Professional Documents

Culture Documents

Rain Gun II PDF

Uploaded by

khalidcosmosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rain Gun II PDF

Uploaded by

khalidcosmosCopyright:

Available Formats

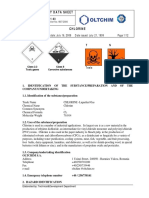

TECH SPECS

2000 Series Rain Guns Three Inch, Full and Part Circle

Longer life, improved performance and better value guaranteed!

The new 2000 Series Rain Gun brings Rain Bird back to the forefront of quality, performance, and reliability. This next generation model incorporates recent end user feedback and new materials to bring you the best value in todays high volume sprinkler market. To back up this claim, Rain Bird offers the best warranty in the industry. For all agricultural applications, the 2000 Series Rain Gun is backed by an unprecedented 3-year warranty. No other gun manufacturer in the industry stands behind their product for this long.

SR2005

High Standards means Longer Life

Some of the factors that lead to long life and low maintenance: Rain Guns are manufactured to the highest standards in a factory that is ISO9002 certified. Every Rain Gun is water tested before it leaves the factory. Trip mechanisms are reinforced with stainless steel washers and cotter pins. Straightening vanes are extruded directly into the body to reduce fluid turbulence and add strength and distance to the water stream.

Lower Maintenance

Rain Guns are designed to keep working for years with minimal maintenance. Grease maintenance is eliminated with permanently sealed bearings. Many of our competitors pack their bearings less than 30% full. This unfilled space allows for continued inside

SR2005 and F2004 Features

23 body trajectory Dual spring loaded, cast aluminum arms Adjustable aluminum spoon design Set of 6 metric taper bore nozzles included 21, 23, 26, 28, 30, 33 mm Ring orifice nozzles available .87, .99, 1.1, 1.2, 1.29, & 1.38 inches (22, 25, 28, 30, 33, 35 mm) Integral straightening vanes Stronger body assembly Improved trip assembly Self-adjusting brake mechanism Sealed lube-for-life bearing Improved trip-collar adjustments DN 80 (3) 4 or 6 hole flange mount standard NPT and BSP flange adapters Counterweight available for sloped conditions

Part Numbers

SR2005

Slow Reverse, Full/Part Circle Rain Gun

F2004

Full Circle Rain Gun

How to Order: SR - 2005 - NPT

Arc Settings

SR=Slow Reverse F=Full Circle

(optional) Female Flange Adapter

NPT=Standard Pipe Thread BSP=British Standard Pipe

Model

Lower Maintenance continued

condensation and water infiltration that can lead to an eventual breakdown of the grease, corrosion, and bearing failure. This is why F2004 and SR2005 Rain Gun bearings are permanently sealed and packed 70% full with a robust, wide temperature range, water resistant silicone grease. The braking system on these models is also maintenance free. The springloaded clutch self-adjusts to keep consistent rotation times through the life of the gun. All body joints are bonded and threaded together through a chemical process that is rated for up to 7 tons of pressure. The trip collars are easily adjustable and stay in place without the use of tools or time consuming adjustments. The bearing assembly is marked every 10 to make arc adjustments easier.

Outstanding Performance

Rain Bird Rain Guns are built to perform and to last. The dual arm design of our part circle guns provides better distribution and uniformity than single arm designs. The cast aluminum spoons are adjustable to provide greater control of the rotation speed. Stainless steel springs are used to absorb excess shock from the arms which allows for a much smoother arm stroke, and the removal of excess counterweights.

Performance Data - U.S. Units

SR2005/F2004 - GNS-2005T Taper Bore Nozzles

NOZZLE SIZE

.8"

PSI @ Nozzle 58 60 70 80 90 100 109

(ft.) (gpm) (ft.)

.9"

(gpm)

1.0"

(ft.) (gpm) (ft.)

1.1"

(gpm)

1.2"

(ft.) (gpm) (ft.)

1.3"

(gpm)

Rad. 144 146 154 158 162 168 172

Flow 141 144 155 166 176 186 193

Rad. 148 149 157 162 166 169 174

Flow 170 173 186 199 212 224 233

Rad. 153 155 165 169 171 172 174

Flow 220 224 242 258 274 289 301

Rad. 164 166 178 186 193 196 198

Flow 256 260 282 301 319 336 351

Rad. 169 171 184 195 204 212 210

Flow 298 303 328 350 372 392 409

Rad. 177 179 188 193 197 -

Flow 363 369 398 426 451 -

SR2005/F2004 - GNS-2005O Ring Orifice Nozzles

NOZZLE SIZE

.87"

PSI @ Nozzle 60 70 80 90 100 110

(ft.) (gpm)

.99"

(ft.) (gpm)

1.10"

(ft.) (gpm)

1.20"

(ft.) (gpm)

1.29"

(ft.) (gpm)

1.38"

(ft.) (gpm)

Rad. 133 138 143 148 153 157

Flow 110 120 129 136 143 150

Rad. 143 148 154 159 163 167

Flow 142 154 165 175 184 193

Rad. 151 157 163 169 174 179

Flow 181 199 216 227 238 249

Rad. 160 167 174 180 186 191

Flow 224 245 262 278 293 306

Rad. 167 175 183 189 196 201

Flow 274 296 318 337 356 371

Rad. 177 184 192 199 205 210

Flow 326 352 378 401 424 441

The Best Value

All accessories are included in each box including: Standard 2 mm (.03) neoprene gasket and bolt kit. Set of 6 taper bore nozzles 21, 23, 26, 28, 30, & 33 mm sizes. Glycerin filled pressure gauge to ensure optimal setup. Aluminum body construction with stainless steel hardware to provide all the value at the lowest price possible.

Performance Data - Metric Units

SR2005/F2004 - GNS-2005T Taper Bore Nozzles

NOZZLE SIZE

21 mm

BARS @ (m) Nozzle Rad. 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 44,0 45,8 47,5 48,3 49,0 50,3 51,5 52,5

(m3/hr)

23 mm

(m) (m3/hr)

26 mm

(m) (m3/hr)

28 mm

(m) (m3/hr)

30 mm

(m) (m3/hr)

33 mm

(m) (m3/hr)

Flow 32,1 34,0 35,9 37,6 39,3 40,9 42,5 43,9

Rad. 45,0 46,8 48,5 49,5 50,5 51,0 51,5 53,0

Flow 38,6 40,9 43,1 45,2 47,3 49,3 51,2 53,0

Rad. 46,5 48,8 51,0 51,5 52,0 52,3 52,5 53,0

Flow 50,0 53,0 56,0 58,6 61,1 63,6 66,1 68,4

Rad. 50,0 52,5 55,0 56,8 58,5 59,3 60,0 60,5

Flow 58,1 61,7 65,3 68,3 71,3 74,1 76,9 79,8

Rad. 51,5 54,3 57,0 59,3 61,5 63,3 65,0 64,0

Flow 67,7 71,8 75,8 79,4 83,0 86,4 89,8 92,8

Rad.

Flow

54,0 82,4 56,0 87,3 58,0 92,2 58,8 96,6 59,5 100,9 60,5 104,5 -

SR2005/F2004 - GNS-2005O Ring Orifice Nozzles

NOZZLE SIZE

20.32 mm 22.86 mm 25.40 mm 27.94 mm 30.78 mm 33.02 mm

BARS @ (m) Nozzle Rad. 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 43,5 45,5 46,8 48,1 49,2 50,2 51,2 52,1

(m3/hr) (m) (m3/hr) (m) (m3/hr) (m) (m3/hr) (m) (m3/hr) (m) (m3/hr)

Flow 32,5 33,6 35,7 37,6 39,4 41,0 42,4 43,8

Rad. 46,2 48,6 50,1 51,3 52,5 53,3 54,6 55,6

Flow 42,4 43,6 46,2 48,6 50,7 52,7 54,6 56,3

Rad. 49,4 51,5 53,0 54,4 55,6 56,7 57,7 58,7

Flow 51,8 53,4 56,7 59,6 62,3 64,8 67,0 69,2

Rad. 51,5 54,2 55,9 57,4 58,8 60,1 61,2 62,3

Flow 62,2 64,5 68,6 72,2 75,5 78,5 81,4 84,0

Rad.

Flow

Rad. 59,9 61,6 63,2 64,7 66,0 67,2 -

Flow 91,7 92,7 102,2 106,8 111,1 114,9 -

53,6 73,5 57,0 77,4 58,8 82,1 60,3 86,3 61,7 90,2 63,1 93,7 64,3 97,0 65,4 100,0

Parts Diagram and Description

Ref. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

Part Description Arm Cap (2) Arm Nut (2) Arm Shaft Reverse Spoon Bracket Assembly Reverse Arm Assembly Nozzle Retainer Forward Spoon Bracket Assembly Forward Arm Assembly Arm Ball Bearing Forward Arm Spring Trip Yoke Assembly Upper Yoke Bushing Elbow/Range Tube Assembly O-Ring (2) Brake Assembly Bearing Assembly Friction Collar (2 Required)` Snap Ring Ball Bearing Lock Nut O-Ring Bearing Sleeve Lower Yoke Bushing Trip Lever Bushing Trip Lever Assembly Reverse Arm Spring GNS-2005T Taper Nozzle (6) Set GNS-2005O Ring Nozzle (6) Set

Part Numbers Included in Kit B Included in Kit B Included in Kit B 71-P00382 71-P50809 71-P50302 71-P00364 71-P50807 71-P00324 71-P50295 71-P50215 Included in Kit A 71-P50803 Included in Kit A 71-P50814 71-P50975 71-P50116 71-P50344 71-P50549 71-P50796 71-102155 71-P50795 Included in Kit A Included in Kit A 71-P50331 71-P50296 L00250 L00255

29 30 31 32

Accessories Bearing Wrench Riser Installation Kit Rear Counterweight Glycerin Filled Pressure Gauge (not shown) Spare Parts Kit

71-P50697 71-P00368 L00260 71-P00080

A B

Maintenance Kit Arm Shaft Kit

71-P50364 71-P50365

Specifications (For Specifiers)

The full circle or part circle impulse drive sprinkler shall be a single nozzle type, capable of covering ________(feet/meters) radius, at ________ (PSI/bars) with a discharge rate of ______ (GPM/M3H). The sprinkler body and bearing sleeve shall be of heat treated, cast aluminum. Straightening vanes shall be integral to the body. The sprinkler arm, springs, fulcrum shafts, and trip mechanisms shall be stainless steel. The drive nozzle trajectory shall be 23 degrees from horizontal. The rotation of the sprinkler shall be accomplished by a spring loaded, vertical oscillating arms, actuated by the outlet water stream. The part circle models shall have a slow-reverse feature for reduced vibration and greater safety. The nozzle shall be of durable, chemically resistant plastic and shall be easily replaceable. A set of six taper bore nozzles shall be included with the gun - 21, 23, 26, 28, 30, 33 mm. The nozzle size shall be molded into the plastic for easy identification. The bearing assembly shall be permanently sealed and packed 70% with a wide temperature range, water resistant silicone grease. The brake mechanism will be spring loaded and self-adjusting. On part circle models, adjustable friction collars will be supplied to set arc adjustments without the use of tools, and the bearing assembly will be marked in ten degree increments to facilitate adjustments. The F2004 shall be for full circle operation only. The SR2005 shall have adjustable part circle or full circle operation. The sprinkler shall have a DN 80 4 or 6 hole patterns with a 2 mm (.08) neoprene gasket and bolt kit shall be supplied with the gun. An optional (NPT/BSP) flange adapter will be supplied to adapt the flange inlet to a (3/76 mm) female inlet. The sprinkler shall carry a three year warranty against original defects in material or workmanship in agricultural applications. The sprinkler shall be supplied by Rain Bird Corporation, Glendora, California.

Rain Gun Warranty

Agricultural Applications Our latest generation of Rain Guns is built on a legacy of knowledge, trust, and feedback from end users like you. Our warranty is simple and in line with Rain Birds reputation as the most reliable agricultural sprinkler in the world. To back up our claim, we offer the best warranty in the agriculture industry. For all agricultural applications, we offer a three-year; no questions asked warranty including free service or parts replacement. Product replacement, full credit, or return in lieu of spare parts or service is at Rain Birds discretion upon approval. Approval may include product testing. Non-agricultural Applications We understand that Rain Guns are often utilized in applications that may be more demanding than general agricultural applications. In these circumstances, Rain Bird offers an eighteen month warranty including free service or parts replacement, but excludes coverage in the following general applications or environments: Electrolytic conditions, such as high salt environments or salt water spray applications Applications where environmental conditions are not compatible with the materials used in Rain Guns Caustic or corrosive chemical conditions or spray applications Abrasive fluid spray applications

Rain Gun Safety

Operating Rain Guns remotely under circumstances where the operator cannot see the gun being activated can be dangerous if persons or animals are close to the device. When activated these guns can come on with significant force. Operators should also be aware of trip hazard, over-head obstruction, thrust, etc. for their applications, to prevent any bodily harm. If an operator has any question pertaining to Rain Gun Safety please contact your local dealer or Rain Bird representative.

Rain Bird Corporation Agri-Products Division 633 W. Foothill Blvd. Glendora, CA 91741-2469 Phone: (800) 435-5624 Fax: (626) 852-7310

Rain Bird International, Inc. 145 N. Grand Ave. Glendora, CA 91741-2469 Phone: (626) 963-9311 Fax: (626) 963-4287 1-800-HELLO-AG 6am-6pm MST M-F

www.rainbird.com Rain Bird. The Intelligent Use of Water.

Registered Trademark of Rain Bird Corporation 2003 Rain Bird Corporation 3/03 PN L207

You might also like

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- Pressure Washer Operations ManualDocument16 pagesPressure Washer Operations ManualkhalidcosmosNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Design of Movable WeirsDocument45 pagesDesign of Movable WeirsDan BitcaNo ratings yet

- Struers Application Note - Metallographic Preparation of High Alloy Tool SteelDocument6 pagesStruers Application Note - Metallographic Preparation of High Alloy Tool SteelCan ERTANNo ratings yet

- Fundamentals Hvac R Carter StanfieldDocument3 pagesFundamentals Hvac R Carter Stanfieldzvonkomihajlovic48910% (1)

- Nozzle Check ValvesDocument12 pagesNozzle Check Valvesjshadwan100% (1)

- GMW3359Document4 pagesGMW3359lev501No ratings yet

- Digital Offset Color: Indigo TechnologyDocument11 pagesDigital Offset Color: Indigo Technologykhalidcosmos100% (1)

- Catalog Accesorii AEGDocument116 pagesCatalog Accesorii AEGGhiuli Aptisa100% (2)

- GDT Training PyramidDocument1 pageGDT Training PyramidkhalidcosmosNo ratings yet

- Lifting Beams Stop LogDocument4 pagesLifting Beams Stop LogkhalidcosmosNo ratings yet

- Predicting Uniaxial Compressive Strength by Point Load Test - Significance of Cone PenetrationDocument8 pagesPredicting Uniaxial Compressive Strength by Point Load Test - Significance of Cone PenetrationLucas Francisco Contreras TorresNo ratings yet

- Drill StemDocument28 pagesDrill Stemchonubobby100% (1)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Mazda B2500, 1999, 2.5L-SpecsDocument4 pagesMazda B2500, 1999, 2.5L-SpecsAdiel Alexis Pérez100% (3)

- PSM 2Document23 pagesPSM 2luisNo ratings yet

- Control Choke Valve 9000Document8 pagesControl Choke Valve 9000sabi_shi100% (2)

- Ingersollrand P260WIRDocument2 pagesIngersollrand P260WIROjik OnlineNo ratings yet

- ValvesDocument8 pagesValvespravin_2011No ratings yet

- b3311 722-2Document7 pagesb3311 722-2Arnaldo BenitezNo ratings yet

- Steel Structure AssessmentDocument23 pagesSteel Structure AssessmentYudi Agung NugrohoNo ratings yet

- Okb Top SeriesDocument4 pagesOkb Top SeriesIrma Pokvić-Ramulj100% (1)

- Continuous Rolling MillDocument8 pagesContinuous Rolling Millrazen_inNo ratings yet

- Global Communication and Advisers CorpDocument32 pagesGlobal Communication and Advisers Corpkhalidcosmos100% (1)

- Cilindros Hidráulicos Parker - 2H - 1110-UkDocument42 pagesCilindros Hidráulicos Parker - 2H - 1110-UkPeterson MagroNo ratings yet

- Goulds AF: Axial Flow PumpsDocument11 pagesGoulds AF: Axial Flow PumpsKarthick VenkateshNo ratings yet

- CI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsDocument12 pagesCI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsAndre Gazali MalikNo ratings yet

- 806 Model G Right Check Riser MeasurementsDocument2 pages806 Model G Right Check Riser MeasurementsSandro ChavezNo ratings yet

- Viking Johnson Dismantling Joint+BrochureDocument13 pagesViking Johnson Dismantling Joint+BrochureecocadecNo ratings yet

- No.13 PRT2 Timing Belt Rings 01 UK PDFDocument4 pagesNo.13 PRT2 Timing Belt Rings 01 UK PDFhepcomotionNo ratings yet

- TFP950 10 2010Document6 pagesTFP950 10 2010elpelaracingNo ratings yet

- Formed-Cylinders 2007-04 LoDocument14 pagesFormed-Cylinders 2007-04 LomartinvandoornNo ratings yet

- High Pressure, High Performance Vane Pump PLL - 2325Document2 pagesHigh Pressure, High Performance Vane Pump PLL - 2325dromakiNo ratings yet

- Roller Screw BrochureDocument8 pagesRoller Screw BrochureRjgandhi65No ratings yet

- 14 General Shop ToolsDocument14 pages14 General Shop ToolsEbied Yousif AlyNo ratings yet

- BB3000 Line Boring MachineDocument8 pagesBB3000 Line Boring MachineadnyaNo ratings yet

- TEREX Halco Hammers & BitsDocument35 pagesTEREX Halco Hammers & BitsNelson F. Leon CarvajalNo ratings yet

- Bell & Gossett SuctionDiffusersDocument4 pagesBell & Gossett SuctionDiffusersAnonymous 7xHNgoKE6eNo ratings yet

- Master Stream, AnsulDocument2 pagesMaster Stream, AnsulpsycopaulNo ratings yet

- Chicago Pneumatic Breakers Brochure (US)Document12 pagesChicago Pneumatic Breakers Brochure (US)Sumit BhasinNo ratings yet

- Pulleys TechDocument8 pagesPulleys TechashkansoheylNo ratings yet

- 650 SchematicDocument4 pages650 Schematicab5951No ratings yet

- AVT Ball & Butterfly Brochure 05 Latest 12 PageDocument12 pagesAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyNo ratings yet

- Fujiaire DuctedDocument6 pagesFujiaire Ductedbudikarya11810% (1)

- 3DX SchematicDocument4 pages3DX Schematicab59510% (1)

- Actuador NeumaticoDocument12 pagesActuador NeumaticoJose Alfredo Rojas UribeNo ratings yet

- Bore Gages Series 511Document4 pagesBore Gages Series 511Tuan Dzung HoangNo ratings yet

- Screw Pump Brochure USA LowResDocument12 pagesScrew Pump Brochure USA LowResSandeep LeeNo ratings yet

- Series TDV Specification SheetDocument2 pagesSeries TDV Specification SheetWattsNo ratings yet

- FL6003 PDFDocument4 pagesFL6003 PDFMauricio Barrios CastellanosNo ratings yet

- Pehj0087 02Document4 pagesPehj0087 02arturolachira176No ratings yet

- Double Block Bleed TOSVDocument8 pagesDouble Block Bleed TOSVplanet123No ratings yet

- Suction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsDocument2 pagesSuction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsZMCONTROLNo ratings yet

- Bernard Q - Gun Parts Break DownDocument13 pagesBernard Q - Gun Parts Break DownullwnNo ratings yet

- Al 5000 PDFDocument2 pagesAl 5000 PDFalexrm12No ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- Tech Leader Power ChucksDocument3 pagesTech Leader Power ChucksmachineCanNo ratings yet

- 231,241,271 SchematicDocument4 pages231,241,271 Schematicab5951No ratings yet

- MasterSeries 876V Specification SheetDocument4 pagesMasterSeries 876V Specification SheetFEBCONo ratings yet

- Description Assembly Order No.: Static DataDocument30 pagesDescription Assembly Order No.: Static DataMROstop.comNo ratings yet

- AeroV CatalogDocument8 pagesAeroV CatalogMudzofar SofyanNo ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- Goulds Pumps 3355 SeriesDocument7 pagesGoulds Pumps 3355 Seriesmcastillo7385100% (1)

- Puma 2100 2600 3100 EnglishDocument32 pagesPuma 2100 2600 3100 EnglishUrke VukNo ratings yet

- TC 12303Document12 pagesTC 12303prasen10No ratings yet

- SpecDocument2 pagesSpecneversigNo ratings yet

- Guth VSR Modulating ValvesDocument8 pagesGuth VSR Modulating ValvesRaul Guevara TorresNo ratings yet

- The Crazy Cool Can Cup Aka How To Turn A Pop Can PDFDocument5 pagesThe Crazy Cool Can Cup Aka How To Turn A Pop Can PDFkhalidcosmosNo ratings yet

- Beer Tin Barometer PDFDocument7 pagesBeer Tin Barometer PDFkhalidcosmosNo ratings yet

- Card Board Chair PDFDocument4 pagesCard Board Chair PDFkhalidcosmosNo ratings yet

- MSBatch PDFDocument2 pagesMSBatch PDFkhalidcosmosNo ratings yet

- Shadesf PDFDocument4 pagesShadesf PDFkhalidcosmosNo ratings yet

- Castellated BeamsDocument5 pagesCastellated BeamskhalidcosmosNo ratings yet

- MFC J6910DW PDFDocument2 pagesMFC J6910DW PDFkhalidcosmosNo ratings yet

- Silo For PentoniteDocument1 pageSilo For PentonitekhalidcosmosNo ratings yet

- 01 POSCO E&C Brochure-Eng 2012 V3.0Document32 pages01 POSCO E&C Brochure-Eng 2012 V3.0khalidcosmosNo ratings yet

- Notes: Apply Two Layer of Anti Corrosion Paint Then Apply Third Layer of Semi Glossy Paint. Check Height of Base Assembly For AdjustmentDocument1 pageNotes: Apply Two Layer of Anti Corrosion Paint Then Apply Third Layer of Semi Glossy Paint. Check Height of Base Assembly For AdjustmentkhalidcosmosNo ratings yet

- Silo SectionDocument1 pageSilo SectionkhalidcosmosNo ratings yet

- Saw k4 User ManualDocument9 pagesSaw k4 User ManualkhalidcosmosNo ratings yet

- Cement RollerDocument1 pageCement RollerkhalidcosmosNo ratings yet

- Bending 2Document1 pageBending 2khalidcosmosNo ratings yet

- Builder M RM PowerDocument4 pagesBuilder M RM PowerkhalidcosmosNo ratings yet

- Datasheet: Leica Viva TS11Document4 pagesDatasheet: Leica Viva TS11Donovan HarrellNo ratings yet

- Atla ContourDocument6 pagesAtla ContourkhalidcosmosNo ratings yet

- Islam GuideDocument1 pageIslam GuidekhalidcosmosNo ratings yet

- Dolby Volume TV TechpaperDocument6 pagesDolby Volume TV TechpaperkhalidcosmosNo ratings yet

- Builder M RM PowerDocument4 pagesBuilder M RM PowerkhalidcosmosNo ratings yet

- VD4 11ka Manual PDFDocument42 pagesVD4 11ka Manual PDFhonghoaso1100% (1)

- Installation and Maintenance Instructions For Ashcroft Type 91 Series Adapter KitDocument1 pageInstallation and Maintenance Instructions For Ashcroft Type 91 Series Adapter KitvaltierrillaNo ratings yet

- T10A Secondary Cells: Chapter - 1Document15 pagesT10A Secondary Cells: Chapter - 1lvsaruNo ratings yet

- Denver Equipment Company Handbook - IndexDocument6 pagesDenver Equipment Company Handbook - IndexCristiam MercadoNo ratings yet

- Msds Cl2Document12 pagesMsds Cl2Ganjar Tri Gita AzhariNo ratings yet

- TdsDocument2 pagesTdsSudipta BainNo ratings yet

- ADIDASSDocument3 pagesADIDASSkessa thea salvatoreNo ratings yet

- Sub Sec 1 To 9Document7 pagesSub Sec 1 To 9khan4luvNo ratings yet

- Entrance Canopy Standard-VietLong-LayoutDocument1 pageEntrance Canopy Standard-VietLong-LayoutNguyễn Việt LongNo ratings yet

- FDA Updates On Hand Sanitizers Consumers Should Not Use FDADocument7 pagesFDA Updates On Hand Sanitizers Consumers Should Not Use FDAMary Claire PattonNo ratings yet

- Cryogenic CCDocument18 pagesCryogenic CCWayne MonneryNo ratings yet

- 3046 Heavy Equipment Maintenance RepairDocument12 pages3046 Heavy Equipment Maintenance Repairام احمدNo ratings yet

- ME - 32021 Materials and Geometry of Cutting ToolsDocument27 pagesME - 32021 Materials and Geometry of Cutting ToolsWILYNo ratings yet

- Do - 026 - s2023 (Item 624 Roadway Lighting)Document13 pagesDo - 026 - s2023 (Item 624 Roadway Lighting)QWERTY YUYUPNo ratings yet

- PlumbingDocument62 pagesPlumbingAnonymous iTzCnMNo ratings yet

- Metals: 3D Printed Acetabular Cups For Total Hip Arthroplasty: A Review ArticleDocument18 pagesMetals: 3D Printed Acetabular Cups For Total Hip Arthroplasty: A Review ArticleUtkarsh AnandNo ratings yet

- Noise and Vibration in PM Motors - Sources and RemediesDocument35 pagesNoise and Vibration in PM Motors - Sources and RemediesVirgilioNo ratings yet

- Steve DistillationDocument14 pagesSteve DistillationChandni SeelochanNo ratings yet

- Muller Tapping MachineDocument8 pagesMuller Tapping MachineKUMAARRRNo ratings yet

- Brosura - Transfer Station 4 PrestoDocument4 pagesBrosura - Transfer Station 4 PrestoNebojsa JovicicNo ratings yet

- SailDocument52 pagesSailcitunairNo ratings yet

- Performance Data: Schedule of Technical Data Genius Cooling Tower Model: GPC 125M Project: Afc Bukit JalilDocument1 pagePerformance Data: Schedule of Technical Data Genius Cooling Tower Model: GPC 125M Project: Afc Bukit JalilJeghiNo ratings yet

- WELD-2008v05 Down To The WireDocument2 pagesWELD-2008v05 Down To The WirepeterNo ratings yet