Professional Documents

Culture Documents

Saw Cutting Chart

Uploaded by

HammondMachineCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saw Cutting Chart

Uploaded by

HammondMachineCopyright:

Available Formats

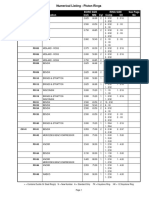

Cutting Charts

These recommendations are based on our experience and tests

made under optimum metal sawing conditions. If specific

considerations such as cutting rate, surface finish, accuracy or

tool life are of major concern, you may have to deviate from

the basic recommendation given. If you are in doubt call the

MARVEL HOT LINE, 1-800-628-8462, for our recommendation.

Spartan PA 10, PA 13, PA 18

Follow Tooth Pitch, and Speed Selection for the

appropriate blade width and material size. Then follow

feed color code as shown on the machine console.

Type of Blade

Blade Marvel No. 8 Mark II, V-10A, PA 10

Size of Stock

Up to 4 Stock

Materials

Carbon Steel

Free Machining

Carbon Steels

Teeth

1015-1050

5/8 MT

1065

5/8 MT

1095

5/8 MT

4/6

MT

4/6

MT

4/6

MT

1137, 1151

L1141

1141

Cast Iron

Chrome

Moly

Chrome

Chrome

Van Silicon

5/8 MT

4130-4150

5/8 MT

41L40-41L50

4/6 MT

4340

4/6 MT

4340HT, (321BHN) 4/6 MT

4620, 4720

4/6 MT

4820

5/8 MT

5120

5/8 MT

52100

5/8 MT

6150

5/8 MT

8620

5/8 MT

9310

5/8 MT

T-1, T-2, T-4, T-5

M-1, M-2, M-3, M-4 4/6 PV

Tool

Steels

T-15, M-15

4/6 PV

D-2, D-3, D-6

A-2, A-4, O-7

O-1, O-2, O-6

4/6 PV

4/6 PV

W-1, W-2, W-3 4/6 PV

H-12, H-13, H-21 4/6 PV

10

S-1, S-2, S-5

4/6 PV

M-42, M-43

4/6 PV

P-20

4/6 PV

Over 4 Stock

No. 8 Mark II

No. 8 Mark II

No. V-10A

No. V-10A

Pressure

Pressure

Speed Pressure

Speed Pressure

Teeth

C/Rate

C/Rate

C/Rate

C/Rate

Lbs.

Lbs.

FPM

Lbs.

FPM

Lbs.

2008020090120260

60-75

4-6

100

6-10 3/4 MT 280

100

7-10

140

9-12

1408014590120180

60-80

4-5

100

5-6 3/4 MT 180

100

5-7

140

7-8

140100

145100120180

60-80 2-3.5 120

3-4 3/4 MT 180

120

4-5

140

5-6

20070200120240

60-80

5-8

110

8-11 3/4 MT 240

60-80 6-12

145

9-13

20070200120

280

60-80

5-8

110

8-11 3/4 MT 280

60-80 6-12

145

9-13

20070200120

280

60-80

5-8

110

8-11 3/4 MT 280

60-80 6-12

145

9-13

12080120100160

50-60

4-5

100

5-6 3/4 MT 160

50-60 4-5

110

5-6

1758018080120220

70-90

4-5

100

5-7 3/4 MT 230

110

4-6

150

7-10

185808018580120240

100

5-6

100

8-10 3/4 MT 240

110

5-7

150 10-12

1258012585130150

75-90

3-4

120

4-5 3/4 MT 150

110 3-4.5

160

4.5-7

80110

60-90 60-80

2-3

100

3-4 3/4 MT 75-95 70-90 3-4

130

4-5

80110

60-90 60-80

2-3

100

3-4 3/4 MT 60-90 70-90 3-4

130

4-5

19580195100120220

70-90

4-5

110

5-7 3/4 MT 230

120

5-7

140

7-9

195100195100120220

70-90

3-5

120

5-7 3/4 MT 240

110

4-6

140

7-9

1357010013580120150

100

3-4

120

4-5 3/4 MT 150

110

3-5

140

5-6

8010014090110220

100

3-4

110

4-5 3/4 MT 210

110 3.5-4.5 120

5-6

19510019580110220

70-90

4-5

110

5-6 3/4 MT 220

100 4.5-5.5 120

6-7

100100110110140 65-80- 2-3

120

3-4 3/4 MT 150 70-90

3-4

130

4-5

701007065110100

60-90

2-3

110

3-4 3/4 PV 100

105

2-3

130

4-5

801008070110100

70-95

1-2

110

2-3 3/4 PV 110

110

2-3

130

2-3

651006580110100

70-90 2-2.5 110 2.5-3.5 3/4 PV 100

100 2-2.5

130 2.5-3.5

10010010090110140

70-90

3-4

120 3.5-4.5 3/4 PV 140

110 3.5-4.5 130

4.5-6

11010011590110160

70-90 2-2.5 120

3-4 3/4 PV 180

110

2-3

130

5-6

11511011590120160

70-90

2-4

130

3.5-4 3/4 PV 160

100 3-4.5

140

5-7

951109580120140

70-90

2-3

130

3-4 3/4 PV 150

100

3-4

140

5-6

701107080120100

70-90 1-1.5 130

1.5-2 3/4 PV 100

100 1-1.5

140

2-2.5

851107590120140

70-90

2-3

130

3-4 3/4 PV 140

110 3-3.5

140

5-6

A R M S T R O N G - B L U M

M A N U F A C T U R I N G

C O .

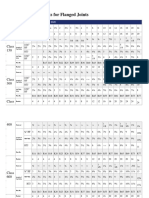

Cutting Charts (contd)

KEY

C/RATE

Indicates KUT-ALL (MT)

and Eagle Beak (PR)

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 MT

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PV

Cutting Rate in Square

Inches Per Minute

Heavy Duty 11/4 Blade

Heavy Duty 11/2 Blade

No. 13A, 15, 15APC, 81, 81APC, PA13

No. 15M10, 15APCM10, 25, MV525, 2125, PA18

Up to 5 Stock

Teeth

Marvel MAX (PV)

Over 5 Stock

Over 5 Stock

Speed Pressure

Speed Pressure

C/Rate Teeth

C/Rate Teeth

FPM

Lbs.

FPM

Lbs.

30080240120330

120

17-25 3/4 MT 300

180

20-26 2/3 PR

195100200140240

120

9-11 3/4 MT 260

240

11-13 2/3 PR

150100150120180

120

5-9

3/4 MT 180

200

8-10 2/3 PR

2108021080290

100- 12-18 3/4 MT 280

120

8-14 2/3 PR

2707027080300

100

22-30 3/4 MT 300

120

24-34 2/3 PR

24010024080280

120

20-30 3/4MT

280

120

20-30 2/3 PR

120100120140160

120

8-12 3/4 MT 160

180

8-12 3/4 PR

195110200190275

180

10-15 3/4 MT 275

260

12-16 3/4 PR

220150200190300

200

11-15 3/4 MT 300

260

14-18 3/4 PR

130150135190200

200

6-10 3/4 MT 190

260

7-11 3/4 PR

9014090140120

180

5-7

3/4 MT 120

180

5-8

3/4 PR

130140130150175

180

8-10 3/4 MT 175

190

9-11 3/4 PR

195140195150240

180

8-11 3/4 MT 240

190

9-12 3/4 PR

200140200150255

180

9-11 3/4 MT 255

190

10-12 3/4 PR

145140140150180

190

7-8

3/4 MT 190

190

7.5-9 3/4 PR

145150145160220

190

6-8

3/4 MT 220

220

7-9

3/4 PR

195160195160260

220

9-11 3/4 MT 260

240

10-12 3/4 PR

110120120130185

180

6-7

3/4 MT 180

180

6-7.5 3/4 PR

8513095140120

160

3-4

3/4 PV 120

180

4-4.5 3/4 PV

8013090140120

170

2-3.5 3/4 PV 120

180

2-3.5 3/4 PV

7013070140110

180

3-4

3/4 PV 110

180

3-4

3/4 PV

115140115150180

160

7-8

3/4 PV 180

200

7-8

3/4 PV

150140150150200

160

6-7

3/4 PV 200

210

6-8

3/4 PV

130150115150200

200

5-7

3/4 PV 180

200

5-7

3/4 PV

110150110150160

180

5-6

3/4 PV 160

200

5-6.5 3/4 PV

7514075140110

150

2-2.5 3/4 PV 140

180

2-2.5 3/4 PV

120150120150160

180

3-4

3/4 PV 160

180

3-5

3/4 PV

Size of Stock

Speed Pressure

Materials

C/Rate

FPM

Lbs.

240195300

330

20-26

1015-1050

Carbon

200300260

390 13-15.5

1065

Steel

150180180

300 9.5-12

1095

210150280

180 9.5-17

1137, 1151

Free

270405Machining

300

450

24-32

L1141

240150Carbon Steels

280

180

20-30

1141

120180Cast Iron

160

240 9.5-14.5

200285275

390 14.5-19

4130-4150

200300300

450 17-21.5

41L40-41L50

135285190

390 8.5-13

4340

Chrome

90210Moly

120

270

6-9.5 4340HT, (321BHN)

130225175

285

11-13

4620-4720

195225240

285 11-14.5

4820

200225255

285 12-14.5

5120

Chrome

140225190

285

9-11

52100

145240220

330 8.5-11

6150

195240Chrome

260

360 12-14.5

8620

Van Silicon

120195180

270

7-9

9310

95210T-1, T-2, T-4, T-5

120

270

5-5.5 M-1, M-2, M-3, M-4

90210120

270

2.5-4

T-15, M-15

70210110

270

3-3.5

D2, D3, D6

115225A2, A4, O7

180

270 8.5-9.5

O1, O2, O6

150225Tool

200

315

7-9.5

W-1, W-2, W-3

Steels

115225180

300

6-8

H-12, H-13, H-21

110225160

300

6-8

S-1, S-2, S-5

75210140

270

2.5-3

M-42, M43

150225180

270

3.5-6

P-20

W W W . S A W I N G . C O M

11

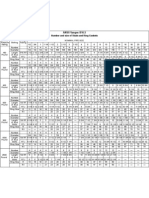

Cutting Charts (contd)

These recommendations are based on our experience and

tests made under optimum metal sawing conditions. If specific

considerations such as cutting rate, surface finish, accuracy or

tool life are of major concern, you may have to deviate from

the basic recommendation given. If you are in doubt call the

MARVEL HOT LINE, 1-800-628-8462, for our recommendation.

Type of Blade

Medium Duty 1 Blade Marvel No. 8 Mark II, V-10A

Size of Stock

Up to 4 Stock

Materials

Teeth

201, 202, 304

4/6 PV

303, 303F

4/6 PV

310, 308, 316,

330

4/6 PV

321-347

4/6 PV

416-430F

4/6 PV

436

4/6 PV

440A, 440C

4/6 PV

Stainless Steel

403, 410, 420F 4/6 PV

17-4PH, 17-7PH 4/6 PV

Non-Ferrous

Metals

A286

4/6 PV

Aluminum

Manganese

Bronze

Aluminum

Bronze

4/6 MT

4/6 MT

Copper

4/6 MT

Monel K

4/6 PV

Inconel-X

3/4 PV

4/6 MT

Hastelloy A 3/4 PV

Hastelloy

Hastelloy B 3/4 PV

Hastelloy C 3/4 PV

Titanium

3/4 PV

Structural

Size & Shape

No. 8 Mark II

No. V-10A

Pressure

Speed Pressure

C/Rate

C/Rate Teeth

Lbs.

FPM

Lbs.

75100100

70-90

1-2

120

2-3 3/4 PV

90100140

70-90

2-3

120

3-4 3/4 PV

75100100

60-85

1-2

120

2-3 3/4 PV

70100100

60-80

1-2

120

2-3 3/4 PV

85100140

70-90

2-3

120

3-4 3/4 PV

70100110

70-90

1-2

120

2-3 3/4 PV

70100100

70-90 2-2.5 120

3-3.5 3/4 PV

100100150

70-90

2-3

120

3-4 3/4 PV

70100100

60-80

1-2

120

2-3 3/4 PV

10065-80 60-80 1-1.5 120

1.5-2 3/4 PV

250100400

40-90 8-14 120

8-14 3/4 MT

140100180

40-70

2-4

110

3-5 4/6 MT

120110140

50-85

1-3

120

2-4 3/4 MT

150110200

50-90

2-4

120

4-6 3/4 MT

10070-90 50-80

1-2

120

2-3 3/4 PV

8010060-90 100

.5-1

120

1-2 3/4 PV

12012060-90 130

1-1.5 130

3-4 3/4 PV

12012060-90 130

1-1.5 130

2-3 3/4 PV

12012060-90 130

.5-1

130 1.5-2.5 3/4 PV

12012060-90 130

.7-1.3 130

1-1.5 3/4 PV

Medium Duty 1 Blade

Marvel No. 8 Mark II, V-10A

Pressure

Teeth

Speed

Lbs.

C/Rate

Bar Size Angles, Channels, Beams

6/10 MT

Structural Shapes & Tubes Up To 80# Per Ft.

6/8 MT

Structural Shapes Up To 100# Per Ft.

4/6 PR2

Structural Shapes Over 100# Per Ft.

3/4 PR2

12

Over 4 Stock

200260

200260

200260

240280

A R M S T R O N G - B L U M

4060

4060

6080

6080

No. 8 Mark II

No. V-10A

Pressure

Speed Pressure

C/Rate

C/Rate

Lbs.

FPM

Lbs.

8090120110

110

2-3

140

3-4

100100120150

120

4-5

140

5-6

75100120100

110 1.5-2.5 140

2-4

8070120110

100 2-2.5

140

3-4

11070120150

100 2.5-3

140

4-5

8070120120

100 2-2.5

140

3-4

7570120100

100 2.5-3

140 3.5-4.5

11080120155

100 3-3.5

140

4-5

7580120110

100 2-2.5

140

3-4

8012065-85

100

1-2

140

2-2.5

25050120450

120

7-15

140 12-20

140110180

50-80

2-5

120

4-6

12550120150

100

1-4

130

2-5

15050120210

100

2-5

130

5-7

11060-90 50-90 2-2.5

130

2-3

11060-90 50-85

1-2

130

1-2

12014060-90

140

.5-1

160

2-3

12014060-90

140

.5-1

160 1.5-2.5

12014060-90

140

.5-1

160 1.5-2.5

12014060-90

140 .7-1.3

160

1-1.5

Heavy Duty 11/4-1 1/2 Blade

No. 13A, 15, 15A, 81, 81A PC, 25

Pressure

Teeth

Speed

Lbs.

C/Rate

5-7

4/6 PR2

7-9

4/6 PR2

7-9

4/6 PR2

10-12

3/4 PR2

240280

240280

240280

240280

M A N U F A C T U R I N G

70100

70120

70120

80130

Up To

12

Up To

12

Up To

15

Up To

15

C O .

Cutting Charts (contd)

KEY

C/RATE

Indicates KUT-ALL (MT)

and Eagle Beak (PR)

Marvel MAX (PV)

Heavy Duty 114 Blade

Heavy Duty 112 Blade

No. 13A, 15, 15APC, 81, 81APC

No. 15M10, 15APCM10, 25, MV525, 225

Up to 5 Stock

Teeth

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PV

4/6 PR

4/6 PR

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

Cutting Rate in Square

Inches Per Minute

Over 5 Stock

Speed Pressure

C/Rate

FPM

Lbs.

80150120

180

3-4

100160150

190

5-6

75150110

170

2.5-3

80140115

180

3-4

110150170

190

5-6

80150120

180

2.5-3

75130120

160

4-5

110150155

190

4-5

75140120

180

3-4

14065-85

170

2-3

200100350

140

15-30

13080180

120

5-10

12580150

150

3-5

170100250

140

5-9

8060-95

150

2-3

10060-90

150

2-3

10060-90

150

4-5

10060-90

150

3-4

10060-90

150

2-3

10060-90

150

1.5-2

Teeth

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

3/4 PV

Over 5 Stock

Speed Pressure

C/Rate Teeth

FPM

Lbs.

80160120

200

4-6

3/4 PV

100160150

190

6-6.5 3/4 PV

75150110

170 2.5-3.5 3/4 PV

85160120

190 3.5-4.5 3/4 PV

110160170

190

6-7

3/4 PV

80160120

180

3-4

3/4 PV

75160120

190

4-5

3/4 PV

110160155

180

4-5

3/4 PV

75150120

185

3-4.5 3/4 PV

15065-85

170

2-2.5 3/4 PV

200100400

140

15-35 2/3 PV

130100190

150

5-10 3/4 PV

14090155

150

2-6

3/4 PV

17090250

150

5-9

3/4 PV

8060-95

150

2-3

3/4 PV

10060-90

150

2-3

3/4 PV

12060-90

160

4-5

2/3 PV

12060-90

160

3-4

2/3 PV

12060-90

160

2-3

2/3 PV

12060-90

160

1.5-2 2/3 PV

Size of Stock

Speed Pressure

C/Rate

FPM

Lbs.

80240120

300

4-6

100240150

285

7-8

75225110

255

3-4

85240120

285

4-5

110240170

285

7-8.5

80240120

270

3.5-5

75240120

285

5-6

110240155

270

5-6

75225120

277

3.3-6

22565-85

255

2.5-3

200150400

210

18-42

130150190

225

6-12

140140155

225

2.5-7

170135250

225

6-11

12060-95

225 2.5-3.5

15060-90

225 2.5-3.5

18060-90

240

5-6

18060-90

240

3.5-5

18060-90

240 2.5-3.5

18060-90

240

2-2.5

Materials

201, 202, 304

303, 303F

310, 308, 316, 330

321, 347

416, 430F

Stainless

Steel

436

440A, 440C

403, 410, 420F

17-4PH, 17-7PH

A286

Aluminum

Manganese

Bronze

Aluminum

Bronze

Copper

NonFerrous

Metals

Monel K

Inconel-X

Hastelloy A

Hastelloy B

Hastelloy

Hastelloy C

Titanium

CALL US TOLL-FREE

AND GET THE ANSWERS

For SAWING MACHINE inquiries:

MARVEL HOT LINE

1-800-4-SAWING

1-800-628-8462

(1-800-472-9464)

In Illinois 1-800-4-MARVEL

(1-800-462-7835)

W W W . S A W I N G . C O M

Want to talk with Marvels

metal sawing specialists?

Need answers to metal

sawing problems?

Confused about the right

blade to use?

13

You might also like

- Treasures PDFDocument26 pagesTreasures PDFElmanydia Smith100% (5)

- Checklist For Const Building Supervisors PDFDocument84 pagesChecklist For Const Building Supervisors PDFMiky Tema100% (4)

- Welding ManualDocument32 pagesWelding ManualHammondMachineNo ratings yet

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- Complete Guide ToDocument21 pagesComplete Guide ToDHOBO100% (1)

- Building 4.6/5.4L Ford Horsepower on the DynoFrom EverandBuilding 4.6/5.4L Ford Horsepower on the DynoRating: 5 out of 5 stars5/5 (1)

- Laterite StoneDocument38 pagesLaterite StoneRaghu Thyagaraj100% (3)

- PistolsHandbook12 10 15Document157 pagesPistolsHandbook12 10 15SanelaBožičkovićNo ratings yet

- Blueprint Reading NAVEDTRA 14040 1994Document200 pagesBlueprint Reading NAVEDTRA 14040 1994dawnk31297% (39)

- EIM CodeDocument1 pageEIM CodeRayan AlfredNo ratings yet

- CNC Machine ToolsDocument137 pagesCNC Machine ToolsDr_M_Soliman88% (8)

- Ansi Bolting Chart 1/2" To 4": Nominal Pipe SizeDocument8 pagesAnsi Bolting Chart 1/2" To 4": Nominal Pipe SizeUNESNo ratings yet

- Stud bolt length chartDocument1 pageStud bolt length chartRyan Goh Chuang HongNo ratings yet

- Flocon Flange Tables GuideDocument5 pagesFlocon Flange Tables GuideAngel AngeleyeNo ratings yet

- Duplex Stainless Steel SAF 2304, 2205, SAF 2507Document12 pagesDuplex Stainless Steel SAF 2304, 2205, SAF 2507Anonymous skBAwexNo ratings yet

- Bolt Stud Dimensions For FlangesDocument1 pageBolt Stud Dimensions For FlangesMULAYAM SINGH YADAVNo ratings yet

- Controlled Bolt Tightening ChecklistDocument10 pagesControlled Bolt Tightening Checklistanjangandak2932No ratings yet

- Table of Ampacities For Wire Sizes, Conversion of AWG To Metric Sizes and Number of Conductors in A ConduitDocument20 pagesTable of Ampacities For Wire Sizes, Conversion of AWG To Metric Sizes and Number of Conductors in A ConduitJay Sunga Villan0% (1)

- Cabezal WorkoverDocument1 pageCabezal WorkoverJonathan AguirreNo ratings yet

- GP Tool Joint Dimensional ValueDocument3 pagesGP Tool Joint Dimensional ValuecalamarejoNo ratings yet

- Plumbing Review: DAY 1: 29 May 2016 Danilo V. RavinaDocument93 pagesPlumbing Review: DAY 1: 29 May 2016 Danilo V. Ravinajurhym doteNo ratings yet

- Stud Bolt Length For Upload PDFDocument1 pageStud Bolt Length For Upload PDFDiego Martínez FernándezNo ratings yet

- GP Tool Joint Dimensional Value PDFDocument2 pagesGP Tool Joint Dimensional Value PDFamerNo ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Mechanics of Composite Materials - 2017 PDFDocument2 pagesMechanics of Composite Materials - 2017 PDFJAGANNATH PRASADNo ratings yet

- Stud bolt length chartDocument1 pageStud bolt length chartTharindu JeewanaNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationsunitkghoshNo ratings yet

- Fast Reference: CompressorDocument8 pagesFast Reference: CompressorJUNFERNNo ratings yet

- NT, NSHD, NB & DV End-Suction Centrifugal Pumps To En733 (Din 24255)Document28 pagesNT, NSHD, NB & DV End-Suction Centrifugal Pumps To En733 (Din 24255)jorgeNo ratings yet

- Flange Dimension ChartDocument10 pagesFlange Dimension ChartSalvador TelloNo ratings yet

- 56 3260Document188 pages56 3260Abdul RachmanNo ratings yet

- 56 3260Document188 pages56 3260Abdul RachmanNo ratings yet

- Stud Bolt LengthDocument1 pageStud Bolt LengthSanthosh100% (1)

- Certification 3g Dan 4g Aws d1Document12 pagesCertification 3g Dan 4g Aws d1AvebFrederiksenNo ratings yet

- Rotary Seal Design GuideDocument434 pagesRotary Seal Design GuideBhargav Suvagiya100% (3)

- Bolt ChartDocument1 pageBolt ChartNaveen TripuraneniNo ratings yet

- ELEVATOR AND DRILL COLLAR BORE CHART DIMENSIONSDocument5 pagesELEVATOR AND DRILL COLLAR BORE CHART DIMENSIONSMauro Lozano100% (1)

- Group 6: 10K High Pressure Fittings Tubing Nipples AdaptorsDocument26 pagesGroup 6: 10K High Pressure Fittings Tubing Nipples AdaptorskarthikNo ratings yet

- UFC Agency-Specific DocsDocument10 pagesUFC Agency-Specific DocsrsadibNo ratings yet

- Series G4000-FDA Specification SheetDocument2 pagesSeries G4000-FDA Specification SheetWattsNo ratings yet

- 6 - Stud Bolt & Ring Joint MeasurementDocument2 pages6 - Stud Bolt & Ring Joint MeasurementErin JohnsonNo ratings yet

- Elevator Bore ChartsDocument5 pagesElevator Bore ChartsjolualNo ratings yet

- Series VL Air Cylinders For Valve Actuation: Catalog HY08-0947-1/NA April, 2004Document12 pagesSeries VL Air Cylinders For Valve Actuation: Catalog HY08-0947-1/NA April, 2004Anthony Saavedra AbarulloNo ratings yet

- Commercial ComponentsDocument0 pagesCommercial ComponentsChevronelleNo ratings yet

- RFQ 2Document21 pagesRFQ 2Jay VanpariaNo ratings yet

- Flange Bolt ChartsDocument1 pageFlange Bolt ChartsQUAMAR ALAM100% (1)

- Cooper Bearing - PartsDocument20 pagesCooper Bearing - PartsAndrei Krivda100% (1)

- Tyco Flange Tech DetailsDocument0 pagesTyco Flange Tech DetailsRajesh KanalaNo ratings yet

- Catalogo Anillos GrantDocument62 pagesCatalogo Anillos GrantOrlando SilvaNo ratings yet

- Flange Bolt Sizing ChartDocument2 pagesFlange Bolt Sizing ChartRICARDO RUEDANo ratings yet

- ANSI B16.1 Flanged CatalogDocument20 pagesANSI B16.1 Flanged Catalogjdsa123No ratings yet

- Regulador Pilotado Mod. GP2000Document2 pagesRegulador Pilotado Mod. GP2000vanguevNo ratings yet

- Catalogue 2014Document20 pagesCatalogue 2014Nasser Haroub100% (1)

- Type Inserts With Hole: WNMG 08 04 04-FHDocument4 pagesType Inserts With Hole: WNMG 08 04 04-FHTungstenCarbideNo ratings yet

- Stud Bolt Length For Upload PDFDocument1 pageStud Bolt Length For Upload PDFvishnu300022No ratings yet

- Stud bolt length chartDocument1 pageStud bolt length chartPat AuffretNo ratings yet

- Stud Bolt Length For UploadDocument1 pageStud Bolt Length For UploadDan PastorNo ratings yet

- Stainless Steel U-Bolts for PipesDocument1 pageStainless Steel U-Bolts for PipessrupeshlecNo ratings yet

- March Pump Manual 7 Plastic 0155 0046 1000 Rev32Document2 pagesMarch Pump Manual 7 Plastic 0155 0046 1000 Rev32Asima Jaya TamaNo ratings yet

- Recommended Bolt Lengths Data: Wafer LUG HDocument1 pageRecommended Bolt Lengths Data: Wafer LUG Hshashikanth79No ratings yet

- A Pi Ring Joint Flange DataDocument2 pagesA Pi Ring Joint Flange DataSusin LimNo ratings yet

- Ricambi CSA TankDocument20 pagesRicambi CSA TankАлексей ГалайдинNo ratings yet

- Kennedy ShaveDocument2 pagesKennedy ShavesitaNo ratings yet

- A FDJ 927534567Document14 pagesA FDJ 927534567icsNo ratings yet

- Bombas L0242Document2 pagesBombas L0242Neo ZaoNo ratings yet

- Capscrew Markings and Torqure ValuesDocument4 pagesCapscrew Markings and Torqure ValuesNaing Min HtunNo ratings yet

- High Quality Cast Iron Flanged WheelsDocument2 pagesHigh Quality Cast Iron Flanged WheelsvishvasNo ratings yet

- Catalogo de GusanosDocument33 pagesCatalogo de GusanosPedro JuradoNo ratings yet

- Number & Size of Bolts For Flanged Joints: Class 150Document3 pagesNumber & Size of Bolts For Flanged Joints: Class 150Sidney RiveraNo ratings yet

- ANSI Flanges B16.5: Number and Size of Studs and Ring GasketsDocument1 pageANSI Flanges B16.5: Number and Size of Studs and Ring GasketsJon SmithNo ratings yet

- 06 635Document8 pages06 635Fernando SabinoNo ratings yet

- 10.flange Bolts, STD TeesDocument7 pages10.flange Bolts, STD TeesNIRMAL SINGHNo ratings yet

- P08-1021-I-MN-1044 Rev 1 Simark - Flanged Turbine ManualDocument12 pagesP08-1021-I-MN-1044 Rev 1 Simark - Flanged Turbine ManualrehanNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- January February March AprilDocument1 pageJanuary February March AprilMunirah AliNo ratings yet

- Adult Protective Services: Louisiana Department of Health and Hospitals Office of Aging and Adult ServicesDocument21 pagesAdult Protective Services: Louisiana Department of Health and Hospitals Office of Aging and Adult ServicesHammondMachineNo ratings yet

- USA AS300 Instruction-6.6 0 (CG)Document28 pagesUSA AS300 Instruction-6.6 0 (CG)HammondMachineNo ratings yet

- Steel Weight2Document1 pageSteel Weight2Ahmed Bilal SiddiquiNo ratings yet

- 2018 Farmers Almanac SpecialDocument8 pages2018 Farmers Almanac SpecialHammondMachineNo ratings yet

- Troy Bilt Mustang 50Document80 pagesTroy Bilt Mustang 50HammondMachineNo ratings yet

- Single Zone LCD Operation Manual 17590Document14 pagesSingle Zone LCD Operation Manual 17590HammondMachineNo ratings yet

- Sump SharkDocument12 pagesSump SharkHammondMachineNo ratings yet

- Smokin Cajun Grill ManualDocument14 pagesSmokin Cajun Grill ManualHammondMachineNo ratings yet

- Guide 7 Home CanDocument13 pagesGuide 7 Home CanHammondMachineNo ratings yet

- Social Faux Pas: Kids and Puppies and Dominance: by Jennifer SobieDocument20 pagesSocial Faux Pas: Kids and Puppies and Dominance: by Jennifer SobieHammondMachineNo ratings yet

- OTS Installation GuideDocument47 pagesOTS Installation GuideMARSILFERNo ratings yet

- Hustler Z Super Z Owner's ManualDocument45 pagesHustler Z Super Z Owner's ManualHammondMachine0% (1)

- Saw Cutting ChartDocument4 pagesSaw Cutting ChartHammondMachineNo ratings yet

- Color Code ChartDocument14 pagesColor Code ChartManoj Kumar100% (1)

- Pennsylvania Steel Color Codes Cold Finished Bars: Red/white Red/white Red/white Red/whiteDocument2 pagesPennsylvania Steel Color Codes Cold Finished Bars: Red/white Red/white Red/white Red/whiteHammondMachineNo ratings yet

- Gator Xuv SpecsDocument2 pagesGator Xuv SpecsHammondMachineNo ratings yet

- Flex A Seal Sms SB RB SsDocument8 pagesFlex A Seal Sms SB RB SsHammondMachineNo ratings yet

- Fleetwood2005 PR FDocument20 pagesFleetwood2005 PR FHammondMachine100% (2)

- Tavistock BrochureDocument140 pagesTavistock BrochureCreepersBKNo ratings yet

- Snag List-Hyatt House Hvac and Chiller System Valve Pakage CD Fa Duct Rooms or Areas Fcu and Duct ConnectionDocument10 pagesSnag List-Hyatt House Hvac and Chiller System Valve Pakage CD Fa Duct Rooms or Areas Fcu and Duct ConnectionriyasudheenmhNo ratings yet

- Standards For RehabilitationDocument55 pagesStandards For RehabilitationJuan Carlos Ryan ValdezNo ratings yet

- BBMP WT PH 2Document363 pagesBBMP WT PH 2Praveen PrakashNo ratings yet

- 1 Kanal Boundary Wall Est v2 (20150602)Document1 page1 Kanal Boundary Wall Est v2 (20150602)Farhat DurraniNo ratings yet

- PengaruhPenambahanSeratPolypropylenepadaKuat PDFDocument10 pagesPengaruhPenambahanSeratPolypropylenepadaKuat PDFNick YogaNo ratings yet

- Bending and Folding Machine DifferenceDocument1 pageBending and Folding Machine DifferenceabdiNo ratings yet

- Development of Cu-Cr Alloy For Wear Resistance ApplicationDocument27 pagesDevelopment of Cu-Cr Alloy For Wear Resistance Applicationraghavendrajoshi87No ratings yet

- Product and Engineering Manual: 4.7 Existing Building Tie-In DetailsDocument22 pagesProduct and Engineering Manual: 4.7 Existing Building Tie-In DetailsgvgbabuNo ratings yet

- IMOA Shop Sheet 104Document2 pagesIMOA Shop Sheet 104tomasinkaNo ratings yet

- Determining The Time of Setting of Portland CementDocument3 pagesDetermining The Time of Setting of Portland CementRizette PaloganNo ratings yet

- Bug Holes in PrecastDocument5 pagesBug Holes in PrecastMichel DaoustNo ratings yet

- FW and FSWDocument8 pagesFW and FSWKural AmudhanNo ratings yet

- Nafufill KM 250Document2 pagesNafufill KM 250Richard AmoahNo ratings yet

- EFFECTS OF COMMON ALLOYING ELEMENTS IN ALUMINIUM AND STEELDocument4 pagesEFFECTS OF COMMON ALLOYING ELEMENTS IN ALUMINIUM AND STEELamber2211No ratings yet

- Roof Terracing: Construction and Materials-Iii (Rar - 302)Document24 pagesRoof Terracing: Construction and Materials-Iii (Rar - 302)jashndeep100% (1)

- CBSE Class 3 EVS Practice WorksheetDocument2 pagesCBSE Class 3 EVS Practice WorksheetHEMANIDHI GUPTANo ratings yet

- Pickling Paste 101Document2 pagesPickling Paste 101George BogdanNo ratings yet

- Quantity Estimation of Building Basic Health UnitDocument30 pagesQuantity Estimation of Building Basic Health UnitWintun73No ratings yet

- PWD CSRDocument210 pagesPWD CSRRakesh Paraliya100% (2)

- ELASTIC GRINDING TOOLS FOR MATTING, DEBURRING, EFFECT GRINDING, FINE GRINDING AND POLISHINGDocument26 pagesELASTIC GRINDING TOOLS FOR MATTING, DEBURRING, EFFECT GRINDING, FINE GRINDING AND POLISHINGLakshmananan NagarajanNo ratings yet

- Mascrete LH - FinalDocument12 pagesMascrete LH - FinalOng Tai BoonNo ratings yet

- Engineering Utilities 2Document8 pagesEngineering Utilities 2Vanissa MontillaNo ratings yet