Professional Documents

Culture Documents

BMC 1100 & 1300 Workshop Manual

Uploaded by

Michael CarnellCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BMC 1100 & 1300 Workshop Manual

Uploaded by

Michael CarnellCopyright:

Available Formats

SERVICE

1100 Marks I & II,

1300, and KESTREL

Workshop

Manual

Quote Part No. AKO 3615 G when nrderlng this

publie::at.ion, which a1so replAcesAKD 3238 A and

AKD3294A

The British Motor Corporation Limited

BMC Service division

Cowley, Oxford, England

Telephone: Oxford 78941

Telegrams: BMCSERV. Telex. Oxford

re/ex: BMCSERV. Oxford 83145 and 83146

0 ....... , Cabl .. : BMCSERV. Telex. Oxlord. England

1 ... 7i."mI"_1 Q THE llUTlSH HOTOII. COAPOItATiON UMIT"EO. ~

2

INTRODUCTION

Tbi& MaDual has been prepared to provide s(r.tioe: operators witb tbe neces.sa.ry infor-

mation for concel maintenance and repair; it also serves &5 a readyreference book for

service suptI"YisioQ and covers ilems of procedure for guidaoce of both the fully qualified aDd

tbe mechanic. The pases aDd iUUSlraliOOI arc numbered consecutively

within eacb Section. and the Section title and letter arc shown HI tbe top of each page.

Maiotcoance iteros withio tbe Sectioas sbould be cerried out at tbe intervals specwed

in tbe Pa$$port to Service Of Driver's Handbook.

IMPORTANT

On cars fiued with emission control equipmcnt (EJ:haust POri Air Injcclion)

service operations and adjuSlme:nts showing symbol must be followed by an exhaust

emission check.

Servicing and adjusting e:oghle emission control equipment nlllst be carried out In

accordance with Ihe inslruclions given in Workshop Maoual Suppleruent AKD 4957.

1100. laue 6. Itnl8

CONTENTS

Introduction

General Data

Engine

Syncbromesh transmission 1098 c.c.

Automatic traosmission

1275 c.c.

Ignition

Synchromesh transmission

Aut(')matic trllnsmission . ,

Cooliog System

Fuel System

Synchromesh Irantraission

Automatic Iransmission

Clutch ..

Transmission

Synchromesh transmission

Automatic traGsmission

Drive Shafts

Steering ..

Broking System

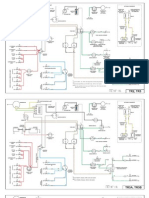

EleclriC31

Wbeels and

Dody

Air-cooditioning SYilem

Recommended Lubrica..ots

1100. 6. IOUI!

..

. .

..

..

..

..

Section

A

Aa

Ab

D

Ba

c

D

Da

F

F.

G

H

J

K

L

M

0

P

End of Manual

3

ENGINE

Type$

Number of cylinders

Bore

Stroke

Capa.city

firiug order

GENERAL

Compression ratio : Siogk-carboreuer flpplication

TwiQcarbureu er application

Valve operation

B.M.E.P. ,

Hip compres.sioo

low co(l'lprcs.sioo

Torque :

High cnmpreuiCln

Low compression

Oversize bore: 1st

Ma x.

CrankshaH

Milia jourIlOlI diameter

MiILimum regrind diameter

Craokpio jouroal diameter

Cnlllkpio mioimum regrind di"mch:r

End-clearance

End-thrust

Main burinp

Number and type

Malerial

l.eoglh

Diametrical clearance ..

Undcrsiz.es

COllnecting rods

.Le.ogtb bet ..... een ceotres

Bigd Mirinp

Materinl

Beariog side-clearancc

Bearing diamclfical clearance

PLttoQS

Type

Clearances: 8otlom of skirt

Top of sltirt

Ovcrsizcl

PistOD riq.t

"

"

"

Compression : Type : Top ring:

"

"

"

"

Second aod third riogs

Width: Top ring

lIOO, issue 8. .5610

Second and third riogs

lWckoess

f:iUect gapt

Clearance in groove

DATA

JOAMW, 10GR, 10V.

4.

2-543 in. (64-58 rom.).

3296 in. (83'72 mm.).

67 cu. in. (1098 c.c.).

1,3,4,2.

85 : 1 (7'5 ; 1 ;J vaiJable).

89 : 1(8'1 : I available) .

Ovcrbead by pusb-rod.

Single cnrburelfe,

npplical;o1l

135 Ib./sq. in. at

2.500 f.p.m.

128 Ib./sq. iD. at

3,000 r.p.m.

60 lb. fl. at 2,500 I . p.m.

57 lb. n. al 3,000 f.p.m,

+'010 in. ('254 mill.).

+ 020 io. ('508 rom,).

Twill-carbureller

IIpplicQlioli

ia. at

2,750 r.p.m.

136Ib./sq. iD. ftt

2,150 r. p.m.

61 lb. fI . :lt 2, 750 ( .p. l)) .

60 lb. rt. :It 2,750 r.p.m.

\ 7505 to 1751 in. (44' 46 to 44' 47 mm.).

17105 io. (43'45 mN.).

16254 to 16259 io. (41 ' 2810 41 ,29 mm.).

1'5854 in. (40'27 mrn.).

' 002 to -003 io. ('051 to 076 rom.).

Taken at centre main bearing.

3 sbeU type.

Steel-hac ked lead-broozc. Icnd-indium-plalcd.

1,* in. (27 10m.).

001 to 0027 io. (025 10 ,070 mm.).

- 010 in., --020 io., -030 io.., - 040 io.

(- '254Illm., -508 mm., --,762 O'lm., -1016 rum.)

5' 75 in. (14'605 cm.) .

Steel-bllck.:d lead-bronze, lead-indium-plated.

008 to 012 io. (' 203 10 305 mm.),

001 to -0025 in. ('025 to '063 mm.).

Solid skirt.

000510 0011 )0 , (-oU 10 028 moo.).

0021 10 00:>7 in. ('053 to 094 mm.).

+010 in., +-020 in. (+'254 mm., + '508 mm.).

Plain internal cbamfer (chromc-faced).

Tapered.

06210 ' 0625 in. (1 ' 575 to 1587 mm.).

0615 to ,0625 in. {I' 558 to ( ,587 mm.).

10610 112 in. (269 to 284 mm,).

,007 to -012 io. (-178 to -305 mm.),

002 to -004 io_ ('051 to 102 mal.).

GENERAL DATA-continued

Oil conlrol: Type (early models)

Widtb .

Gudgeon pia

Type

Fit in piston

Ya),et

Thickness

Fin!:/J gap

to groove

Type (later models)

Rails fitted gap

Side spriogs filled gap

Seal 101el

Exhaust

Head diameter : Inlet

..

Slotted SCr<'per.

124 to 125 ill. (J' 15 to J 17 mm.).

' 106 to 112 in. (2'69 to 284 nun.).

007 to 012 in. (' 18 to JO mm.).

-(1015 (0 OOJ5 in. ('04 to09 "'m.).

DuaHex 61.

012 to 028 in. (-30 to 78 nun.).

'100 to ISO in. (2' 5 to 375 rom.) .

Fully floaling.

Hand posh fil

.. 45.

.. 45.

H51 to 1-156 in. (29'23 to 29J6 nlm.).

InJet (l:uer models, (win-carburelter appli

catioo) 1213 to 1218 iD. (3081 to JO' 94 111m.).

1000 to 1005 in. (25'40 to 25'S3 mm.).

279J to 2798 in. (7'094 to 7107 mm.).

2788 to 2793 in. (7'081 to 7094 rom.).

'J12 in. (7'925 mm.).

Exhaust

Stein diameter: Inlet ..

Exhaust

Valve lift

Valve stem (0 guide clearouce: Inlet

Exhaust

Valve rocker clearaoc.: : Ruoni.ng

TimiD&

Valve rocleer busb bore (reamed)

VaJ,c timlag

Timina mark..iogs

Chain pitch aDd number of pitches

Iolet valve: Opeos

Closes

Exhaust valve: Opens ..

Closes . .

Valve pldeI

Length: 10lel aDd exhaust

Valve spriogs (twia-carburellu application)

Free leoltb: Inlet and exhaust

Number or Ylork.iog coils

PJ"C$$ure: Jnlet aDd exbaust: Valve open

Valve closed

Vain "riD" (JiD"e-c:arbar'etW application)

Free lealth : Inlet aDd exhaust

of working coils

Pressure: lnltt aod eltbau$t: Valve open

Valve closed

T_

Type

Diameter

Leoa'h ..

C.-.rl

Journal diAll\eters: Front

Centre

Rca,

End-Boat

000a0I DsIa 2

. .

.

.

.

.

.

'OOIS to 0025 in. ('038 to 064 mID.).

002 to OOJ in. ('OSI to 076 DUn.).

012 iD. lOS mm.) (cold}.:

029 in. ('74 Inro.).

5630 to 5635 in. (14' 30 to 143t2 IWD.).

Dimples on lim.i.og wbeels, marb OD lIywbce1.

i io. (9-52S mID.). 52.

S B.T.O.C.

WA.B.D.C.

51 B.B.D.C.

21 A.T.O.C.

1'531 in. (38'89 mm.).

Ouler

1'750 in. (44'45 rom.)

<It

88 lb. (399 kg.)

52 lb. (23-6 kg.)

1'750 in. (44'45 moo.).

<It.

8S lb. (386 k,.).

S2S lb. (23-8 "'.).

Barrel.

a12 in. (20'64 mm.).

IS io. (3810 mal.).

Inner

1672 io. (42' 41 mm.).

61

30 lb. (1l6 kg.).

IB lb. (82 kg.).

16655 10 1-666 il). (42'304 to 42316 mm.).

162275 to 162325 in. (41-218 to 41'231 D\D1.).

13725 to 1-3735 in. (34'862 to )4,887 mm.).

003 to 007 in. ('076 10 '178 nuu.).

J too. .IIIue'. 5610

GENERAL DATA-contillued

Bearings : Type

laside diameter : Front

Centre ..

Reor

Clearance

ENGINE LUBRlCA nON SYSTEM

Oil pump

Typ"

Relief pressure valve operates

Relief valve spring: Free length

on 6lter

Typ"

Capacity

Oil prestllCe

Normal running

Idliug (nunimum)

tolJRL SYSTEM

Carburet ten

Make and type

Diameter

kl

Need1es: Staadard

Weak

Rich ..

Fitled length

"

..

Piston spring:

Twi n-c:trburett er applicatioo

"uti pump

Malee and type

Delivery rale

Delivery pressure

COOLING SYSTEM

Thermostat selling

Sraodard

Cold climates ..

Hot climates

Pressure (blow-oO)

IGNIl10N SYSTEM

Sparlting plugs

Size

Plug gap ..

CO"

Distributor

Distributor cootact poiots gap ..

. .

Static igaitioD timiDg: SiogJe-carbureuer applicalion

Twin<arburetter applicatioo ..

Disu-ibulor test data :

. . White-metallined, sleel-backed.

' 667(0 ' 6675 in. (42'342 to 42355 mm.).

'62425 to 162415 In. (41 -256 (0 41 269 mm.).

13745 to 13750 ia, (34-91210 34-925 rom.).

001 to 002 io. (-025 to 'OSI mm.).

[nlerDal gear or vane.

60 Ib.,'q. in, (4-2 kg./CIIl.

2

).

2et io. (72'63 mm.).

2/r i{l. (5477 mm.),

Full-flow, with paper e!emeDI.

I piot (1'2 U.S. pints, -57 lilre).

60 Ib./sq. in. (4-2 kg.fem.:).

IS Ih.jsq. in. (I-oS kg./em.!).

.. S.U. 1)pe HS2. Single or twin.

Ii ill . (31 75 ram.).

090 io. (2-29 mm.).

Single Twin

AN OJ.

E8 GV.

H6 06.

Red.

Rluc.

S. U. electric: SP 0( AUF 200.

56 pints/ br. (67 U.S. piots/hr., 32 Jjt(es/hr.).

to 3Ib./sq. in. ('17 10 21 kg./cm.,).

S2" C. (180' P.).

SS' C. (190' F.).

74' C. (165' F.).

IJ Ib./sq. in, ('91 kg,fc.tn.

t

).

Champion N5.

14 m.m.

025 in. ('635 mm.).

LA 12.

2504.

014 to -016 io. ('36 to 40 mm.).

J' B.T.D.C.

5' D.T.D.C.

Twio..carburctter applicatioD. bigh and low compression:

Automatic advaoce .. .. SlarlS 700 r.p.m., finisbes 28-32" al 5,000 f.p.m.

Vac.uum advance lotal (craokshafl degrees) 14" at 7 in. Hg.

Dwell aogle 60"3".

1100. IIsuc 8. 5610

GENERAL DATA-contil/ued

Si ngl e...carburettcr application. higb comprcssion:

Autom:uic "dvallce:

(Up to Engine No. IOAMW{flll H559141 )

(From Engi ne No. IOAMW(Taj H5S9242)

Vacuum adv;lnce tolnl (craokshaft degree .. )

Dwell aogle ..

SiDglc-carburetter application, low compre.<:sion:

Automatic advaoce ..

Vacuum adviloce 10lal (crankshaft degues)

Dwell logJe

CLUTCH

(Earll an)

Type

Diameter

Faciog maletial

Coil springs

CaIOl)r

Clu(cb fluid

(Later all'1I) IS above except

Typo

Diaphragm spriog

ColoW"

GEARBOX

Number of forward speeds

Synchromesh

Rarios : Top

Third

Second

First

Reverse ..

Overall ral ios: Top

Third

Secood ..

First

ReYerse ..

Speedorot:ler gear ratio ..

. ,

Road spud in top gear at 1,000 (.p.m.

STEERING

Type

StocriDg-wbeel turns-lock to lock

SteeriDg-wbcel di<"lUle.t.er ..

Camber &ogle .. ,

Castor angle

Swivel hub indinatioo

TC)C-(Iu(

. ,

. ,

Slatts 300 T.p.m., fini shes 30-34 at 5,500 T.p.m.

'. Starts 600 f.p.m., finishclt 30-34 at 5,400 T.p.m.

! l ' at 13 in. Hg.

60

0

)-,

Slarts 700 f.p.m" ftoisbes 32-36 at 5,600 T.p.m.

20" at 17 io. Hg.

60 :, ),

Single dry plate (coil springs).

71 in. (181 IDOl .).

Wouod yarn.

.' 6.

Black/White spot.

LoekhC<'d disc br:lke noid (Series II) .

SiDgle dry plate. (diRphragm spring).

I.

. . Green.

Secood, third, and fourth gears.

I <l , J.

1'412 : 1.

2172 : I.

3-627 , J.

3-627 , J.

.. 4' 133 : I.

. . 5-83 , J.

898 , 1.

1499 : 1.

1499 , 1.

17/6.

15 m.p.b. (24 km.p.b.) approx.

Rack and pillion.

3t

l6i in. (41'2 ero.).

lopositive lO) .

5+- poshive l -

10- CD

Steering lock: angle of outer wheel wilb inner wheel at 20

0

- in. (1 '6 rum.)_ coodition.

19-.

SUSPENSION

rrollt

Fluid pressure:

Aus(in, Morris, M.O.

M.G. (Normalair) ..

Priocess , .

20S lb./sq. in. (IHI

2 Ib./sq. iD. (' 14

. . 220 Ib./sq. io. (15'46 kg./ern.').

+ 10 Ib./sq . in. ('7

-0 lb./sq. in. (0 kg./em.,).

230 lb./sq. in. (16' 17 kg./ern.,).

+2Ib./sq. ill . (' 14

Unladen

condition.

1100. TS.flIC II. 5610

GENERAL DATA-contillued

Amli n, Morris, Riley,] 1300 Autorn:'lic only

Wolsclcy. M.G.

Pbs 1300 Aul omalic;

R_

Toe-oul ..

Camber ..

DIl'FERENTIAJ.

Ratio

ELECTRICAL EQUIJ'MEI'IT

SYJlcm

Cbargiol system

83ttcry

Capacity

Electrolyte 10 6U (Inc cell

Sianer motor

Dynamo . .

MalOl1lum output

Conuol boll:

Cul-ouL Cut-in volU,lc

VOltage

Revem CUlTCot

Regulator (aI1,500 r.p.ru. dynamo speed):

.,

225 Ih./:coq. in. kg,le,",:,)

:L1 lb . .Isq. in. ( I.lli g.fern.

2

) .

.. 250 Ib. :'sq. in. kg . .'c m.

2

) ,

= 2 Ih.!sq. io. ('I'" kg. 'em.2),

io. (3' 1& 011'0 .) .

,.

.. 4 133: I (15/62).

12-volt, positive cnrlb.

Current voltage cootrol.

Lucas N9 or NZ9.

Lucas D? or OZ9-llllec

40 .amp.-br. a' 2O-br. rate.

i pint (380 c.c., 1 u.s. pin I).

Lucas MHO.

Lucas C40.

22 amps.

luClis R8340.

126 to 1)'4.

9') to 11 '2.

80 amps. (wax.).

Opeo..cirtuit setting at 20- C. (68 F.) 142 to 148 volt".

For ambient tempenrurcs other than 20- C. (6S- P.) the roUowiog

:allowances sliould bt: made to the above SCUll'll :

For every 10- C. (18

0

F.) above 20- C. (68- F.) subtract 2 volt .

For every 10- C. (IS- F.) below 20- C. (68- F.) add '2 volt.

BRAKES

Type

Fluid

Frool

Disc. diameter

Pad area (lOW)

Swept nre" (tataJ)

Lining material

Minimum pad thickness

R ....

Drum diamelU

Lillio, dimensioos

Swept area (total)

Lining material

WHEELS

Type

1100. Issue 10. 10lti

Lockheed bydraulic; disc froDI, drum leading

aDd .railiuS shoes.

Lockheed Disc IJrake Fluid (Series JI).

8 ia. (20,] cm.).

16'S sq. in. ll06'5 cm.').

1).l2 sq. in. (8594 em.').

Mintex M78. FG. (F.xcept U.S.A. and Sweden).

Ferodo 2426F. FG. U.S. A. and Sweden.

- in . (1'59 mrn.).

8 ia. (20-3 cm.).

768 x 12j x 094 in. (195'0 x )1 7 x 239 mm.).

.. 63 sq. in. (406 CIll .I).

Ferodo AM8. FF.

4J X 12, ventilated <lise (Mk. I models).

4Cx 12. veotilated disc (Mk.ll and 1300 rnodeb).

Geoenl Oala ,

GENERAL DATA-continued

TYRES

Siu

Tyre Normal : Front (aU models)

Rear (SaJooo)

Rear (CouotrymanfTravelkr)

CAPACITIFS

Transmission castog (including filt er)

Cooling system (without heater)

Heater

Fuel tank ._

Hydro!astic suspension

GENERAL DIMENSIONS

OveraU length

Overall width

Overall beig,lJ1

Wbeelbase

Tfack: Front

Rear

Turning circle:

Ground clearanu . .

Ground clearaQce:

Luggage compartmenl

WElGIITS

Kubsidc (appro:.:.)

Kerbside (appro:.:.) : Countryman{rraveller

Maximum lowing. ,

TORQUE WRENCH SElTINGS

Cylinder bead stud oulS ..

ConnocUng rod big-end bolts

Mnin bearioS boIlS

Flywbttl centre-bolt

Rocker br::lckel outs

TraDsrnissioo case to crankcase

Cylinder side covers

Second typc--deep pres.led cover

Timiog cover-l in. UNF. bolt

Timing covet-A- ill, UNF. bolt

Water pump

Water outlet elbow

Oil filter ..

Oil pump . .

Manifold '0 cylinder head

Rocker cover

Crank.shafl pulle), out

. .

..

Transmission case stud$-i in. dia. UNe.

Trusmissioo sruds--/r- in. dia. UNC. . .

Tranlmission case stud Duu--i in. UNF.

Traosmi$Sion case stud nuts-,\- in. UNF.

5-50-12 or 145-12 SP41

.' 28 Ib/sq. in,

(1'97

241b./sq. in.

(1-1 kg.fcm.

'

).

26 Ib./sq. in.

(1'84

12 Ib.fl;q. in.

(2'24 kg./cm.I).

28 Ib./sq. in.

(1 -97 kg.fern.').

28 Ib.J$Cl. in.

(1 97

8, pints (10'2 U.S. pints. 483 lilet.s).

Sf piots (6-8 U.S. pints. 3'27

1 pint (1-2 U.S. pints,

.. 8 gallons (9 U.S. gallons, 36I.itres).

. . 5 pints (6 U.S. pints, 284 litres).

12 fl . 2i io. (3718 m.).

5 ft. OJ in. (1 ' 534 m.).

4 fl . 5 io, (l3,1. f'T'.).

7 fl, 9t io. (2'375 m.).

4 ft. 3! in. (1'297 ro.)] Static

4 ft. 2i in. (1'272 ro.) condition.

34 O. 9 in. (10'59 ro.).

6 io. (15'24 c.m).

6, io. (l5'5 em.).

cu. ft. ('21 m.').

1,782 lb. (808 kg.).

1.820 lb. (825 kg.).

1,344 lb. (610 kg.).

.. 40 lb. (I, (5'5 kg. 10.).

.. 35 lb. n. (48 kg. m.).

60 lb. n, (8,] kg. 01 .) .

110/115 lb. ft . (IH/15' 9 kg. m.) .

25 lb. fl . (3-46 kg . ... ).

. . 6 lb. ft. (.g kg. m.).

2 lb. ft. ('28 kg. 01.).

5 lb. ft. ('7 kg. m.).

.. 6 lb. fl. (.g kg. m.).

141b. n. (1 '9 kg .... ).

17 lb. n. (2') kg. m.).

8 lb. n. (1-1 kg .... ).

10 to 15 lb. n. (1 '38 to 207 kg. m.).

.. 91b. n. (1'2 lea. m.).

15 lb. O. (21 kg. m.).

4 lb. ft . (,56 kg. m.).

.. 10 lb. ft. (96 kg. m.).

8 lb. n. (1-1 kg. m.).

6 lb. ft. ('8 kg. m.).

25 lb. fl. (J'46 kg. m.).

Bonom GOver set screws---J io. dia. UNe. (change speed IOwu)

Firsl motion sball. Dut

Ig lb. fl. (2'5 kg. ro.).

6 lb. n. (.g kg .... ).

IS lb. n. (20'74 k .. m.).

150 lb. ft. (20'74 kg . ... ). Third molioo .baft nut

Ocacrnl Dala 6 1100. Issue 10. 10288

GENERAL DATA-continued

Flywhul housing bolls and stud nuts ..

Distributor clamp boll: Fixed nut type

Fixed bolt type

Final dri,e

Driven gear 10 differential cage

sb".rt 6ange outs

End cover boils (differential bousing)

Drive shaft 'U' boll mllj

Drain plug

SII5pCDIIOD and liteerlag

Steeriog lever to hub bolts

Steeriog lever ball joint out

Sturin, knuckle ball pin bottolIl out

Steering knuckle ball pin lOr nut

Steering knuckle ball pin retainer

Prool bub nut (drive shaft)

Rear suspension antiroll bar fL'(ing bolts

Rear suspension stub axle out

Front suspension upper arm pivot pia aut ..

Front suspension lower arm pivot pin nut

Steering-wheel Qut

Road wheel outs

Disc to bub

Frant swivel bub to calliper

Sleering-colullln clllmp bolE

((00. bsuc:l. 10288

18 lb. ft. (2'5 kg. m.).

SO lb. in. (-576 kg. m.).

30 lb. io. (-]45 kg. mol

55 to 60 lb. fl. (7-6 to 8] kg. m.).

70 lb. ft. (9-6 kg. m.) (and align to next split pin hole).

18 lb. flo (2-5 kg. m.).

10 to 1251b, n. ( 13810 ,73 kg. m.).

40 to 50 lb. ft (5-51 (0 69 kg. m.).

30 to 35 lb. fl (4'15 10 48 "g. m.).

25 lb. ft. (N6 kg. m.).

. . 35 to 40 lb. fl:. (48 to 55 kg. m.).

35 to 40 lb. flo (48 to 5'5 kg. m.).

70 lb. ft. (96 kg. m.).

!5O lb. ft. (W'74 kg. m.) min. (align (0 next split pin

bole).

70 lb. ft. (96 kg. m.).

60 lb. ft. (S'3 kg. m.) (aligo to Rex! split pin bole).

J5 to 40 lb. ft. {4'S to 55 kg. ro.}.

]5 to 40 lb. R. {4g to 55 kg.

50 lb. ft. (6'9 kg. m.).

42 lb. ft. (58 kg. m.).

40 to 45 lb. flo (5'5 to 62 kg. m.l.

45 to 50 lb. ft. (6'2 to 7 kg. m.).

3 to 9 lb. ft. (H to ] ,25 kg. m.).

Oencttl Data ,

GENERAL DATA

1100 AUTOMATIC

The following infonuatioa is appUe.ble to the J 100 Aa!olDlotic and should be used io coQjUJIction with tbe preoediD.

'Pecwcatioa (or .he 1100 SalOaD.

ENGINE

Type

Comprt.$sioD ralio

Eogioe idle speed (approx.)

D.H.P.

Torque

LUBRICATION SYSTEM

011 pamp

Type

Oll Wltr

Type

Capacity

Oil pressllft.

Normal running speed and temperature

Idliog (mioi.mum) at normal running tempenlturc

FUEL SYSTEM

Carbarellu

Malee and type

DialDeter

Needle ..

IGNITION SYSTEM

Distributor

Timiog marks

Timing: Distributor No. 41134A: Static

Siroboscopic

Distributor No. 41181A: Sialic

Siroboscopic

DIFFERENTIAL

Ralio: Early models

Later models

AUTOMATIC TRA,"SMISSION

Ralios: Top

Tbitd

Secoud

rirst

Reverse

QveraU (alios: Top

Third

Sccood

FirsE

Reverse

SlXedomelcr

1100. Issue I. S610

IOAG.

89 : l.

650 r.p.m.

S6 at 5,500 r.p.m.

61 lb. n. (8-44 kg. m.) at 2,000 f.p,m.

Hobourn Eaton.

FuU-6ow.

I pial (1-2 U.S. piols, 57 lim:).

60 Ib./sq. io. (4-22 kg.{cm.').

15Ib./sq. io. ( I -OS k g / c m ~

S. U. Type HS4.

11 ill . (38' 1 0001.) .

DL (Staodard), ED (Weak), DQ (rucb).

Lucas 2504.

Dimples 00 liming whct:ls, nlarks on COllverler.

.. 7 B.T.D.C.

10 B.T.D.C. al 600 r.p.rn.

.. 50) B.T. D.C.

80) B.T.D.C. 31600 r.p.ro.

3048, I.

3'21 : 1.

10 , I.

146 , I.

1845 : I.

269 , I.

269 , I.

Early models

. . 4; I.

584 : I.

738 : J.

1016 : I.

1076 ; I.

7/17.

liJler model

376 : I.

549 : 1.

6'94 : I.

10-11 : t.

10' 11 : 1.

GENERAL DATA-conlinued

1100

TORQUE CONVERTI:R

Type

IUtio

Convener output gear ratio

Eod-float

DRIVE SHAFTS

Make aDd type of jOiDl

TORQUE WRENCH_ SETI1NGS

CODverter centre bolt

Converter (six central bolts)

CODverter drai!} plugs

Converter housing bolts .

..

Differcoliol driving finDgt securing boUs

Gear u.in bearing caps ..

Gear tra in carrier slIap ..

Input ,baft oul

Servo unit securing bolls

Top aDd reverse clufch hub out. .

to cogine securing oul

Valve block securing bolts

Valve block: bolts (securing three sections)

g-in. U NF. bolts

j-in. UNF. bolts ..

CAPACITIES

Traosmiuioo ClUing (iocludiog filter)

capacity (approx.) ..

GENERAL DIMENSIONS

Kubside wcighl : Salooo (Automatic) ..

WEIGHT OF COMPONENTS

Eogi.oe IIDd traosmission assembly

Aulomatic lrltosmissiOD ,.

Gtnernl [')lIa 10

..

3-elcrocllt.

2 : 1 maximum.

H5 : 1.

,0035 10 0065 in. (-089 to 164 ffiO'l .).

. . Hardy Spicer, Hange joint.

110 to 115 lb. ft. (15-2 to 15' 9 kg. m.).

2210 24 lb. ft . (H)4 to 332 kg. m.).

.' 22 to 24 lb. n. (3' 04 to 332 kS- m,).

IS lb. ft . (25 k8. m.).

40 to 45 lb. ft. (5-53 to 6622 kg. m.).

12 lb. fl (166 kg. m.) .

12 lb. ft . (1 66 kg. m.l.

. . 70 lb. ft . (96 k8. m.).

17 lb. ft . (235 kg. m.).

ISO lb. ft. (207 k8. m.).

12 lb. ft . (1 ' 66 kg. 00.).

17 lb. fr. (235 kg. m.).

7 lb. ft. (97 kg. m.).

18 to 20 lb. fe, (2' 5 to 277 kg. ro.).

30 lb. ft . (4 15 kg. m.).

I) pinlS (738 litrc.s. 16 U.S. pj,nts) .

9 piots (5 litres, II U.S. piOlS).

1,848 lb. (8388 kg.).

357 lb. (162 k8.) .

112 lb. (508 kg.).

1100. lssut I. S61G

GENERAL DATA

1275 cc. POWER UNITS

The fuUowlng informatioa is .pJlliuble to models OHced with tbe 1275 (.c. pOlYtr nnil and sbould be used 10 CODJUilCtiOO

trilh tbe preceding sper;Wcatioo rOt tbe 1100 Salooo.

ENGINE

Type

Number of cylinders

Bore

Stroke

Capacity

Firing ordu

Valve operAtion ..

Compression racio: H.C.

L.c.

B.M.E.P.: H.C. ..

Torque: H.C.

Oversize bore: 1st

Max.

Cral1ll.sbafl

Majo jouroal diameter

Craokpin journal diameter

Crnoksl't .. f( end thrust

Cranksbaft end float . .

MaJD bearings

Number aDd Iypt:

Material

LenSlh ..

Di;lmetrica) clearance ..

UndersiZe$:

COnDecting rods

Type

Lenglh between centres

Blg....end beariDgs

Type and material

Length . .

DiatnelricaJ clUJ.nc.c ...

EndHoat of crankpin _.

Pislon!

Type

. .

Cleamnct in cylinder: Top of skirt

Bottom of sk.irt

Number of rings

..

Width of ring Grooves: Top, second. third ..

1100. I. 10288

Oil cootrol ..

Gudgeon pia base ..

12G find 12H.

4.

278 in. (70'61 mm.).

32 in. (81-28 rom.).

778 eu. in. (1274-86 c.c.).

1.3,4,2.

Overhead by pusb-rod.

88 : I.

8 : I.

134Ib.fsq. io. (9' 4 kg.fcm,t) al 3,500 T.p.m.

69 lb. fl. at ),500 T.p.m.

-010 io. (25 mm.),

-020 in. (-51 mm.).

.. 2'0005102-0010 in. (50'81 to S(}82 mm.).

'750410, 7509 iI), (444510 4447 mm.).

T"kcn in tbrust \wlshers at cealre main bearin,.

00210 003 in. (,05 10 07 moo.) .

Three trun-wall; split sbells copper-lead-indium.

VP3. lead-indium at NFM/3B.

975 to 985 in. (2476 to 2502 mm.).

001 10 0027 in. ('025 10 -07 mm.).

020 ill . (,51 mm.) and 040 in. (1 ,02 mm.).

H'Orizolltaliy splil lug ead, plilin small end.

5748 to 5792 in. (21'36 t'O 2J 59 mm.).

ThiQ-waU; Sled-backed, copperlendindiu." plated.

840 10 850 io. (21'33 to 2959 rom.).

001 to 0025 In. (,02 to 06 rom.).

006 to 010 in. (-15 to 25 mID.).

Alumioium, solid skirt, dished crown.

0029 to 0037 in. (,07 to 09 mm.).

0015 to 0021 in. ('04 to 05 mm.).

4 (3 I oil cootrol).

048410 0494 in. (1 23 (0 122 rom.).

157810 '1588 in. (4'01 to 40] mm.).

8125 to 8129 in. (20' 64 to 2965 mm.).

Cieaer&J Data 11

GENERAL DATA-contill/led

1275 cc. POWER UNITS-continued

Puton rio"

Compression: Type: Top .. Internally cbamferet1 chrome.

Second and third .. Tapered cast iron.

Width Top }

Secood 81ld Third :: 0615 [0 0625 in. (1'51 to 160 mm.).

fitted gap: Top .. 011 to 016 io. (-28 to ,05 DlIIl.).

Second and (tUrd 008 to 013 in. ('20 to 33 mm.).

Rin::; to groove clearance: Top ,. .. } .OOI5 I .0035 ' ('04 . N>. )

Second Aod ,bird 0 In. 10 u:>' IDID ..

Oil control;

Type ..

Fitted gnp: Rails

Side spring

Gudgeon Ill!

Type

Fit in piston

Diameter (outer)

Fit to cOlloecling rod

Cam.,h.rt

Jourulll diameters: Front

Centre

Rc,u

Bearing liuer inside diameter:

UD-reamed lifter fitting: Front

Centre

Rear

Reamed after fitting : Front

Centre

RCilr

Beariogs: Type

Diametrical clcilrllncc . .

End-thrust

Endfl oat

Cam lin

Drive

Timing eh;'lia

T.ppets

Type

Outside diameter

Length .

Rocker gear

Rocker short : Diameter

Rocker IIrm: Bore

..

Bush inside diameter

General Dat a ! 2

. .

..

.. . .

.. Duanclt 61.

:: }.OI2 to ,028 in. (30 to 70 mOJ.).

in conoecting rod.

Hnud push 61.

'8123 to 8125 in. (20'6) 10 2064 mm.) .

0008 to 0015 in. (-02 to 04 mm.) interference.

16655 It') 1-6660 ill . (42' 304 10 42' 316 mm.).

162275 10 162325 in. (41'218 1041231 mill.).

1' 3727510 J.J7350 in. (34' 86610 34889 rom.).

1652 in. (41'98 rum.).

161 in. (40'89 mm.).

136 in. ()4'52 mill.).

1-6670 to ',6675 ill. (42'34 to 42)5 mm.).

162425 to 162475 ill. (41 ' 25 to 41,)7 mm.).

13745 to ) ,3750 in. (3491103492 mm.).

While metal-lined,

001 to 002 in. (,02 10 05 tnm.).

Taken on lc1t:<1ling plate.

003 to 007 ia. ('07 to 18 0111;'1.).

' 318 in. (8'07 mm.).

Duplex chilin and gear from cr:4nkshafl.

j in. H"52 mm.) piteb X 52 pitches.

Bucket.

81125 to 81175 in. (20'60 to 2062 mm.).

\495 to 1505 io. (3797 to 38,2.] mm.).

5615 to 5625 in. (14'26 to 1429 mm.).

686 to 687 in. (17' 45 mm.).

5630 to 5635 in. (14') to 1431 mm.) .

1100. Issue I. 10288

GENERAL DATA-continued

1275 ce. POWER UNITS---t:-onJiJllltn

Valves

Seat angle: Inlet and exhaust

Head diameter: Inlet ..

Exhaust

Stem t.liRmeter: Inlet ,.

Exhaust

"

Stem to guide clearance: Inlet <'Ind exhaust

Vfllve Urt: Inlet and exhaust .,

Valve guides

Leogl.b: Inlet

Exhaust

Fitted height above ,eac Exhaust

Inlet

Valn springs

12H Engint's

Free length

Fitted length

Load .!It fitted lengtb ..

Load at top of lift

No. or working coils ..

120 engines

Fret: Ic:ngth

Fitted length

Load at fitted length

Load at top of lift

Valve crash

Valn. tinllng

Ti11lir.1g marks

Rocker c1c...,runce: Running

Timio:;

Ir:llet valve: Opens

Clost.3

v"lve: Opens.

Closes.

"

ENGlNE LUBRICA TlON SYSTEM

Oil pnmp

Type

Oil pressure relief volve

..

Relief valve spring: Free lcngth

Fitted length . .

"

"

..

Load fI t fittetl length.

OU filler

Type

Capacity

1100. I$&UC I. 10298.

"

"

"

"

, .

45,

[)07 to 1312 in. (33':2lo )),21 mm.),

to 1'1565 in. (29'24 to 2937 Dlm.).

'2793 to -2798 in. (7'09 to 7' 1 J DlIn.).

-2788 to 2793 in. (7'08 to 7-09 rom.).

0015 to 0025 in. (04 to -08 mm.).

'318 in. (8'07 mm.).

HiS75 io. (42-87 mm.),

\8437 io. (46'83 mm.).

}'540 io. (13-72 mm.,.

I '95 in. (49'13 mm.).

1'3!!3 in. (34'715 mm.).

.. 795 lb. (36'03 kg.).

124 lb. (563 kg.).

.. 4, .

OYler

182R in. (46474 mm.).

1383 in. (35128 mm.).

51 lb. (23'1 kg.).

87 lb. (39'5 kg.).

6.750 r.p.lll.

Dimples (111 timing gears.

0 12 in. ('30S moo.) cold.

021 in. ('S33 rom.).

B.T.D.C.

45" B.n.D.c.

51" B.B.D.C.

21

0

A.T.D.C.

Inlier

1703 in. (43'259 mm.).

1210 ill. (32'258 rom.).

251b. (11'3 kg.).

44 lb. (20 kg.).

Internal gear, splined drj\lt: from c<1IDshafl.

SO Ib.Jsq. ill. (5'3 kg.

286 in. (72'64 nun.).

.. 2'156 in. (5477 mm.).

13 to 14 lb. (590 to 635 kg.).

Fullflow type; renewable element; pressure: differen-

tialswilcb.

I pint (1'2 U.S. pints, S7lilre).

GenerAl D.1lA 13

GENERAL DATA-continued

1275 ce. POWER UNITS-continlled

System pressure:

Ruoruog

Idling

IGNITION SYSTEM

COO

Resislaoa: III 2 ~ C. (68

0

F.) primary winding

CoCl5umpLioo : (goitioo switched on ..

At 2,000 r.p.m.

DIstribD10r

Rotatioo of rolor arm

Cam closed period

Cam open period

Automalie advance

SeriAl number ..

Automatic ndV3na: eomlDcncts

Maximum advaoce

Deceleration check (vacuum pipe discooneclcd)

Cootaet point gap selling

Breaker spring tension

Coodenser C-;Ipacity

Timing marks ..

Static timi ng

Stroboscopic timing

Sparking pIngs

Sa.

Gap

COOUNG SYSTEM

Thermosta! selfillgs

Standard

Hot countries ..

Cold c:ounlries ..

FUEL SYSTEM

CarbureUer

Choke diameter

Jet size ..

Na:dles ..

Pislon spring

Gontrai 0-.113 !4

70 Ib./sq. in. (4-92 kg. cm.t).

IS Ib./sq. in. (I OS kg, em").

Lucas LA 12.

32 to 3' 4 ohms.

36 amps.

125 amps,

Lucas 2S D4.

Anti..elockwise.

6Q"3",

30"3".

Centrifugal.

41214A.

300 r.p.lIl.

18-22",

11 10 IS" al 2,800 r.p.m.

6 to 10" al 2,000 (.p.rn.

4 to 8 at 1,600 f.p.m.

014 ( 0 -016 in. (-35 to'4O nun.).

18 to 24 07 . (510 to 6S05 gm.).

1 8 to 24 mE

Flywheel and poinler on clutch cover.

S" aT.D.c.

10" ll.T.O.C. a! 600 r.p.m.

Champion N9Y.

14mm.

024 to 026 in. (' 62 (0 66 mm.).

&2 c. (1&0 F.).

74" C. (165" P.).

8' C. (190 F.).

Single s.u. type HS4.

Ii in. (38" mm.).

090 in. (2'29 mm.).

SWnfl:ird OZ, Weal.: CF, Rich BQ.

Red.

HOG. Issull I. 10288

GENERAL DATA-continued

1275 ce. POWER UNITS-contil/ued

GEARBOX

Number of forward speeds

SyncbrofDesb ; 1300 Moods

1275 c.c. engines

Ratios:

Top

Third

Second

First

Reverse

Overall ,alios:

Top

Third

Secoud

Reverse

Speedometer gear ralio .'

. .

Early 1275 c.c. engines

)-0: I

],426: I

2420: I

3829 : I

3829 : I

)-44 : 1

491 : I

83 , I

13 16 : 1

1) 16: I

Road speed i.n lop gear at 1,000 r.p,m.: )-65 : I ratio

),44 : I ratio

WEIGHTS OF COMPONEI"liTS

Engine

. .

Engine and Iransmission assembly

TORQUE WRENCH SETTINGS

Cylindu head sl ud nuts ..

1100. Tuue 1. IOlSS

..

4.

All (our forward speeds .

Second, third and fourth gears .

lAfer 1275 c.c. ellgines

)-0 : 1

17/6.

1 412 : 1

2' 112: 1

3627: I

J-627: I

365: J

516 : L

i 92 : L

1)21 : )

1321 : I

17 m.p.h. (275 km.p.b.).

18 m.p.b. (29 km.p.h.),

254 lb. ( 115 kg.).

69 lb. (31 kg.).

339 lb. (lS4 kg.).

.. 50 Ih. ft . (6-91 kg. 00 .).

1300 monels

1-0: I

143 : I

2'22 : I

352: I

) -54 : I

3-65 , 1

522 : I

8,08,1

12-85 : I

1292: I

Genual Oala U

GENERAL DATA

1300 AND 1100 MK. II MODELS

Tbe foUowing ioformatiOf\ is opplk"blc to the IJOU. 1100 Mk. II aufGaIRlic transmission, laler 1100 Mk. II slDthro-

mesh !.Iud Austio America mndels, and should be UStd in conjUlltDon wilh Ihe preceding specifications.

BRAKES

Type

Fluid

Fluid (American Markel)

Fro.,

Disc diameter

Pad area (lolal)

Swept area (total)

lining material

Minimum pad thickness

Cylinder diameter

Rear

Cylinder diameter

WRENCH STTL'1GS

Brake calliper pivot pin screws ..

Joertia valve end plug

Pressure failure switch

Pressure failule switch as!.embly end plug

Lockhecu hydraulic; frolll, single swinging

disc; rear, drum, leading ;lOd Irailing shoes.

L(lcklll"cd Disc Brake Fluid Series If or 329.

Lockht"cd Disc Droke Fluid 329 onl)'.

84 in. (21336 111111.),

nS6 sq. in. (l2U

148 sq. in. (955 em.').

Minltx M 7It FG.

nil!. (1 59 1Il1ll. ).

:! in. (50-8 mm. ).

80 ill. (20<32 mm.).

M 10 80 lb. in. (,75 10 92 kg. m.).

50 lb. ft. (6'91 kg. m.).

15 1h. in. (,17 kg. m.).

200 lb. in. (23 kg. m.).

StC Workshop MaDual AKO 4957 fot Aastiu Arne.rica engine toniog data.

1100. T&.Suc 2. 12872 Gcncr.\l 0;,\\, 11

SECTION A

General description

Camsbaft

Crankcase dosed-circuit breathing

CraoJcshart sod main be'lrings

Cranksbart primary gear

Lubriellted boshes

Noo-Iubricated bushes

tCylinder head

, .

Cylioder liners

tDocarboniuag

Distributor driviog spindle

Enginc aod traosmissioo

Eogine mountings . .

E){baust syslem

Fi rst ruotion sbaft outer race

Fly'wheel and c1utcb

Coil spring type

Diaphtagru sprios type

Flywbeel bousing

Flywbeel relaining ,crew Imud

FlywbuJ slartcr ring

Front sub-rrame and eogiae aS$ctnbly

Iolet and exbaust maoifold(s)

LubricatioD ..

Oil control pistoo rio8s- Duaficx 61

Oil pressure ,.

Relief valve

Oil pump

riston riogs . .

Pistotli aDd connect ina rods

Piston sizes and cyliDder bores

Priolary gear oil seal

TappeLS

TimiDg cover . .

TimiDI gears

Tools ..

TnlQSl'I)issioo . .

Valves

Grinding

Guides ..

tRoeker .adjustment

Rocker busbes ..

Rockers ..

Seat inserts

tTiming ..

THE ENGINE

..

. ,

, .

. ,

, .

, .

, .

tThtloe must be rollowed by au exlaaust emissioD check

1100. luue 1. S610

, .

, .

A.2S

A.4

A.29

A.30

A.37

A.9

A.36

A.IO

A.16

A.33

A.34

A.40

A.3oS

A. 11

A.38

A.22

A.S

A.32

A, IS

A.6

A.I

AAI

A.2

A.l

A.24

A.21

A.26

A.28

A.39

A.14

A.l9

A.20

end of Section

A.21

A.II

A.12

A.1l

A.IS

A.8

A.7

A.31

A.21

' . . -

A

A.I

A

--------_ .. _ ... _---_ .. __ . __ .. _-_._-.

TIlE POWER UNIT AND TRANSMISSION

(fwin-carbnretter Version)

i

!

AlI'llHIW I

I

I

_____ ... __ .. ___ ._ ... _ ._ . __ ..... __ . __ .. _ ...... __ . ___ ..... _ .................... _ .... __ .. .J

A.2 1100. l ~ t c 1. 5610

TIlE ENGINE

A

GENERAL DESCRIPTION

The overhead-valve engine is of unit construction wilh

one reverse and four forward gears assembl.:d inl O a

combined transmission casing and oil sump below the

engine crankcase. The unit is transversely mounted on

OeMble r ubber mountings. Drive is transmiued from the

ditrcrcotial by sbort driving ShOlfts to c:lch of the front

wheel hubs.

Engine arc in line in lhe left-hand side of

Ihc cylinder head. Oil senls arc titled to the v81ve stems

and there is normal pro,,'isioD on the valve rockers for

clearance

The camshaft, running in three whitc-mclal

is roller-chain-driven frum the cranksh"n. wilb synthetic

rubber chain Icnsioncrs. Both the oil pump and the

distributor are driven from Ihe camshaft., the dislributor

by a lronsvu$C shan with helical gear dri .. e.

Pistons carry Ihrec (;ompression rings and one sloned

oil control ring. The gudgeon pins are fully Ooaling and

the connect ing rods have renewable sleel-backed big-end

bearings ..... ith karl-indium- or Icad-tin-plalcd

The oil supply for fhe engine, gears. and differential is

carried in the transmi ssion else below (he crankcase, find

is tt:plcnidled through a filler aperture in Ihe valve

rocker cover.

Oil is dmwn fronl the base of Ihe Iransmission casina

by a rot ary pump mounted on Ihe rtar end of th.,; crank-

case and delivered to a full-flow eX(CJoal oil filter. passil"lg

on Ihrough drilled passages to the main, big.-end, and

c.amshafi bearings. Jet boles in tbe connttling rods

deliv!:C oil quickly to the cylinder walls, and the overhcad

rocker gear is provided with oil at reduced pressure via

the t:amshaft front bearing.

The tappets are lubricaled by oil returning from the

rocker gear by way of the pusb-rod apertures and by

The eX[emal oil filler carried 00 tbe right-hand siue of

the engine crankclsc is of (be ruu-oo","', n:ncwab)e-e)ement

type. It is conncctad to (he main oil gallery by a drilled

passage.

SecliOD A.I

LUBRICAnON

Checking the engine oil level

[nspect the oil level in the ensine and .transmission,

aed lOp up if necessary to tbe 'MAX.' or 'FULL' roark on

the dipstit:k. The oi l filler cap is on the top of Ibe engioe

valve cover and is released by turning it anti-cloekwise.

Clunging the cDgioe oil

Drain the oil from the engine and trdnsmi ssion by re--

mo ..... ing the magnetic drain plug on the rear right-hand

side of the transmission casing. Draining is preferable

when the engine is hot as the oil will flow more readilyhl

Ihis COouilion; allow at least 10 minutes for draining

before replacing tbe plug. The drain plug washer should

be renewed on alternate oil changes.

1100. 1. 51'\)0

Changing lIIe epgine nil filter

The oi l filter is of the rutt-fiow typt and tile bo .... 1

should be washed in fuel. The filler is rele4lsed by Uf)-

screwing the central bolt securing tbe filter to Ibe filter

head. When refitting ensure that the seating washer (or

the filter bod)' is eorr..:elly posit ioned, dcaD, and service-

able_ Ensure that Ihe wasbers below Ibe clemen! iruide

the bowl are fitted correcLly. The sma]) fdL or rubber

w<lsher must be positioned betweeCl tlle clement pressurc

plate and the washer a.bove the pressure spring.

It is essential (or correct oil fillration tbat the sca.ling

(feU or rubber) washer should be in good condition and

11 suug fil 00 tile c.eulre-seetlrilJg bolt.

NOT E.-Disconnect the battery before eommeoei.ng

work on fhe. filler.

Section A.2

OIL PRESSURE

Mo..-rU aDd M.G. carly models

When the isnit.ion is switched on a wami!!!", light io

tht instrument panel will glow, llnd if Ihe system IS

working corrl!Ctly it wil: 30 out when the engine IS

runni..cg.

Should Lhe oil pressure warning light contioue to glow

when the ensine is running at or abc"I\'c a fast idJiog

spccu, rhe cause tUay be lack of oil. low oil pressure, or

the need of a new oil filter element aDd engiac/t{"3os-

missioa {'IiI change. To locate the cause of the trouble

proceed as follows:

(I) Check the Icvel of the oil in the cogine and traus-

mission, and top up if necessary.

(2) If the light contilluC5 to &low when the engine is

running diseonneel th.e lead from lht oil

head. If the light IheLl goes oul fit a DCW oi l filter

clement and change the engine/transmission oil;

this should be done as soon possible: within a

maximum of a further 300 miles (500 km.).

[f the light still glows \\ilh the rulcr lead dis-

coonected aDd the c.ogine running, Slop the engine

immediately _nd t.arry out the follnwing.

(3) Check [hat there is no air leak. at the pump pick-up

union on the suction side of the pump and tbat

the oil pump is Ilot worn a.nd is (or.ctioo.illg

correetly_ See Section A.1A for oil pump removal

and dismantling.

(4) Cheek: that the straioer in the transmission casing

is clean and 110t choked with sludge.

(5) Check tbat the bearings to which the oil is fed

under pressure ha.ve the correct workillS clear

anccs. Should the bearings be worn and the clear-

ances excessive, the oil will escape more readily

from the sides of [he be.-U"ings, particularly wben

the oil is warm and becomes more fluid.

AU models exct'pl Morn.. aDd M.G. early mode.IJ

The information and instructions gi\'en apply to

above owdc1s "eXCCP! that !w() warning ligbts arcfitted,

one for oil pressure and one fcor the pil filter. If the oil

-' .J

A

THE ENGINE

I. Spring clip_

2. Cover.

J. DiaphngrrL

Fig. A.I

4. Meluinl: needle.

S. Spring.

6. Crucifonn l\IidC$.

filter warning light continues to glow when tbe engine is

running at or above a fast idling speed 8. new oil filter

element must be fined and the engine/transmission oil

cbanged within a maximum of a further 300 miles (500

kOI.).

fr Ibe oil pressure warning light glows when the

engine is ronniDg carry out tbe instructions aumbered

(I). (l). (4). nnd (5).

AU models

TIlt poilils menlinned can all cause a drop in

COll,tinuous cold runniog aDd the unnecessary use or

the mixture control are oOeo the C.1USCS .,( oil dilution by

petrol (fuc;) and a consequent faU off in pfCliSllre.

l'\OT'-The lutomatic: relief \'21'c in tbe lubriClitioD

system deals wilh DOY uces.'iivc oil pressure wbee starting

from cold. Wbea bot, the pr<!SSure drops Il! the oil bl-comcs

'more. fluid. Dcbih of the relief nlve are given in Section

A.J.

Section A.3

OIL PRFSSURE RELIEF VALVE

The Don-adjustable oil pressure relief valve is situated

.t the rear right-band side of the cylinder block and is

held in positioo by a domed hexagon nllt aDd sealed by

two fibre or one copp:: r washer. The relief valve spring

mainta ios a valve cup Clgains! a sealing machined in the

cylinder block to provide a!.l extra return passage ror the

oil should I:'e pressure be..cOOlc excessive.

The vnJve cup sbould examined to ensure that it is

scating corr<!ctly aDc tbat tbe spring has not 10sl its

tension. The cup caD be r emoved and ground into its

seating wiln Service tool 18G 69 a.nd the spring checked

by measuring its length to give the required relief

pressure (see 'GENERAL DATA'). Fit a new eup and

spriog ir neces.u.ry.

A.4

SectioD A.4

CLOSED-ClRCUlT BREATHING

(When 6Hcd)

Fresb air enters the eng.ine Illtougb two boles and a

ruter in the filler cap on the rocker eavcr. The air theo

passes to tbe crankCASe down the push-rod driUings. The

crankcase fumes leave the engine througb a breather out-

Itt pipe on the froDt engine side cover. Oil droplets aDd

mist are Irnpped in an oil separator btfore the fumes pISS

through a breather control VAlve and 10 the iotake mani

fold. Ibus providing closed-circuil crnnkcase brealb.iog.

OilftUer C3p

Detach the filler c"'p from the engine rocker cover and

fit a new filler eap/6lter assembly.

Breather control "alye

Remove the spring clip and dismantle the valve. Clean

all metal paris with solvent (uichlorelbylene, fuel, dC.).

If deposits arc difficult to remove immerse ill boiling

water before tile solvent. Do oot use an abrasive.

Clean UlC diapbragm with detergeot or mdhytated

spirils.

Replace componena showiog signs of wear or damage.

Reassemble the valve, milking sure the metering needle

is in the cruciform guides and the diaphragm is scated

correctly.

NOTE..-The tim-type "Ive assembly (witbollt the

cruciform guides) is suric:e.d as an assembly.

SectioD A.S

FLYWHEEL RETAL'/ING SCREW THREAD

The flywheel reuining screw thread in the end of tbe

eraokshaft is not Standard Whit ..... orth but is Whitworlh

forOl :

Diameter i in, 16 T.P.'. In- in. fulllbread.

If it is fouod necessary 10 clean up the tbread, the

operntioo must be confined to dellling up. This-thread is

highJy stressed aDd must always bt: up to full size,

Section A.6

INLET AND EXHAUST MANlFOLD(S)

Removing

Remove tbe carburetter(s) and air cleaner as detailed

in Section D. Slacken 01T and release the ex.baust pipe

clamp. When fitted, remove the c1osed<ircuit breather

coateol valve, by slackening tbe adaptor hose clip, aDd

removing (be suppOrt brAcket. Remove the DUts nod

washert securing lbe malli(old(s) to tbe cylinder bead;

withdraw tbe maoifold(s).

Refitting

Reverse tbe above order, but thoroughly clean the

joint faces aod 51 a oew gasket, placing tbe perforated

metal face of tbe gasket lowards the manifold(s}.

1100. 1. 56tO

TIlE ENGINE

A

S.<lion A.7

VALVE ROCKERS

Rtmovi.og

Drain che cooling system u;o Stion C2; usc a dean

container (or Ibe (Oni Ol0! if il conlains auli-fru:zc

intended (or further Uk.

Remove Ihe air de"oer as in Section D.

Unscrew Ihe securing screws aod lift oft' fach:,

00\'(" Ia.kiog care nOI 10 damage the cork gasket

Sll'ckcn Ihe rocker shaft bracket tilting nuts aoo 1M:

uterlll\\ cylinder head siud outs gradually. a tUfO at a

time, ill che order sbown in Fig. A.4, until all the load

is rc:lca5cd.

NOTE.-The u.:ttm.t cyliollu hud liDog IIUt!; ruust

be sb.ckeaed at the SlIme time as tbe rocker sb&ft securing

DUb. and ic fhe orderginD ill Fig. A.4, otherwise distortion

may like place Gluf f("Swt ill warer fitwiUie its way into the

(yliader beres and the n.n.<nniss.iOD CasiDi.

Completely unscrew the: rod:cr shaft bracku nuts and

remove the rocku )ssembly. together with the br2d:ets.

Withdraw the push-rods, at the same time m.:uL:inl

Ihem (or replacemenf in their posilions.

DijCltaDlWlg

Kemo ... e Ihe grub screw locating 'he mcker sban in tbe

frool rocker mounting bra.cht . Wirhdraw the splil pios,

Rat washer, and washer (rom the end of the shaCt

nnd slidelhc rockers, brackds,lUld spri,,!;!;: frOIl) tb.e sbafl.

the screwed plug fiUed to one end of the ,b2f\

and clean nUl t,he oihv.1)'.

When reassembtipgcoO'lmcnce with .be from mauoling

brackel, it wilh the grub screw. Follow up with

Ihe (clnlil1illg brackets ilnd spriogs, replAciog 'hero in

their origin,,1 position on the sban. The screwed plug end

of the: 'hafl should be positioned to tbe froDt oflhe engine.

Re6ttiA&

lte6t1inl! is A reversal of the u:mo\'al procedure, wilh

special emphrnis on Ole tightcning of the rocker brackel

and cylinder b::;ul !\ IOO OUIS; thcse must be lightened in

Ihe order ShOWI1 in Fig. A.4 and 10 the torque wrench

lilure giveo under 'GENERAL DATA',

Refer to Secljon A.15 roc details of valve rnckt:r

adjuslment.

....

Fig. A.2

Tile o/Yol,e Tocku, l'illiclt mlLfl IIDI

bl!

I U)(). lssue 4. 72130

Fit. A.3

III/Ieff ubuslting lite. jorced.,ype vn/pe rocker make

rtr",;" '"ot ,h, joint in fhe bush is il' (h, positioll

;l1dicot,d

Section A.S

VALVE ROCKER BUSHES

Rcbushing or the preSSt:d'feci valve rocker tilted at

3n to the rotSed is Dol practical aDd must

not be undecl:lkell. When bushes become \Yora oew

r()(;ker assembHe$ must be fitted. The fOrged type of

rocker can, ho",,-cver, be rebusbcd, aDd tbe: foUowing

procedure is given fOT this Iype: of Tockcr only.

H,emove aud dismaoUe tht: TOekeT shaft assembly as

detai led in Seclion A.1.

To remove and replace worn bushes the use of spcc;illl

Service tools ISG 226 and 18G 226 A, .c.o;mprising ..

drm 3(1d 3nvil, is recommended. Busbe'1 and rockeB

are very easily damaged by the use of improvi7.ui drifts:.

The anvil is recessed to bold tbe rod:C'T in positioo

while Ihe worn bush is driven or pressed out.

Press the. new bush inlo Ibe rocker bore with the butt

joint of the bush positioned OIl Ihe top of lht: boJ'C'. as in

Fig. A.3. The drift is rccessed 10 prevt:n! rhe budJ Operunl

wben being driven illio pOlli tion.

It ...... m be necessary to drill (he oil boles in tbe bUlb

10 coincide with the oilways in the roclcer. Shoukl the

oil hole tn the adjllster end be drilled before lbe busb is

fitted, extra care must be talcen to keep the holes to the

bush and rocker in line during Ib.e opetation.

If Ibe holes arc drilled after tJl(: following pro-

cedure must be adopted. Remove tbe adjuster screw a.od

use fl No. 4) drill ('089 in. [2'26 mm.)) 10 drill out tbe

end pillS and 10 eontinuc tbe oil\Y3}' through tJle bush.

Replug the eod after the opention with a rivet (pa.rt No.

se 2436) and weld it in position .

Tbe bole in tbe top of tJle rocker barrd must be

continlled Ibrougb the bush wilh a No. 47 ('0785 in.

11 '98 mm.D diameter driU. Finally. buroish-rc.a.m the

bush to {he dimensioru; given under "GENERAL DATA '.

A.S

A

THE ENGINE

SectioD A.9

RcmoYln&

CYLINDER IIEAD

r- Jl

I

Drain cooling system (sec Section C2). If anti

frene mixture is in usc it should bedrained illlo l\ suitable

dean conlmer.

Oisconnut (he negative cable rrom the bauery.

Slack,en the retaining clip on the hose connecting the

radiator to the lhermt'Slal housing and pull the hllse

clear nf Ibe bous..ing.

Rcmo'''c the radiator til>plate.

Remove the cnrbureuer(s) antl ai r ckallers as descrihed

in Section D. Take out the two rocker cover relilining

screws and rubber cups aod Ihe cover.

o\'er the studs. lower Ihe cylinder head into posiliol1 and

fit the cyl..inder head securing nuts finger tight.

InseT' the push-rods, replacing them in the positions

from which they wcre taken. Replace the rocker assembly

and scc urill1;!. !HIlS and lit the fill,!;cr tight. Tighten all

Ihe nuts gradually, a turn 011 a lime, in tbe order gi\'en in

Fig. A.4.

Whenever the head has been disturbed or thc valves

have been ground in or otherwise it is ncce!;$ary

to cbeek the valve dCOIrances as in Section A.IS. These,

nf course, will be finally adjusted after the engine has

Ixcn completely reassembled and WI) for a shon period.

Repllu;e the inlet :md exhaust manifold(s).

If a he<l.lcr is filt<!d attach the Itcater hose 10 the hc.1ter

control valve and rcfit thc suction advance pipe 10 the

thermostal housing.

Fig . ..4.4

ortler of and tightening Ille cylinder he(ld retoilling llUIS

Detach tbe bigh-tension cables and remove the spark-

ing plugs. care not 10 r

l

.1m.1ge tbe porcelilin

insulators.

Remove the sUclion advancc pipe cli p from 6xture

00 the WOller control vah'e housing. If the car is filled

wilh a heater remove the hose and cOlltrol cable from the

cont rol valve, which is situaled at the rear right-hand

top of the cylinder head.

Slacken the top clip on Ihe waler by-pass hose.

Remove the inlet and exh:lUst manirold(s) as described

ill Section A.6.

Remove the rocker atisemhly as described in Section

A.7, nol forgetling 10 slacken the cxternal cylinder head

bolding nuts at the same time. Withdraw thc pushrods,

keeping Ibelll in order or removal.

The eyJintlcr head may now be rcmov<!d.

NOTE.-To facilitate breaking Ihe cytioder bead joint.

tap each side of the bead with" ha01D1er, using a piece of

wood to take Inc lila\\'. When lifting the head

a direct pull should be &h'cn so thai lbe bead is pulled

eveo.ly up the studs.

Refitting

Make sure that the surraccs of both the cylindcr block

and tbe cyJimJcr head arc clean and U!;C a !lew cylinder

hcad it is not to usc jointing compound

or grease for the gasket. It will be noti ced that the

cylinder bead gasket is marked 'FRONT' and 'TOP' so

that it will be fitted corrcctly. Having sUpped the gasket

A.6

Replace the rocker cover, ocing careful to fit ils cork

gasket correctly into and securing il by ils nuts,

washers, and rubber cups.

Replace the c-1rburett.er(s) a nd air cleaner (Section

0).

Secure Ihe radiator Lie-plale and reconnect the radi:lIor

hose (0 Ihe thcrmostat housing.

Couueet Ihe negative cable to the battery lerminal;

close the water drain lap and plug, and refill the cooling

system as in Section C.2.

Swilch on Ihe ignition and check the fuel system for

Jeuks .

Start Ihe engine. and rUIl il unlil Ihe norm;11 workins

temperature is reached. Remove Ihe rocker cover and

check Ihe valve clearances (sec ScetiLln A.15). Replace Ihe

rocker cover.

Refit the bOllnet.

Section A_I0

DECARBONIZING

Remove tbecylindcr head as described in Seclion A.9,

Withdraw Ihe v;1h'cs as descrihed in Section A. I I.

Remove tbe cylinder head g;ukel and plug Ihe water-

ways with a dean rilg.

If special equipment is nOI available for c..Iccarbonizing

it will he necessary to scrape Ihe carbon deposit rrom

the piston crowns, cylinder hlock, and cylinder bc.1d,

using a blunl sc.raptr.

1100. T.uuc 4. 72330

THE ENGINE

A

A riog of carbon should be left rouod tbe peripbery

of the piston croWD and we rim of carbon round the

lOp of the cylinder bore should not be toucbed. To

facilitate tbis an old piston ring can be sprune ioto the

bore so thai it rests 00 top of the piston.

The c)'linder h.ead is next givC'O 3HemioD. The sparkjog

plugs must be cleaned aDd adjusted. Clean off tbe carbon

deposit from Ibe valve stems, vaJve ports, and combustion

spaces of cylinder bead. Remove all traces of cachon

dost witb compressed air or by the vigorous usc of a lyre

pump and tben tborougbly clean with paraffin (kerosene)

and dl')' off.

Fit a new cylind.::r bead gasket when repbciog the

head. noting that the gasket is marked to indicate tbe top

face aud the frOllt eod.

Seetio. A.lI

VALVES

Remomc

Remove tbe cylioder head as detai.led in Section A.9.

Remove Ihe cotter clip, compress Lbe valve springes)

wilb a valve spring compressor, and remove tbe split

colters.

Relellosc th.e valve spring(s) and remo"'e Ihe

Remove the retaining cap, valve spriog(s), and rubber

seal. Withdraw the valve from the guide.

Keep tbe in their relative positions when

removed from lbe cylioder head to ensure replacerneol

io tbeir original VAlve guides.

RetirtiD:l:

Place each valve io il$ respective guide and (it lhe

spriog(s) and the retaining C.1p. Compress the spring{s)

and li.t a Dew sealing rubber 10 the valve stem, push Ihe

B

Fig. A.S

componenl paris of 'he tlSsembly, sliowing

(A) ,he double sprint Dnd (D) ,he single

spring appJicollons, and (fJJJel) ,lie location 0/

the yolve S(!al ot the bollom ()f ,lIe coller groove

1100. fsue 5. 5610

/ .

u,.

Fig. A.6

Compressing a I'Qll'e spring with Service fool 45

sea.lagainst Lbe boltoal of the colter letes!, and

refit the cotters. Ensure IhAt tbe rubber seal is not pushc=d

out of the cotler roc:.c=ss 01110 tbe larger diil(l1elc=r of the

slc=rn, rc=lease the compressing 1001. and 6t the split

cotter rewining clip.

Section A.12

VALVE-GRINDlNG

Remove the val vC'S as in Sc=ctioo A.1)'

Each vah'e must bt clc..1ned thoroughly Olud cxnmined

careruJly for pitting. Valvc.s in a pilled conditioa should

be (Cfaced with a suitable uinder or DeW val ves sbould

be 6tted. Stamp Bny new valve with tbe nUlDber of the

port to whicb it is fitted ,

If the valve sea.U1 sbow siglls of pitting or unevenness

they should be trued by Ihe use of Service tools. These

lools will save lengthy and wasteful grinding in. When

using a cutLiog tool take caTe to remove only as much

metal a! to ensure 8 true surface. Wora valve

seats usuall y have a glass-hard surfatt, aod the glaze

breaker should be used to prepare the voUve seat surface

for any rttutting thai may be necessary. Narrowing

cutlers should be used to resto..-e tbe valve seats to the

original standard.

When grinding a val ... e 0010 its seating the valve face

should be smeared li ghtly with fine- or mt:dium-g,rade

carborundum pasle and then lapped in with Do suction

gri nder. Avoid the use of excessive quantities of grinding

paste and see that it remains in the region of the valve

seating only.

A light coil spring placed under the valve head wiU

assist considerably in the process of grinding. l1le vaJve

should be groUtld to its scat wiLb a semi-robry motioo

and occasionally aUowcd to rise by the pressure of the

coil spring. This assists in spreading tbe paste

evenly over Ibe valve face and seat. It is neces5llry to

Coury out tbe operatioll until .a dull, (ven, mat

surface free from ble{llish is produced 00 Ihe valve seat

and valve face.

A.7

A

THE ENGINE

Fig. A.7

Whenfiuing ,olve gllides they must be drb'tn ill unfif

'hey ore it- in, (15-1 mm.) above Ih8 machined joct!

of 'he 'IIolve sp"-IIg seol

On completion. the valve scal aDd ports sbould be

cleaned with :l rag sOAked in paraffin (kerosene). dried.

and then Iborough1y cleaned by compressed air. The

valves should be washed in pal'ilffin (kerosene) and all

traces of grinding paste removed.

Refer to Section A. II for details of v:llve refitting.

Seclio. A.J3

VALVE GUlDFS

Removing

RCDlOve Ihe cylinder head as shown in Section A.9.

Remove the appropriate valve aDd $pricg(s) RS in

Seetion A.II. Rest the cylinder head with its macb.ioed

(ace downwards on a clean surface and drive the vo,lvc

gwde downwards into the combustion space witb a

suilable--sucd drift. This should take the form of :l.

bardened-sted punch ,\- in. (II mm.) in diameter al,d

not Icss than 4 in. (10 em.) in length, with a loeating

spigot II' ill. (7'14 mm.) diarneler ma-:bined on one end

(or a lellglb of 1 in. (2' 5 em.) to engage tbe bore or the

guide.

Re8Hiag

When fitting new valve guides they should bc drivcn in

hom tbe top of the cyliader head, The inlet valve guide&:

must he inserted with the largl!:$( chamfer at the lop, and

the euaust valve guides should have their eounterbored

ends at the bollom. The valve guides should be dri ven

iota tbccombustion until they nrc H in. (IS' ) rom.)

above the machined surfau of (he valve spring sealiog

(see Fig. A.7).

Seelio. A.14

TAPPElS

Remoying

Remove the ($ee Sectioll D) and the

rocker covce.

Remove tbe manifold(s) (sec Seelion A.6).

Remove tbe rocker assembly as in Section A.1 and

withdraw the pusb-rods. keepillg them in their respective

A.I

POSitions to ensure their replaeemenl onto the same

tappets. Remove the tappet covers and lirt out the

tappets, also keeping them in their correct order to assisl

in replacing them in their originalloeations.

FittiA&

Refitting is a reversal of the remmlal sequellce.

New tappels should be filled by selective assembly so

that they JUSt fall into their guides under IheiT own

weight when lubricated.

is a reversal of (he above procedure, bul

care should be (aken (0 see Ihal Ihe lappet cover join IS

art. oil-Light and thai the rockers are adjusted 10 give the

correct valve clearance;.

Section A.IS

VALVE ROCKER ADJUSTMENT

If the engioe is to give its best performance and Ihe

valves are to retain Ihe;r muimum useful life it is

eS$cnlialto maintain the correct \lal\'e dearnnce. Accord-

ingly it is recommended thai the clearance be checked

al regular intervals and any uecessary adjustmeots made.

The clearance for both tbe inlct Rnd exhaust valves

is -012 in. ('305 truD.) when the engioe is cold. The eogine

has bn de.signed to operate with this clearance and no

depulW'e rrom it is permissible.

Provision for adjusting the valve clearance is nlade in

Ihe rocker arm by an adjustable screw aod lockmll.

Tbe rocker adjusLing screw is released by slackening

tbe hexagon loclc.nut with a spanner while bolding the

screw against rotalion witb II screwdriver. The valve

clearance can then be sci by carefuUy rotating the rocker

screw while cbecki ng Ibe clearance with a feeler gauge.

This screw is then relocked by tightening the

locknut while again holding the screw against rotation.

II is important to note tbat while the clearance is

being SCI Ibe tappel of the valve being operated upon

is on the back orifS cam, i.e. opposite to the peak.

Fig. A.8

The clearance between (he I'alve stem and rDcker

mlHt be 011 in. (' 305 mm.) with the mgine cold

1100. Issue 5. j610

TIlE ENGINE

A

As Ibis cannot be observed ;,\ccurately the rocker

;:u.ljushncnl is more easily carried out in the following

order, and this also avoids turning the crsl)k.sbafi over

more Ihlln is DCCCSsary.

Adjust No. I rocker wilh No.8 valve fuJly open

II II 3 II ,. .0 6" ., II

, ... 5 ...... 4 ......

.... 2 ,."7 .. ,,

.. ,,8 .... 1 ""

. 6 ,. II ., 3 ,. t.

.. ,. 4 II " II 5.. II

.. P 7 ,. ,. 2 ., ,.

A,)6

DlSTRl8UTQR DRJVlNG SPlNDLE

Removiog

Remo\"(: the distributor as detailed in Section O.

Take OU! the screw securing (be distributor housing 10

the cylinder block alld withdraw the hOLlsing.

Screw a ,\ in. UNF. boh approltiUlalely 31 in. (89 mm.)

long inlO tbe lapped end of the disnibulor drive spindle

and wi(hd(l)W Ihe spindle.

Refittiog

Turn tbe cra"kshaft until No. I piston is at T.O.C. Oil

its compression stroke:. When the valves 011 No.4 cylinder

arc 'rocking' (i.e. ex.hauSI just closing and inlet

opening). If the engine is set so lhal the 1/4 mark on tbe

Oywheel is in line witb tbe pointer on the clutch coveT,

or the dimples in tbe crankshaO and camshaft gears arc

in line, Ihe piston is exaetJy al T.D.C.

SCre ..... the *" in. by Ji in. UNF. boll iuto the threaded

end of the distributor drive gCDr lind, boldiog tbe drive

ge:ar with tbe slot just below Ihe borizontal aad lnc large

offset uppermost, eater the gear. As tlle gear engages

.... ith the camsbaft the slot will turo in an aoti-<:Ioc.kwise

direction until it is approximately io tbe two o'clock

position.

Remove Ihe bolt from the gear and insert tbe distri-

butor housiog aDd secure it with the special bolt aDd

washer.

Fig. A.9

The d/slT/bulor dr;ye with Ihl! slot in the corrut

Dnd the large offset upptrmost

1100. rssuc 6. 5610

Fig. A.lO

Tile li"';lIg marks Oil Ille jlyu'heel COIJ seen with

,he oid of 0 mirror offer UllloyjnE the inspection coyer.

T. D.C. posif/on is indicated by ,he mark J/4 shohln

inset: and IS- morks (Ire nlso provided

Ensure tbat the COTm:.t bolt is used aod tbat (he head

docs not protrude above the face of Ihe housiog.

Rdit the distributor, referring 10 Seclion 0.7 if the

clamp plate h:l$ bun rcleilSed.

Sedion A.I?

Removing

FLYWHEEL AND CLUTCH

(Coil Spriol type)

Remove (be battery and bauery c31rier.

Remove the sWIer as io Section L.6.

Withdraw the split pin from Ihe dutch opernLing lever

pivot, release the tension spring. pull tbe push-rod (rom

Ihe hydraulic slave cylinder, and remove the lever

assembly from the clutch cover.

Withdraw tbe slave cylioder mouDting screws .nd

secure the cylinder against the engine bullc.bcad.

Remove the exhoust pipe clamp and the radillor

cowling steady bracket.

Remove the DUIS aod set screw, securing the rur

enginc mOl/otiog to the sub-frame side-member and

exlract Ihe set screws securing the clutch cover to the

6ywhcel housiog.

Raise: the eogine with lifting equipment sufficiently ooly

10 e1labJe the cover to be removed. Make sure Ihat tbe

fan blades do not make contact with. and damage, Ihe

radiator core.

Remove the retaining nuts and remove the clutch

thrust plate (rom the pressure spring housing.

It is essential tbat the eDglne is turned to T.O.C. 00

Nos. I aod 4 eylioden belore removing the llywbOt:1.

In lhis positioo tbe 4C' washer localiog the primary geu

is fitted wirb the bridge linking the two flats above tbe

cranksbaft and cannot drop. (f this precaution is Ool

fakeD the 'C' wasber cao fall aod become wedged belfiDd

the Bywbeel oll seal and prevent the removal of the

nywheel without serious damage to the seal.

".9

.

_

_

.

_

.

.

_

.

.

_

.

.

_

.

.

.

.

.

.

_

.

_

_

.

.

.

-

-

-

-

-

_

.

.

.

.

_

-

_

.

_

.

.

.

.

.

.

.

.

.

.

.

_

.

.

.

.

.

.

.

_

.

.

.

.

_

.

_

.

.

.

.

_

-

-

.

.

_

.

-

-

.

-

-

-

I

!

T

H

E

C

Y

L

I

N

D

E

R

H

E

A

D

A

N

D

V

A

L

V

J

<

:

G

E

A

R

I

i

I

,

3

1

I

7

'

,

3

2

\

:

l

i

Q

)

'

-

<

f

f

f

f

i

1

1

l

[

;

J

\

1

1

:

:

:

\

1

-

.

\

\

B

,

,

I

I

.

2

.

2

6

2

9

2

8

3

0

2

5

2

7

2

0

"

"

-

'

"

,

'

I

=

,

?

,

[

I

.

.

"

,

-

1

3

2

1

1

-

-

-

'

"

.

(

.

/

B

-

-

_

.

_

-

-

-

-

-

_

.

.

.

.

_

_

.

.

.

.

.

_

.

.

.

.

.

.

.

.

.

,

.

.

_

.

.

.

,

.

.

.

5

3

.

_

.

_

.

.

.

_

-

&

-

'

2

(

;

.

.

-

0

;

:

:

'

I

'

.

,

!

.

.

.

.

.

1

)

.

.

.

.

.

,

-

-

-

-

-

-

_

.

.

.

_

.

.

.

_

.

.

.

.

_

.

_

-

-

-

_

.

.

.

.

.

_

.

.

!

>

-

!

l

1

"

-

.

.

-

.

-

-

-

-

-

-

.

-

-

-

-

-

-

_

.

_

_

.

_

.

_

_

.

.

.

.

.

.

.

.

.

_

.

.

.

.

.

.

.

.

.

-

.

-

.

.

-

.

-

-

-

.

-

.

-

-

.

.

_

-

-

-

-

,

f

,

.

;

:

l

'

"

o

i

I

I

I

I

I

I

f

I

,

i

.

.

N

.

D

t

l

c

r

i

l

'

l

i

r

M

I

.

C

y

l

i

D

d

c

t

h

e

a

d

.

2

.

V

.

l

y

e

;

u

i

d

e

.

,

.

P

l

u

,

.

W

i

l

e

r

o

u

t

l

e

t

c

l

b

o

.....

S

1

u

d

.

s

.

R

o

c

l

t

e

r

b

r

l

d

e

t

"

l

i

d

(

s

b

o

n

)

.

,

.

R

o

c

k

e

r

b

n

l

c

k

e

l

s

r

u

d

(

l

o

n

g

)

.

7

.

M

a

o

i

f

o

l

d

s

t

l

l

d

.

S

N

<

!

.

C

o

Y

e

r

-

p

1

1

l

1

e

.

1

0

.

C

o

'

i

C

r

j

o

i

l

n

.

I

I

.

W

i

s

h

e

r

.

1

2

.

N

U

l

.

"

.

J

n

k

l

w

l

Y

C

.

"

.

E

x

h

a

u

s

t

y

a

"

"

'C

.

I

S

.

O

i

l

i

e

r

s

p

r

:

i

c

t

.

"

.

G

u

i

d

e

s

h

r

o

u

u

.

1

7

.

P

:

l

c

k

i

"

.>

::

M

I

:

.

"

.

S

p

r

i

n

e

c

u

p

.

"

.

V

a

l

v

e

C

O

l

i

e

r

.

2

1

C

l

r

c

l

i

p

.

.

.

.

_

-

.

K

E

Y

T

O

T

H

E

C

Y

L

I

N

D

E

R

H

E

A

l

>

A

N

I

>

V

A

L

V

E

G

E

A

R

N

D

e

s

e

r

/

p

l

l

o

,

.

N

o

.

l

H

S

C

'

;

P

f

"

,

"

"

.

R

o

c

k

e

r

s

h

a

f

l

.

"

.

O

i

J

I

3

D

p

i

e

c

e

.

2

2

.

t

l

o

c

l

:

;

e

r

s

h

a

R

p

l

\

l

C

.

"

C

u

p

w

u

h

e

r

.

2

3

.

R

.

o

c

k

e

r

s

h

a

r

I

"

I

l

l

S

(

s

c

r

e

w

t

'

\

I

)

.

4

J

.

N

.

,

,

.

.

R

o

c

k

e

r

l

I

r

s

c

k

e