Professional Documents

Culture Documents

Hydrocom - For Recipcompressor

Uploaded by

sumantabal_uceOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrocom - For Recipcompressor

Uploaded by

sumantabal_uceCopyright:

Available Formats

HydroCOM

Edition 4.01

General Description HydroCOM 4.0

makes compressor control and monitoring an easy job

General Description 4.01.doc

2008-04-09

1 2 3

INTRODUCTION ...................................................................................................3 ABBREVIATIONS .................................................................................................3 GENERAL FUNCTION..........................................................................................4

3.1 3.2 3.3 3.4 What is HydroCOM? ...............................................................................................................................4 Functional description ...........................................................................................................................5 The reverse flow control ........................................................................................................................6 Control layout .........................................................................................................................................8

3.5 Certificates and approvals .....................................................................................................................9 3.4.1 Explosion protection..........................................................................................................................9 3.4.2 Electromagnetic Compatibility (EMC) and safety of low voltage devices ..........................................9

THE COMPONENTS OF HYDROCOM...............................................................10

4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 HydroCOM actuators............................................................................................................................10 Compressor Interface Unit CIU............................................................................................................11 External Power Supply.........................................................................................................................12 Isolation Amplifier ................................................................................................................................12 TDC-sensor ...........................................................................................................................................12 Hydraulic Unit (HU)...............................................................................................................................12 HydroCOM Service Software (HSS) ....................................................................................................14 Fast-TIM.................................................................................................................................................14 Compressor Condition Monitoring (RecipCOM)................................................................................15 Rod-Position Analyser (RPA) ..............................................................................................................17

INSTALLATION EXAMPLES..............................................................................18

General Description 4.01.doc

2008-04-09

Introduction

This document describes the functions and equipment of HydroCOM in general. The equipment delivered may slightly differ from the descriptions in this document.

Abbreviations

The following abbreviations are used throughout this manual Device for suction valve control Compressor Interface Unit Compressor Condition Monitoring Distributed control system External Power Supply, 48VDC Transmitter Interface Module: Decentral data acquisition device for fast and slow signals DCS Distributed control system GIM General Interface Module HydroCOM-RecipCOM On-line compressor condition monitoring system HSS HydroCOM Service Software HU Hydraulic Unit IA Isolation Amplifier IPS Internal Power Supply OPC OLE for process control PLC Programmable logic controller RPA Rod Position Analyser for rider ring wear and run-out monitoring SIM Stage Interface Module TDC Top Dead Center Actuator CIU RecipCOM DCS EPS Fast-TIM

General Description 4.01.doc

2008-04-09

General function

3.1 What is HydroCOM?

The reliable, efficient, flexible compressor control system for optimal use of resources. HydroCOM is a hydraulically actuated computerised compressor control system. HydroCOM is a system for the stepless capacity control of reciprocating compressors in a range between (0) 10 -100 %. The minimum continuous load depends on gas composition, operating conditions and compressor design parameters. HydroCOM is based on components of the injection technology for large diesel engines, enhanced by state of the art digital computing and control technology. Hydraulically actuated unloaders keep the suction valves open during part of the compression cycle. Thus part of the gas taken into the cylinder during the suction cycle is pushed back into the suction plenum. In this way the gas volume per working stroke can be controlled. This system saves compression power at part load, since the energy consumption of a compressor is proportional to the quantity of gas compressed per compression cycle. The capacity closed loop control is done by the DCS / PLC or an optionally supplied loop controller. HydroCOM provides in addition to control as a standard feature suction valve nest temperature measurement. Temperature sensors are integrated in each actuator. HydroCOM 4.0 is a control and monitoring platform. Fast-TIMs can not be only used for temperature and rider ring wear monitoring. On top of that the on-line compressor condition and performance monitoring system, HydroCOM-RecipCOM, can be installed. Fast-TIMs feature decentralized data acquisition and bus communication. They are designed to be installed at or close to the compressor and save field wiring and installation costs.

General Description 4.01.doc

2008-04-09

3.2

Functional description

The following diagram shows the schematic layout of HydroCOM and the optionally supplied Fast-TIMs and the on-line monitoring system, HydroCOM-RecipCOM:

Fig. 1.: Schematic system layout

All suction valves are equipped with HydroCOM actuators. They perform the actual control task delaying the closing of the suction valves at part load. Hydraulic unit (HU) and hydraulic piping supply the mechanical energy to the actuators. The actuators are connected by the HydroCOM-Bus to the Compressor Interface Unit (CIU). The CIU provides the electronic control of the actuators and serves as interface between the HydroCOM system and DCS / PLC where closed loop control is performed. The communication between DCS, PLC or loop controller and HydroCOM is based on analog and binary signals. As alternative the on board Modbus interface can be used. HydroCOM 4.0 features data acquisition of fast signals and can be upgraded into a monitoring platform. The measurements can be read as analog signals or via the digital Monitoring Interface (Modbus). If the on-line compressor condition monitoring system HydroCOM-RecipCOM is installed, the CIU is the interface for the RecipCOM-PC. The TDC-sensor synchronizes CIU with compressor speed and gives reference of the crank shaft position. The CIU performs the real time calculation of suction valve opening and closing time and sends the commands to the actuators. Thus compressor output becomes a simple analog control variable for the plant operator. By using digital control technology the HydroCOM system can react within 3 revolutions to change compressor output. Therefore HydroCOM is the ideal choice for those applications where fast and precise control is required. HOERBIGER engineers use the Windows based HydroCOM Service Software (HSS) for system configuration. But the HSS is also an comprehensive user tool for data display and HydroCOM service.

General Description 4.01.doc

2008-04-09

3.3

The reverse flow control

The capacity control method is based on the so called reverse flow control principle. A portion of the gas which was taken into the cylinder during the suction cycle is pushed back into the suction line during the compression cycle.

p Dr pD A D

Energy savings at 50% part load

Cr

pS B

V

Fig. 2.: The principle of reverse flow regulation The above indicator diagram shows the functional principle of HydroCOM. Cylinder pressure is displayed as pV-diagram. At position C (bottom dead center, BDC) the compression cycle starts. Without the HydroCOM system, under full load operation, the gas is compressed immediately after passing BDC. When the cylinder pressure reaches D the discharge valve opens. The gas is pushed out of the cylinder. When the piston reaches A (top dead center, TDC) the re-expansion begins. The gas which due to the cylinder clearance is still in the cylinder, re-expands. When the cylinder pressure reaches the suction pressure (B) the suction valve opens and gas is taken into the cylinder. The power necessary for the operation of the compressor is proportional to the area enclosed by the indicator pressure curve.

Check Check valve valve Solenoid Solenoid valve valve Hydraulic Hydraulic cylinder cylinder

Hydraulic Hydraulic unit unit

Unloader Unloader Suction Suction valve valve

Fig. 3.: HydroCOM Actuator The suction valve sealing elements are controlled by the unloader. The unloader is driven by the HydroCOM actuators. In the actuator a fast switching solenoid is foreseen. Just before suction valve opening the General Description 4.01.doc 6 2008-04-09

solenoid switches and hydraulic oil flows into the actuators hydraulic cylinder. The high pressure piston moves the unloader downwards the valve guard. After BDC the unloader delays the closing of the suction valve during compressor part load. Thus cylinder pressure follows from C to Cr instead of from C to D. The required power consumption is therefore much lower than at full load. The slight pressure increase ( C - Cr) is due to pressure losses in the suction valve. As the gas flows back from the cylinder chamber into the suction line, the quantity of gas in the cylinder available for compression is reduced. At Cr the solenoid switches, oil flows out of the hydraulic cylinder, the unloader moves upwards and the suction valve closes. The compression follows the line from Cr to Dr. As shown in the diagram the indicated power for app. 50% load is only about half of the power required for full load. Thus the principle of reverse flow regulation saves energy compared to bypass control.

General Description 4.01.doc

2008-04-09

3.4

Control layout

The compressor is either controlled by the DCS, PLC or an external loop controller that may be optionally provided by HOERBIGER. One of the process variables (e.g. discharge pressure, suction pressure, flow volume..) is selected as control variable. The user defines a set point for this variable. A PI-controller is assigned to each stage of the compressor. The first stage is controlled according to the process variable. The output of the first controller operates primarily the first stage. The interstage suction pressures are selected as control variables for the higher stages. The capacity delivered by each stage is varied by 4..20mA controller signals which are linked to the CIU. The enclosed basic sketch shows this principle. A start-up function is to be provided in the controller. It includes the start-up unloading and start-up ramp for smooth loading of the compressor. Optionally HOERBIGER may give assistance in the DCS/PLC configuration or may deliver a programmed ABB loop controller.

DCS PLS / SPS

Set Point PIRegler Controller 0 100 % Set Point PIRegler Controller 0 100 %

Start Ramp Rampe

Skalierung Scale

Skalierung Scale

1. Compressor Stage

Suction Pressure 1. Stage

4 20 mA Signal

Suction Pressure 2. Stage

St uf e 1. Sa ug dr uc k

Ko m pr es so rst uf 1. e

St uf e 2. Sa ug dr uc k

Ko m pr es so rst uf 2. e 4 20 mA Signal

CIU

SIM 1

CIU SIM 2

PT 1. Stage Stufe

PT 2. Stage Stufe

Fig 4.: principle of suction control

General Description 4.01.doc

2008-04-09

2. Compressor Stage

3.5

Certificates and approvals 3.4.1 Explosion protection

The compressor must not be operated with other gases than specified at the time of placing the order. If the compressor shall be operated with other gases written approval has to be obtained from HOERBIGER. The certification is based on the directive 94/9/EC (ATEX) - Equipment and protective systems intended for use in potentially explosive atmospheres. Standards: electrical apparatus for explosion hazardous location EN 50014 general regulations EN 50018 flame-proof enclosure d EN 50019 type of protection "e" Additionally for the Fast-TIMs: EN 50020 type of protection i Since most HydroCOM applications are installed in potentially explosive atmospheres, all components that are to be installed at the compressor are explosion proof. The explosion protection certification is valid for all gases of the explosion groups IIA and IIB plus hydrogen. The certificate does not allow operation with Oxygen or Acetylene. In detail following protection classes are used: Protection class EEx-d is applied to the actuators electric housings where the valve electronics, the solenoid and the hydraulic piston are placed. EEx-e is applied to the connection box and the construction of the solenoid. Exception: The connection box for CSA and FM Div. 1 is EEx-d The electric housing of the Fast-TIM is built in protection class EExd. The connection box for power supply and field bus connection is designed as per EEx-e. The connection box for connecting the transmitters is supplied as per EEx-i.

Conformity with European Directives is based on a type examination by a Notified Body, the required production tests, and the marking on the device. Following certifications have been received up to now for the actuator: EU: ATEX certified : Electrical Ex-protection: Mechanical Ex-protection:

II 2G EEx de IIB+H2 T4 II 2G c

USA (FM):

AEx de IIB+H2 T4 Class I, Div. 1, Group B, C, D, T4 Class I, Div. 1, Group B, C, D (CSA) Ex de IIB + H2 T4

Canada: Japan:

The Fast-TIM can be marked as follows : EU: II 2G EEx e d [ia] IIB+H2 T4 USA+Canada: Class I, Div1, Groups B, C, D, T4 (FM + CSA)

3.4.2 Electromagnetic Compatibility (EMC) and safety of low voltage devices

HydroCOM complies with the EMC regulations and the safety regulations for low voltage devices.

General Description 4.01.doc

2008-04-09

The components of HydroCOM

Figure 1 outlines all components and supply lines of the HydroCOM system. The components are described in the following sections. HydroCOM Actuators Compressor Interface Unit (CIU) External Power Supply (EPS) Isolation Amplifier (IA) TDC-sensor Hydraulic Unit (HU) HydroCOM Service & Configuration Software (HSS) Transmitter Interface Modules (Fast-TIMs) and HydroCOM-RecipCOM

4.1

HydroCOM actuators

The HydroCOM actuators control the valve unloaders and thus control the compressor suction valves. The hydraulic pressure is supplied by the hydraulic unit (HU). The actuators are electronically controlled by the CIU via the real-time HydroCOM field bus. Each actuators is supplied with 48VDC by the external power supply (EPS). The actuators comprise of the valve housing, the seal housing and the electric housing.

Valve Valve Housing Housing

Oil Oil inlet inlet Solenoid Solenoid Valve Valve cartridge cartridge Soft Soft touch touch damper damper Oil Oil outlet outlet Piston Piston cartridge cartridge High High pressure pressure piston piston

Seal Seal Housing Housing

Leakage Leakage out out Flare Flare connection connection Wiper Wiper rings rings Guiding Guiding rings rings Sealing Sealing rings rings Temperature Temperature sensor sensor

Electric Electric Housing Housing

Connection Connection box box Printed Printed circuits circuits incl. incl. Microcontroller Microcontroller and and Valve Valve driver, driver, Fuses, Fuses, Bus Bus Interface Interface Unloader Unloader Rod Rod

Fig 5.: The HydroCOM Actuator

In the valve housing the 3/2 way valve is actuated by the solenoid and the retracting spring. Depending on the position of the 3/2 way valve the actuator piston is either exposed to the pressure maintained by the hydraulic unit or to atmospheric pressure (tank). The high pressure of the actuator acts directly on the unloader rod. Up streams of the 3/2 way valve a check valve is located. During the phase of reverse flow through the suction valve the hydraulic oil is trapped by the check valve. Consequently the pressure in the high pressure cylinder can exceed the pressure of the hydraulic unit. A two stage throttle (soft-touch-damper) is installed in each actuator in order to protect the moving parts of the unloading system and the valve sealing elements against excessive impact stress. The soft-touch-damper consists of a start bypass volume and an orifice. The bypass volume is filled during the first phase of the closing operation ( 30% to 60% of the valve lift). After the bypass volume has been filled up the oil pressure increases and General Description 4.01.doc 10 2008-04-09

dampens the closing of the sealing elements considerably before hitting the seat. The seal housing provides the sealing of the unloader rod. Sealing is performed by a wiper element, several sealing elements and guiding rings. Between the upper and lower sealing element a ring chamber with flare gas connection is located. A temperature sensor is located within this seal housing with the sensing point very close to the suction valve cover. The suction valve cover temperature is used for continuous monitoring of suction valves and flow regulation. The measurements can be transferred via CIU analog outputs or Modbus interface to the DCS/PLS or HydroCOM-RecipCOM. During operation some oil may gather at the bottom of the piston. The oil leakage is tapped by a leakage oil connection into a collecting tank. The actuator electronics are mounted within the flameproof electric housing (EEx-d). The electronics control the solenoid, measure the valve nest temperature and hydraulic pressure (option). Each Actuator is equipped with a microprocessor to fulfill these tasks. This microprocessor solves drive, monitoring, and communication functions. The electrical lines (48VDC and HydroCOM field bas) are connected the EEx-e connection box.

4.2

Compressor Interface Unit CIU

HOERBIGE

HOERBIGE

HOERBIGE

HOERBIG

CIU on TDC Enable Simulation Warning Error Phyd low

HOERBIG

HOERBIG

5V

Code

Code

Code

15V

Scroll/ Clear

Scroll/ Clear

Scroll/ Clear HSS

HydroCOM

CIU-4 IPS

SIM-4

SIM-4

SIM-4

GIM-4

Fig. 6.: Front view HydroCOM-CIU The HydroCOM-CIU (Compressor Interface Unit) serves as interface between the HydroCOM-system and the DCS / PLC. The controller output defined for each compressor stage is translated into the opening and closing signals for the suction valves. The valve nest temperatures, measured by the actuators, are transferred to the DCS / PLC via the CIU. Further the transmission of enable-, warning-, error- , and simulation signals is effected by the CIU. The CIU is configured and serviced via the RS-232-Interface. The interface is mounted on the front of the CIU. The TDC sensor synchronizes the CIU with compressor speed and crank shaft position. The CIU calculates the valve actuation timing. Signals between CIU and the controller can be exchanged via parallel wiring (hardwired) or Modbus. The Compressor Interface Unit consists of up to six Stage Interface Modules (SIM - one for each compressor stage), the General Interface Module (GIM) and the Internal Power Supply (IPS). The modules are placed in a 19" subrack. Up to eight valves as well as up to two Fast-TIMs can be controlled per SIM. Head-end and crank-end valves can be driven independently. There must be one HydroCOM field bus line to the compressor per SIM. Please refer to the assembly manual for the specification of the bus cable. FastTIMs for fast signals like indicator pressure and rod position are to be connected to a separate SIM.

General Description 4.01.doc

11

2008-04-09

4.3

External Power Supply

The External Power Supply (EPS) provides actuators and Fast-TIMs with 48VDC.

4.4

Isolation Amplifier

The isolation amplifier transfers the TDC signal from the hazardous area (intrinsically safe circuit) to the CIU in the safe area. Input, output and supply voltage are electrically isolated from each other.

4.5

TDC-sensor

The TDC-sensor synchronizes the HydroCOM system with compressor speed and determines the position of the crankshaft. Each revolution the TDC-sensor sends one reference impulse to the CIU. CIU and TDC-sensor are electrically separated by the isolation amplifier IA. The TDC-Sensor is a cylindrical, inductive proximity switch according to DIN 19234 (NAMUR).

4.6

Hydraulic Unit (HU)

The Hydraulic Unit supplies hydraulic energy to the actuators. Depending on the suction pressure of the highest controlled compressor stage the pump increases oil pressure from atmospheric pressure to up to 200 bar. The oil is fed to the actuators via hydraulic lines that can be shut-off. There are pulsation dampers close to inlet and outlet of the valves. The oil is led back un-pressurized. Besides the oil supply lines a leakage oil line has to be connected to a separate collector tank. (The specification of the piping system can be found in the assembly and installation manual). The drawing below shows the basic design of the hydraulic unit. Hydraulic oil is pumped via a gear pump into the system. The oil is connected to the circuits of each stage via redundant high-pressure-filters with check valves (visual blocking indication). For each compressor stage one circuit is used. The maximum operating pressure is maintained through a pressure control valve. Any overflowing oil is cooled down in a cooler and is sent via a return filter to the tank. By a built in thermostat the oil cooling circuit will be switched off at low ambient temperatures to avoid too low hydraulic oil temperatures. Following additional equipment is integrated in the hydraulic unit: Level switch Oil pressure transmitter Temperature transmitter Optionally an oil pan can be supplied.

General Description 4.01.doc

12

2008-04-09

Fig. 7.: Hydraulic unit size NG120 (left) und size NG 63 (right)

Return line from the Actuators Shut-off ball valves Return line

Supply line to the Actuators

Shut-off ball valves Feeding line Pressure transmitter PT

Bypass for detensioning HU

Pressure gauge Switch-over high pressure double filter Pollution display

3m

3m

Pressure relief valve

Motor Oil cooler with fan

Thermostat Pollution display

Airing filtre for tank Filling filtre for tank M

10m

Return filter

10m

Temperature transmitter Level switch TT LS

500m

Oil level display Oil tank Oil pump

max min

Drain valve

Fig .8.: Hydraulic unit principle design

General Description 4.01.doc

13

2008-04-09

4.7

HydroCOM Service Software (HSS)

The HSS is used for configuration, analysis and service of following HOERBIGER products: HydroCOM HydroCOM-RecipCOM ROD-Position Analyzer (on-line rider ring wear monitoring)

A PC with Microsoft Windows operation system is required. The system requirements are specified in the HSS user manual.

4.8

Fast-TIM

Fast-TIMs (Fast-TIM transmitter interface module) enable decentralized data acquisition and bus communication. Fast-TIMs are designed for connecting fast signals (e.g. indicator pressure, rod drop) and slow signals (e.g. valve nest temperature). Fast-TIMs contain power supply and barriers for intrinsically safe transmitters and are mounted on or next to the compressor frame, reduce field wiring and cut installation costs significantly. Since the Fast-TIMs are installed like the actuators in the field its electronic is mounted in flame-proof housings. The electric connection is identical to the actuator. In addition to the actuator there is an additional connection box for intrinsically safe transmitters:

Indicator pressure

Piston rod position (rod drop)

Temperature Pressure Vibrations Flow

Fig .9.: Possible transmitter connections Fast-TIM The following types are available Fast-TIM/8C: 8 channels: All channels for 4-20mA transmitters (slow or fast signals) 6 channels: 4 channels for 4-20mA transmitters. 2 channels for rod drop transmitters. 4 channels: All 4 channels for rod drop transmitters

Fast-TIM/6M

Fast-TIM/4R

General Description 4.01.doc

14

2008-04-09

4.9

Compressor Condition Monitoring (RecipCOM)

The optional on-line compressor condition monitoring system (recipCOM), HydroCOM-RecipCOM is specifically designed for reciprocating compressor. HydroCOM-RecipCOM is an on-line RecipCOM-System for monitoring valves, rider rings, piston rings, packings, rod load and rod load reversal, controls, crosshead/piston connection and process parameters. Signals are sampled synchronically by the Fast-TIM and transmitted via HydroCOM bus to the CIU. The CIU receives the digital data and controls data acquisition. The CIU makes the data available to the RecipCOM-PC performing analysis and monitoring. The industrial type RecipCOM-PC can be installed in the HydroCOM control cabinet. Data from your PLC/DCS are integrated via Modbus or OPC. Full network integration enables user access via network (LAN, WAN, Internet) or modem with the HOERBIGER supplied Visu-Software. HydroCOM-RecipCOMs modular structure provides a variety of functions: Process Overviews for a schematic display of the main operating conditions HydroCOM Status Monitoring for visualization and logging of HydroCOM status Trend Monitor: Signals and calculated parameters are logged for historical and trend analysis PV Diagram Analysis of indicated pressure for on-line condition and performance monitoring Wear Monitoring: 36 segment analysis of piston rod position and rider ring wear monitoring Machine Status: Traffic lights clearly indicate compressor status and alarms Integration of process data from PLC/DCS vie MODBUS or optional OPC Log Book (alarm list) Ring-buffer for dynamic signals (indicator pressure, rod position) High resolution ring-buffer for process data

General Description 4.01.doc

15

2008-04-09

Fig 10.: Examples User Interface HydroCOM-RecipCOM

General Description 4.01.doc

16

2008-04-09

4.10

Rod-Position Analyser (RPA)

The Rod-Position Analyser is an optional on-line monitoring system to monitor rider-ring wear and vertical piston rod run-out. The RPA measures and analyses the position of the piston rod at each degree crank angle and provides following values: Stand-out of rider rings: The RPA is the on-line feeler gauge to determine the standout (clearance between piston and liner) during operation. Based on the trend in the DCS, the remaining lifetime of the rider rings can be estimated and the compressor shutdown for their replacement be planned. Run-out: Additionally the RPA works as on-line dial indicator to determine the vertical run out during operation. A change in run-out indicates excessive crosshead clearance, alignment problems and a loose connection between piston and crosshead. In addition to the CIU, EPS and TDC-sensor the rod-position probes have to be installed. The probes are fixed to the pressure packing and are wired to the Fast-TIM that is mounted locally at the compressor. The values for stand-out and run-out are transmitted to PLC/DCS with the CIU analog outputs (4..20mA) or Modbus.

Fig 11.: Mounting position RPA probes

General Description 4.01.doc

17

2008-04-09

Installation examples

The following picture shows the typical installation of the HydroCOM system on a double acting, horizontal reciprocating compressor.

Actuators

Wiring and Piping for leakage oil & leakage gas

Hydraulic Unit

Pipes and hoses for the Hydraulic system

Fig 12.: Typical HydroCOM installation

The installation of the HydroCOM system includes the following points: Installation of the valves and unloaders Installation of the Actuators on the suction valve covers Installation of the Hydraulic Unit Installation of the CIU, EPS, IA within the safe area (in a cabinet) Installation of all pipes and hoses Installation of the wiring Programming of the DCS (or installation of the ABB external loop controller if ordered from HOERBIGER)

If required HOERBIGER offers turnkey installations.

General Description 4.01.doc

18

2008-04-09

You might also like

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Hydrocom Specification Petronor NP HISA V1 - 0Document33 pagesHydrocom Specification Petronor NP HISA V1 - 0Nattapong Pongboot100% (1)

- Hydrocom General Description 4.01Document18 pagesHydrocom General Description 4.01Nattapong PongbootNo ratings yet

- CMCDocument9 pagesCMCChuma KhanNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- HSS English User Manual 06ADocument29 pagesHSS English User Manual 06ALeon SanchezNo ratings yet

- 07 - Hyd2.0 Installation PDFDocument85 pages07 - Hyd2.0 Installation PDFSudhir SainiNo ratings yet

- HydroCOM Energy SavingsDocument21 pagesHydroCOM Energy Savingsabhik1790% (1)

- Centrifugal CompressorDocument220 pagesCentrifugal CompressorShahnaz Estahbanati0% (1)

- Samson PRV Mounting and Operating InstructionDocument20 pagesSamson PRV Mounting and Operating InstructionRick CalaguiNo ratings yet

- 1 1Document9 pages1 1Ankush SehgalNo ratings yet

- Screw Compressors 2019Document12 pagesScrew Compressors 2019Dzana Kadric0% (1)

- Running Performance: Service/Stage Data Performance OutputDocument2 pagesRunning Performance: Service/Stage Data Performance OutputJose RattiaNo ratings yet

- Loadsharing compressor networksDocument15 pagesLoadsharing compressor networksDev0009No ratings yet

- High Pressure CompressorsDocument16 pagesHigh Pressure CompressorsnghiaNo ratings yet

- D1-170 Ecosmart en PDFDocument8 pagesD1-170 Ecosmart en PDFrakacyuNo ratings yet

- Recip Overview Brochure HSR OnlyDocument11 pagesRecip Overview Brochure HSR OnlyMuhammad ImranNo ratings yet

- Diaphragm Pump Seminar ReportDocument58 pagesDiaphragm Pump Seminar ReportMahaManthraNo ratings yet

- (Book) ch8 - 15 Compressor Control and Optimization PDFDocument31 pages(Book) ch8 - 15 Compressor Control and Optimization PDFAtef Lasheen50% (2)

- Anti SurgeDocument12 pagesAnti SurgebatoqkaNo ratings yet

- Adjust Axial Bently Nevada ProbesDocument3 pagesAdjust Axial Bently Nevada Probesmic-grNo ratings yet

- Beginner's Guide To Centrifugal Compressor System Design & SimulationDocument17 pagesBeginner's Guide To Centrifugal Compressor System Design & Simulationkavinmech1No ratings yet

- F 0077 e 55Document6 pagesF 0077 e 55Bùi Cảnh TrungNo ratings yet

- Three-Stage Compressor Power CalculationDocument6 pagesThree-Stage Compressor Power CalculationRifka Aisyah0% (1)

- Driving Centrifugal Compressor TechnologyDocument52 pagesDriving Centrifugal Compressor TechnologySHRIKANT GADENo ratings yet

- Sizing Technical Brief FinalDocument3 pagesSizing Technical Brief FinalBelalNorNo ratings yet

- Camcs L PlantairDocument20 pagesCamcs L PlantairSergio MoncadaNo ratings yet

- Pump DecokingDocument8 pagesPump Decokingrohl55No ratings yet

- ARIEL Maint intervalSEK PDFDocument7 pagesARIEL Maint intervalSEK PDFMargaret Daugherty100% (1)

- Ufn3 Treinamento e ManutençãoDocument62 pagesUfn3 Treinamento e ManutençãoRodneiNo ratings yet

- Masoneilan SVI II AP Installation and Maintenance Manual (Rev G) PDFDocument180 pagesMasoneilan SVI II AP Installation and Maintenance Manual (Rev G) PDFFelixAvila67% (3)

- Field Performance Testing For Centrifugal CompressorsDocument7 pagesField Performance Testing For Centrifugal CompressorsRicardo BecNo ratings yet

- Reciprocating Compressor ImprovementsDocument13 pagesReciprocating Compressor ImprovementsSANJANA SINGHNo ratings yet

- API 618 Compressors1 PDFDocument0 pagesAPI 618 Compressors1 PDFAnonymous ffje1rpaNo ratings yet

- SRL CompressorsDocument20 pagesSRL Compressorssthe03No ratings yet

- Centrifugal Compresssor Pre-Commissioning ChecklistDocument3 pagesCentrifugal Compresssor Pre-Commissioning ChecklistNikhil JadhavNo ratings yet

- Bombas Reciprocantes PDFDocument43 pagesBombas Reciprocantes PDFSamuel Arias CamachoNo ratings yet

- Load Sharing CompressorDocument2 pagesLoad Sharing CompressorleakNo ratings yet

- SIS - Safety Instrumented Systems - A Practical ViewDocument4 pagesSIS - Safety Instrumented Systems - A Practical ViewMugesh KannaNo ratings yet

- Field Surge Test ProcedureDocument10 pagesField Surge Test ProcedureShyam Adhikary0% (1)

- Centrifugal Compressor HorsepowerDocument9 pagesCentrifugal Compressor HorsepowerCurtis DookieNo ratings yet

- Flowmeter Selection ChartDocument1 pageFlowmeter Selection Chartmilton1987No ratings yet

- FM200 Filling System/ Equipment: Solution A: Filling Machine+ Vacuum Pump+ Weighing SystemDocument2 pagesFM200 Filling System/ Equipment: Solution A: Filling Machine+ Vacuum Pump+ Weighing Systemal boshia100% (1)

- Control Valves ArrangementDocument11 pagesControl Valves ArrangementPrasanna kumar subudhi100% (1)

- Vertical PumpsDocument16 pagesVertical PumpsAdel ShatlaNo ratings yet

- Ingersoll Rand Oil Free CompressedAirTechnologyIAS 0701015 enDocument12 pagesIngersoll Rand Oil Free CompressedAirTechnologyIAS 0701015 envkees1987No ratings yet

- TYPE 8B1/8B1T: Elastomer O-Ring SealsDocument6 pagesTYPE 8B1/8B1T: Elastomer O-Ring SealshukNo ratings yet

- Centrifugal Compressor Surge and Speed ControlDocument14 pagesCentrifugal Compressor Surge and Speed ControlWaqas AhmedNo ratings yet

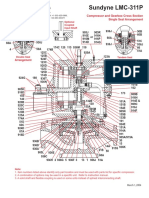

- Compressor Api617 Lmc311p Sundyne Cross-SectionDocument1 pageCompressor Api617 Lmc311p Sundyne Cross-SectionMiguel SoteloNo ratings yet

- OHH OHHL E00697 (Pump Zulzer)Document6 pagesOHH OHHL E00697 (Pump Zulzer)Jose Sosa CojNo ratings yet

- 04 Actuator EnglDocument14 pages04 Actuator Englsumantabal_uceNo ratings yet

- AGA 3 Gas Flow Equation For Orifice Plates - Learning Instrumentation and Control EngineeringDocument10 pagesAGA 3 Gas Flow Equation For Orifice Plates - Learning Instrumentation and Control EngineeringJanuar ReasNo ratings yet

- DHRC Catalog - F164LR.Document28 pagesDHRC Catalog - F164LR.mdalt9180No ratings yet

- AUDIT CENTRIFUGAL COMPRESSOR OIL SEALSDocument33 pagesAUDIT CENTRIFUGAL COMPRESSOR OIL SEALSMuhammad afzal100% (1)

- DRIVE SYSTEM Hydraulic and PneumaticDocument50 pagesDRIVE SYSTEM Hydraulic and PneumaticNor AzlanNo ratings yet

- Hydro ComDocument18 pagesHydro ComOmprakash_janaNo ratings yet

- Hydrocom: High Energy Savings and Excellent ControllabilityDocument8 pagesHydrocom: High Energy Savings and Excellent Controllabilityrahilshah100No ratings yet

- Hydrocom enDocument8 pagesHydrocom enJai-Hong ChungNo ratings yet

- Z-008 Criticality Analysis For Maintenance PurposesDocument34 pagesZ-008 Criticality Analysis For Maintenance PurposesGustavo Farelo SuarezNo ratings yet

- API Plan 53-Accumulator Bladder ChargingDocument11 pagesAPI Plan 53-Accumulator Bladder Chargingsumantabal_uceNo ratings yet

- 04 Actuator EnglDocument14 pages04 Actuator Englsumantabal_uceNo ratings yet

- 01 Genera Lover View of Step Less Capacity Control of Reciprocating CompressorDocument15 pages01 Genera Lover View of Step Less Capacity Control of Reciprocating Compressorsumantabal_uceNo ratings yet

- Screw Pump ManualDocument24 pagesScrew Pump Manualsumantabal_uceNo ratings yet

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Screw Pump ManualDocument24 pagesScrew Pump Manualsumantabal_uceNo ratings yet

- 03 Hydraulic Unit of Step Less Capacity Control of Reciprocating Compressors.Document5 pages03 Hydraulic Unit of Step Less Capacity Control of Reciprocating Compressors.sumantabal_uceNo ratings yet

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Balancing of RotorsDocument20 pagesBalancing of RotorsChetan Mistry100% (1)

- Cat 602-1 032510Document58 pagesCat 602-1 032510sumantabal_uceNo ratings yet

- Fmea PumpDocument8 pagesFmea Pumpsumantabal_uceNo ratings yet

- A guide to hydrodynamic bearingsDocument28 pagesA guide to hydrodynamic bearingssumantabal_uceNo ratings yet

- Vol 1 of 3Document12 pagesVol 1 of 3sumantabal_uceNo ratings yet

- Coppus Product GuideDocument6 pagesCoppus Product GuideSayed KassarNo ratings yet

- Wiring Diagram V7Document1 pageWiring Diagram V7NadeeshNo ratings yet

- McCormick X60 Series (2011-2014) - RP67 - X60.50 Tractor Service Repair Manual PDFDocument25 pagesMcCormick X60 Series (2011-2014) - RP67 - X60.50 Tractor Service Repair Manual PDFfjkkekmdmNo ratings yet

- InTech-Fluid Structure InteractionDocument23 pagesInTech-Fluid Structure InteractionDeepak MahapatraNo ratings yet

- Nordson 2018 Replacement Parts Catalog PDFDocument318 pagesNordson 2018 Replacement Parts Catalog PDFsaadalam218_773301970% (1)

- Hydraulic Pressure TestDocument4 pagesHydraulic Pressure TestBola AdelNo ratings yet

- Keperluan Document Sebagai Dasar Penerbitan SLODocument4 pagesKeperluan Document Sebagai Dasar Penerbitan SLOFaturrakhman KhairanNo ratings yet

- Tractor Operator AgricultureDocument9 pagesTractor Operator AgricultureConstantin CarpenNo ratings yet

- DX SPLIT Acum L Cadx l50hzDocument21 pagesDX SPLIT Acum L Cadx l50hzFARIDNo ratings yet

- Kumera-848027c - Installation and Maintenance - en - 2015-08 PDFDocument40 pagesKumera-848027c - Installation and Maintenance - en - 2015-08 PDFgilbertogatoNo ratings yet

- Best Practice Manual-Fluid PipingDocument43 pagesBest Practice Manual-Fluid Pipingapi-3869476100% (1)

- Lecture # 8: Dr. Muzaffar AliDocument37 pagesLecture # 8: Dr. Muzaffar Alikamran bhatNo ratings yet

- Smokevent Calculation..Document2 pagesSmokevent Calculation..Karthy GanesanNo ratings yet

- Bagatelle Showroom Structural AnalysisDocument15 pagesBagatelle Showroom Structural AnalysisDhiraj BeechooNo ratings yet

- Parts of A CarDocument5 pagesParts of A CarMaria MolinaNo ratings yet

- Atlas Copco QES RangeDocument8 pagesAtlas Copco QES RangeDave WallaceNo ratings yet

- Mechanical Sensors 25augustDocument74 pagesMechanical Sensors 25augustSasikumar SukumaranNo ratings yet

- Fan Application GuidelineDocument6 pagesFan Application GuidelineEdward SabedraNo ratings yet

- Newco Product Line BrochureDocument8 pagesNewco Product Line BrochureshahganNo ratings yet

- SDFDSF PDFDocument2 pagesSDFDSF PDFJohnny CcanchiNo ratings yet

- S Emi Rotary Hand Wing Pumps: A Plication PDocument2 pagesS Emi Rotary Hand Wing Pumps: A Plication PMarketing CTNNo ratings yet

- Heat Flow Calculations Made Using The V C: Ventilation Test InstrumentsDocument6 pagesHeat Flow Calculations Made Using The V C: Ventilation Test Instrumentsretrospect1000No ratings yet

- Trusses ExamplesDocument13 pagesTrusses ExamplesShaikh Yaseen MehmoodNo ratings yet

- Soil Mechanics Problems QBDocument4 pagesSoil Mechanics Problems QBKalasekar M SwamyNo ratings yet

- GEO3701 Unit 3Document94 pagesGEO3701 Unit 3Asithandile Punqunqu MpayipheliNo ratings yet

- Curvilinear Motion and ProjectilesDocument15 pagesCurvilinear Motion and ProjectilesAltammar1367% (3)

- Adsorption Gas Treatment Plant - Design Information: Spec. NumberDocument5 pagesAdsorption Gas Treatment Plant - Design Information: Spec. NumberabhmarsNo ratings yet

- ME8091 Automobile Engineering1Document2 pagesME8091 Automobile Engineering1AyyanrajNo ratings yet

- FT4 C PDFDocument5 pagesFT4 C PDFGeorge John AmegashieNo ratings yet

- Trilectron DAC900 TMEverestDocument394 pagesTrilectron DAC900 TMEverestVictory GSENo ratings yet

- Kit de Joint de Verin CaterpillarDocument2 pagesKit de Joint de Verin CaterpillarzephyrinNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksFrom EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)