Professional Documents

Culture Documents

Mining Grade Control

Uploaded by

minerito2211Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mining Grade Control

Uploaded by

minerito2211Copyright:

Available Formats

Mining Grade Control Past, Present and Future

W J Shaw1

ABSTRACT

The objectives of mining grade control are presented and examples of the techniques used in various open pit and underground mines are used to define the attributes of good grade control. Reasons are discussed for the success of various improved practices. The progressive development of grade control is presented and the balance between quantitative and qualitative data is analysed. The skills and resources required for grade control on mine sites that are using best practice are also presented. A number of problems in grade control have been solved recently however there are still issues that need to be addressed. Examination of the grade control process frequently stops after sample quality has been examined. There is much more beyond this that can now be optimised using conditional simulation models. Other future directions of mining grade control are also suggested. An extensive bibliography of published papers on grade control is included that will be maintained and updated on a website.

OBJECTIVES OF MINING GRADE CONTROL

Objectives for grade control and for mining geology have been presented previously: The objective of grade control is to maximise the value of ore mined and fed to the mill. The objectives of mining geology are primarily to enable the mining company to maximise profits by reducing the risk associated with geological (and other) uncertainty. (Shaw, 1990a). This issue of risk management will be addressed later as it is now more amenable to quantitative analysis than it was ten years ago. In analysing different approaches to grade control it becomes apparent that there are similarities and differences between various mining styles, various commodities and between the old ways and the new. Some comparisons are presented here to explore what grade control is, how it has developed and where it is going. There are always assumptions and unless these are stated at the outset they can remain hidden. Let us start by ensuring that we are in all cases talking about good practices; there is little to be gained by supposing that grade control is now done by people who are more dedicated, or better trained than was the case in the past. We will try to identify concrete improvements in techniques that have contributed to improving grade control.

SAMPLING

In most parts of the world grade control sampling is now done mechanically, although in the past, and still in some less developed countries, cheap labour meant that sampling was done by hand. Very successful grade control of high-grade underground gold mines relied in the past on panning of gold samples during mining. It is remarkable today to see remnant underground workings that now define the high-grade trends in an open pit mine. Large open pit gold mines currently exist where artisan miners using hand panning steal gold overnight, leaving behind trenches in the richest parts of the ore. The primitive grade control techniques that defined such high-grade trends are obviously very successful. All sampling, whether it is manual or by trenching or drilling, should conform to the principles of sampling defined by Gy (1979), to ensure that the sample collected is representative. Elaboration and improvements on this theory by Pitard (1993) and Francois-Bongaron (1998) have made it more relevant to

1. FAusIMM, Principal Consultant, Mining and Resource Technology Pty Ltd, Level 3, Kirin Centre, 15 Ogilvie Road, Mt Pleasant WA 6153.

gold deposits. Good grade control depends on good data. Application of sampling theory at many mine sites has made a significant improvement to the quality of that data. One of the biggest issues that faces open pit mining operations is the balance between using blast holes and dedicated reverse circulation (RC) drilling for sampling. It is not easy to balance the costs and the benefits of these methods, although some new strategies are further discussed later. Blast hole sampling is attractive in hard rock mining because the holes are already available. The disadvantages of blast hole sampling (contamination and sample loss, leading to poor precision and bias) are not always easy to quantify and there are few good published comparative studies. The trend setting operations often had to rely on subjective trials to justify a change to RC drilling, but now many successful mines take the view that such dedicated drilling provides better quality data in a more timely manner, enhancing their capacity for selective mining. This was certainly not the case ten years ago when dedicated RC drilling (eg as discussed in Shaw, 1990b, at the first Mining Geology Conference) was novel. The quality of RC drilling has improved significantly with the introduction of face-sampling hammers rather than crossover subs. Drilling companies have also responded to pressure to reduce costs while meeting higher standards of sampling quality. In many cases now the sampling quality is stipulated in drilling contracts and mine sites routinely carry out validation tests on sampling equipment. Trenching techniques have changed from using rip lines to cutting sampling trenches using rotary saws or chain saws (both variants of DitchWitch equipment). The smaller consistent particle size overcomes many of the disadvantages of trenching and enables samples that have demonstrably better repeatability to be collected systematically. There is little to be gained now by comparative test work between rip lines and DitchWitch trench samples, although very little has been published. Case studies such as Pratt and Jankowski (1993) provide an insight into the importance of geological controls in deciding the correct orientation for grade control sampling. Underground face sampling continues to rely mainly on manual methods, ie collecting rock chips using a hammer and chisel. There are variations on this approach depending on the orientation of sampling and whether channels are cut or samples are collected over an area. Alternatives generally rely on sludge sampling of blast holes, or sampling muck piles of blasted material or trucked ore. Sampling broken ore often shows poor representativity and bias due to the particle size variation. Dedicated drill sampling is generally adopted in large underground mines once safety factors are seen as an issue. Where the geometry of the orebody and the mining method can support it, drilling well in advance of mining enables design of the ore blocks to be based on true grade control sampling. Any other sort of sampling is really too late to have much impact on the grade of the ore blocks and is best described as reconciliation sampling. Such sampling can only explain why the grade was different to expectations; it cannot help to control the grade. In examining the various sampling methods we have defined some important considerations. Good grade control sampling must be: safe, unbiased, representative (ie correct in terms of Gys sampling theory), and timely (so that the results can usefully define the ore blocks).

4th International Mining Geology Conference

Coolum, Qld, 14 - 17 May 2000

223

W J SHAW

ASSAYING

A similar approach can be taken to examining assaying or indeed any other part of the grade control process. Assaying is one of the most easily verified stages in grade control since the use of Standard Reference Samples and inter-laboratory checks can identify and control bias, while the submission of field duplicates and pulp repeats can quantify precision at various stages of subsampling and assaying. Assaying techniques vary significantly with different commodities. The adoption of standard assaying techniques is usually unassailable. Some operations however opt for partial extractions or quasi-metallurgical testwork that may emulate some part of the mining or processing. For example it is not unusual in bauxite operations to measure the silica that is digested by caustic soda at a specific pressure and temperature. Some mineral sands operations define attributes as rock, sand and slimes at specific sieve sizes. Ferrous metal mines may use wet screening to emulate scrubbing or the effects of crushing and sizing in the mill. Such metallurgical assays can all suffer from the same problem: they assume that the test mimics some part of the ore treatment or handling process. The problem with such tests is that the mill configuration can change over time, rendering the testing technique less relevant. Even standardised empirical tests (such as the decrepitation index for iron ore) cannot account for changing practices over time and so need to be reinterpreted for different conditions. Of course grade control must be orientated towards predicting those aspects of the ore processing that affect the value of the ore and there will always be a need for such information. Effort has to be put into developing cost-effective techniques that can be reinterpreted as the mill configuration changes. One of the big problems facing bulk shipping ores is the issue of the Lump/Fines ratio and partitioning of grades and penalty elements into various size fractions. The Lump/Fines ratio of the ore changes with increased crushing, transport and handling. While this is hard to predict it is evident that the response of the ore to such physical treatment may be controlled by the mineralogy of the ore. Normative mineral analysis is being adopted for more and more deposits (Lipton et al, 1999). By assaying for a suite of elements and then combining these according to theoretical mineral compositions, the ratios of various minerals can be estimated. Tying the physical characteristics of ore to such normative mineral estimates may lead to a better understanding of such physical attributes as the Lump/Fines ratio. Problems in ensuring the useful application of consistent techniques for longer term reconciliations can also arise with partial extraction assays. Of course care should be taken to ensure that the digestion techniques have not been changed over time. However even when consistently applied the use of partial extractions such as cyanide bottle roll tests (or even aqua regia) for gold can be misinterpreted when reconciling with the mill. Again it is best to ensure that such metallurgical assays are constantly benchmarked. The use of modern assaying techniques such as the Leco furnace for S (which can provide assays for other volatile elements) and ICP assays (which can provide assays for a broad spectrum of elements) means that in many operations there is now more information available than in the past. Assaying for more than one element for grade control will become more common. This imposes new demands on data management and interpretation. Adding to the previous list, good grade control assaying should be: based on measurable attributes that may safely be used to predict metallurgical performance; and comprehensive so that all the required data is collected.

GEOLOGICAL DATA

A grade control system that is not built on a relational database to manage the assay data is heading for trouble. While this may be now well recognised, few operations perform well at collecting and managing soft data (mapping and drill hole logging). The incorporation of mapping data into mining grade control is still an important goal for most mines. This will require accessible 3D-visualisation software built on a relational database. Finding the correct balance between soft geological data and hard assay data has proved difficult for many operations. Where there is abundant assay data (for example in those operations that sample blast holes) there is often a tendency to discount individual assays. If the sampling repeatability is poor, even the average grades of the ore blocks may be regarded with some scepticism during mining and the ore blocks may then be radically altered, reclassified to a lower grade stockpile or even set aside for resampling after mining. The ultimate reflection of poor confidence in sampling and assays (the hard data) is a total reliance on visual control (soft data) with close supervision of the contacts by mining geologists who make subjective judgements about whether material is ore or waste. At the other end of the spectrum is a total reliance on the hard assay data with a complete disregard of geological controls. The impact of such a policy has been long appreciated in resource estimation with a significant move away from the unconstrained kriging approaches that were prevalent during the 1980s. However the use of contouring or even kriging to define ore block boundaries is still evident at some sites. Sometimes there is such an emphasis on collecting hard assay data and interpreting it that the mining geologists do not have time to do mapping, let alone incorporate the results into the ore block designs. This approach appears most prevalent in operations that use close spaced trenching or blast holes to sample every mining flitch. It is often worth investigating whether the geology (soft data) is being effectively used, especially if assay turn-around times are critical to ensuring the ore blocks can be designed before the ore is dug. A grade control system that disregards the geological controls will never be optimal. On the other hand, a system that maximises the use of good quality information in an efficient manner can release staff away from the tedium of manually interpreting ore blocks in a subjective manner so that they can put effort into the mapping that will control future ore blocks. The balance between hard and soft data is dynamic. Good assay data provides new insights into geological controls. Good mapping can significantly reduce grade control costs when the operation moves away from sampling everything towards targeting mineralised zones with high quality sampling. The geological data also provides the controls that enable the best balance between quality and quantity of sampling to be achieved. Adding to the criteria for good grade control: all available data should be stored in a relational database with 3D coordinates (for integration with mining software); an appropriate balance should be achieved between hard and soft data for defining ore blocks; and the gathering of expensive hard data (assays) should be guided by the availability of cheaper soft data (mapping).

INTERPRETATION OF ORE BLOCKS

The need to convert data to information (and eventually to knowledge and then wisdom) must not be overlooked. Many grade control systems get bogged down in data collection, validation and subjective manual interpretations. These aspects of the grade control process can be very time consuming and frustrating, when the data (hard and soft) is being under-utilised.

224

Coolum, Qld, 14 - 17 May 2000

4th International Mining Geology Conference

MINING GRADE CONTROL PAST, PRESENT AND FUTURE

In the past, for open pits the grade control assay data and mapping were plotted on cross-sections and bench plans for manual interpretation. The process of defining ore block boundaries consisted of interpreting major lode directions and contouring the cut-off grade boundary based on the assays. These two separate sets of information were then merged and the final cut-off grade boundary was defined. At this stage the mining selectivity needed to be considered and so the mineable ore block boundary was then superimposed, digitised and finally marked out on the ground. As described, this process involved a number of iterations and under the pressure of production it was not always possible to ensure that an audit trail existed that would validate the final ore blocks. It was apparent that different practitioners on the same mine site could interpret the same data quite differently and that there was no easy way to arbitrate or define the objective truth. This frequently resulted in the definition of quite different ore block shapes on consecutive mining benches in open pits. For underground mining based on drill sampling well in advance of ore block development, the interpretation problem can be addressed using computer systems to ensure three-dimensional integrity of the interpretations. For operations relying on face sampling of the next development cut, or sampling stoped ore, the decision as to what will be mined has already been made and the sampling is of no value in controlling the grade. A risk management approach to mining grade control can be developed based on conditional simulation (Dowd, 1996; Khosrowshahi and Shaw, 1997; Shaw and Khosrowshahi, 1997; Schofield and Rolley, 1997). Conditional simulation involves generating a set of independent possible outcomes (realisations) on a close spaced grid, that honours the real data (hence the word conditional) and models the spatial variability of the real data set. The construction of a robust conditional simulation model that encompasses a large number of realisations can provide extensive information about the expected grade and the degree of variability at closely spaced points. A number of questions frequently come up that have not perhaps been adequately addressed in the literature: Conditional simulation appears to artificially increase the level of sampling how can this be possible? The approach taken is to generate a series of new values between the true samples. These new values should have a similar mean, dispersion and histogram as the available true data and should produce a similar variogram. In addition, all the true values are retained and honoured. Of course the new values are artificial; they are not real new sample points and we would be foolish to believe them immediately since we have generated only one possibility (a first realisation) from the infinite number of alternatives that meet our target parameters. If conditional simulation can give us possible realisations of the small-scale variability - which one of these is correct? No single realisation is more valid than another. The approach taken is to use these to define the expected variability at each simulated point. Every realisation is conditioned to the real data this means that the real data influences every point. In areas where there are a lot of high grades you can have a greater expectation of similar high grades. In areas where the real grades are mostly waste the effect is the opposite. This is intuitively acceptable. That is why it is important to deal with a large number of realisations. The approach to use is thus to generate many realisations and to use them to indicate the likely risk of grades being high or low at any point. If we have 50 realisations (or 100, or 200), the distribution of the values at each point is used to represent our expectation at that point. If we have modelled the grade (and any attribute can be modelled) we could determine the probability that the grade will be above or below a nominated cut-off grade. From this we can make a decision based on how we perceive this distribution will affect us. Since the risk is the

inverse of the confidence we can select our risk position according to our current circumstances. A risk analysis approach enables the mining geologist to produce ore blocks that are less subjective, that honour the nominated cut-off grades, and that allow the risk profile (less dilution or less ore loss) to be varied for each ore type. The dense grid of simulated values enables the final ore boundaries to be defined to a better resolution than the actual grade control sampling pattern. Even in manual methods this is often done by the more experienced practitioners who push the ore blocks out a bit around the high grades near boundaries to be sure they do not lose any ore, at the expense of taking a bit more dilution. At operations that find this approach successful the geologists have been able to devote more attention to mapping and to incorporate real geological controls on grade. Is the technique being widely used for grade control mark outs? No, it is not yet common practice. MRT currently has six sites using our Ore Block Optimisation (OBO) system, and there are a number of other practitioners offering systems. There is little published yet on the approach used or the results. The most recent summary of the current state of the art was at the International Symposium on Geostatistical Simulation in Mining (28 - 29 October, 1999 in Perth) for which the proceedings are still in press.

OBSERVED IMPROVEMENTS IN GRADE CONTROL PRACTICES

Ten years ago reverse circulation drilling was rarely used for grade control but now it is accepted as best practice. The same can be said for good quality sample preparation: it is now generally the practice to split 3 kg from the sample at the drill rig and to pulverise this split using total prep, ie reducing it all to better than 90 per cent passing 75 microns before subsampling for assaying. Other innovations are also gaining in popularity, including better stockpile management, more comprehensive ore tracking, audit trails, quality assurance and comprehensive reconciliation reporting for management. The reason for the success of various approaches is not hard to find. The evolutionary process, ie survival of the most fit, is at work ensuring that less successful practices (and mining companies) are gradually eliminated through open transparent competition. In some places the older ways survive, due to misallocation of resources or protectionism by their adherents, however in the long run the most successful practices eventually get adopted and then persist. Even five years ago there was less consideration given to validating assay quality than there is today because there are now more practitioners around that understand the problems that arise if data is dirty. The mining industry has had a reasonably successful track record at adopting these many innovations. Both the measurable benefits and the intangible advantages of conditional simulation will ensure that risk based definition of ore blocks will be adopted at more and more operations.

SKILLS AND RESOURCES

Training of mining geologists that supervise grade control is of major importance. The author has run a grade control workshop course (Shaw, 1991) with over 450 participants. Many of the ideas presented are now implemented routinely in grade control all over the world. Other specialist courses in sampling and in geostatistical estimation techniques have also made a significant contribution. There is little evidence yet of the ultimate objective being reached, that of a specific mining geology discipline with specialisation in mining grade control. Without doubt this will happen as more practitioners find that a systematic approach to

4th International Mining Geology Conference

Coolum, Qld, 14 - 17 May 2000

225

W J SHAW

grade control makes it a rewarding profession and more mine managers see the economic benefits of scientific grade control practices. The skills required of a mining geologist involved in good grade control are: data management and presentation, geological mapping, statistical analysis, and reporting and communication. A sound appreciation of the principles in a number of specialist areas is also required: geostatistics and resource estimation, sampling theory, cut-off grade theory, discounted cash flows (the time value of money), mining engineering, and mineral processing and metallurgy. Resources that enhance the ability of grade control practitioners to perform well are now commonplace on most mine sites, but include: a data audit trail, a relational database, and appropriate mining software for plotting and interpretation of data.

In forecasting the future directions for grade control it is still apparent that there needs to be improvements in the following areas: better sampling on drill rigs; safer sampling underground; better representativity in gold mines with coarse gold; continuous survey control; better integration of mapping and assay data at various scales; more integration of mine and mill tracking systems with grade control predictions; and better prediction of ore movement during blasting.

CONCLUSIONS

Mining grade control has come of age in the last 15 years with recognition on many mine sites that it plays an integral part in the successful economic exploitation of mineral resources. Mines cannot do without grade control because while geological boundaries may be sharp in many cases grades are continuous rather than discrete. Since grade control is by definition about controlling the grade, the relationship between the discrete geological controls and the continuous mineralisation controls must be clearly established. This can be done by: understanding all the various inputs to good mining; keeping a balance between hard and soft data; ensuring that grade control is optimal by continuously evaluating the costs and the benefits; and using risk based strategies to support decision-making.

PROBLEMS IN GRADE CONTROL THAT HAVE BEEN SOLVED RECENTLY

Examination of the grade control process often starts with sample quality but sometimes the analysis never progresses. There is much more beyond sampling that can now be optimised using conditional simulation models. There is a clear relationship between the sampling density and costs of sampling. The relationship is less clear between the costs of sampling and the benefits in terms of reduced ore loss, dilution and misclassification. Understanding and balancing the costs and benefits of various strategies is a major issue for many operations. This relationship can sometimes be defined for individual deposits by trial sampling or similar programs, or by conditional simulation. In the former there are often many parameters and operational factors that cannot be controlled (for example the deposit can only be finally mined in one way). Using conditional simulation, many different strategies can be trialled. Cases have been previously presented (eg Shaw and Khosrowshahi, 1997) that indicate the application of conditional simulation to solving the problems of sampling grid optimisation and ore block optimisation. While there is still much to do in refining such techniques a sound general approach has been established. Thus good grade control must be demonstrably cost-effective (ie it must show a positive cost-benefit).

ACKNOWLEDGEMENTS

Many of the ideas presented by the author on mining grade control over the last ten years have been developed in conjunction with mine site personnel and grade control course participants whose support is greatly appreciated. Many operations develop and solve specific problems and the industry benefits when such advances are presented in open forums. Many of the real innovations leading towards a quantitative approach to mining grade control have been developed with the support and assistance of Dr Sia Khosrowshahi and my other colleagues at Mining and Resource Technology Pty Ltd and their support is gratefully acknowledged.

BIBLIOGRAPHY

This bibliography includes references sourced from many publications and previous reviews (Bettenay and Shaw, 1990; Bell and Reeves, 1979). While it is extensive at this stage it is strongly influenced by the authors personal views. This bibliography will reside on a web-site at www.mrtconsulting.com.au and new entries will be added to provide a comprehensive on-going reference to published work on mining grade control.

Australian Standards Committee QR/4, 1990. Quality control: guide to the use of control chart methods including Cusum techniques. Standards Australia, Standards Australia, Sydney, 59 p. Ayris, M, 1990. Determining drill hole deviation. Strategies For Grade Control, Australian Institute of Geoscientists Bulletin,10:37-41. Barnes, J F H, 1987. Practical methods of drill hole sampling. Meaningful Sampling in Gold Exploration, Australian Institute of Geoscientists Bulletin, 7:145-170. Bell, G D and Reeves, M, 1979. Kriging and geostatistics: a review of the literature available in English, Proc Australas Inst Min Metall, 269:17-27. Bettenay, L F and Shaw, W J, 1990. A check list for effective grade control. Strategies For Grade Control, Australian Institute of Geoscientists Bulletin, 10:91-93.

FUTURE DIRECTIONS OF MINING GRADE CONTROL

Supervision of actual mining practices and control of the ore through various stockpiles will continue to improve. The actual monitoring of ore movements will become easier as sites adopt truck-despatch systems based on Differential GPS survey control. However these systems need to interface with the data management systems used by grade control if they are to produce useful information. Real time accessible survey control in all parts of the mine will also make geological mapping significantly more effective.

226

Coolum, Qld, 14 - 17 May 2000

4th International Mining Geology Conference

MINING GRADE CONTROL PAST, PRESENT AND FUTURE

Border, S N, 1991. Optimisation of cut-off grades during design of underground mines, in Proceedings Mining Industry Optimisation Conference, pp 21-27 (The Australasian Institute of Mining and Metallurgy: Melbourne). Carras, S N, 1987. Gold Sampling - The importance of getting it right. Meaningful Sampling in Gold Exploration, Australian Institute of Geoscientists Bulletin, 7:1-26. Coles, A J, Hadlow, H R and Levy, I W, 1993. Reconciliations at the Kundana Gold Mine, WA (Selective blasting of ore and waste, and its effect). Open Pit to Underground - Making the Transition, AIG Bulletin, 14:95-102. Collings, M, Lenartowicz, D and Alexander, K R, 1989. Dominion Mining Limited - Cosmo Howley Gold Mine, in Proceedings World Gold 89: Gold forum on technology and practices, Proceedings of the First Joint International Meeting between SME and The AusIMM, Reno, Nevada, November 5-8 (Eds: R B Bhappu and R J Harden). Cook, J N, 1971. Grade control procedures at the Iron Prince Quarry, Whyalla, SA, in Proceedings 1971 Adelaide Regional Conference, paper No 4 (The Australasian Institute of Mining and Metallurgy: Melbourne). Cook, J N and McIntyre, R I, 1973. Use of computers for grade estimation, iron ore quarries, South Australia, BHP Tech Bulletin, 17(2):28-33. David, M, 1977. Geostatistical ore reserve estimation. Developments in Geomathematics, 2, 364 p (Elsevier: Amsterdam). David, M, Dowd, P and Korobov, S, 1973. Forecasting departure from planning in open pit design and grade control, in Proceedings 10th International APCOM Symposium, 1972, Colorado 1974, pp 131-153. Davis, B M, Trimble, J and McClure, D, 1989. Grade control and ore selection practices at the Colosseum gold mine, Mining Engineering, pp 827-830. Dowd, P A, 1996. The use of conditional simulation in grade control, in Proceedings Mining Geostatistics Conference, Kruger National Park, South Africa, 19-22 September 1994, pp 11-25 (Geostatistical Association of South Africa). Dudley, R J, 1988. Contribution of grade control costs to production costs in open pit gold mining. Economic Geology Research Unit, Contribution 18, Geology Dept, James Cook University, Queensland. Eyde, T H and Eyde, D T, 1984. Application of geology to problems of sampling and grade control unique to industrial mineral deposits. 1984 fall meeting of the Society of Mining Engineers of AIME, Denver, CO (Ed: R Metz), Soc Min Eng Am Inst Min Metall and Pet Eng, pp 83-89. Fietz, G C, 1993. Short term mine management systems - an integrated approach to blast design, grade control, stockpile management and reconciliation, in Proceedings International Mining Geology Conference, pp 35-41 (The Australasian Institute of Mining and Metallurgy: Melbourne). Francois-Bongaron, D, 1998. Gys Formula - Conclusion of a New Phase of Research, AIG Bulletin, 22:1-10. Gill, J E, Blais, R A and Haw, V A (Eds), 1968. Ore Reserve Estimation and Grade Control, in Proceedings of a Symposium held in Quebec, September 25-27, 1968: CIM Special Volume No 9. Gillies, A D S, 1992. Application of geostatistics to construct a coal quality model, Proc Australas Inst Min Metall, pp 1-8. Guarascio, M and Raspa, G, 1974. Valuation and production optimization of a metal mine, in Proceedings 12th International APCOM Symposium, Colorado 1974, Colorado 1974, F50-64. Guibal, D G, 1987. Procedure and example of grade control in open pit mining, in Proceedings Pacific Rim Congress 87, pp 855-857 (The Australasian Institute of Mining and Metallurgy: Melbourne). Gy, P, 1979. The sampling of particulate materials: theory and practice. Developments in Geomathematics, 4, 431 p (Elsevier: Netherlands). Hazen, S W, 1967. Assigning an area of influence for an assay obtained in mine sampling. US Bureau Mines, Rep Invest, US Bureau of Mines, 6955. Hazen, S W, 1967. Some statistical techniques for analysing mine deposit sample and assay data, US Bureau of Mines Bulletin, 621. JORC, 1999. Australasian code for reporting of Mineral Resources and Ore Reserves (The JORC Code), prepared by the Joint Ore Reserves Committee of the Australasian Institute of Mining and Metallurgy, Australian Institute of Geoscientists and Minerals Council of Australia (JORC), effective September, 16 p.

Journel, A G, 1974. Grades fluctuation at various scales of mine output, in Proceedings 12th International APCOM Symposium, Colorado 1974, Colorado, F78-94. Journel, A G and Sans, H, 1974. Ore grade control in sub horizontal deposits, Transactions of Institution of Mining and Metallurgy, 83(812):A79-A84. Kavanagh, M E, 1987. Comparison of RAB, RC percussion and grade control drilling Gabanintha gold mine, Western Australia. Meaningful sampling in gold exploration, Perth, 26 October, Australian Institute of Geoscientists Bulletin, 7:171-180. Keough, D C and Hunt, S J, 1990. Statistical determination of a safe sampling protocol: case studies at Granny Smith and Big Bell, Western Australia. Strategies for Grade Control, Australian Institute of Geoscientists Bulletin, 10:31-36. Khosrowshahi, S and Shaw, W J, 1997. Conditional simulation for resource characterisation and grade control - principles and practice, in Proceedings World Gold 97, pp 275-282 (The Australasian Institute of Mining and Metallurgy: Melbourne). Krige, D G, 1951. A statistical approach to some basic valuations problems on the Witwatersrand, J Chem Metall Min Soc South Africa, 52(6):119-139. Krige, D G, 1959. A study of the relationship between development values and recovery grades on the South African Goldfields, J S Afr Inst Min Metall South Africa, 59:317-331. Krige, D G, 1961. Developments in the valuation of gold mining properties from bore hole results, in Proceedings 7th Comm Min and Metall Congress South Africa, pp 537-561. Krige, D G, 1964. A review of the impact of statistics on mine valuation in the gold mining industry, J S Afr Inst Min Metall, 64:373-380. Krige, D G, 1970. The development of statistical models for gold ore valuations in South Africa, in Proceedings 6th International Mining Congress, Madrid. Krige, D G, 1970. The role of mathematical statistics in improved ore valuation technique in South African gold mines, in Topics in Mathematical Geology, A Special Research Report (Eds: M A Romanova and O V Sarmanov), pp 243-261 (Consultants Bureau: New York). Krige, D G, 1977. Applications of statistics and geostatistics in ore valuation in South Africa, 109 p (Australian Mineral Foundation: Adelaide). Krige, D G and Munro, A H, 1968. A review of some conceptual and practical implications of the use of valuation surfaces for gold ore reserve estimation, in Ore reserve estimation and grade control, Special Publication, 9, pp 33-40 (The Canadian Institute of Mining and Metallurgy). Lacy, W C, 1985. Mining geology; the industrys hope, in Applied mining geology; problems of sampling and grade control. Battle Mt Gold Co, United States, (Ed: R Metz) pp 1-6. Lacy, W C, (Ed), 1983. Mining Geology. Benchmark Papers in Geology, 69, 466 p (Hutchinson Ross: USA). Lipton, I T, Shaw, W J and Waltho, A E, 1999. Characterisation of ore types and beneficiation behaviour using normative minerals, in Proceedings PACRIM 99, pp 427-433 (The Australasian Institute of Mining and Metallurgy: Melbourne). Nami, M and Verrezen, L, 1986. The use of sedimentology to improve valuation in gold mines, Gold Mining Technology, Johannesburg, 1:15-23. Newton, M J, 1974. The application of geostatistics to mine sampling patterns, in Proceedings 11th International APCOM Symposium, Colorado 1974, Arizona, D44-58. OLeary, J O, 1979. Ore reserve estimation methods and grade control at the Scully Mine,Canada - an integrated geological/geostatistical approach, Mining Magazine, pp 300-314. Peele, R, 1944. Mining Engineers Handbook, 3rd Edition in 2 Volumes (John Wiley and Sons: New York). Pitard, F F, 1993. Pierre Gys sampling theory and sampling practice, 2nd Edition, 1, 488 p (RC Press: Florida). Pratt, J D R and Jankowski, P, 1993. The geology and grade control at Bannockburn gold mine Leonora District, WA, in Proceedings International Mining Geology Conference, pp 195-206 (The Australasian Institute of Mining and Metallurgy: Melbourne). Robertson, I G and Sehic, O A, 1993. Ore quality control for process optimisation, in Proceedings International Mining Geology Conference, pp 227-234 (The Australasian Institute of Mining and Metallurgy: Melbourne).

4th International Mining Geology Conference

Coolum, Qld, 14 - 17 May 2000

227

W J SHAW

Royle, A G, 1979. Estimating small blocks of ore: how to do it with confidence,World Mining, April, pp 55-57. Royle, A G, 1980. Geostatistics, 168 p (McGraw-Hill, Inc: New York). Schofield, N and Rolley, P, 1997. Optimisation of Ore Selection in Mining: Method and Case Studies, in Proceedings Third International Mining Geology Conference, pp 93-97 (The Australasian Institute of Mining and Metallurgy: Melbourne). Shaw, W J, 1990a. Management of grade control and mining geology an overview, Strategies for Grade Control, Australian Institute of Geoscientists Bulletin, 10:1-7. Shaw, W J, 1990b. Grade control for gold mining at Mt Magnet, Reedy, Rothsay and Youanmi in the Murchison District, WA, in Proceedings Mine Geologists Conference, pp 83-92 (The Australasian Institute of Mining and Metallurgy: Melbourne). Shaw, W J, 1991. Grade control course notes: mining geology, grade control and reconciliation. A short workshop course on grade control. Mining and Resource Technology Pty Ltd, Perth, WA. Shaw, W J, 1993. Practical solutions to some grade control problems and why they work: a few case studies, in Proceedings International Mining Geology Conference, pp 171-176 (The Australasian Institute of Mining and Metallurgy: Melbourne). Shaw, W J and Khosrowshahi, S, 1992. Optimising grade control procedures in large and small open pit mines, in Proceedings Third Large Open Pit Mining Conference, pp 251-254 (The Australasian Institute of Mining and Metallurgy: Melbourne). Shaw, W J and Khosrowshahi, S, 1997. Grade control sampling and ore blocking: optimisation based on conditional simulation, in Proceedings Third International Mining Geology Conference, pp 131-134 (The Australasian Institute of Mining and Metallurgy: Melbourne).

Shaw, W J, Khosrowshahi, S, Horton, J and Waltho, A E, 1998. Predicting and monitoring errors in sampling, sample preparation and assaying, More Meaningful Sampling in the Mining Industry, (Eds: B Davis and S E Ho) AIG Bulletin, 22:11-19. Siddall, G B and Baxter, K G, 1990. Does the mill control the grade? Strategies for Grade Control, Australian Institute of Geoscientists Bulletin, 10:77-82. Stephens, A J and Chapman, G J, 1993. Optimisation of sampling procedures at the Fimiston open pit Kalgoorlie, in Proceedings International Mining Geology Conference, pp 185-194 (The Australasian Institute of Mining and Metallurgy: Melbourne). Storrar, C D, 1977. South African Mine Valuation, 472 p (Chamber of Mines of South Africa: Johannesburg) Taylor, M J, 1993. Grade control review at Boddington gold mine, SW region WA, in Proceedings International Mining Geology Conference, pp 177-183 (The Australasian Institute of Mining and Metallurgy: Melbourne). Truscott, S J, 1947. Mine Economics, Sampling - Valuation Organisation - Administration, second edition, 366 p (Mining Publications Ltd: London). Wright, A, Feyerabend, W C and Kastelic, R L, 1992. Integrity of samples acquired by deep, reverse-circulation drilling below the water table at the Chimney Creek project, Nevada (and subsequent discussion in Jan 1993), Mining Engineering, 44(4):343-351.

228

Coolum, Qld, 14 - 17 May 2000

4th International Mining Geology Conference

You might also like

- Reconcilliation Part 3Document24 pagesReconcilliation Part 3shahidaliNo ratings yet

- Use of Twinned Drillholes in Mineral Resource Estimation: BzalovDocument12 pagesUse of Twinned Drillholes in Mineral Resource Estimation: BzalovErwin FernandezNo ratings yet

- Statistical Evaluation of Geochemical Au Sample Quality : Ghana Mining Journal, Pp. 7 - 14Document8 pagesStatistical Evaluation of Geochemical Au Sample Quality : Ghana Mining Journal, Pp. 7 - 14ChristianKamisi100% (1)

- Grade Control and Reconciliation PDFDocument11 pagesGrade Control and Reconciliation PDFuttamksr67% (3)

- Sampling Practice in The Gold MiningDocument164 pagesSampling Practice in The Gold MiningEray Yurtseven100% (1)

- Kanmantoo Copper Mine Ore Reserve EstimateDocument19 pagesKanmantoo Copper Mine Ore Reserve EstimatekokoamikNo ratings yet

- Abzalov - 2008 QAQCDocument14 pagesAbzalov - 2008 QAQCFernando Solis Castillo100% (1)

- Surface Mining and Design PDFDocument44 pagesSurface Mining and Design PDFMartin JanuaryNo ratings yet

- Grade Control Classi CationDocument25 pagesGrade Control Classi CationhamidNo ratings yet

- AUSIMM Grad Program Guidelines - GeologistDocument1 pageAUSIMM Grad Program Guidelines - GeologistMatthew FistNo ratings yet

- Mine Geology .FinalDocument74 pagesMine Geology .Finalissy van phiriNo ratings yet

- SRK Resource Estimation With Leapfrog EDGE PDFDocument2 pagesSRK Resource Estimation With Leapfrog EDGE PDFAnonymous OnVLQHbXNo ratings yet

- 12-QAQC Insertion Rate-Is There An Industry Standard-V6.7Document22 pages12-QAQC Insertion Rate-Is There An Industry Standard-V6.7Waldo Cea SepùlvedaNo ratings yet

- 05 Strategic Mine Planning 1Document39 pages05 Strategic Mine Planning 1minerito22110% (1)

- Talk 2 Paul Stenhouse - SRK Consulting UK PDFDocument17 pagesTalk 2 Paul Stenhouse - SRK Consulting UK PDFAncalle FroylanNo ratings yet

- NI 43-101 Technical Report - Mineral Resource Estimate - Segovia Project - ColombiaDocument204 pagesNI 43-101 Technical Report - Mineral Resource Estimate - Segovia Project - ColombiaSantiago duque muñoz100% (2)

- Mining Grade Control - Past, Present and FutureDocument6 pagesMining Grade Control - Past, Present and FutureParag Jyoti DuttaNo ratings yet

- Grade Control For Australian Open Pit Gold MinesDocument14 pagesGrade Control For Australian Open Pit Gold Mineswaldo100% (1)

- Grade Control PDFDocument156 pagesGrade Control PDFArif RahmatNo ratings yet

- Geometallurgy Austmine - SRK - StandardDocument11 pagesGeometallurgy Austmine - SRK - StandardJhair Jhamidh100% (1)

- Ore Reserve EstimationDocument11 pagesOre Reserve EstimationMijail ACNo ratings yet

- Ausimm Guide To Authors 2011Document21 pagesAusimm Guide To Authors 2011Brian HutchinsonNo ratings yet

- AusencoDocument20 pagesAusencoloisNo ratings yet

- Geometallurgy Roles and Application in Mining OperationDocument25 pagesGeometallurgy Roles and Application in Mining OperationFahrul Rozzi Usman100% (1)

- Ore Dilution Vs Mine To MillDocument9 pagesOre Dilution Vs Mine To MillMiguel Torres100% (1)

- QKNA For Mining GeologistDocument10 pagesQKNA For Mining GeologistAchanNo ratings yet

- Mineral Resources Ore Reserves Guidelines-Aug2006 - 2 - DraftDocument31 pagesMineral Resources Ore Reserves Guidelines-Aug2006 - 2 - DraftMiguel MiguelitoNo ratings yet

- Mining Sampling ProtocolDocument7 pagesMining Sampling ProtocolKarim Marmouri100% (1)

- 6870 - 301-5 - Ore Reserve PDFDocument23 pages6870 - 301-5 - Ore Reserve PDFMaame Adwoa MaisieNo ratings yet

- BOOK - Cut-Off - Grades PDFDocument311 pagesBOOK - Cut-Off - Grades PDFdrina_pdNo ratings yet

- Channel Sampling: Channel Sampling Is Laborious, Tedious, Time Consuming and ExpensiveDocument7 pagesChannel Sampling: Channel Sampling Is Laborious, Tedious, Time Consuming and ExpensivelovelyNo ratings yet

- An Integrated Mine PlanDocument8 pagesAn Integrated Mine PlanVachist WangelNo ratings yet

- Cut-Off Grade Estimation - QueensMineDesignWikiDocument7 pagesCut-Off Grade Estimation - QueensMineDesignWikiJean-Paul MwambaNo ratings yet

- Grade Control Drilling With RC and QAQC of SampleDocument43 pagesGrade Control Drilling With RC and QAQC of SampleJulian I Swandi100% (2)

- Geometallurgy What Why and HowDocument46 pagesGeometallurgy What Why and HowW ZuoNo ratings yet

- Cut-Off Grade PDFDocument11 pagesCut-Off Grade PDFjuan100% (2)

- Geometalurgy - ITB 281115Document30 pagesGeometalurgy - ITB 281115Kevin MusterNo ratings yet

- Ore Reserve Estimation Prospecting ExplorationDocument19 pagesOre Reserve Estimation Prospecting ExplorationArianne Valdez0% (1)

- Underground Mine GeologyDocument58 pagesUnderground Mine Geologyfarhan fahmiNo ratings yet

- Geological ModelingDocument6 pagesGeological ModelingCristian RuizNo ratings yet

- Beyond Reconciliation - A Proactive Approach To Mining DataDocument7 pagesBeyond Reconciliation - A Proactive Approach To Mining DataCraigNo ratings yet

- Safe Mine Design and Mining Methods-Smallscale.Document51 pagesSafe Mine Design and Mining Methods-Smallscale.tkubvosNo ratings yet

- Surface Mining MethodsDocument15 pagesSurface Mining MethodsMatthew Butler50% (2)

- 4.09 Deswik - Sched For UGM Tutorial v4.1Document191 pages4.09 Deswik - Sched For UGM Tutorial v4.1Margareth Guerrero Arias100% (2)

- Strategic Mine Planning 1Document25 pagesStrategic Mine Planning 1manuelglt100% (3)

- Best Practice in Mine PlanningDocument7 pagesBest Practice in Mine PlanningAnonymous nz1HcVTNo ratings yet

- Resource ModellingDocument16 pagesResource ModellingZulmy Ikhsan W100% (1)

- Selecting Shaft or DeclineDocument8 pagesSelecting Shaft or DeclineStephen HolleyNo ratings yet

- How To Value An Exploration ProjectDocument36 pagesHow To Value An Exploration ProjectAlvaro MadridNo ratings yet

- Mine Geology: Unearth GeoscienceDocument26 pagesMine Geology: Unearth GeoscienceJulian I SwandiNo ratings yet

- Origin of Mineral DepositsDocument11 pagesOrigin of Mineral DepositsTogi JoshuaNo ratings yet

- Opencast Mining MethodDocument7 pagesOpencast Mining MethodjaypadoleNo ratings yet

- Ore Body Modelling: Concepts and TechniquesDocument33 pagesOre Body Modelling: Concepts and Techniquesفردوس سليمانNo ratings yet

- Mining Grade Control PDFDocument6 pagesMining Grade Control PDFYenefer Irene VillanuevaNo ratings yet

- Bench and Pilot Plant ProgramsDocument10 pagesBench and Pilot Plant ProgramsNataniel LinaresNo ratings yet

- Sgs Min Tp2002 04 Bench and Pilot Plant Programs For Flotation Circuit DesignDocument10 pagesSgs Min Tp2002 04 Bench and Pilot Plant Programs For Flotation Circuit DesignevalenciaNo ratings yet

- Article Completo. Yann Camus - SgsDocument7 pagesArticle Completo. Yann Camus - SgsLuis Alfonso Galvan MoralesNo ratings yet

- Section 1 Sampling Techniques and Data: JORC (2012) Code - Table One SummaryDocument5 pagesSection 1 Sampling Techniques and Data: JORC (2012) Code - Table One SummaryMoe HoNo ratings yet

- NPV or IRR - Why Not BothDocument5 pagesNPV or IRR - Why Not Bothminerito2211No ratings yet

- Conveyor System at South BulgaDocument5 pagesConveyor System at South Bulgaminerito2211No ratings yet

- Applying Risk Analysis To Asses Economic Viability To UG Golden Sunlight MineDocument10 pagesApplying Risk Analysis To Asses Economic Viability To UG Golden Sunlight Mineminerito2211No ratings yet

- Application of Whittle 4D To Risk Manag. in OP OptimisationDocument12 pagesApplication of Whittle 4D To Risk Manag. in OP Optimisationminerito22110% (1)

- Application of Whittle 4D To Risk Manag. in OP OptimisationDocument12 pagesApplication of Whittle 4D To Risk Manag. in OP Optimisationminerito22110% (1)

- Feasibility Studies - Scope and AccuracyDocument8 pagesFeasibility Studies - Scope and Accuracyminerito2211No ratings yet

- Geostatistical Design of Infill Drilling ProgramsDocument10 pagesGeostatistical Design of Infill Drilling Programsminerito2211No ratings yet

- MisUse of MonteCarlo Simulation in NPV Analysis-DavisDocument5 pagesMisUse of MonteCarlo Simulation in NPV Analysis-Davisminerito2211No ratings yet

- Optimization of Shovel-Truck System in OPDocument7 pagesOptimization of Shovel-Truck System in OPminerito2211100% (1)

- Planning and Design of Surface MinesDocument6 pagesPlanning and Design of Surface Minesminerito2211No ratings yet

- Block Size Selection in OPDocument8 pagesBlock Size Selection in OPminerito2211No ratings yet

- 05 Strategic Mine Planning 1Document39 pages05 Strategic Mine Planning 1minerito22110% (1)

- Application of Conveyors For UG HaulageDocument11 pagesApplication of Conveyors For UG Haulageminerito2211No ratings yet

- Use of Monte Carlo Simluations For Operations ManagementDocument4 pagesUse of Monte Carlo Simluations For Operations Managementminerito2211100% (1)

- Evolution of Strategic LTP at Anglo PlatinumDocument6 pagesEvolution of Strategic LTP at Anglo Platinumminerito2211No ratings yet

- Economic Modelling and Its Application in Strategic PlanningDocument12 pagesEconomic Modelling and Its Application in Strategic Planningminerito2211100% (1)

- XPAC7 Autocheduler Training GuideDocument64 pagesXPAC7 Autocheduler Training Guideminerito2211100% (8)

- Chapter 20Document70 pagesChapter 20minerito2211No ratings yet

- IP10G-CLI User Guide Version 6.7 March2011Document124 pagesIP10G-CLI User Guide Version 6.7 March2011JorgIVariuS100% (1)

- EL3020 Data PDFDocument24 pagesEL3020 Data PDFichrakNo ratings yet

- Thermal Plasma TechDocument4 pagesThermal Plasma TechjohnribarNo ratings yet

- School: Leadstar University College of Graduate Studies MBA Transformational LeadershipDocument13 pagesSchool: Leadstar University College of Graduate Studies MBA Transformational Leadershipaddisu zewde100% (1)

- The Effectiveness of Acceptance and Commitment-BasDocument18 pagesThe Effectiveness of Acceptance and Commitment-BasRaphaele ColferaiNo ratings yet

- Tokopedia Engineer CultureDocument25 pagesTokopedia Engineer CultureDIna LestariNo ratings yet

- BC-5800 Liquid SystemDocument114 pagesBC-5800 Liquid SystemДмитрийNo ratings yet

- Pressostato SUCO - 0159Document3 pagesPressostato SUCO - 0159Hugo Lemos ArthusoNo ratings yet

- TDS LF-361Document2 pagesTDS LF-361ofershochetNo ratings yet

- LC1D1801 Telemecanique LC1-D18-01 Contactor ReplacementDocument1 pageLC1D1801 Telemecanique LC1-D18-01 Contactor Replacementjamal debakNo ratings yet

- Questions & Answers On EDC OverviewDocument89 pagesQuestions & Answers On EDC Overviewkibrom atsbhaNo ratings yet

- Summer Report On WEB DevelopmentDocument30 pagesSummer Report On WEB DevelopmentADITYA25% (4)

- A Guide To Flame Photometer AnalysisDocument17 pagesA Guide To Flame Photometer Analysisarun231187100% (1)

- Pulley Groove Dimensions and SelectionDocument1 pagePulley Groove Dimensions and Selectionandysupa100% (1)

- Test AND Measurement: Eagle PhotonicsDocument90 pagesTest AND Measurement: Eagle PhotonicsPankaj SharmaNo ratings yet

- Apache Derby DatabaseDocument4 pagesApache Derby DatabaseJohn KrcmarikNo ratings yet

- Ssp431 Audi Rs 6Document44 pagesSsp431 Audi Rs 6gil_cs100% (1)

- The Basics of Business Management Vol I PDFDocument284 pagesThe Basics of Business Management Vol I PDFKnjaz Milos100% (1)

- Bohol HRMD Plan 2011-2015Document233 pagesBohol HRMD Plan 2011-2015Don Vincent Bautista Busto100% (1)

- Validation Protocol For Efficacy of Chemical DisinfectantsDocument8 pagesValidation Protocol For Efficacy of Chemical DisinfectantsMohamed KamalNo ratings yet

- Company Name Country Service Function/Type Contact: RigzoneDocument4 pagesCompany Name Country Service Function/Type Contact: RigzonekokabawaNo ratings yet

- ASHRAE - HVAC Noise and Vibration ControlDocument93 pagesASHRAE - HVAC Noise and Vibration Controlmnt6176100% (3)

- 3-Phase Brushless DC Motor Controller/Driver With Back-Emf SensingDocument12 pages3-Phase Brushless DC Motor Controller/Driver With Back-Emf SensingPero01No ratings yet

- F1160 1479757-1Document8 pagesF1160 1479757-1Thaweekarn ChangthongNo ratings yet

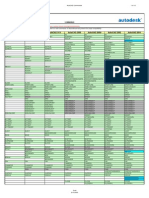

- Autocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004Document12 pagesAutocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004veteranul13No ratings yet

- Vocal Mixing TipsDocument16 pagesVocal Mixing Tipsshawn7800No ratings yet

- Domino's PizzaDocument37 pagesDomino's PizzaAristianto Pradana0% (3)

- Trafo Manual ABBDocument104 pagesTrafo Manual ABBMarcos SebastianNo ratings yet

- ("Love",:Ruby) .Each ( - I - P I)Document32 pages("Love",:Ruby) .Each ( - I - P I)hervalNo ratings yet