7X7X5/16 HSS7X7X1/4

W14X43 W14X38 W14X34 W14X30 W14X26 W14X22 W12X336 W12X305 W12X279 W12X252 W12X230 W12X210 W12X190 W12X170 W12X152 W12X136 W12X120 W12X106 W12X96 W12X87 W12X79 W12X72 W12X65 W12X58 W12X53 W12X50 W12X45 W12X40 W12X35 W12X30 W12X26 W12X22 W12X19 W12X16 W12X14 W10X112 W10X100 W10X88 W10X77 W10X68 W10X60 W10X54 W10X49 W10X45 W10X39 W10X33 W10X30 W10X26 W10X22 W10X19

WT7X21.5 WT7X19 WT7X17 WT7X15 WT7X13 WT7X11 WT6X168 WT6X152.5 WT6X139.5 WT6X126 WT6X115 WT6X105 WT6X95 WT6X85 WT6X76 WT6X68 WT6X60 WT6X53 WT6X48 WT6X43.5 WT6X39.5 WT6X36 WT6X32.5 WT6X29 WT6X26.5 WT6X25 WT6X22.5 WT6X20 WT6X17.5 WT6X15 WT6X13 WT6X11 WT6X9.5 WT6X8 WT6X7 WT5X56 WT5X50 WT5X44 WT5X38.5 WT5X34 WT5X30 WT5X27 WT5X24.5 WT5X22.5 WT5X19.5 WT5X16.5 WT5X15 WT5X13 WT5X11 WT5X9.5

HSS7X7X3/16 HSS7X7X1/8 HSS7X5X1/2 HSS7X5X3/8 HSS7X5X5/16 HSS7X5X1/4 HSS7X5X3/16 HSS7X5X1/8 HSS7X4X1/2 HSS7X4X3/8 HSS7X4X5/16 HSS7X4X1/4 HSS7X4X3/16 HSS7X4X1/8 HSS7X3X1/2 HSS7X3X3/8 HSS7X3X5/16 HSS7X3X1/4 HSS7X3X3/16 HSS7X3X1/8 HSS7X2X1/4 HSS7X2X3/16 HSS7X2X1/8 HSS6X6X5/8 HSS6X6X1/2 HSS6X6X3/8 HSS6X6X5/16 HSS6X6X1/4 HSS6X6X3/16 HSS6X6X1/8 HSS6X5X1/2 HSS6X5X3/8 HSS6X5X5/16 HSS6X5X1/4 HSS6X5X3/16 HSS6X5X1/8 HSS6X4X1/2 HSS6X4X3/8 HSS6X4X5/16 HSS6X4X1/4 HSS6X4X3/16 HSS6X4X1/8 HSS6X3X1/2 HSS6X3X3/8 HSS6X3X5/16 HSS6X3X1/4 HSS6X3X3/16 HSS6X3X1/8 HSS6X2X3/8 HSS6X2X5/16

W10X17 W10X15 W10X12 W8X67 W8X58 W8X48 W8X40 W8X35 W8X31 W8X28 W8X24 W8X21 W8X18 W8X15 W8X13 W8X10 W6X25 W6X20 W6X15 W6X16 W6X12 W6X9 W6X8.5 W5X19 W5X16 W4X13

WT5X8.5 WT5X7.5 WT5X6 WT4X33.5 WT4X29 WT4X24 WT4X20 WT4X17.5 WT4X15.5 WT4X14 WT4X12 WT4X10.5 WT4X9 WT4X7.5 WT4X6.5 WT4X5 WT3X12.5 WT3X10 WT3X7.5 WT3X8 WT3X6 WT3X4.5 WT3X4.25 WT2.5X9.5 WT2.5X8 WT2X6.5

HSS6X2X1/4 HSS6X2X3/16 HSS6X2X1/8 HSS5-1/2X5-1/2X3/8 HSS5-1/2X5-1/2X5/16 HSS5-1/2X5-1/2X1/4 HSS5-1/2X5-1/2X3/16 HSS5-1/2X5-1/2X1/8 HSS5X5X1/2 HSS5X5X3/8 HSS5X5X5/16 HSS5X5X1/4 HSS5X5X3/16 HSS5X5X1/8 HSS5X4X1/2 HSS5X4X3/8 HSS5X4X5/16 HSS5X4X1/4 HSS5X4X3/16 HSS5X4X1/8 HSS5X3X1/2 HSS5X3X3/8 HSS5X3X5/16 HSS5X3X1/4 HSS5X3X3/16 HSS5X3X1/8 HSS5X2-1/2X1/4 HSS5X2-1/2X3/16 HSS5X2-1/2X1/8 HSS5X2X3/8 HSS5X2X5/16 HSS5X2X1/4 HSS5X2X3/16 HSS5X2X1/8 HSS4-1/2X4-1/2X1/2 HSS4-1/2X4-1/2X3/8 HSS4-1/2X4-1/2X5/16 HSS4-1/2X4-1/2X1/4 HSS4-1/2X4-1/2X3/16 HSS4-1/2X4-1/2X1/8 HSS4X4X1/2 HSS4X4X3/8 HSS4X4X5/16 HSS4X4X1/4 HSS4X4X3/16 HSS4X4X1/8 HSS4X3X3/8 HSS4X3X5/16 HSS4X3X1/4 HSS4X3X3/16

HSS4X3X1/8 HSS4X2-1/2X3/8 HSS4X2-1/2X5/16 HSS4X2-1/2X1/4 HSS4X2-1/2X3/16 HSS4X2-1/2X1/8 HSS4X2X3/8 HSS4X2X5/16 HSS4X2X1/4 HSS4X2X3/16 HSS4X2X1/8 HSS3-1/2X3-1/2X3/8 HSS3-1/2X3-1/2X5/16 HSS3-1/2X3-1/2X1/4 HSS3-1/2X3-1/2X3/16 HSS3-1/2X3-1/2X1/8 HSS3-1/2X2-1/2X3/8 HSS3-1/2X2-1/2X5/16 HSS3-1/2X2-1/2X1/4 HSS3-1/2X2-1/2X3/16 HSS3-1/2X2-1/2X1/8 HSS3-1/2X2X1/4 HSS3-1/2X2X3/16 HSS3-1/2X2X1/8 HSS3-1/2X1-1/2X1/4 HSS3-1/2X1-1/2X3/16 HSS3-1/2X1-1/2X1/8 HSS3X3X3/8 HSS3X3X5/16 HSS3X3X1/4 HSS3X3X3/16 HSS3X3X1/8 HSS3X2-1/2X5/16 HSS3X2-1/2X1/4 HSS3X2-1/2X3/16 HSS3X2-1/2X1/8 HSS3X2X5/16 HSS3X2X1/4 HSS3X2X3/16 HSS3X2X1/8 HSS3X1-1/2X1/4 HSS3X1-1/2X3/16 HSS3X1-1/2X1/8 HSS3X1X3/16 HSS3X1X1/8 HSS2-1/2X2-1/2X5/16 HSS2-1/2X2-1/2X1/4 HSS2-1/2X2-1/2X3/16 HSS2-1/2X2-1/2X1/8 HSS2-1/2X2X1/4

HSS2-1/2X2X3/16 HSS2-1/2X2X1/8 HSS2-1/2X1-1/2X1/4 HSS2-1/2X1-1/2X3/16 HSS2-1/2X1-1/2X1/8 HSS2-1/2X1X3/16 HSS2-1/2X1X1/8 HSS2-1/4X2-1/4X1/4 HSS2-1/4X2-1/4X3/16 HSS2-1/4X2-1/4X1/8 HSS2-1/4X2X3/16 HSS2-1/4X2X1/8 HSS2X2X1/4 HSS2X2X3/16 HSS2X2X1/8 HSS2X1-1/2X3/16 HSS2X1-1/2X1/8 HSS2X1X3/16 HSS2X1X1/8 HSS20X0.500 HSS20X0.375 HSS18X0.500 HSS18X0.375 HSS16X0.625 HSS16X0.500 HSS16X0.438 HSS16X0.375 HSS16X0.312 HSS16X0.250 HSS14X0.625 HSS14X0.500 HSS14X0.375 HSS14X0.312 HSS14X0.250 HSS12.750X0.500 HSS12.750X0.375 HSS12.750X0.250 HSS10.750X0.500 HSS10.750X0.375 HSS10.750X0.250 HSS10X0.625 HSS10X0.500 HSS10X0.375 HSS10X0.312 HSS10X0.250 HSS10X0.188 HSS9.625X0.500 HSS9.625X0.375 HSS9.625X0.312 HSS9.625X0.250

HSS9.625X0.188 HSS8.625X0.625 HSS8.625X0.500 HSS8.625X0.375 HSS8.625X0.322 HSS8.625X0.250 HSS8.625X0.188 HSS7.625X0.375 HSS7.625X0.328 HSS7.500X0.500 HSS7.500X0.375 HSS7.500X0.312 HSS7.500X0.250 HSS7.500X0.188 HSS7X0.500 HSS7X0.375 HSS7X0.312 HSS7X0.250 HSS7X0.188 HSS7X0.125 HSS6.875X0.500 HSS6.875X0.375 HSS6.875X0.312 HSS6.875X0.250 HSS6.875X0.188 HSS6.625X0.500 HSS6.625X0.432 HSS6.625X0.375 HSS6.625X0.312 HSS6.625X0.280 HSS6.625X0.250 HSS6.625X0.188 HSS6.625X0.125 HSS6X0.500 HSS6X0.375 HSS6X0.312 HSS6X0.280 HSS6X0.250 HSS6X0.188 HSS6X0.125 HSS5.563X0.500 HSS5.563X0.375 HSS5.563X0.258 HSS5.563X0.188 HSS5.563X0.134 HSS5.500X0.500 HSS5.500X0.375 HSS5.500X0.258 HSS5X0.500 HSS5X0.375

HSS5X0.312 HSS5X0.258 HSS5X0.250 HSS5X0.188 HSS5X0.125 HSS4.500X0.375 HSS4.500X0.337 HSS4.500X0.237 HSS4.500X0.188 HSS4.500X0.125 HSS4X0.313 HSS4X0.250 HSS4X0.237 HSS4X0.226 HSS4X0.220 HSS4X0.188 HSS4X0.125 HSS3.500X0.313 HSS3.500X0.300 HSS3.500X0.250 HSS3.500X0.216 HSS3.500X0.203 HSS3.500X0.188 HSS3.500X0.125 HSS3X0.250 HSS3X0.216 HSS3X0.203 HSS3X0.188 HSS3X0.152 HSS3X0.134 HSS3X0.125 HSS2.875X0.250 HSS2.875X0.203 HSS2.875X0.188 HSS2.875X0.125 HSS2.500X0.250 HSS2.500X0.188 HSS2.500X0.125 HSS2.375X0.250 HSS2.375X0.218 HSS2.375X0.188 HSS2.375X0.154 HSS2.375X0.125 HSS1.900X0.188 HSS1.900X0.145 HSS1.900X0.120 HSS1.660X0.140 Pipe12STD Pipe10STD Pipe8STD

Pipe6STD Pipe5STD Pipe4STD Pipe3-1/2STD Pipe3STD Pipe2-1/2STD Pipe2STD Pipe1-1/2STD Pipe1-1/4STD Pipe1STD Pipe3/4STD Pipe1/2STD Pipe12XS Pipe10XS Pipe8XS Pipe6XS Pipe5XS Pipe4XS Pipe3-1/2XS Pipe3XS Pipe2-1/2XS Pipe2XS Pipe1-1/2XS Pipe1-1/4XS Pipe1XS Pipe3/4XS Pipe1/2XS Pipe8XXS Pipe6XXS Pipe5XXS Pipe4XXS Pipe3XXS Pipe2-1/2XXS Pipe2XXS

HSS20X12X.625 HSS20X12X.500 HSS20X12X.375 HSS20X12X.313 HSS20X8X.625 HSS20X8X.500 HSS20X8X.375 HSS20X8X.313 HSS20X4X.500 HSS20X4X.375 HSS20X4X.313 HSS20X4X.250 HSS18X6X.625 HSS18X6X.500 HSS18X6X.375 HSS18X6X.313 HSS18X6X.250 HSS16X16X.625 HSS16X16X.500 HSS16X16X.375 HSS16X16X.313 HSS16X12X.625 HSS16X12X.500 HSS16X12X.375 HSS16X12X.313 HSS16X8X.625 HSS16X8X.500 HSS16X8X.375 HSS16X8X.313 HSS16X8X.250 HSS16X4X.625 HSS16X4X.500 HSS16X4X.375 HSS16X4X.313 HSS16X4X.250 HSS16X4X.188 HSS14X14X.625 HSS14X14X.500 HSS14X14X.375 HSS14X14X.313 HSS14X10X.625 HSS14X10X.500 HSS14X10X.375 HSS14X10X.313 HSS14X10X.250 HSS14X6X.625 HSS14X6X.500 HSS14X6X.375

Angle

L8X8X1-1/8 L8X8X1 L8X8X7/8 L8X8X3/4 L8X8X5/8 L8X8X9/16 L8X8X1/2 L8X6X1 L8X6X7/8 L8X6X3/4 L8X6X5/8 L8X6X9/16 L8X6X1/2 L8X6X7/16 L8X4X1 L8X4X7/8 L8X4X3/4 L8X4X5/8 L8X4X9/16 L8X4X1/2 L8X4X7/16 L7X4X3/4 L7X4X5/8 L7X4X1/2 L7X4X7/16 L7X4X3/8 L6X6X1 L6X6X7/8 L6X6X3/4 L6X6X5/8 L6X6X9/16 L6X6X1/2 L6X6X7/16 L6X6X3/8 L6X6X5/16 L6X4X7/8 L6X4X3/4 L6X4X5/8 L6X4X9/16 L6X4X1/2 L6X4X7/16 L6X4X3/8 L6X4X5/16 L6X3-1/2X1/2 L6X3-1/2X3/8 L6X3-1/2X5/16 L5X5X7/8 L5X5X3/4

HSS14X6X.313 HSS14X6X.250 HSS14X6X.188 HSS14X4X.625 HSS14X4X.500 HSS14X4X.375 HSS14X4X.313 HSS14X4X.250 HSS14X4X.188 HSS12X12X.625 HSS12X12X.500 HSS12X12X.375 HSS12X12X.313 HSS12X12X.250 HSS12X12X.188 HSS12X10X.500 HSS12X10X.375 HSS12X10X.313 HSS12X10X.250 HSS12X8X.625 HSS12X8X.500 HSS12X8X.375 HSS12X8X.313 HSS12X8X.250 HSS12X8X.188 HSS12X6X.625 HSS12X6X.500 HSS12X6X.375 HSS12X6X.313 HSS12X6X.250 HSS12X6X.188 HSS12X4X.625 HSS12X4X.500 HSS12X4X.375 HSS12X4X.313 HSS12X4X.250 HSS12X4X.188 HSS12X3-1/2X.375 HSS12X3-1/2X.313 HSS12X3X.313 HSS12X3X.250 HSS12X3X.188 HSS12X2X.313 HSS12X2X.250 HSS12X2X.188 HSS10X10X.625 HSS10X10X.500 HSS10X10X.375 HSS10X10X.313 HSS10X10X.250

L5X5X5/8 L5X5X1/2 L5X5X7/16 L5X5X3/8 L5X5X5/16 L5X3-1/2X3/4 L5X3-1/2X5/8 L5X3-1/2X1/2 L5X3-1/2X3/8 L5X3-1/2X5/16 L5X3-1/2X1/4 L5X3X1/2 L5X3X7/16 L5X3X3/8 L5X3X5/16 L5X3X1/4 L4X4X3/4 L4X4X5/8 L4X4X1/2 L4X4X7/16 L4X4X3/8 L4X4X5/16 L4X4X1/4 L4X3-1/2X1/2 L4X3-1/2X3/8 L4X3-1/2X5/16 L4X3-1/2X1/4 L4X3X5/8 L4X3X1/2 L4X3X3/8 L4X3X5/16 L4X3X1/4 L3-1/2X3-1/2X1/2 L3-1/2X3-1/2X7/16 L3-1/2X3-1/2X3/8 L3-1/2X3-1/2X5/16 L3-1/2X3-1/2X1/4 L3-1/2X3X1/2 L3-1/2X3X7/16 L3-1/2X3X3/8 L3-1/2X3X5/16 L3-1/2X3X1/4 L3-1/2X2-1/2X1/2 L3-1/2X2-1/2X3/8 L3-1/2X2-1/2X5/16 L3-1/2X2-1/2X1/4 L3X3X1/2 L3X3X7/16 L3X3X3/8 L3X3X5/16

HSS10X10X.188 HSS10X8X.625 HSS10X8X.500 HSS10X8X.375 HSS10X8X.313 HSS10X8X.250 HSS10X8X.188 HSS10X6X.625 HSS10X6X.500 HSS10X6X.375 HSS10X6X.313 HSS10X6X.250 HSS10X6X.188 HSS10X5X.375 HSS10X5X.313 HSS10X5X.250 HSS10X5X.188 HSS10X4X.625 HSS10X4X.500 HSS10X4X.375 HSS10X4X.313 HSS10X4X.250 HSS10X4X.188 HSS10X4X.125 HSS10X3-1/2X.500 HSS10X3-1/2X.375 HSS10X3-1/2X.313 HSS10X3-1/2X.250 HSS10X3-1/2X.188 HSS10X3-1/2X.125 HSS10X3X.375 HSS10X3X.313 HSS10X3X.250 HSS10X3X.188 HSS10X3X.125 HSS10X2X.375 HSS10X2X.313 HSS10X2X.250 HSS10X2X.188 HSS10X2X.125 HSS9X9X.625 HSS9X9X.500 HSS9X9X.375 HSS9X9X.313 HSS9X9X.250 HSS9X9X.188 HSS9X9X.125 HSS9X7X.625 HSS9X7X.500 HSS9X7X.375

L3X3X1/4 L3X3X3/16 L3X2-1/2X1/2 L3X2-1/2X7/16 L3X2-1/2X3/8 L3X2-1/2X5/16 L3X2-1/2X1/4 L3X2-1/2X3/16 L3X2X1/2 L3X2X3/8 L3X2X5/16 L3X2X1/4 L3X2X3/16 L2-1/2X2-1/2X1/2 L2-1/2X2-1/2X3/8 L2-1/2X2-1/2X5/16 L2-1/2X2-1/2X1/4 L2-1/2X2-1/2X3/16 L2-1/2X2X3/8 L2-1/2X2X5/16 L2-1/2X2X1/4 L2-1/2X2X3/16 L2-1/2X1-1/2X1/4 L2-1/2X1-1/2X3/16 L2X2X3/8 L2X2X5/16 L2X2X1/4 L2X2X3/16 L2X2X1/8

HSS9X7X.313 HSS9X7X.250 HSS9X7X.188 HSS9X5X.625 HSS9X5X.500 HSS9X5X.375 HSS9X5X.313 HSS9X5X.250 HSS9X5X.188 HSS9X3X.500 HSS9X3X.375 HSS9X3X.313 HSS9X3X.250 HSS9X3X.188 HSS8X8X.625 HSS8X8X.500 HSS8X8X.375 HSS8X8X.313 HSS8X8X.250 HSS8X8X.188 HSS8X8X.125 HSS8X6X.625 HSS8X6X.500 HSS8X6X.375 HSS8X6X.313 HSS8X6X.250 HSS8X6X.188 HSS8X4X.625 HSS8X4X.500 HSS8X4X.375 HSS8X4X.313 HSS8X4X.250 HSS8X4X.188 HSS8X4X.125 HSS8X3X.500 HSS8X3X.375 HSS8X3X.313 HSS8X3X.250 HSS8X3X.188 HSS8X3X.125 HSS8X2X.375 HSS8X2X.313 HSS8X2X.250 HSS8X2X.188 HSS8X2X.125 HSS7X7X.625 HSS7X7X.500 HSS7X7X.375 HSS7X7X.313 HSS7X7X.250

HSS7X7X.188 HSS7X7X.125 HSS7X5X.500 HSS7X5X.375 HSS7X5X.313 HSS7X5X.250 HSS7X5X.188 HSS7X5X.125 HSS7X4X.500 HSS7X4X.375 HSS7X4X.313 HSS7X4X.250 HSS7X4X.188 HSS7X4X.125 HSS7X3X.500 HSS7X3X.375 HSS7X3X.313 HSS7X3X.250 HSS7X3X.188 HSS7X3X.125 HSS7X2X.250 HSS7X2X.188 HSS7X2X.125 HSS6X6X.625 HSS6X6X.500 HSS6X6X.375 HSS6X6X.313 HSS6X6X.250 HSS6X6X.188 HSS6X6X.125 HSS6X5X.500 HSS6X5X.375 HSS6X5X.313 HSS6X5X.250 HSS6X5X.188 HSS6X5X.125 HSS6X4X.500 HSS6X4X.375 HSS6X4X.313 HSS6X4X.250 HSS6X4X.188 HSS6X4X.125 HSS6X3X.500 HSS6X3X.375 HSS6X3X.313 HSS6X3X.250 HSS6X3X.188 HSS6X3X.125 HSS6X2X.375 HSS6X2X.313

HSS6X2X.250 HSS6X2X.188 HSS6X2X.125 HSS5-1/2X5-1/2X.375 HSS5-1/2X5-1/2X.313 HSS5-1/2X5-1/2X.250 HSS5-1/2X5-1/2X.188 HSS5-1/2X5-1/2X.125 HSS5X5X.500 HSS5X5X.375 HSS5X5X.313 HSS5X5X.250 HSS5X5X.188 HSS5X5X.125 HSS5X4X.500 HSS5X4X.375 HSS5X4X.313 HSS5X4X.250 HSS5X4X.188 HSS5X4X.125 HSS5X3X.500 HSS5X3X.375 HSS5X3X.313 HSS5X3X.250 HSS5X3X.188 HSS5X3X.125 HSS5X2-1/2X.250 HSS5X2-1/2X.188 HSS5X2-1/2X.125 HSS5X2X.375 HSS5X2X.313 HSS5X2X.250 HSS5X2X.188 HSS5X2X.125 HSS4-1/2X4-1/2X.500 HSS4-1/2X4-1/2X.375 HSS4-1/2X4-1/2X.313 HSS4-1/2X4-1/2X.250 HSS4-1/2X4-1/2X.188 HSS4-1/2X4-1/2X.125 HSS4X4X.500 HSS4X4X.375 HSS4X4X.313 HSS4X4X.250 HSS4X4X.188 HSS4X4X.125 HSS4X3X.375 HSS4X3X.313 HSS4X3X.250 HSS4X3X.188

HSS4X3X.125 HSS4X2-1/2X.375 HSS4X2-1/2X.313 HSS4X2-1/2X.250 HSS4X2-1/2X.188 HSS4X2-1/2X.125 HSS4X2X.375 HSS4X2X.313 HSS4X2X.250 HSS4X2X.188 HSS4X2X.125 HSS3-1/2X3-1/2X.375 HSS3-1/2X3-1/2X.313 HSS3-1/2X3-1/2X.250 HSS3-1/2X3-1/2X188 HSS3-1/2X3-1/2X.125 HSS3-1/2X2-1/2X.375 HSS3-1/2X2-1/2X.313 HSS3-1/2X2-1/2X.250 HSS3-1/2X2-1/2X.188 HSS3-1/2X2-1/2X.125 HSS3-1/2X2X.250 HSS3-1/2X2X.188 HSS3-1/2X2X.125 HSS3-1/2X1-1/2X.250 HSS3-1/2X1-1/2X.188 HSS3-1/2X1-1/2X.125 HSS3X3X.375 HSS3X3X.313 HSS3X3X.250 HSS3X3X.188 HSS3X3X.125 HSS3X2-1/2X.313 HSS3X2-1/2X.250 HSS3X2-1/2X.188 HSS3X2-1/2X.125 HSS3X2X.313 HSS3X2X.250 HSS3X2X.188 HSS3X2X.125 HSS3X1-1/2X.250 HSS3X1-1/2X.188 HSS3X1-1/2X.125 HSS3X1X.188 HSS3X1X.125 HSS2-1/2X2-1/2X.313 HSS2-1/2X2-1/2X.250 HSS2-1/2X2-1/2X.188 HSS2-1/2X2-1/2X.125 HSS2-1/2X2X.250

HSS2-1/2X2X.188 HSS2-1/2X2X.125 HSS2-1/2X1-1/2X.250 HSS2-1/2X1-1/2X.188 HSS2-1/2X1-1/2X.125 HSS2-1/2X1X.188 HSS2-1/2X1X.125 HSS2-1/4X2-1/4X.250 HSS2-1/4X2-1/4X.188 HSS2-1/4X2-1/4X.125 HSS2-1/4X2X.188 HSS2-1/4X2X.125 HSS2X2X.250 HSS2X2X.188 HSS2X2X.125 HSS2X1-1/2X.188 HSS2X1-1/2X.125 HSS2X1X.188 HSS2X1X.125 HSS20X.500 HSS20X.375 HSS18X.500 HSS18X.375 HSS16X.625 HSS16X.500 HSS16X.438 HSS16X.375 HSS16X.312 HSS16X.250 HSS14X.625 HSS14X.500 HSS14X.375 HSS14X.312 HSS14X.250 HSS12.75X.500 HSS12.75X.375 HSS12.75X.250 HSS10.75X.500 HSS10.75X.375 HSS10.75X.250 HSS10X.625 HSS10X.500 HSS10X.375 HSS10X.312 HSS10X.250 HSS10X.188 HSS9.625X.500 HSS9.625X.375 HSS9.625X.312 HSS9.625X.250

HSS9.625X.188 HSS8.625X.625 HSS8.625X.500 HSS8.625X.375 HSS8.625X.322 HSS8.625X.250 HSS8.625X.188 HSS7.625X.375 HSS7.625X.328 HSS7.5X.500 HSS7.5X.375 HSS7.5X.312 HSS7.5X.250 HSS7.5X.188 HSS7X.500 HSS7X.375 HSS7X.312 HSS7X.250 HSS7X.188 HSS7X.125 HSS6.875X.500 HSS6.875X.375 HSS6.875X.312 HSS6.875X.250 HSS6.875X.188 HSS6.625X.500 HSS6.625X.432 HSS6.625X.375 HSS6.625X.312 HSS6.625X.280 HSS6.625X.250 HSS6.625X.188 HSS6.625X.125 HSS6X.500 HSS6X.375 HSS6X.312 HSS6X.280 HSS6X.250 HSS6X.188 HSS6X.125 HSS5.563X.500 HSS5.563X.375 HSS5.563X.258 HSS5.563X.188 HSS5.563X.134 HSS5.5X.500 HSS5.5X.375 HSS5.5X.258 HSS5X.500 HSS5X.375

HSS5X.312 HSS5X.258 HSS5X.250 HSS5X.188 HSS5X.125 HSS4.5X.375 HSS4.5X.337 HSS4.5X.237 HSS4.5X.188 HSS4.5X.125 HSS4X.313 HSS4X.250 HSS4X.237 HSS4X.226 HSS4X.220 HSS4X.188 HSS4X.125 HSS3.5X.313 HSS3.5X.300 HSS3.5X.250 HSS3.5X.216 HSS3.5X.203 HSS3.5X.188 HSS3.5X.125 HSS3X.250 HSS3X.216 HSS3X.203 HSS3X.188 HSS3X.152 HSS3X.134 HSS3X.125 HSS2.875X.250 HSS2.875X.203 HSS2.875X.188 HSS2.875X.125 HSS2.5X.250 HSS2.5X.188 HSS2.5X.125 HSS2.375X.250 HSS2.375X.218 HSS2.375X.188 HSS2.375X.154 HSS2.375X.125 HSS1.9X.188 HSS1.9X.145 HSS1.9X.120 HSS1.66X.140 Pipe12SCH40 Pipe10SCH40 Pipe8SCH40

Pipe6SCH40 Pipe5SCH40 Pipe4SCH40 Pipe3-1/2SCH40 Pipe3SCH40 Pipe2-1/2SCH40 Pipe2SCH40 Pipe1-1/2SCH40 Pipe1-1/4SCH40 Pipe1SCH40 Pipe3/4SCH40 Pipe1/2SCH40 Pipe12XS Pipe10SCH80 Pipe8SCH80 Pipe6SCH80 Pipe5SCH80 Pipe4SCH80 Pipe3-1/2SCH80 Pipe3SCH80 Pipe2-1/2SCH80 Pipe2SCH80 Pipe1-1/2SCH80 Pipe1-1/4SCH80 Pipe1SCH80 Pipe3/4SCH80 Pipe1/2SCH80 Pipe8XXS Pipe6XXS Pipe5XXS Pipe4XXS Pipe3XXS Pipe2-1/2XXS Pipe2XXS

17-Sep-13

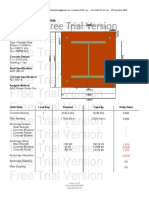

Connections I Tab: WT on HSS Analysis Method: LRFD Beam Location:

Beam to HSS with Tee Section

Based on 2005 Specification for Structural Steel Buildings

Column Size: HSS8X8X1/4 Column Fy: 46.00 ksi Column Fu: 58.00 ksi Beam Size: Beam Fy: Beam Fu: d tw bf tf T Factored Reaction: Beam Span: Bolt Size: Bolt Type: Bolt Pitch s: W16X50 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 37.00 k

tnom #VALUE! b #VALUE! tdes #VALUE!

ht

#VALUE!

#VALUE! #VALUE!

WT Size: Tee Fy: Tee Fu: d tw bf tf k1 Multiplier Ru = 3.00 in N 3.00 in

WT5X24.5 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! 13/16 1.00 37.00 k

kdet #VALUE! Leh = #VALUE! Enter either a Stated Beam Enter either a Stated Beam Reaction or the Beam Span. Reaction or the Beam Span. Use the delete key to erase the Use the delete key to erase the unused space. unused space. #VALUE! Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

kdet #VALUE! Beam Cap. Reaction a: N or X? g:

3/4 A325 3.00 in

Shear Per Bolt =

Max WT stem Thickness = #VALUE! #VALUE! WT Lev : C req'd = Number of Bolts: Tee Length = 1.25 in #VALUE! #VALUE! 4 Bolts #VALUE! 11.50 in Beam Leh : #VALUE! #VALUE! Tee Leh : #VALUE! Min Tee L= C= #VALUE! 2.81 1.50 in #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Beam Web tw>WT tw?

Controlling Available Strengths Strength Bolt Shear Strength #VALUE! #VALUE! #VALUE! Tee Stem Shear Yield Strength Shear Rupture Strength Flexural Yield Strength Flexural Rupture Strength Block Shear Strength Bearing Strength at Holes Beam Web Shear Yield Strength Bearing Strength at Holes ### #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! (Deff)max #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Block Shear/Bearing Ls = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Lt = Edge = Bearing = #VALUE! #VALUE! #VALUE!

This test ensures This test ensures that any bolt hole that any bolt hole deformation will deformation will occur in the WT occur in the WT stem and not in the stem and not in the Beam web. This is Beam web. This is not an AISC not an AISC requirement. requirement.

Table 9-3a #VALUE! Table 9-3b 230.63 k/in Table 9-3c #VALUE!

#VALUE! #VALUE!

#VALUE! #VALUE!

#VALUE! Min Weld D = Dmin = Weld D for load = Weld Strength = #VALUE! #VALUE!

(70ksi electrodes) #VALUE! #VALUE! 1.16 #VALUE! #VALUE! #VALUE! (Deff)max #VALUE!

#VALUE! with 4 - 3/4 A325 Bolts

#VALUE!

17-Sep-13

Connections I Tab: Single Plate to HSS Analysis Method: LRFD Beam Location:

Beam to HSS with Single Plate Shear Connection

Based on 2005 Specification for Structural Steel Buildings

Column Size: Column Fy: Column Fu:

HSS6X6X3/8 46.00 ksi 58.00 ksi

tnom #VALUE! tdes #VALUE! b_tdes #VALUE!

b ht ht_tdes #VALUE!

#VALUE! #VALUE! #VALUE!

#VALUE! Connection Face Width Spec K1.2, Check column wall thickness: (b/t)max = Beam Size: Beam Fy: Beam Fu: d tw bf tf T kdet Factored Reaction: Beam Span: Bolt Size: Bolt Type: Bolt Hole Type: Number of Bolts: Plate Length Lp = Local Buckling Check eb = W18X35 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 39.00 k Plate Thickness Plate Fy: Plate Fu: Plate Leh : Plate Lev : #VALUE! 35.15 5/16 36.00 ksi 58.00 ksi 1.50 in 1.50 in #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Punching Shear tpmax: #VALUE! Bolt Dia/2+1/16: #VALUE! Beam Leh : Beam Cap. Reaction a: Bolt Pitch s: N or X? g: 3.00 in 3.00 in N 3.00 in Multiplier Ru = 1.75 in 1.00 39.00 k Shear Per Bolt #VALUE!

#VALUE! Enter either a Factored Enter either a Factored Reaction or a Beam Span. Reaction or a Beam Span. Use the delete key to erase Use the delete key to erase the unused space. the unused space. Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

3/4 A325 STD 3 Bolts 9 0.25 0.00 in

Rotational Ductility: #VALUE! #VALUE! Bolt C =

1.00 Controlling Available Strengths Capacity Bolt Shear Strength #VALUE! #VALUE! #VALUE! Plate Shear Yield Strength Shear Rupture Strength Block Shear Strength Bearing Strength at Holes Beam Web Shear Yield Strength Bearing Strength at Holes Block Shear/Bearing Ls = #VALUE! Lt = #VALUE! #VALUE! #VALUE! #VALUE! Bearing = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Edge = Other = #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE!

#VALUE! #VALUE!

Weld (70ksi electrodes) Weld Strength #VALUE!

#VALUE!

#VALUE! with (3) - 3/4 A325 Bolts

17-Sep-13

Connections I Tab: Thru Plate to HSS Analysis Method: LRFD Beam Location:

Beam to HSS with Thru Plate Shear Connection

Based on 2005 Specification for Structural Steel Buildings

Column Size: HSS6X4X1/8 Column Fy: 46.00 ksi Column Fu: 58.00 ksi Note: Note: Since Since the capacity of the connection connection depends on the weld on on the bolt bolt side of the connection, conservatively design design all double sided connections as single single sided

tnom #VALUE! tdes #VALUE! b_tdes #VALUE!

b ht ht_tdes #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! 6.00 in #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Beam Size: Beam Fy: Beam Fu: d tw bf tf T Factored Reaction: Beam Span: Bolt Size: Bolt Hole Type: Number of Bolts: Plate Length Lp = Local Buckling Check eb =

W18X35 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 19.80 k

Plate Thickness Plate Fy: Plate Fu: Plate Leh : Plate Lev : Beam Leh : kdet #VALUE! Beam Cap. Reaction Multiplier Ru =

1/4 36.00 ksi 58.00 ksi 1.50 in 2.75 in 1.50 in

#VALUE!

#VALUE!

#VALUE!

19.80 k Shear Per Bolt #VALUE!

3/4 a: 3 STD Bolt Pitch s: 3.00 in #VALUE! N or X? N 3 Bolts #VALUE! 11.5 Bolt Dia/2+1/16: #VALUE! 0.25 #VALUE! 1.00 in Bolt C =

Enter either a Factored Enter either a Factored Reaction or a Beam Span. Reaction or a Beam Span. Use the delete key to erase Use the delete key to erase the unused space. the unused space. Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

#VALUE!

2.62 Controlling Available Strengths Capacity Bolt Shear Strength #VALUE! #VALUE! #VALUE! Plate Shear Yield Strength Shear Rupture Strength Block Shear Strength Bearing Strength at Holes Beam Web Shear Yield Strength Shear Rupture Strength Beam Web Brg Strength #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Block Shear/Bearing Ls = #VALUE! Lt = Edge = Other = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Bearing =

Weld (70ksi electrodes) Design Weld Force #VALUE! Weld Strength #VALUE! #VALUE! #VALUE! with (3) - 3/4 A325 Bolts

Weld Size: #VALUE! #VALUE!

3/16

Fillet

Use 3/16 Fillet Weld Each side of plate

17-Sep-13

Connections I Tab: Single Plate to W Flg Analysis Method: LRFD Beam Location:

Beam to W Column Flange with Single Plate Shear Connection

Based on 2005 Specification for Structural Steel Buildings

Column Size: Column Fy: Column Fu: Beam Size: Beam Fy: Beam Fu: d tw bf tf T k1 kdet

W14X90 50.00 ksi 65.00 ksi W16X50 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

tf #VALUE!

Conventional Conventional Configuration Configuration SingleSinglePlate Shear Shear Connection Connection 1/4 36.00 ksi 58.00 ksi 1.50 in 1.25 in #VALUE!

Plate Thickness: Plate Fy: Plate Fu: Plate Leh : Plate Lev :

#VALUE! #VALUE!

Beam Leh : Bolt Dia/2+1/16:

1.75 in

#VALUE!

#VALUE! #VALUE! Enter either a Factored Enter either a Factored Reaction or a Beam Span. Reaction or a Beam Span. Use the delete key to erase Use the delete key to erase the unused space. the unused space. Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

Factored Reaction: Beam Span: Bolt Size: Bolt Hole Type: Bolt Type: Number of Bolts: Plate Length Lp = Local Buckling Check eb =

49.60 k

3/4 STD A325 4 Bolts 11.50 in 0.25 in 0.00 in

Beam Cap. Reaction Min a = a: Bolt Pitch s: N or X?

2.25 in 3 3.00 in N

Multiplier 1.00 Ru = 49.60 k (Beam Leh + 0.5) Shear Per Bolt #VALUE! g: 3.00 in

Rotational Ductility: #VALUE! #VALUE! C= 1.00 Controlling Capacity #VALUE! Block Shear/Bearing Ls = #VALUE! Lt = #VALUE! #VALUE! #VALUE! Bearing = #VALUE! #VALUE! Edge = #VALUE! #VALUE! Other = #VALUE! #VALUE!

Available Strengths Bolt Shear Strength #VALUE! #VALUE! Plate Shear Yield Strength Shear Rupture Strength Block Shear Strength Bearing Strength at Holes Beam Web Shear Yield Strength Bearing Strength at Holes #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE!

Weld (70ksi electrodes) Weld Strength #VALUE! #VALUE! #VALUE!

#VALUE!

#VALUE! #VALUE!

17-Sep-13

Connections I Tab: Axial Load on SPSC Analysis Method: LRFD Beam Location: 0

Axial Load Check

Beam to W Column Flange with Single Plate Shear Connection

Based on 2010 Specification for Structural Steel Buildings

Supporting Member Size: Fy: Fu: Beam Size: Beam Fy: Beam Fu: Plate Thickness: Plate Leh : Plate Lev : Plate Fy: Plate Fu: Factored Vertical Reaction: Factored Brace Vertical Reaction: Factored Horiz Reaction: Plate Yielding Rupture

W14X90 50.00 ksi 65.00 ksi W16X50 50.00 ksi 65.00 ksi 1/4 1.50 in 1.25 in 36.00 ksi 58.00 ksi 49.60 k 130.00 k

d tw kdet d tw kdet

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 3

bf tf T bf tf T

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

k1 #VALUE! 1/2 flange = #VALUE! Beam Leh : 1.75 in #VALUE!

Vertical Bolt Pitch s: Total Vertical Load =

Maximum Plate Thickness = #VALUE! #VALUE! Load Angle = ex = C= #VALUE! 69.12 deg 3.00 in 6.300 #VALUE!

49.60 k

Combined Load = 139.14 k 4 Rows and 1 Columns of Bolts Bolt Shear Strength = #VALUE!

Shear Capacity = Shear Capacity = Fcr =

#VALUE! #VALUE! #VALUE!

Tensile Capacity = Tensile Capacity = Von-Mises reduction Capacity = Capacity = 2.4db = Kl/r = #VALUE! Fcr = #VALUE! Tensile Capacity = Tensile Capacity =

#VALUE! #VALUE!

Combined = #VALUE! Combined = #VALUE!

#VALUE! #VALUE!

Flexural Yield Flexural Rupture Bearing Buckling Block Shear

1.2Lc = K= L-shaped plane Shear Capacity = C-shaped plane Shear Capacity =

#VALUE! 1.2

#VALUE! #VALUE! #VALUE!

Bearing = #VALUE! Capacity = #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE!

#VALUE! #VALUE!

Combined = #VALUE! Combined = #VALUE!

Beam Bearing Block Shear Tensile Yield Tensile Rupture 1.2Lc = Shear Capacity = A = d*tw = Net Area = #VALUE! #VALUE! #VALUE! #VALUE! 2.4db = Tensile Capacity = #VALUE! #VALUE! Bearing = #VALUE! Combined = #VALUE! Capacity = #VALUE! Capacity = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

0.85 Ag = #VALUE! Ae = #VALUE!

Weld Weld =

(70ksi electrodes) 69.12 Weld L = Table 8-4 C = 11.50 4.033 aL = 3.00 Capacity = a= 0.261 #VALUE! #VALUE!

Note: Additional bolt columns shown on Note: Additional bolt columns shown on this calculation override the single bolt this calculation override the single bolt column shown on the vertical load column shown on the vertical load calculation. calculation.

#VALUE! and 4 Rows & 1 Columns 3/4 A325 - N Bolts

17-Sep-13

Connections I Tab: Extended Single Plate Analysis Method: LRFD Beam Location:

Beam to Supporting Member with Extended Single Plate Shear Connection

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: Fy: Fu: Beam Size: Beam Fy: Beam Fu: Plate Thickness: Plate Leh : Plate Lev : Plate Fy: Plate Fu: Factored Reaction: Beam Span: Bolt Size: Plate Bolt Hole Type: Bolt Type: Number of Rows of Bolts: Plate Lp = Centroid of Bolt Group C=

W14X90 50.00 ksi 65.00 ksi W16X36 50.00 ksi 65.00 ksi 1/2 1.50 in 1.50 in 36.00 ksi 58.00 ksi 36.00 k

d tw kdet d tw kdet

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

bf tf T bf tf T

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

1/2 flange = Beam Leh :

#VALUE! 1.50 in #VALUE! #VALUE!

Maximum Plate Thickness: #VALUE! #VALUE!

Extended Extended Configuration Configuration #VALUE! SingleSingle- Plate Plate Shear Shear Connection Connection

3/4 STD A325 4 Rows 12.00 in #VALUE! #VALUE!

Beam Cap. Reaction Min x = x: Bolt Pitch s: N or X?

2.00 in 2.25 in Shear Per Bolt 3.00 in #VALUE! g= N #VALUE! #VALUE! #VALUE! Number of bolt columns: 2 #VALUE! #VALUE!

Multiplier 1.00 Ru = 36.00 k (Beam Leh + 0.5)

Enter either a Reaction or a Beam Enter either a Reaction or a Beam Span. Use the delete key to erase Span. Use the delete key to erase the unused space. the unused space. Minimum Bolt Length = #VALUE! Calc'd Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE! #VALUE!

a: #VALUE! e: Column CL to first Bolt Col =

Plate Width =

#VALUE!

Available Strengths Bolt Shear Strength #VALUE! #VALUE! Plate Shear Yield Strength Shear Rupture Strength Block Shear Strength Bearing Strength at Holes Flexural Yield Strength Flexural Rupture Strength Plate Buckling Strength Beam Web Shear Yield Strength Beam Web Brg Strength Weld Weld size D: Weld Strength Weld Strength #VALUE! #VALUE! (70ksi electrodes) #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Controlling Capacity #VALUE! Block Shear/Bearing Ls = #VALUE! Lt = #VALUE! #VALUE! #VALUE! Edge = #VALUE! #VALUE! Bearing = #VALUE! #VALUE! Other = #VALUE! #VALUE! #VALUE! #VALUE! Block Shear Table Check Table 9-3a #VALUE! Table 9-3b 170.10 k/in Table 9-3c #VALUE! Check: #VALUE! von-Mises Fcr = #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE!

#VALUE! #VALUE! For welds on one side of web only #VALUE! For welds on both sides of web

#VALUE! #VALUE!

17-Sep-13

Connections I Tab: Extended Single Plate Analysis Method: LRFD Beam Location: 0

Axial Load Check

Beam to Supporting Member with Extended Single Plate Shear Connection

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: Fy: Fu: Beam Size: Beam Fy: Beam Fu: Plate Thickness: Plate Leh : Plate Lev : Plate Fy: Plate Fu: Factored Vertical Reaction: Factored Brace Vertical Reaction: Factored Horiz Reaction: Plate Yielding Rupture

W14X90 50.00 ksi 65.00 ksi W16X36 50.00 ksi 65.00 ksi 1/2 1.50 in 1.50 in 36.00 ksi 58.00 ksi 36.00 k 130.00 k

d tw kdet d tw kdet

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Bolt Pitch s: 3

bf tf T bf tf T

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

k1 #VALUE! 1/2 flange = #VALUE! Beam Leh : 1.50 in #VALUE!

Increase Plate Length? Total Vertical Load = 36.00 k #VALUE! 74.52 deg #VALUE! #VALUE! #VALUE!

No

Combined Load = 134.89 k Load Angle = Vertical Load Eccentricity ex = 4 Rows and 2 Columns of Bolts Bolt Shear Strength = #VALUE! C= #VALUE!

Shear Capacity = Shear Capacity =

#VALUE! #VALUE!

Tensile Capacity = Tensile Capacity =

#VALUE! #VALUE!

Flexural Yield Flexural Rupture Bearing Axial Block Shear

Fcr = 1.2Lc = K= L-shaped plane Shear Capacity = C-shaped plane

#VALUE! #VALUE! 1.2

Capacity = Capacity = 2.4db = Kl/r = #VALUE! Fcr = #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE!

Bearing = #VALUE! Axial Capacity = #VALUE! #VALUE! #VALUE! Interaction = #VALUE! Interaction = #VALUE! Interaction = #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE!

Tensile Capacity = #VALUE!

Tensile Capacity = P/Pa = P/Pa = #VALUE! #VALUE!

Gross Shear, Axial, & Bending Interaction Net Shear, Axial, & Bending Interaction Shear and Axial Block Shear Interaction Beam Bearing Block Shear Weld Weld = (70ksi electrodes) 74.52 Weld L = 1.2Lc =

#VALUE! #VALUE! #VALUE!

#VALUE!

2.4db = Tensile Capacity =

#VALUE! #VALUE!

Bearing = #VALUE! #VALUE!

#VALUE!

12.00

Capacity =

#VALUE!

#VALUE!

Stabilizer Plates

Stabilizer Plate Fy = Lst = Plate Moment = fv =

50.00 ksi #VALUE! #VALUE! 2.71 ksi Capacity = Capacity = #VALUE! #VALUE! Wst = Plate Tk = fb = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Use Wst = 12.00 in Use Plate TK = 1.00 in Interaction = #VALUE! #VALUE!

Fillet Weld W2 = Fillet Weld W3 =

5/16 1/4

17-Sep-13

Connections I Tab:Single Plate (EX) Analysis Method: LRFD Beam Location:

Beam to Supporting Member with Single Plate Shear Connection (EX)

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: Fy: Fu: Beam Size: Beam Fy: Beam Fu: Plate Thickness: Plate Leh : Plate Lev : Plate Fy: Plate Fu: Factored Reaction: Beam Span: Bolt Size: Plate Bolt Hole Type: Bolt Type: Number of Rows of Bolts: Plate Lp = Centroid of Bolt Group

W14X90 50.00 ksi 65.00 ksi W21X55 50.00 ksi 65.00 ksi 1/2 1.50 in 1.25 in 36.00 ksi 58.00 ksi 100.00 k

d #VALUE! tw #VALUE! kdet #VALUE! d #VALUE! tw #VALUE! kdet #VALUE!

bf tf T bf tf T

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

1/2 flange = #VALUE! Beam Leh : 1.50 in #VALUE! #VALUE!

Maximum Plate Thickness: #VALUE! #VALUE!

#VALUE!

Beam Cap. Reaction Min a = a: Bolt Pitch s: N or X?

3/4 STD A325 5 Rows #VALUE! 14.50 in 4.50 in

2.00 in 3.00 in 3.00 in N #VALUE! Number of bolt columns: 3.00 in 6.43 Controlling Capacity #VALUE!

Multiplier 1.00 Ru = 100.00 k (Beam Leh + 0.5) Shear Per Bolt #VALUE! g: 3.00 in 2 4.5

Enter either a Factored Reaction Enter either a Factored Reaction or a Beam Span. Use the delete or a Beam Span. Use the delete key to erase the unused space. key to erase the unused space.

Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

a: C=

e:

Plate Width =

7.50 in

Available Strengths Bolt Shear Strength #VALUE! #VALUE! Shear Plate Shear Yield Strength Shear Rupture Strength Block Shear Strength Bearing Strength at Holes Flexural Yield Strength Flexural Rupture Strength Plate Buckling Strength Beam Web Shear Yield Strength Shear Rupture Strength Beam Web Brg Strength Weld Weld size D: Weld Strength #VALUE! #VALUE! #VALUE! (70ksi electrodes) #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

This This is is a a special special case: case: Standard Standard Single-Plate Single-Plate Shear Shear Connection Connection calculated calculated using using the the Extended Extended Configuration Configuration requirements. requirements.

#VALUE!

Block Shear/Bearing Ls = #VALUE! Lt = Edge = #VALUE! #VALUE! #VALUE! #VALUE!

Table 9-3a

#VALUE!

#VALUE! #VALUE! #VALUE! Bearing = Other = #VALUE! #VALUE! #VALUE!

Table 9-3b 214.65 k/in Table 9-3c #VALUE!

von-Mises Fcr =

#VALUE!

#VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! and 5 Rows & 2 Columns 3/4 A325 Bolts

17-Sep-13

Connections I Tab: Single Plate (EX) Analysis Method: LRFD Beam Location: 0

Axial Load Check

Beam to Supporting Member with Single Plate (EX) Shear Connection

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: Fy: Fu: Beam Size: Beam Fy: Beam Fu: Plate Thickness: Plate Leh : Plate Lev : Plate Fy: Plate Fu: Factored Vertical Reaction: Factored Brace Vertical Reaction: Factored Horiz Reaction: Plate Yielding Rupture

W14X90 50.00 ksi 65.00 ksi W21X55 50.00 ksi 65.00 ksi 1/2 1.50 in 1.25 in 36.00 ksi 58.00 ksi 100.00 k 130.00 k

d tw kdet d tw kdet

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Bolt Pitch s: 3

bf tf T bf tf T

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

k1 #VALUE! 1/2 flange = #VALUE! Beam Leh : 1.50 in #VALUE!

Increase Plate Length? Total Vertical Load = 100.00 k #VALUE! Combined Load = 164.01 k Load Angle = Vertical Load Eccentricity ex = 5 Rows and 2 Columns of Bolts Bolt Shear Strength = #VALUE! C= #VALUE! 52.43 deg 4.50 in 8.345 #VALUE!

No

Shear Capacity = Shear Capacity =

#VALUE! #VALUE!

Tensile Capacity = Tensile Capacity =

#VALUE! #VALUE!

Flexural Yield Flexural Rupture Bearing Buckling Block Shear

Fcr = 1.2Lc = K= L-shaped plane Shear Capacity = C-shaped plane

#VALUE! #VALUE! 1.2

Capacity = Capacity = 2.4db = Kl/r = #VALUE! Fcr = #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE!

Bearing = #VALUE! Capacity = #VALUE! #VALUE! #VALUE! Interaction = #VALUE! Interaction = #VALUE! Interaction = #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE!

Tensile Capacity = #VALUE!

Tensile Capacity = P/Pa = P/Pa = #VALUE! #VALUE!

Gross Shear, Axial, & Bending Interaction Net Shear, Axial, & Bending Interaction Shear and Axial Block Shear Interaction Beam Bearing Block Shear Weld Weld = (70ksi electrodes) 52.43 Weld L = 1.2Lc =

#VALUE! #VALUE! #VALUE!

#VALUE!

2.4db = Tensile Capacity =

#VALUE! #VALUE!

Bearing = #VALUE! #VALUE!

#VALUE!

14.50

Capacity =

#VALUE!

#VALUE!

Stabilizer Plates

Stabilizer Plate Fy = Lst = Plate Moment = fv =

50.00 ksi #VALUE! #VALUE! 2.71 ksi Capacity = Capacity = #VALUE! #VALUE! Wst = Plate Tk = fb = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Use Wst = 12.00 in Use Plate TK = 1.00 in Interaction = #VALUE! #VALUE!

Fillet Weld W2 = Fillet Weld W3 =

5/16 1/4

17-Sep-13

Connections I Tab: Single Plate to W Flg Analysis Method: ASD Beam Location: ISC W24x55 to W12x53 423C2

ISC Beam to W Column Flange with Single Plate Shear Connection

Based on 2005 Specification for Structural Steel Buildings

Column Size: Column Fy: Column Fu: Beam Size: Beam Fy: Beam Fu: d tw bf tf T k1 kdet

W12X53 50.00 ksi 65.00 ksi W24X55 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 1 #VALUE!

tf #VALUE! d #VALUE!

SPSC Plate Thickness: Plate Fy: Plate Fu: Plate Leh : Plate Lev : Beam Leh : X' thickness: Plate Fy: Plate Fu: Beam Cap. Reaction a: 3 Bolt Pitch s: 3.00 in A325 N or X? X Multiplier R=

3/8 36.00 ksi 58.00 ksi 2.25 in 2.00 in 2.25 in 1/2 36.00 ksi 58.00 ksi 1.00 55.00 k Shear Per Bolt #VALUE!

#VALUE!

#VALUE! #VALUE! #VALUE!

Reaction: Beam Span: Bolt Size: Bolt Hole Type: Number of Bolts: Plate Length Lp = Local Buckling Check eb = C=

55.00 k

Enter either a Factored Enter either a Factored Reaction or a Beam Span. Reaction or a Beam Span. Use the delete key to erase Use the delete key to erase the unused space. the unused space. Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

7/8 STD

4 Bolts #VALUE! 13.00 in #VALUE! #VALUE! #VALUE! 0.25 in #VALUE! 0.00 in 1.00

Rotational Ductility: #VALUE!

Weld Size 1 = #VALUE! Fillet based on plate thickness Weld Size 2 = 5/16 #VALUE! Controlling Capacity #VALUE! Block Shear/Bearing Ls = #VALUE! Lt = #VALUE! #VALUE! #VALUE! Bearing = #VALUE! #VALUE! Edge = #VALUE! #VALUE! #VALUE! Other = #VALUE! Flange Plate

Available Strengths Bolt Shear Strength #VALUE! #VALUE! SPSC Plate Shear Yield Strength Shear Rupture Strength Block Shear Strength Bearing Strength at Holes Beam Web Beam Web Brg Strength #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE!

Shear Yield Strength

#VALUE!

#VALUE!

Weld (70ksi electrodes) W1 Weld Strength #VALUE! W1 Weld Strength #VALUE!

#VALUE!

#VALUE!

#VALUE! Use W2 = 5/16 in Fillet Weld

#VALUE! with (4) - 7/8 A325 Bolts

#VALUE! Each side of SPSC plate

17-Sep-13

Connections I Tab: Single Plate to Girder Web Analysis Method: LRFD Beam Location:

Beam to Girder Web with Single Plate Shear Connection

Based on 2005 Specification for Structural Steel Buildings

Girder Size: Girder Fy: Girder Fu: Beam Size: Beam Fy: Beam Fu: d tw bf tf Min. Top Cope Depth x Length Beam Cope Depth: Beam Cope Length: Factored Reaction: Beam Span: Bolt Size: Bolt Hole Type: Bolt Type: Number of Bolts: Plate Length Lp = Local Buckling Check eb =

W21X62 50.00 ksi 65.00 ksi #VALUE! W18X35 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 2.00 in 4.00 in 39.80 k

tw #VALUE! d #VALUE! tf #VALUE!

kdet bf

#VALUE! #VALUE!

#VALUE! #VALUE! Plate Thickness 1/4 Plate Fy: 36.00 ksi Plate Fu: 58.00 ksi Plate Leh : Plate Lev : 1.50 in 1.50 in

#VALUE!

#VALUE! #VALUE!

T #VALUE! kdet #VALUE! #VALUE! #VALUE! #VALUE! Beam Offset: Beam Lev : Beam Leh :

Maximum Gross Beam Shear = #VALUE! 0.00 in 1.50 in 1.75 in '(+ is above beam, - is below) Web d left (ho) #VALUE! Enter either a Factored Reaction Enter either a Factored Reaction or a Beam Span. Use the delete or a Beam Span. Use the delete key to erase the unused space. key to erase the unused space. Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE! #VALUE!

Beam Cap. Multiplier 1.00 Reaction Ru = 39.80 k Min a = 2.25 in (Beam Leh + 0.5) 3/4 a: 3 Shear Per Bolt STD Bolt Pitch s: 3.00 in #VALUE! A325 N or X? N #VALUE! g = #VALUE! Not standard spacing 4 Bolts Rotational Ductility: #VALUE! #VALUE! 12 0.25 0.00 in #VALUE! C= 1.00 Controlling Capacity #VALUE! Block Shear/Bearing Ls = #VALUE! Lt = #VALUE! #VALUE! #VALUE! Bearing = #VALUE! #VALUE! Edge = #VALUE! #VALUE! Other = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Snet = Fcr = #VALUE! #VALUE! Ls = Lt = #VALUE! #VALUE! #VALUE!

Bolt Shear Strength Plate Shear Yield Strength Shear Rupture Strength Block Shear Strength Bearing Strength at Holes Beam Web Shear Yield Strength Shear Rupture Strength Block Shear Strength Bearing Strength at Holes Coped Beam Strength

Strengths #VALUE!

#VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Edge = #VALUE! Other = #VALUE!

#VALUE! Bearing =

e=

5.50 in

Weld Weld Strength

#VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Each side of plate

#VALUE! with (4) - 3/4 A325 Bolts

17-Sep-13

Connections I Tab: Single Plate to Girder Web (D) Analysis Method: LRFD Beam Location:

Deep Beam to Girder Web with Single Plate Shear Connection

Based on 2005 Specification for Structural Steel Buildings

Girder Size: Girder Fy: Girder Fu: Beam Size: Beam Fy: Beam Fu: d tw bf tf T Beam Offset: Min. Top Cope Depth x Length Top Cope Depth: Top Cope Length: Factored Reaction: Beam Span: Bolt Size: Bolt Hole Type: Bolt Type: Number of Bolts: Plate Length Lp = Local Buckling Check eb =

W16X40 50.00 ksi 65.00 ksi #VALUE! W16X40 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 0.00 in #VALUE! 1.25 in 3.00 in 39.80 k

tw #VALUE! d #VALUE! tf #VALUE!

kdet bf

#VALUE! #VALUE! #VALUE! 1/4 36.00 ksi 58.00 ksi 1.50 in 1.50 in 1.75 in 1.50 in #VALUE! 1.25 in 3.00 in 0.55 39.80 k #VALUE! #VALUE! Web d left (ho) #VALUE! Enter #VALUE! either a Factored Reaction Enter either a Factored Reaction or a Beam Span. Use the delete or a Beam Span. Use the delete key to erase the unused space. key to erase the unused space. Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Plate Thickness Plate Fy: Plate Fu: Plate Leh: Plate Lev: Beam Lev: kdet Beam Leh: #VALUE! '(+ is above beam, - is below) #VALUE! Min. Bott Cope D x L #VALUE! Bottom Cope Depth: #VALUE! Bottom Cope Length: Beam Cap. Reaction Multiplier Ru =

3/4 STD A325 4 Bolts 12.00 in 0.25 in 0.00 in

a: 3 Shear Per Bolt Bolt Pitch s: 3.00 in #VALUE! N or X? N g = #VALUE! Rotational Ductility: #VALUE! #VALUE! #VALUE! C=

1.00 Controlling Available Strengths Capacity Bolt Shear Strength #VALUE! #VALUE! #VALUE! Plate Shear Yield Strength Shear Rupture Strength Block Shear Strength Bearing Strength at Holes Beam Web Shear Yield Strength Shear Rupture Strength Block Shear Strength Bearing Strength at Holes Coped Beam Strength #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Weld Weld Strength #VALUE! #VALUE! Ls = Lt = Bearing = Edge = Snet = Fcr = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Each side of plate Other = #VALUE! e= 4.75 in #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Block Shear/Bearing Ls = #VALUE! Lt = #VALUE! #VALUE! #VALUE! Bearing = #VALUE! #VALUE! Edge = #VALUE! #VALUE! Other = #VALUE!

#VALUE! with (4) - 3/4 A325 Bolts

17-Sep-13

Connections I Tab: Web Weld-Bolt to WF Analysis Method: LRFD Beam Location:

Double Angle Welded to Beam, Bolted to Supporting Member

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: Supporting Member Fy: Supporting Member Fu: Beam Size: Beam Fy: Beam Fu: d tw bf tf Beam Offset: Min. Top Cope Depth x Length Beam Cope Depth: Beam Cope Length: Factored Reaction: Beam Span: Bolt Size: Bolt Hole Type: Bolt Type: Number of Rows of Bolts: Angle Length =

W21X62 50.00 ksi 65.00 ksi #VALUE! W18X50 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 2.00 in 4.00 in 60.00 k

tw d tf kdet

#VALUE! #VALUE! #VALUE! #VALUE!

Is supporting member Beam or Column? bf #VALUE! Angle Size: L4X3-1/2X1/4 t #VALUE! Angle Fy: 36.00 ksi Angle Fu: 58.00 ksi 1.25 in 1.4300 in #VALUE!

3.5 OSL #VALUE! Gage = GOL = #VALUE! #VALUE!

#VALUE!

Angle OSL Lev : Angle OSL Leh : kdet #VALUE! T #VALUE! #VALUE! #VALUE! #VALUE! Beam Cap. Reaction Bolt Pitch s: N or X? g= 3.00 in X 3.63 in Beam setback: Shelf 'b' Max. weld size

3/4 STD A325 3 Rows 8.5

Shelf is less than AISC requirements. based on angle thickness ho = #VALUE! Multiplier 1.00 Enter either a Factored Enter either a Factored Ru = 60.00 k Reaction or a Beam Span. Use Reaction or a Beam Span. Use the delete key to erase the the delete key to erase the unused space. Shear Per Bolt unused space. #VALUE! Not standard spacing Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

1/2 0.3750 in #VALUE!

#VALUE! Controlling Capacity #VALUE! L= Ls = Lt = Bearing = Edge = 7.25 #VALUE! #VALUE! #VALUE! #VALUE! Other = #VALUE! #VALUE!

Available Strengths Bolt Shear Strength #VALUE! #VALUE! Angle Shear Yield Strength Shear Rupture Strengh OSL Block Shear Bearing Strength at Holes Beam Web Block Shear Strength Shear Yield Strength Coped Beam Strength

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE!

Ls = Lt = Snet = Fcr =

8.88 k #VALUE! #VALUE! #VALUE!

Beam web design strength per inch of thickness = e= #VALUE! #VALUE!

Weld Weld Size: Weld Strength Girder Web Bearing Strength at Holes #VALUE! 3/16 #VALUE! Fillet #VALUE! #VALUE! #VALUE! (70ksi electrodes) Min web tk #VALUE! #VALUE! #VALUE!

#VALUE!

#VALUE!

#VALUE! #VALUE! Support Design Strength/1" tk. = #VALUE!

#VALUE! with (3) Rows - 3/4 A325 Bolts

17-Sep-13

Connections I Tab: Web Weld-Bolt to WF (D) Analysis Method: LRFD Beam Location:

Double Angle Welded to Deep Beam, Bolted to Supporting Member

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: Supporting Member Fy: Supporting Member Fu: Beam Size: Beam Fy: Beam Fu: d tw bf tf T Beam Offset: Min. Top Cope Depth x Length Top Cope Depth: Top Cope Length: Factored Reaction: Beam Span: Bolt Size: Bolt Hole Type: Bolt Type: Number of Rows of Bolts: Angle Length =

W16X31 50.00 ksi 65.00 ksi #VALUE! W18X50 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 0.00 in #VALUE! 1.25 in 4.00 in 60.00 k

tw #VALUE! d #VALUE! tf #VALUE!

bf kdet

#VALUE! #VALUE! #VALUE! #VALUE! 3.5 OSL #VALUE! Gage = #VALUE! GOL = #VALUE!

Angle Size: L4X3-1/2X1/4 t #VALUE! Angle Fy: 36.00 ksi Angle Fu: 58.00 ksi Angle OSL Lev : Angle OSL Leh : Beam setback : kdet #VALUE! Shelf 'b' : (+ is above beam, - is below) #VALUE! Min. Bott Cope D x L #VALUE! Bottom Cope Depth: #VALUE! Bottom Cope Length: Beam Cap. Reaction Bolt Pitch s: 3.00 in A325 N or X? N g = #VALUE! Multiplier Ru = 1.25 in 1.4300 in 1/2 0.3750 in #VALUE! 3.00 in 4.00 in 1.00 60.00 k

Shelf is less than AISC requirements. #VALUE! #VALUE! #VALUE! Web d left (ho) #VALUE! Enter either a Factored Reaction Enter either a Factored Reaction or a Beam Span. Use the delete or a Beam Span. Use the delete key to erase the unused space. key to erase the unused space. Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

3/4 STD A325 3 Rows #VALUE! 8.5

Shear Per Bolt #VALUE! Not standard spacing

Available Strengths Bolt Shear Strength #VALUE! #VALUE! Angle Shear Yield Strength Shear Rupture Strengh OSL Block Shear Bearing Strength at Holes Beam Web Block Shear Strength Shear Yield Strength Coped Beam Strength #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Controlling Capacity #VALUE!

#VALUE! #VALUE!

Ls = Lt =

#VALUE! #VALUE! #VALUE! #VALUE! Other = #VALUE!

#VALUE! Bearing = #VALUE! Edge =

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

Ls = Lt = Snet = Fcr =

8.88 k #VALUE! #VALUE! #VALUE!

Beam web design strength per inch of thickness = #VALUE!

e = #VALUE!

Weld Weld Size = Weld Strength Girder Web Bearing Strength at Holes #VALUE! #VALUE! #VALUE! #VALUE! 3/16 #VALUE! Fillet #VALUE! #VALUE! #VALUE! Min web tk #VALUE! #VALUE! #VALUE! (70ksi electrodes)

#VALUE! with 3 Rows - 3/4 A325 Bolts

Support Design Strength/1" tk. = #VALUE!

#VALUE!

17-Sep-13

Connections I Tab: Web Bolt-Bolt to WF Analysis Method: ASD Beam Location:

Double Angle Bolted to Beam, Bolted to Supporting Member

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: Supporting Member Fy: Supporting Member Fu: Beam Size: Beam Fy: Beam Fu: d tw bf tf T Beam Lev : Beam Leh : Reaction: Beam Span: Bolt Size: Bolt Hole Type: Number of Rows of Bolts: Angle Length =

W21X62 50.00 ksi 65.00 ksi #VALUE! W18X50 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 1.25 in 1.75 in 40.00 k

tw #VALUE! d #VALUE! tf #VALUE!

Is supporting member Beam or Column? bf #VALUE!

Angle is A36 Angle Size: L4X3-1/2X1/4 t #VALUE! Angle Lev : 1.25 in Angle Leh : 1.2500 in Angle OSL Leh : kdet Beam setback : #VALUE! Beam Offset: Min. Top Cope Depth x Length Cope Depth: Cope Length: Beam Cap. Reaction Bolt Pitch s: 3.00 in A325 N or X? N g= 3.25 in Multiplier R= 1.1875 in 1/2 0.00 in #VALUE! 2.00 in 4.00 in 1.00 40.00 k Shear Per Bolt #VALUE! Not standard spacing

#VALUE! #VALUE! 3.5 OSL #VALUE! Gage = #VALUE! GOL = #VALUE! Angle Gage = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Enter either a Factored Reaction Enter either a Factored Reaction or a Beam Span. Use the delete or a Beam Span. Use the delete key to erase the unused space. key to erase the unused space. Web Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE! Support Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

3/4 STD 3 Rows #VALUE! 8.5

Available Strengths Bolt Shear Strength #VALUE! #VALUE! Angle Shear Yield Strength Shear Rupture Strength Block Shear along Web Bearing Strength at Holes OSL Block Shear Beam Web Shear Yield Strength Shear Rupture Strength Block Shear Strength Bearing Strength at Holes Coped Section Flexural Yield Cope Local Web Buckling

Controlling Capacity #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! Angle Ls = Lt = #VALUE! #VALUE! #VALUE! #VALUE! OSL Ls = Lt =

#VALUE! #VALUE! #VALUE! #VALUE!

Bearing = #VALUE! Edge = #VALUE! Other = #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Ls = Lt = Edge = Snet = Fcr =

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Beam web design strength per inch of thickness = #VALUE!

#VALUE! Bearing =

Other = #VALUE! e = #VALUE!

Girder Web Bearing Strength at Holes #VALUE!

#VALUE!

#VALUE!

#VALUE! #VALUE! Support Design Strength/1" tk. = #VALUE!

#VALUE! with 3 Rows - 3/4 A325 Bolts

17-Sep-13

Connections I Tab: Web Bolt-Bolt to WF (D) Analysis Method: LRFD Beam Location:

Double Angle Bolted to Deep Beam, Bolted to Supporting Member

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: Supporting Member Fy: Supporting Member Fu: Beam Size: Beam Fy: Beam Fu:

W18X35 50.00 ksi 65.00 ksi #VALUE! W21X55 50.00 ksi 65.00 ksi

tw #VALUE! d #VALUE! tf #VALUE!

bf

#VALUE!

d #VALUE! Angle OSL Leh : tw #VALUE! bf #VALUE! tf #VALUE! kdet T #VALUE! #VALUE! Beam setback : Beam Offset: 0.00 in Min. Top Cope Depth x Length #VALUE! #VALUE! Beam Lev : 2.00 in Top Cope Depth: 2.00 in Beam Leh : 2.00 in Top Cope Length: 4.50 in Factored Reaction: Beam Span: Bolt Size: Bolt Hole Type: Bolt Type: Number of Rows of Bolts: 64.00 k Beam Cap. Reaction Bolt Pitch s: A325 N or X?

Angle is A36 Angle Size: L4X3-1/2X5/16 t #VALUE! Angle Lev : 2.00 in Angle Leh : 2.5000 in 1.1875 in

#VALUE! #VALUE! 5 OSL #VALUE! Gage = #VALUE! GOL = #VALUE! Angle Gage = #VALUE! #VALUE!

1/2 Min. Bott Cope D x L #VALUE! #VALUE! #VALUE! Btm. Cope Depth: 2.25 in

1 1/8 STD A325 5 Rows

g=

#VALUE! Btm. Cope Length: 4.50 in Web d left (ho) #VALUE! Multiplier 1.00 Enter either a Factored Reaction Enter either a Factored Reaction Ru = 64.00 k or a Beam Span. Use the delete or a Beam Span. Use the delete key to erase the unused space. key to erase the unused space. 3.50 in Shear Per Bolt N #VALUE! Web Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE! #VALUE! Not standard spacing Support Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

Angle Length = 18 Available Strengths Bolt Shear Strength #VALUE! #VALUE! Angle Shear Yield Strength Shear Rupture Strengh Block Shear at Web Bearing Strength at Holes OSL Block Shear Beam Web Block Shear Strength Shear Yield Strength Shear Rupture Strengh Bearing Strength at Holes

Controlling Capacity #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! Angle Ls = Lt = #VALUE! #VALUE! #VALUE! #VALUE! OSL Ls = Lt =

#VALUE! #VALUE! #VALUE! #VALUE!

Bearing = #VALUE! Edge = #VALUE! Other = #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE!

Ls = Lt =

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 50.00 ksi

Beam web design strength per inch of thickness = #VALUE!

#VALUE! Bearing = Edge =

Other =

#VALUE!

Coped Beam Strength Girder Web Bearing Strength at Holes #VALUE!

#VALUE!

#VALUE!

#VALUE! #VALUE!

Snet = Fcr =

e = #VALUE!

#VALUE!

#VALUE!

#VALUE!

Support Design Strength/1" tk. = #VALUE! with 5 Rows - 1 1/8 A325-N Bolts

#VALUE!

17-Sep-13

Connections I Tab: Web Bolt-Weld to WF Analysis Method: LRFD Beam Location:

Double Angle Bolted to Beam, Welded to Column Flange

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: Supporting Member Fy: Supporting Member Fu: Beam Size: Beam Fy: Beam Fu: d tw bf tf T Bottom Beam Lev = Beam Leh : Factored Reaction: Beam Span: Bolt Size: Bolt Hole Type: Bolt Type: Number of Rows of Bolts:

W14X730 50.00 ksi 65.00 ksi W21X62 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 2.13 in 100.00 k

tw #VALUE! d #VALUE! tf #VALUE! Angle Size: t Angle Fy: Angle Fu: Angle Lev : Angle Leh : kdet #VALUE! Beam setback : Min. Bott Cope D x L Bottom Cope Depth: Bottom Cope Length: Beam Cap. Reaction Bolt Pitch s: N or X? g: 3.00 in N 3.00 in Multiplier Ru = L6X6X3/8 #VALUE! 36.00 ksi 58.00 ksi 1.25 in 3.0000 in 7/8 #VALUE! 1.25 in 6.25 in 1.00 100.00 k Shear Per Bolt #VALUE! #VALUE! #VALUE! 6 OSL #VALUE!

Angle Gage = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Enter either a Factored Reaction Enter either a Factored Reaction or a Beam Span. Use the delete or a Beam Span. Use the delete key to erase the unused space. key to erase the unused space. Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

7/8 STD A325 #VALUE! 5 Rows

Angle Length = 14.5 Available Strengths Bolt Shear Strength #VALUE! #VALUE! Angle Shear Yield Strength Shear Rupture Strengh Block Shear at Web Bearing Strength at Holes Beam Web Bearing Strength at Holes Shear Yield Strength Shear Rupture Strength Coped Section Flexural Yield Weld Weld Size: Weld Strength 5/16 #VALUE! Fillet #VALUE!

Controlling Capacity #VALUE!

Web d left (ho) #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! Angle Ls = Lt = #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE!

Bearing = #VALUE! Edge = #VALUE! Other = #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! Snet = #VALUE!

Beam web design strength per inch of thickness = #VALUE! e = #VALUE!

#VALUE! #VALUE! Min flg tk #VALUE! #VALUE!

#VALUE! with 5 Rows - 7/8 A325-N Bolts

17-Sep-13

Connections I Tab: Web Bolt-Weld to HSS Analysis Method: LRFD Beam Location:

Double Angle Bolted to Beam, Welded to HSS

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: HSS14X14X1/2 Supporting Member Fy: 46.00 ksi Supporting Member Fu: 58.00 ksi Beam Size: Beam Fy: Beam Fu: d tw bf tf T Bottom Beam Lev = Beam Leh : Factored Reaction: Beam Span: Bolt Size: Bolt Hole Type: Bolt Type: Number of Rows of Bolts: W36X231 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 1.75 in 226.00 k

tnom #VALUE! tdes #VALUE!

b ht #VALUE!

#VALUE! #VALUE! #VALUE!

Angle Size: L4X3-1/2X3/8 t #VALUE! Angle Fy: 36.00 ksi Angle Fu: 58.00 ksi Angle Lev : 1.25 in Angle Leh : 1.2500 in kdet #VALUE! Beam setback : Min. Bott Cope D x L Bottom Cope Depth: Bottom Cope Length: Beam Cap. Reaction Bolt Pitch s: N or X? g: 3.00 in N 2.50 in Multiplier Ru = 1/2 #VALUE! #VALUE! 3.00 in 4.00 in 1.00 226.00 k Shear Per Bolt #VALUE!

3.5 OSL #VALUE! #VALUE! #VALUE! Angle Gage = #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! Enter either a Factored Reaction Enter either a Factored Reaction or a Beam Span. Use the delete or a Beam Span. Use the delete key to erase the unused space. key to erase the unused space. Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

3/4 STD A325 #VALUE! 8 Rows

Angle Length = 23.5 Available Strengths Bolt Shear Strength #VALUE! #VALUE! Angle Shear Yield Strength Shear Rupture Strengh Block Shear at Web Bearing Strength at Holes Beam Web Shear Yield Strength Shear Rupture Strength Bearing Strength at Holes Coped Section Flexural Yield Weld Weld Size: Weld Strength 5/16 #VALUE! Fillet #VALUE!

Controlling Capacity #VALUE!

Web d left (ho) #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! Angle Ls = Lt = #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE!

Bearing = #VALUE! Edge = #VALUE! Other = #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! Snet = #VALUE!

Beam web design strength per inch of thickness = #VALUE! e = #VALUE!

#VALUE! #VALUE! Min HSS tk #VALUE! #VALUE!

#VALUE! with 8 Rows - 3/4 A325-N Bolts

17-Sep-13

Connections I Tab: Shear End-Plate Analysis Method: LRFD Beam Location:

Shear End-Plate

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: Supporting Member Fy: Supporting Member Fu: Beam Size: Beam Fy: Beam Fu: d tw bf tf T

W14X61 50.00 ksi 65.00 ksi #VALUE! W18X50 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 0.00 in

tw #VALUE! d #VALUE! tf #VALUE!

Is supporting member Beam or Column? bf #VALUE! Flange or Web? kdet #VALUE! 1/4 6.00 in 1.25 in 1.2500 in 36.00 ksi 58.00 ksi

C F

Plate Thickness: Plate Width: Plate Lev : Plate Leh : Plate Fy: Plate Fu: kdet #VALUE! Beam Lev : #VALUE!

Gage = #VALUE!

1.25 in

Factored Reaction: Beam Span: Bolt Size: Bolt Hole Type: Number of Rows of Bolts: Plate Length Lp =

60.00 k

Beam Cap. Reaction Bolt Pitch s: 3.00 in A325 N or X? N g= #VALUE! Controlling Capacity #VALUE! 3 in

Multiplier Ru =

1.00 60.00 k Shear Per Bolt #VALUE!

7/8 STD 3 Rows 8.5

Enter either a Factored Reaction Enter either a Factored Reaction or a Beam Span. Use the delete or a Beam Span. Use the delete key to erase the unused space. key to erase the unused space. Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

Available Strengths Bolt Shear Strength #VALUE! #VALUE! Plate Shear Yield Strength Shear Rupture Strengh Block Shear Strength Bearing Strength at Holes Beam Web #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE!

Ls =

#VALUE! #VALUE! #VALUE! #VALUE!

Lt = #VALUE! #VALUE! Bearing = Edge = #VALUE!

Other =

#VALUE!

Fbc = Weld Weld Size: Weld Strength Column Flange Bearing Strength at Holes #VALUE! 3/16 #VALUE! Fillet #VALUE! #VALUE! Min web tk #VALUE! #VALUE! (70ksi electrodes)

#VALUE!

#VALUE!

#VALUE! #VALUE! Support Design Strength/1" tk. =

#VALUE! with 3 Rows - 7/8 A325 Bolts

#VALUE!

17-Sep-13

Connections I Tab: Shear End-Plate (D) Analysis Method: LRFD Beam Location:

Shear End-Plate to Deep Beam

Based on 2005 Specification for Structural Steel Buildings

Supporting Member Size: Supporting Member Fy: Supporting Member Fu: Beam Size: Beam Fy: Beam Fu: d tw bf tf T Beam Offset: Min. Top Cope Depth x Length Beam Cope Depth: Beam Cope Length: Factored Reaction: Beam Span: Bolt Size: Bolt Hole Type: Number of Rows of Bolts: Angle Length =

W10x12 50.00 ksi 65.00 ksi #VALUE! W10x12 50.00 ksi 65.00 ksi #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! 0.000 in #VALUE! 0.75 in 2.25 in 10.00 k

tw #VALUE! d #VALUE! tf #VALUE!

bf kdet

#VALUE! #VALUE! 1/4 6.00 in 1.25 in 1.2500 in 36.00 ksi 58.00 ksi 2.25 in #VALUE! 0.75 in 2.25 in 1.00 10.00 k Shear Per Bolt #VALUE! #VALUE! #VALUE! Web d left (ho) #VALUE! Gage = #VALUE!

Plate Thickness: Plate Width: Plate Lev : Plate Leh : Plate Fy: Plate Fu: kdet #VALUE! Beam Lev :

Min. Bott Cope D x L #VALUE! #VALUE! Bottom Cope Depth: #VALUE! Bottom Cope Length: Beam Cap. Reaction Bolt Pitch s: 3.00 in A325 N or X? N g = #VALUE! Multiplier Ru =

3/4 STD 2 Rows 5.5

Enter either a Factored Reaction Enter either a Factored Reaction or a Beam Span. Use the delete or a Beam Span. Use the delete key to erase the unused space. key to erase the unused space. Bolt Length = #VALUE! Shank Length = #VALUE! #VALUE!

Available Strengths Bolt Shear Strength #VALUE! #VALUE! Plate Shear Yield Strength Shear Rupture Strengh Block Shear Strength Bearing Strength at Holes Beam Web Shear Yield Strength Coped Section Flexural Yield Cope Local Web Buckling Weld Weld Size: Weld Strength Girder Web Bearing Strength at Holes #VALUE! #VALUE! #VALUE! 1/4 #VALUE! Fillet #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Controlling Capacity #VALUE!

#VALUE! #VALUE! #VALUE!

Ls = Lt = Edge =

#VALUE! #VALUE! #VALUE! #VALUE! Other = #VALUE!

#VALUE! Bearing =

#VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! Snet = Fbc = #VALUE! #VALUE! e = #VALUE!

(70ksi electrodes) #VALUE! Min web tk #VALUE! #VALUE! #VALUE! Support Design Strength/1" tk. = #VALUE! #VALUE!