Professional Documents

Culture Documents

Introduction of Ring Main Unit

Uploaded by

faradinoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction of Ring Main Unit

Uploaded by

faradinoCopyright:

Available Formats

INTRODUCTION OF RING MAIN UNIT

DEFINATION A standard piece of switchgear in distribution systems comprising of switches for switching power cable rings and of switches in series with fuses for the protection of distrbution transformers.RMU used for H.T.side. RMU is having 3noS of switches(Circuit Breakers or Isolators or LBS), it is used for two inputs with mechanical or electrical interlock and one outgoing to the load. Either one input with two outgoings. RMU used for redundancy feeder's purpose. Ring main unit is used in a secondary distribution system. It is basically used for an uninterrupted power supply. Alongside, it also protects your secondary side transformer from the occasional transient currents. Depending on your applications and loading conditions you can use a swicth fuse combination or a circuit breaker to protect the transformer. This transformer connected to the switch fuse/ circuit breaker is called your T off. In a common arrangement you have Load break swicthes on both the sides of your T off. Ring main Units come in standard ratings of 11/22/33kV, 630/1250 A, 21 KA/3 secs. TYPE OF RING MAIN UNIT Ring Main Unit is of Indoor or Outdoor Type and can be made extensible on both sides. It consists of 2 Units of 11 KV, 630 Amps, continuously rated, triple pole, non automatic, quick break, air break, fault making load breaking switches, with associated busbars and connections for controlling an incoming/outgoing 11 kV feeder cable. It is fitted with 630A copper busbar, mechanical interlock, ON/OFF indicator and Cable terminating box and one tee-off unit load breaking and fault making switch comprising of one 11 KV, 630 Amps air break switch fuse fitted to three busbars of 630 Amps continuously rated with pull out type HRC fuse with clamp fixing for receiving striker pin for controlling distribution transformers. It is fitted with 630A copper busbar, mechanical interlock, ON/OFF indicator and Cable terminating box. Ring Main Unit can also be provided with two number Load Break Switch with one number tee-off Vacuum Circuit Breaker with protective devices.

Indoor RMU

Outdoor RMU

SERVICE CONDITION A) The RMU shall be capable of operating normally within the following temperature range: Maximum air temperature: + 55 C Minimum air temperature: - 25 C

Manufacturer shall declare whether current de-rating is necessary.Certification offering evidence for the environmental extremes shall be required. B) The RMU shall be capable of being operated in electrically exposed locations. C)The RMU shall be capable of being exposed to high relative humidity and ambient air pollution. C) The RMU shall be suitable for outdoor installations with the following levels of ingress protection: - Insulating medium envelope no less than IP65. - RMU exterior housing no less than IP54 (main door shut). - RMU exterior housing no less than IP41 (main door open).

RATING RMU 11KV Rating Rated voltage Withstand voltage 1 minute Impulse withstand voltage Frequency Load Break Switch Rated current disconnector Fuse switch Rated current Fuse rating Unit kV kV rms kV 500 kVA 12 28 75 1000 kVA 12 28 75

Hz nos A nos A A

50 2 630 1 200 63

50 2 630 1 200 80

DISTRIBUTION TRANSFORMER Rating Voltage ratio at no load Off circuit tapping Withstand voltage 1 minute Impulse withstand voltage Frequency Vector group Type of cooling Unit V 500kVA 1000kVA 11/.433 11/.433

% kV

2.5, 5 28

2.5, 5 28

kV

75

75

Hz

50 Dyn11 ONAN

50 Dyn11 ONAN

LV BOARD Rating Rated current Rated voltage Incoming disconnector Outgoing Fuseway at 20 C Outgoing fuse rating C.T ratio (class 0.2) MD meter P.F meter kWh meter Unit A V A A A 500kVA 800 1000 800 400 160 800/5A nos nos nos 3 1 1 1000kVA 1600 1000 1600 400 160 1600/5A 3 1 1

ENCLOSURE Internal Arc testing 18.4 kA 1 sec IEC 1330 Clause 6 Temperature rise test Class IEC 1330 Clause 4.1 enclosure Index Protection (IP) IP 35 Sound Level test Material/Thickness 60 dBA Electro Galvanised sheet/3.0mm Hot dipped Galvanised CChannel 10

Base Frame

SPECIFICATION

Switchgear The switchgear and busbar shall all be contained in an earth screened cast resin enclosure filled with SF6 at either 0.35/0.55 bar G relative pressure to ensure the insulation and breaking functions. Sealed for life, the enclosure shall meet the sealed pressure system criterion in accordance with the IEC 298 standard (appendix GG 2.3 and 3.3): a system for which no handling of gas is required throughout the 25 years of service life. There shall be no requirement to top up the SF6 gas. In addition, manufacturer shall confirm that maximum leakage rate is lower than 0,1 % / year.It shall provide full insulation, making the switchgear insensitive to the environment (temporary flooding, high humidity).Thus assembled, the active parts of the switchgear shall be maintenance-free and the unit shall be minimal-maintenance.Welded steel/stainless steel SF6 enclosures or a dual skin type design shall not be acceptable.The cast resin enclosure and RMU housing shall have a design such that in the event of an internal arc fault, the operator shall be safe. This should be in accordance with IEC 62271-200. The switchgear enclosure shall be Dark Grey Code 632 to BS 381C.Each switchboard shall be identified by an appropriately sized label which clearly indicates the functional units and their electrical characteristics.

The switchgear and switchboards shall be designed so that the position of the different devices is visible to the operator on the front of the switchboard and operations are visible as well. The MV system shall be totally encapsulated in a resin insulating medium. There shall be no access to exposed MV conductors.In accordance with the standards in effect, the switchboards shall be designed so as to prevent access to all live parts during operation without the use of tools. Dielectric medium SF6 gas shall be used for the dielectric medium for MV RMUs. Oil or Air filled switchgear will not be considered. SF6 gas used for the filling of the RMU shall be in accordance with IEC 376.It is preferable to fit an absorption material in the tank to absorb the moisture from the SF6 gas and to regenerate the SF6 gas following arc interruption.The SF6 insulating medium shall be constantly monitored via a gas pressure indicator offering a simple go, no-go indication. Earthing of metallic parts There shall be continuity between the cast resin earth screen and metallic parts of the switchboard and cables so that there is no electric field pattern in the surrounding air, thereby ensuring the safety of people. Earthing of the main circuit The cables shall be earthed by an integral earthing switch with short-circuit making capacity, in compliance with IEC 129 standard. The earthing switch can only be operated

when the switch is open.The earthing switch shall be operable through the main circuit mechanism and manual closing shall be driven by a fast-acting mechanism, independent of operator action.Mechanical interlocking systems shall prevent the RMU function from being operated from the ON to Earth On position without going through the OFF position. Ring switches They shall consist of 630 amp fault making/load breaking spring assisted ring switches, each with integral fault making/dead breaking earth switches. The switch shall be naturally interlocked to prevent the main and earth switch being switched ON at the same time. The selection of the main and earth switches is made by a lever on the fascia, which is allowed to move only if the main or earth switch is in the off position. Transformer protection feeders The unit shall consist either a 200 or 630 amp tee off spring assisted three position rotating arc type SF6 circuit breaker unit, with integral fault making/dead breaking earth switch, the function shall be naturally interlocked to prevent the main and earth switch from being switched ON at the same time and the CB not allowed to trip in Earth On position. The selection of the main/earth switch lever on the fascia, which is allowed to move only if the main or earth switches in the off position. The lever may be padlocked in either the main or earth position. The manual operation of the circuit breaker shall not have an effect on the trip spring. This should only be discharged under a fault (electrical) trip, the following manual reset operation should recharge the trip spring and reset the circuit breaker mechanism in the main off position.The circuit breaker shall be fitted with a mechanical flag which shall operate under a fault (electrical) trip occurring. The tripped flag should be an unambiguous colour differing from any other flag or mimic.The unit shall also have the option to be fitted with a multi-tap shunt trip coil and auxiliary switch for remote tripping/indication of the tee off circuit breaker. Both the circuit breaker and ring switches are operated by the same unidirectional handle, which once inserted requires a minimum of 3 seconds to remove and re-insert to perform the reverse operation. Electrical characteristics of the circuit-breaker function shall be at least greater than followin values - rated current : 200A/630A - short-circuit breaking capacity : 16/ 21kA

RMU bushings and Cable terminations Bushing It is preferable to have all bushings accessible from the rear and sides of the RMU. Bushings along the front of the RMU are not acceptable. Cable boxes

All of the cable boxes shall be air insulated suitable for dry type cable terminations. Compound filled cable boxes are not acceptable.The cable boxes at each of the two ring switches suitable for accepting H.V. cables approaching from either above or below. Access to the ring switch cable boxes should be available from 180 (two sides) excluding the gland plate. The tee off circuit breaker shall be suitable for either of the following termination arrangements :- Direct coupling to an ESI transformer flange - Cable entry from below via a tee off cable box - Cable entry from above via a tee off cable box The extended function shall be suitable for cable entry from either above or below only. Cable clamps The cable termination and gland arrangements shall be appropriate for the type and style of cables used at the time.

Padlocking facilities The circuit breakers and switches can be locked in the open/closed or earth on position by 1 to 3 padlocks ESI size.

Voltage indicator lamps and phase comparators It shall be possible for each of the functions on the RMU to be equipped with a voltage indication, to indicate whether or not there is voltage on the cables. The capacitive dividers will supply low voltage power to sockets at the front of the unit, an external lamp must be used to indicate live cables.Three outlets can be used to check the synchronisation of phases with the use of an external device.This device shall be in compliance with IEC 1958 standard. Safety of people Any accidental overpressure inside the sealed chamber will be limited by the opening of a pressure limiting device in the cast-resin enclosure. Gas will be released to the rear of the unit away from the operator. Manufacturer shall provide type test report to prove compliance with IEC 62271-200. Operating lever An anti-reflex mechanism on the operating lever shall prevent any attempts to re-open immediately after closing of the switch or earthing switch.All manual operations will be carried out on the front of the switchboard.The effort exerted on the lever by the operator should not be more than 250 N for the switch and circuit breaker. The overall dimensions of the RMU shall not be increased due to the use of the operating handle. The operating handle should have two workable positions 180 apart.

Front plate The front shall include a clear mimic diagram which indicates the different functions. The position indicators shall give a true reflection of the position of the main contacts. They shall be clearly visible to the operator.The lever operating direction shall be clearly indicated in the mimic diagram.The manufacturers plate shall include the switchboards main electrical characteristics. Cable insulation testing It must be possible to test the core or the sheath insulation of the network cables while the RMU remains energised at rated voltage. It shall be preferable to carry out the phase by phase testing through a built-in facility without necessity to have an access to cable compartment. The maximum test voltage shall be less than 38 kV DC for 10 minutes.Any cable test access facility which require the use of an additional loose devise shall not be acceptable. Remote control of the RMUs Remote operation of the RMUs line switches must be possible using motors fitted to the operating mechanism.It shall be possible to fit the motors either directly in manufacturing plant or on site as and when required. Installation on site shall be possible with the RMU fully energised and manufacturer should provide detailed instructions for installation to the control mechanism.The fitting of the motors to the mechanism must not in any way impede or interfere with the manual operation of the switches or circuit breaker. The tenderer may wish to advise of options and cost for remote telecontrol units of the RMU and MV network telecontrol system.

You might also like

- 5-Power & Control Cables PDFDocument11 pages5-Power & Control Cables PDFAnonymous ufMAGXcskMNo ratings yet

- 4BT3.9-G4 0960-0210 - I8 - 201512Document174 pages4BT3.9-G4 0960-0210 - I8 - 201512Lutionnn67% (3)

- Earthing System BasicsDocument62 pagesEarthing System Basicssabill arasyidNo ratings yet

- Furse Catalogue-Lightning Protection PagesDocument55 pagesFurse Catalogue-Lightning Protection PagesWanessa Suárez100% (1)

- Protection and Interlocking Scheme of MV Switchgear: Murtaza Hussain Dy, MGR, Switchgear Engineering DivDocument103 pagesProtection and Interlocking Scheme of MV Switchgear: Murtaza Hussain Dy, MGR, Switchgear Engineering DivgopisettyNo ratings yet

- Welcome To A Presentation On HV/MV SwitchgearDocument26 pagesWelcome To A Presentation On HV/MV SwitchgearAwnish KumarNo ratings yet

- Switchgear Lecture NoteDocument21 pagesSwitchgear Lecture NoteAsif Al MahmudNo ratings yet

- Technical Submittal - 3 WAY & 4 WAY - RMUDocument149 pagesTechnical Submittal - 3 WAY & 4 WAY - RMUفارس معتوقNo ratings yet

- MCCB FundamentalsDocument40 pagesMCCB FundamentalsPinaki Sharma100% (2)

- RMUDocument81 pagesRMUtejpalv100% (2)

- Abb VD4)Document23 pagesAbb VD4)Nayan100% (1)

- Owner: Vedanta Aluminium Limited, Jharsuguda Contractor: Voltech Operation and Maintanance Services Project: Vedanta Smelter-2Document27 pagesOwner: Vedanta Aluminium Limited, Jharsuguda Contractor: Voltech Operation and Maintanance Services Project: Vedanta Smelter-2mari nNo ratings yet

- Cable GlandsDocument20 pagesCable GlandsBalaji VenkatesanNo ratings yet

- Schneider Relay GuideDocument56 pagesSchneider Relay GuideRajendra Prasath Thangamani100% (1)

- ABB MV SwitchgearDocument36 pagesABB MV SwitchgearSINTO THOMASNo ratings yet

- Current Limiting MCCB'sDocument8 pagesCurrent Limiting MCCB'sjannumitsNo ratings yet

- Cable Repair Kit Raychem PDFDocument156 pagesCable Repair Kit Raychem PDFChandrakanthan RamiahNo ratings yet

- RMUDocument20 pagesRMUShahebaz AhmedNo ratings yet

- B767 200-300 BOOK 24 101 - Electrical PowerDocument34 pagesB767 200-300 BOOK 24 101 - Electrical PowerTarik Benzineb100% (1)

- (Ebook - Housing) Indoor Electrical Safety CheckDocument0 pages(Ebook - Housing) Indoor Electrical Safety CheckAgapie Ruxana DorinaNo ratings yet

- EP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..Document14 pagesEP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..dimaomarNo ratings yet

- Ring Main UnitDocument27 pagesRing Main UnitAlana Jackson100% (1)

- Pres18 - Testing and Maintenance 2-02Document41 pagesPres18 - Testing and Maintenance 2-02Vishwanath TodurkarNo ratings yet

- Gis PDFDocument28 pagesGis PDFgloby_pnbNo ratings yet

- IEC 62271-200 - S - Presentation - 031023Document19 pagesIEC 62271-200 - S - Presentation - 031023hmid007No ratings yet

- 220 KV SubstationDocument24 pages220 KV SubstationPuneet Agarwal100% (1)

- Electrical Safety Clearance (Part-6) - Electrical Notes & ArticlesDocument3 pagesElectrical Safety Clearance (Part-6) - Electrical Notes & ArticlesElectrical Radical100% (1)

- Mobile Substation 249Document69 pagesMobile Substation 249nijhumb100% (1)

- ABB IEC LV SwitchgearDocument48 pagesABB IEC LV Switchgearomh129100% (1)

- ABB Kabeldon 2011 Cat HV Cable Joints, Terminations, ConnectorsDocument131 pagesABB Kabeldon 2011 Cat HV Cable Joints, Terminations, ConnectorsistenicNo ratings yet

- SEC StdsDocument65 pagesSEC Stdserson1981No ratings yet

- Specification For RMUDocument9 pagesSpecification For RMUchandranvijeshkumarNo ratings yet

- Cable Termination KitDocument17 pagesCable Termination KitAshutosh Sharma100% (1)

- D-07 11kv SwitchgearDocument12 pagesD-07 11kv SwitchgearShri Anvesha D100% (1)

- Xiria 3.6-24kV Medium Voltage Ring Main Unit - Application Guide PDFDocument52 pagesXiria 3.6-24kV Medium Voltage Ring Main Unit - Application Guide PDFJuan E Torres M100% (1)

- RMUDocument50 pagesRMU030160645100% (5)

- Schneider PPT Autorecloser SectionalizerDocument53 pagesSchneider PPT Autorecloser Sectionalizerprathaban723100% (3)

- UniGear ZS1 TrainingDocument191 pagesUniGear ZS1 TrainingeyachachinNo ratings yet

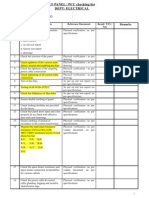

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocument3 pagesLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- Ring Main ManualDocument46 pagesRing Main Manualrajpre1213100% (1)

- Siemens SIVACON S8, IEC 61439 Switchgear and Control PanelDocument43 pagesSiemens SIVACON S8, IEC 61439 Switchgear and Control PanelGyanesh Bhujade100% (2)

- IEC 6142 2 Low Voltage Switchgear and Controlgear AssembliesDocument66 pagesIEC 6142 2 Low Voltage Switchgear and Controlgear Assemblieshoangdungd12100% (1)

- Automatic Transfer Switch Changeover Type - SocomecDocument40 pagesAutomatic Transfer Switch Changeover Type - Socomecallanbatiancila100% (1)

- Low Voltage Switchgear and Control GearDocument9 pagesLow Voltage Switchgear and Control Gearshanmars007No ratings yet

- On TransformerDocument20 pagesOn TransformerMurshedur Rahman100% (7)

- 02 MV Switchgear - IntroductionDocument42 pages02 MV Switchgear - IntroductionThức Võ100% (1)

- Ring Main Unit Siemens 8dhjst IndiaDocument33 pagesRing Main Unit Siemens 8dhjst Indialehaphuong03No ratings yet

- FEWA HV Joints & TerminationsDocument29 pagesFEWA HV Joints & TerminationsMuhammad RazaNo ratings yet

- RMUDocument33 pagesRMUMuhammad NizamuddinNo ratings yet

- 1 - Primary Substations Enel - HV-MVDocument29 pages1 - Primary Substations Enel - HV-MVGiovanni Andre Gonzalez FauneNo ratings yet

- Guide To Low Voltage Circuit Breaker Standards - 2015Document36 pagesGuide To Low Voltage Circuit Breaker Standards - 2015k1gabitzu9789100% (2)

- Earthing and Lightning Protection Systems PDFDocument88 pagesEarthing and Lightning Protection Systems PDFSky LightNo ratings yet

- Circuit Breaker GTSDocument31 pagesCircuit Breaker GTScpandey01_688066930No ratings yet

- Field Test PlanDocument8 pagesField Test PlanMohammed TauseefNo ratings yet

- Transformers & Ring Main UnitsDocument57 pagesTransformers & Ring Main Unitsoadipphone7031100% (1)

- 36kv Indoor VCB & GCBDocument2 pages36kv Indoor VCB & GCBRamesh AnanthanarayananNo ratings yet

- Substations Final 2013Document156 pagesSubstations Final 2013a_j_sanyal259No ratings yet

- Main Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFDocument14 pagesMain Substation Feeder and Ring Main Unit Protection Settings (LPN) PDFprseNo ratings yet

- Ring Main Unit 1Document12 pagesRing Main Unit 1Joseph TingNo ratings yet

- Ring Main UnitsDocument28 pagesRing Main UnitsChristian EstebanNo ratings yet

- Level 3 Gis Manual 36 KV Cubicle 19-06-2014Document48 pagesLevel 3 Gis Manual 36 KV Cubicle 19-06-2014yugie oktavianaNo ratings yet

- Best Practices in Solar PhotovoltaicsDocument43 pagesBest Practices in Solar Photovoltaicsphilipnart100% (1)

- Flyer - MD1501 Series Auxiliary RelaysDocument5 pagesFlyer - MD1501 Series Auxiliary Relaysmuhammad nazirNo ratings yet

- Compact Sub Station BrochureDocument8 pagesCompact Sub Station BrochureAnimesh SahaNo ratings yet

- Protection Against Electric ShockDocument11 pagesProtection Against Electric Shockapi-225932882No ratings yet

- Manual de UPS Del Mamografo de La PoliciaDocument30 pagesManual de UPS Del Mamografo de La PoliciaaxsalazarNo ratings yet

- 16410-Swiches & CBDocument15 pages16410-Swiches & CBuddinnadeemNo ratings yet

- GX30R 100RDocument53 pagesGX30R 100RSergio Garcia100% (1)

- Kilowatt Labs Sirius-Technical Data Sheet-1860-48-B-1C-M-SD-A-GDocument3 pagesKilowatt Labs Sirius-Technical Data Sheet-1860-48-B-1C-M-SD-A-GIvanNo ratings yet

- Chapter 9 Technical Data: 9.1.1 CE MarkDocument24 pagesChapter 9 Technical Data: 9.1.1 CE MarkIngeniería AplicacionesNo ratings yet

- 6 Adjustable Tripping Settings of A Circuit Breaker You MUST Understand - EEPDocument11 pages6 Adjustable Tripping Settings of A Circuit Breaker You MUST Understand - EEPJhonci CoriNo ratings yet

- KEC115/6/7x: Ac Generator Short Circuit and Over Current GuardDocument4 pagesKEC115/6/7x: Ac Generator Short Circuit and Over Current GuardRN NNo ratings yet

- REM54 - techARaDocument100 pagesREM54 - techARamohamed abourayaNo ratings yet

- DSRCDDocument13 pagesDSRCDBDNo ratings yet

- Unit 02A - Elec Equip in Power StationDocument23 pagesUnit 02A - Elec Equip in Power Stationukshinde7368No ratings yet

- Short Circuit Levels Adequation by Network Topology Modifications Using Genetic AlgorithmsDocument6 pagesShort Circuit Levels Adequation by Network Topology Modifications Using Genetic AlgorithmsAnugrah PratamaNo ratings yet

- 0613IB1201-modbus MicrologicDocument144 pages0613IB1201-modbus MicrologicronaldxmenNo ratings yet

- Electrical Circuit Breaker - Operation and Types of Circuit BreakerDocument46 pagesElectrical Circuit Breaker - Operation and Types of Circuit Breakerkumelachewbirre22No ratings yet

- DM-4 Marine Data Sheet 4921240294 UKDocument12 pagesDM-4 Marine Data Sheet 4921240294 UKLeong ChNo ratings yet

- Low Voltage Distribution Products: Price ListDocument61 pagesLow Voltage Distribution Products: Price ListjoaoNo ratings yet

- Low Voltage Air Circuit Breakers: 1.generalDocument3 pagesLow Voltage Air Circuit Breakers: 1.generalNATHANNo ratings yet

- Digital Temperature Controllers Users Manual enDocument440 pagesDigital Temperature Controllers Users Manual enPatrik PulungNo ratings yet

- Power System Protection QPDocument2 pagesPower System Protection QPmaniNo ratings yet

- Catalogue WindlassDocument35 pagesCatalogue WindlassRezha Maulana Kusuma ANo ratings yet

- SINAMICS S120 Parallelschaltung Active Line Modules V1 2 en 2023-12-22 2Document34 pagesSINAMICS S120 Parallelschaltung Active Line Modules V1 2 en 2023-12-22 2c.ingemar.carlssonNo ratings yet

- Switchgear Standard Operating ProceduresDocument22 pagesSwitchgear Standard Operating ProceduresM DuraiNo ratings yet

- Manual EkfcDocument12 pagesManual EkfcDavid GallardoNo ratings yet

- Circuit Breaker BomDocument4 pagesCircuit Breaker BomAnonymous vcadX45TD7No ratings yet