Professional Documents

Culture Documents

PTC H J P: Ydraulic Et Umps

Uploaded by

syamsundariitmOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTC H J P: Ydraulic Et Umps

Uploaded by

syamsundariitmCopyright:

Available Formats

PTC HYDRAULIc JEt PUMpS

Nozzel used to eject power fluid into produced fluid stream.

Power Fluid communication ports and annulus.

Throat where power fluid energy is shared with produced fluid. Pump suction funnel.

Questions and Answers

Q: What advantages do jet pumps offer vs competing lift methods. A: With no moving parts, they are the most reliable of all artificial lift methods. Also all k ey flow wetted areas are manufactured in tungsten carbide material to mitigate erosion. Q: Is a workover required to install / retrieve a jet pump. A: No, using wireline they are set as shown below (right) across a sliding sleeve, or can be set in a straddle assembly across a side pocket mandrel as shown below (left) or across holes punched in the tubing .

Stavanger

Bergen

Aberdeen

Houston

Rio de Janeiro

Q: How do jet pumps work. A: High pressure power fluid, supplied to the pump via the production tubing annulus, mixes and shares its energy with produced fluid within the pump, thus increasing produced fluid pressure. Q: What type of fluid can be used as power fluid. A: Usually water or dead crude. If water is used, it can often be supplied from existing water injection surface and subsea infrastructures Q: How much power fluid is required. A: Depends on the head requirement. The ratio of power fluid to reservoir fluids typically ranges from 0.5(small head) to 5(large head). Also strongly influenced by the available power fluid pressure; the higher the pressure, the lower the power fluid rate required. Q: What differentiates the PTC jet pumps A: Optimised hydrodynamics, materials and coatings result in improved efficiency and reliability. Our optional integral SSSV provides enhanced well integrity. Q: How do jet pumps perform when compared to ESPs A: As illustrated below, a PTC jet pump, equipped with a size 22 nozzle can deliver more head than ESPs, at production rates below 2000 stb/d and at rates between 5000 and 14000 stb/d.

www.ptc.as

You might also like

- Electric Submersible PumpsDocument17 pagesElectric Submersible PumpsFranklyn Frank100% (3)

- Jet Pump PresentationDocument21 pagesJet Pump PresentationSha'ban HussainiNo ratings yet

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsFrom EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsRating: 5 out of 5 stars5/5 (3)

- Hydraulic Valve Test Bench H300Document23 pagesHydraulic Valve Test Bench H300masakpNo ratings yet

- Chapter Five Jet Pumping System (JP)Document33 pagesChapter Five Jet Pumping System (JP)mghareebNo ratings yet

- Lesson 3 - Hydraulic PumpDocument10 pagesLesson 3 - Hydraulic PumppowertrainlNo ratings yet

- SPE 112881 Slip Calculation of Rotational Speed of Electrical Submersible Progressive Cavity PumpsDocument9 pagesSPE 112881 Slip Calculation of Rotational Speed of Electrical Submersible Progressive Cavity PumpsDeisy SteffaniaNo ratings yet

- Performance Characteristics of Centrifugal PumpsDocument7 pagesPerformance Characteristics of Centrifugal PumpsNiroshan Susith Punchihewa100% (1)

- Centrifugal Pump.......... Very ImpDocument22 pagesCentrifugal Pump.......... Very Impavi07me4uNo ratings yet

- 10 1016@j Sna 2018 09 064 PDFDocument19 pages10 1016@j Sna 2018 09 064 PDFAli HydarNo ratings yet

- Defining ESPDocument2 pagesDefining ESPodexNo ratings yet

- QuestionnaireDocument4 pagesQuestionnaireQayyum KhanNo ratings yet

- 2 5445291432019498690 UnlockedDocument14 pages2 5445291432019498690 UnlockedbeiguiiuirrNo ratings yet

- Jet Pump ThesisDocument6 pagesJet Pump ThesisCrystal Sanchez100% (1)

- ESP PumpsDocument42 pagesESP Pumpsmostafa_ibrahim007No ratings yet

- Centrifugal PumpDocument13 pagesCentrifugal Pumpafr5364No ratings yet

- Pumping of LiquidsDocument175 pagesPumping of Liquidscheckmeout803100% (1)

- Research Paper On PumpsDocument4 pagesResearch Paper On Pumpsnikuvivakuv3100% (1)

- Energy Conservationi N Pumps: M.V.Pande Dy - Director NPTI, NagpurDocument37 pagesEnergy Conservationi N Pumps: M.V.Pande Dy - Director NPTI, NagpurmvpngpNo ratings yet

- TECHNICAL Layne Engineering ManualDocument34 pagesTECHNICAL Layne Engineering ManualAnonymous CMS3dL1TNo ratings yet

- Classification of PumpsDocument7 pagesClassification of PumpsJoanna Marie100% (1)

- Chapter 5 Pump and Control Devices PDFDocument68 pagesChapter 5 Pump and Control Devices PDFRana G100% (2)

- Twin Screw Vs Centrifugal & Reciprocating ArticleDocument12 pagesTwin Screw Vs Centrifugal & Reciprocating ArticlecaratorresmNo ratings yet

- Thesis On Centrifugal Pump DesignDocument6 pagesThesis On Centrifugal Pump Designjessicacannellamanchester100% (2)

- Hydraulic MachineryDocument60 pagesHydraulic MachinerySushil Kumar Singh100% (1)

- HM Laboratory Manual 2012Document42 pagesHM Laboratory Manual 2012Sreesh P SomarajanNo ratings yet

- Chapter 05 (Jet Pump)Document3 pagesChapter 05 (Jet Pump)Muhammad FahadNo ratings yet

- Section 06 - PumpsDocument28 pagesSection 06 - Pumpssaadashfaq100% (1)

- Optimizing Pumping Systems P-IDocument4 pagesOptimizing Pumping Systems P-Imatrix69No ratings yet

- PUMPSDocument4 pagesPUMPSJireh LoquinarioNo ratings yet

- Pumps and MotorsDocument16 pagesPumps and MotorsLESLI RODRIGUEZ BENDEZUNo ratings yet

- EK-Pumps For LearningDocument62 pagesEK-Pumps For LearningsaeedNo ratings yet

- Ipe Plate 2 Fluid MachineriesDocument93 pagesIpe Plate 2 Fluid Machineriesjanuel borelaNo ratings yet

- HM Laboratory ManualDocument41 pagesHM Laboratory ManualSreesh P Somarajan100% (1)

- 03 75 To 100 MM Borewell Submersible PumpsetDocument17 pages03 75 To 100 MM Borewell Submersible PumpsetSelvamNo ratings yet

- 75 MM & 100 MM Borewell Submersible Pumpset Performance ChartDocument17 pages75 MM & 100 MM Borewell Submersible Pumpset Performance ChartRaviNo ratings yet

- Hydraulic Ram Pump ThesisDocument8 pagesHydraulic Ram Pump ThesisProfessionalPaperWriterCanada100% (2)

- Optimisation of Pumps in Thermal Power StationsDocument69 pagesOptimisation of Pumps in Thermal Power StationsShaik Nizam UddinNo ratings yet

- Unibloc Engineering ManualDocument58 pagesUnibloc Engineering ManualNoe Isaac Marmolejo MolinaNo ratings yet

- Artificial Lift Methods Overall ComarisonDocument6 pagesArtificial Lift Methods Overall ComarisonJorge J. ÁvalosNo ratings yet

- Artificial Lift Methods ComparisonsDocument6 pagesArtificial Lift Methods ComparisonshamadahutpNo ratings yet

- Variable Speed PumpingDocument22 pagesVariable Speed Pumpingbmat100% (1)

- Variables PpedDocument24 pagesVariables PpedLuis LopezNo ratings yet

- Pumps Design and PerformanceDocument27 pagesPumps Design and PerformanceJefferson SmithNo ratings yet

- Thesis On Water PumpsDocument7 pagesThesis On Water Pumpsezhj1fd2100% (2)

- Pump Basics PDFDocument43 pagesPump Basics PDFtsrinivasan5083No ratings yet

- Functions of A PumpDocument178 pagesFunctions of A PumpKetan Sarmalkar50% (2)

- 02 Openwell Submersible MonoblocsDocument18 pages02 Openwell Submersible Monoblocsabdullah sahibNo ratings yet

- Solar Energy - 5Document16 pagesSolar Energy - 5Raja Iftikhar HaiderNo ratings yet

- Function of A PumpDocument178 pagesFunction of A Pumpmostafa nabilNo ratings yet

- 3 Q 06 Inside InsightsDocument2 pages3 Q 06 Inside InsightsJosé MoránNo ratings yet

- Series Parallel PumpsDocument4 pagesSeries Parallel PumpsMarieRafaelBlanca0% (1)

- Plunger Type Pump and MotorDocument20 pagesPlunger Type Pump and MotorsarumadamanaNo ratings yet

- Pelton Wheel Project Report 1Document15 pagesPelton Wheel Project Report 1Anonymous ytZsBOV92% (13)

- Rotating EquipmentDocument235 pagesRotating EquipmentpraSHANT2331100% (5)

- The Defining Series - Jet Pumps - SLB PDFDocument8 pagesThe Defining Series - Jet Pumps - SLB PDFnoha azamaliNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Lec 1Document11 pagesLec 1syamsundariitmNo ratings yet

- Anti Ragging CommitteeDocument6 pagesAnti Ragging CommitteesyamsundariitmNo ratings yet

- Anti Ragging Self DeclarationDocument2 pagesAnti Ragging Self DeclarationsyamsundariitmNo ratings yet

- Central Workshop: Professor-In-Charge: N.Ramesh BabuDocument1 pageCentral Workshop: Professor-In-Charge: N.Ramesh BabusyamsundariitmNo ratings yet

- Government of Telangana C.T.Department: Form of Way Bill Form X or Form 600Document3 pagesGovernment of Telangana C.T.Department: Form of Way Bill Form X or Form 600syamsundariitmNo ratings yet

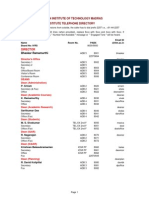

- Email ID Name Room No. Pabx @iitm - Ac.in: Sci. / Tech OfficerDocument1 pageEmail ID Name Room No. Pabx @iitm - Ac.in: Sci. / Tech OfficersyamsundariitmNo ratings yet

- Email ID Name Room No. Pabx @iitm - Ac.in: INSA ScientistDocument1 pageEmail ID Name Room No. Pabx @iitm - Ac.in: INSA ScientistsyamsundariitmNo ratings yet

- Email ID Name Room No. Pabx @iitm - Ac.in: DST Unit of Nano ScienceDocument1 pageEmail ID Name Room No. Pabx @iitm - Ac.in: DST Unit of Nano SciencesyamsundariitmNo ratings yet

- Telephone Directory 0215.1Document1 pageTelephone Directory 0215.1syamsundariitmNo ratings yet

- Email ID Name Room No. Pabx @iitm - Ac.in: Ocean EngineeringDocument1 pageEmail ID Name Room No. Pabx @iitm - Ac.in: Ocean EngineeringsyamsundariitmNo ratings yet

- CPOC-GS-PI-0004 Rev 0 PDFDocument19 pagesCPOC-GS-PI-0004 Rev 0 PDFPCHAN@TOMNo ratings yet

- Valve Section (Auxiliary Valve) - (S - N 232512782 & Below, 232711433 & Below, 232612157 & Below) - 334Document2 pagesValve Section (Auxiliary Valve) - (S - N 232512782 & Below, 232711433 & Below, 232612157 & Below) - 334EUROPARTSNo ratings yet

- Deluge ValveDocument3 pagesDeluge ValveFarhan AhmedNo ratings yet

- Cooling Water System - PIPENETDocument2 pagesCooling Water System - PIPENETekabudiartiNo ratings yet

- Rps-Rr-Surge Anticipating Pressure ReliefDocument3 pagesRps-Rr-Surge Anticipating Pressure ReliefhakseoNo ratings yet

- Pipingpresentationmaster 170219125347Document61 pagesPipingpresentationmaster 170219125347Vignesh Nadimuthu100% (1)

- Safelok Block&BleedValves CatalogueDocument16 pagesSafelok Block&BleedValves CatalogueIdehen KelvinNo ratings yet

- Control Valve - DRAG 100DDocument11 pagesControl Valve - DRAG 100Damer_arauf100% (15)

- 27 - Iwcf Ss Sample Questions - AnswersDocument9 pages27 - Iwcf Ss Sample Questions - Answersshoaib Khalil100% (1)

- TC/TCM Two-Stage Liquid Ring Vacuum Pumps: DimensionsDocument2 pagesTC/TCM Two-Stage Liquid Ring Vacuum Pumps: DimensionsAnthonyNo ratings yet

- Troubleshooting The Positive Displacement RotaryDocument4 pagesTroubleshooting The Positive Displacement Rotaryابو المعالي الهمامNo ratings yet

- Hight Pressure Hydraulic SystemDocument34 pagesHight Pressure Hydraulic SystemVijay AundhakarNo ratings yet

- Control Valve TypesDocument46 pagesControl Valve TypesAnderson SiqueiraNo ratings yet

- Plumbing Code of The PH SummaryDocument7 pagesPlumbing Code of The PH SummaryapinnapinnNo ratings yet

- Grundfosliterature 1576589Document4 pagesGrundfosliterature 1576589Bahtiar AntanaNo ratings yet

- Hydraulic SystmDocument4 pagesHydraulic SystmArchana Choudhary100% (1)

- Subline FDocument4 pagesSubline Fclaudio100% (1)

- Achenbach Smooth - Rough CylinderDocument15 pagesAchenbach Smooth - Rough CylinderVivek KantiNo ratings yet

- Fanno FlowDocument30 pagesFanno FlowAitizaz KhanNo ratings yet

- Fire Valves PDFDocument24 pagesFire Valves PDFSajjadNo ratings yet

- Equivalent Length MethodDocument1 pageEquivalent Length MethodmanikantanNo ratings yet

- Hydraulic Schematic SymbolsDocument8 pagesHydraulic Schematic SymbolsJustice MachiwanaNo ratings yet

- Check Valve AssessmentDocument7 pagesCheck Valve Assessmentjayrolling dollazNo ratings yet

- VABAL/SC/F/A/12/OMS: Overcenter Valves (Danfoss Motor)Document2 pagesVABAL/SC/F/A/12/OMS: Overcenter Valves (Danfoss Motor)jbsb1No ratings yet

- Shijiazhuang Shizun Pump Industry Sales Co., LTD Price List For DistributorDocument2 pagesShijiazhuang Shizun Pump Industry Sales Co., LTD Price List For DistributorBenny ThomasNo ratings yet

- Design of Low Cost Hydraulic Ram Pump For Lifting Water.: DR - Ramakar JhaDocument39 pagesDesign of Low Cost Hydraulic Ram Pump For Lifting Water.: DR - Ramakar JhaJkl Yadav YadavNo ratings yet

- Sistema de Direccion JCBDocument7 pagesSistema de Direccion JCBtaller avansysNo ratings yet

- Flange Reference Chart Ansi Din Jis Dimensions PDFDocument2 pagesFlange Reference Chart Ansi Din Jis Dimensions PDFDedi KosasihNo ratings yet

- Nioec-Sp-00-50 Criteria For Process and MechanicsDocument37 pagesNioec-Sp-00-50 Criteria For Process and MechanicsCalNo ratings yet