Professional Documents

Culture Documents

Ingestive Cleaning ES9-62 Rev L PDF

Uploaded by

reclatis14Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ingestive Cleaning ES9-62 Rev L PDF

Uploaded by

reclatis14Copyright:

Available Formats

SPECIFICATION

INGESTIVE CLEANING SOLAR TURBINE ENGINES

Data Control Level

SPECIFICATION NO. ES 9-62 REVISION:

(Letter, Date and PRD No.)

ISSUED: 04-10-02

(Date and PRD No.)

Release Stamp

A; 10/10/78; EL 2336-1 B; 6/7/82; ERL 5459-1 C; 11/8/85; ERL 8100-3 D; 3/28/88; ERL 9707-1 E; 5/11/89; ERL 9348-5

F; 2/2/90; ERL 0164-1 G; 5/29/92; ERL 10236-1 H; 11/29/94; ERL 11248-1 J; 7/8/98; PRD13562-1 K; 04-10-02; PRD14714-1

Rev. Ltr/

PRD #

Prepared By:

Signature & Title

Date

Pages Affected

06-20-02 L CR 01511

Boe Lotton Approved By:

Page 4

06-20-02

Gene Gerow

ATTENTION This document contains data pertaining to proprietary designs of Solar Turbines Incorporated. Reproduction, manufacture or use of any assembly, subassembly, or part indicated herein or the use of the design of any such assembly, subassembly, or part is permissible only if expressly authorized in advance and in writing by Vice President of Engineering, Solar Turbines Incorporated.

Specification No. ES 9-62 CONTENTS Paragraph 1.0 SCOPE 1.1 1.2 1.3 2.0 3.0 Purpose Cleaning Procedures Cleaning Solutions Page 1 1 1 1 1 2 2 2 2 2 3 4 4 4 5 6 6 6 8 8

DEFINITIONS APPLICABLE DOCUMENTS 3.1 Specifications

4.0

GENERAL REQUIREMENTS 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 On-Crank Vs. On-Line Cleaning Intervals Between Engine Cleaning Cleaning Procedures Cleaning Equipment Ambient Temperature During Engine Cleaning Engine Temperature During Engine Cleaning Recuperated Cycle Applications Flow Requirements

5.0

CLEANING PRODUCT 5.1 5.2 5.3 5.4 Water Cleaning Product Composition [& Mix Ratios] Emulsified Kerosene/Water Solutions Abrasive Cleaners TABLES

Table 1 2 3 4 5 6 On-Crank Requirements for Water/Freeze Point Depressant Mix, Volume Ratio InCold Ambient Temperatures On-Crank Cleaning Solution and Rinse Water Flow Requirements On-Line Cleaning Solution and Rinse Water Flow Requirements Requirements for Water Used in Ingestive Cleaning of Solar Engines

Page 4 5 5 6 7 7

Requirements for Cleaning Product Used in Ingestive Cleaning of Solar Engines Solar Cleaning Solutions for On-Line and On-Crank Cleaning

ii

Specification No. ES 9-62 1.0 SCOPE

1.1 PURPOSE - This specification establishes technical requirements for removing contamination in the compressor air path of Solar turbine engines by ingestive cleaning. 1.2 CLEANING PROCEDURES - The requirements defined herein serve as a basis for establishing proper cleaning procedures such that surface contamination in the compressor air path can be removed without damage to the engine. Details of the cleaning methods, cleaning instructions and suitable equipment for each engine model are not a part of this document as they are provided in the Operation and Maintenance Instruction (OMI) manual and in Solar's Service Bulletins. 1.3 CLEANING PRODUCTS - This specification provides the standards for product acceptance to ensure that the cleaning product(s) used are not harmful to the materials of construction. 2.0 DEFINITIONS

2.1 FREEZE POINT DEPRESSANT Material used to depress the freezing point of the cleaning product. 2.2 CLEANING EQUIPMENT - Accessory equipment used to properly introduce a cleaning product (not solid cleaners) into the air inlet. 2.3 CLEANING MODE - The mode of operation of the engine (on-crank or on-line) while cleaning is performed. 2.4 CLEANING PRODUCT A chemical solution that is introduced into the air inlet for the purpose of ingestive cleaning of the engine. 2.5 CLEANING SOLUTION A detergent and/or solvent material that is mixed with water to produce the cleaning product. 2.6 CLEANING SYSTEM - An appropriate combination of cleaning product, cleaning procedure and cleaning equipment to be used for a particular engine model. 2.7 DETERGENT Cleaning solution that liberates contamination by surface interaction (surfactant). 2.8 INGESTIVE CLEANING - Engine compressor cleaning where cleaning product is introduced through the air inlet. 2.9 ON-CRANK - Engine operation at maximum speed obtainable on starter alone with fuel and ignition deactivated. 2.10 ON-LINE - Engine fired and operating at any power level ranging from idle (no load) to full rated power and load. 2.11 SOLVENT Cleaning solution that dissolves contamination through reaction at molecular bonds.

Specification No. ES 9-62 3.0 APPLICABLE DOCUMENTS

3.1 SPECIFICATIONS - The following documents of the latest issue in effect on the release date of this specification form a part of this specification to the extent specified herein. Solar ES 9-98 Military MIL-D-16791 MIL-F-16884 MIL-E-9500 Detergents, General Purpose (Liquid, Nonionaic) Fuel Oil, Diesel, Marine Ethylene Glycol, Technical Fuel, Air and Water (or Steam) for Solar Gas Turbine Engines

American Society for Testing Materials ASTM D482 ASTM D512 ASTM D770 ASTM D857 ASTM D858 ASTM D1068 ASTM D1293 ASTM D1428 ASTM D1688 ASTM D1888 ASTM D2699 4.0 Standard Test Method for Ash from Petroleum Products Chloride Ion in Water and Waste Water, Test for Standard Specification for Isopropyl Alcohol Standard Test Methods for Aluminum in Water Standard Test Methods for Manganese in Water Standard Test Methods for Iron in Water pH of Water, Test for Sodium and Potassium in Water and Water-Formed Deposits by Flame Photometry, Tests for Standard Test Methods for Copper in Water Particulate and Dissolved Matter, Solids, or Residue in Water Standard Specification for Kerosene

GENERAL REQUIREMENTS

4.1 ON-CRANK VERSUS ON-LINE CLEANING - In general, on-crank cleaning tends to be more effective to remove deposits in the compressor air path. On-line cleaning may be performed in between on-crank cleaning cycles to extend time between on-crank cleaning and to minimize further deposition on to cleaned airfoils. Because the engine is firing during on-line cleaning, the cleaning liquid (either water or cleaning solution) ingested must meet the more stringent requirements defined in this specification to minimize introduction of corrosive/fouling contaminants. 4.2 INTERVALS BETWEEN ENGINE CLEANING Appropriate intervals for both on-crank and on-line cleaning should be determined by recording and trending engine performance

Specification No. ES 9-62 degradation. Cost of the maintenance outage versus that of continued operation with compromised performance. must also be considered. However, one should not delay cleaning so long that contamination becomes impossible to remove completely by on-crank cleaning. Oncrank cleaning is recommended at maximum intervals of every 4,000 hours operation, and before full load power degrades more than 5%. For two shaft turbines operating at full load on T5 topping this typically corresponds to a 2.5% drop in Pcd. For two shaft turbines operating at full load on Ngp topping, degree of compressor fouling is more difficult to quantify. As the compressor fouls, T5 will increase with little change in power or Pcd until T5 topping is achieved. On-line cleaning intervals should be determined by observing the effectiveness in restoring performance. On-line cleaning is best suited to remove the initial buildup of contamination from already clean airfoils. If the airfoils become significantly fouled between on-line cleaning intervals, cleaning will be less effective. Initial on-line cleaning interval should be at most 48 hours of operation. Performance should then be evaluated to determine effect of each cleaning operation, and overall rate of performance degradation. After completing an on-crank cleaning, on-line cleaning interval can be increased to 72 hours of operation. If no significant difference in on-line cleaning effectivenes is observed, the interval may be increased again by 24 hours. Typically, the maximum interval for an effective on-line cleaning program is no more than 96 hours of operation. Recommended minimum intervals between cleaning operations to avoid excessive ingress of cleaning product into the oil system are: On-Crank Cleaning - at least 96 operating hours between each on-crank cleaning cycle On-Line Cleaning - at least 24 operating hours between each on-line cleaning cycle 4.3 CLEANING PROCEDURES - Detailed cleaning procedures are described in the Operation and Maintenance Instruction (OMI) manual provided with each package. An outline of typical procedures are provided here: On-Crank: Shut down turbine normally Cool until turbine case temperature at compressor to diffuser flange is less than 66C (150F) Open air inlet access covers Open air inlet drain port Disconnect and isolate Pcd, buffer air and air sensing lines at connection points to compressor or diffuser Disconnect combustor, torch and exhaust drain lines Prepare cleaning product and cleaning equipment Crank turbine on the starter motor and allow speed to stabilize Apply cleaning product Stop turbine and allow cleaning product to soak for a period of 20 minutes Crank turbine on the starter motor and allow speed to stabilize Apply rinse water Verify that rinse water exiting from drains is clean, indicating that compressor cleaning was effective and repeat cleaning operation as necessary Continue crank for 5-10 minutes after rinse water is consumed Stop turbine Inspect inlet housing and compressor inlet to verify cleanliness Reassemble and reconnect all components and lines Restart turbine and operate for at least one hour to evaporate remaining rinse water

Specification No. ES 9-62 On-Line: Verify that unit is operating normally with steady load and speed Prepare cleaning product and cleaning equipment Apply cleaning product Apply rinse water Isolate cleaning equipment 4.4 CLEANING EQUIPMENT - Use of cleaning equipment designed specifically for each turbine model is important to ensure that adequate and uniform atomization occurs at the compressor inlet. This is particularly important for on-line cleaning to avoid overloading of airfoils that can result from non-uniform distribution or excessively large liquid droplets. Use of inappropriate equipment may result in compressor damage. Cleaning product is introduced to the turbine inlet through manifolds and nozzles mounted directly to the turbine inlet duct, with separate systems for either on-crank or on-line cleaning. Cleaning product can also be introduced manually using a hand held sprayer wand, but only for on-crank cleaning procedure. With either application method, cleaning product volume and flow rates must comply with the requirements defined in Section 4.8 of this specification. 4.5 AMBIENT TEMPERATURE DURING ENGINE CLEANING On-line engine cleaning is permitted only at ambient temperatures above 4C (39F). On-crank engine cleaning is permitted only at ambient temperatures above -20C (-4F). When the ambient temperature is between -20C (-4F) and 4C (39F), a mixture of water and freeze point depressant must be used for on-crank cleaning. The ratio of the water/freeze point depressant mix depends upon the type of freeze point depressant used, and recommended ratios are listed in Table 1. In order to be effective, the solution must be well mixed immediately prior to use. Table 1. On-Crank Requirements for Water/Freeze Point Depressant Mix Volume Ratio in Cold Ambient Temperatures Volume Ratio Freeze Point Depressant : Water 2:3 2:3 1:1

Ambient Temperature -20C(-4F) to 4C(39F) -20C(-4F) to 4C(39F) -10C(14F) to 4C(39F)

Freeze Point Depressant Methanol Mono-ethylene Glycol Isopropyl Alcohol

4.6 ENGINE TEMPERATURE DURING ENGINE CLEANING - Prior to on-crank cleaning, the engine casing surface temperature, measured at the compressor to diffuser flange shall not exceed 65C (150F). 4.7 RECUPERATED CYCLE APPLICATIONS - Water and/or cleaning solutions are not permitted in recuperators except for Harrison and GEA models. For all other recuperator models, on-crank cleaning must be performed at a reduced crank speed of 800 - 900rpm to avoid depositing cleaning refuse in the recuperator. On-line cleaning is not permitted for any recuperated units.

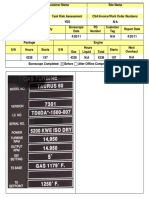

Specification No. ES 9-62 4.8 FLOW REQUIREMENTS - Tables 2 and 3 list the total volume of fluid and flow rate required for on-crank and on-line cleaning for each model turbine. Table 2. On-Crank Cleaning Solution and Rinse Water Flow Requirements Product Family Titan 130 Mars 90/100 Taurus 70 Taurus 60 Centaur 40/50 Saturn 10/20 Mercury 50 On-Crank Cleaning Product Volume 75.7 94.6 liters (20-25 Gallons) 56.8 75.7 liters (15-20 Gallons) 56.8 75.7 liters (15-20 Gallons) 45.4 64.3 liters (12-17 Gallons) 45.4 64.3 liters (12-17 Gallons) 30.3 37.9 liters (8-10 Gallons) 56.8 75.7 liters (15-20 Gallons) On-Crank Rinse Water Volume 94.6 189.3 liters (25-50 Gallons) 75.7 151.4 liters (20-40 Gallons) 75.7 151.4 liters (20-40 Gallons) 64.4 128.7 liters (17-34 Gallons) 64.4 128.7 liters (17-34 Gallons) 37.9 75.7 liters (10-20 Gallons) 75.7 94.6 liters (20-25 Gallons) On-Crank Flow Rate [FOR CLEANING OR RINSE] 17 to 20.8 liter/min (4.5 to 5.5 gpm) 11.4 to 15.1 liter/min (4 to 5 gpm) 7.5 to 11.3 liter/min (4 to 5 gpm) 9.1 to 12.9 liter/min (2.4 to 3.4 gpm) 9.1 to 12.9 liter/min (2.4 to 3.4 gpm) 5.7 to 9.5 liter/min (1.5 to 2.5 gpm) 6.8 to 7.6 liter/min (1.8 to 2.0 gpm)

Table 3. On-Line Cleaning Solution and Rinse Water Flow Requirements On-Line Cleaning Product Volume 75.7 94.6 liters (20-25 Gallons) 56.8 75.7 liters (15-20 Gallons) 56.8 75.7 liters (15-20 Gallons) 45.4 64.3 liters (12-17 Gallons) 45.4 64.3 liters (12-17 Gallons) 30.3 37.9 liters (8-10 Gallons) N/A On-Line Rinse Water Volume 94.6 189.3 liters (25-50 Gallons) 75.7 151.4 liters (20-40 Gallons) 75.7 151.4 liters (20-40 Gallons) 64.4 128.7 liters (17-34 Gallons) 64.4 128.7 liters (17-34 Gallons) 37.9 75.7 liters (10-20 Gallons) N/A

On-Line Flow Rate

Product Family Titan 130 Mars 90/100 Taurus 70 Taurus 60 Centaur 40/50 Saturn 10/20 Mercury 50

[FOR CLEANING OR RINSE] 11.4 to 13.6 liter/min (3 to 3.6 gpm) 8.3 to 10.6 liter/min (2.2 to 2.8 gpm) 5.3 to 7.6 liter/min (1.4 to 2 gpm) 2.3 to 4.5 liter/min (0.6 to 1.2 gpm) 2.3 to 4.5 liter/min (0.6 to 1.2 gpm) 1.5 to 3.8 liter/min (0.4 to 1 gpm) N/A

Specification No. ES 9-62 5.0 CLEANING PRODUCT

5.1 WATER - Water to be used for ingestive cleaning (or rinsing) of any Solar turbine engine shall comply with the requirements set forth in Table 4. Table 4. Requirements for Water Used in Ingestive Cleaning of Solar Engines Max. Limits for On-Crank Cleaning 105 ppmw 100 ppmw ASTM D512 ASTM D3559 ASTM D3373 ASTM D857, D858, D1068, D1688 ASTM D3605, D511 ASTM D1888 ASTM D 1293 100 ppmw 2 ppmw 2 ppmw 10 ppmw Max. Limits for On-Line Cleaning 1.9 ppmw 1.9 ppmw 40 ppmw 0.70 ppmw 0.35 ppmw 3.8 ppmw

Test Method Sodium + Potassium Fluorine Chlorine Lead Vanadium Iron, Tin, Silicon, Aluminum, Copper, Manganese, Phosphorus Calcium + Magnesium Total Dissolved Solids PH ASTM D1428

100 ppmw 350 ppmw 6-9

3.8 ppmw 5 ppmw 6-9

5.2 CLEANING PRODUCT COMPOSITION AND PHYSICAL PROPERTIES Composition and physical properties of cleaning products must comply with the limits defined in Table 5. Failure to comply with these limits can cause corrosive attack and/or other harmful effects resulting in rapid engine deterioration. When the cleaning product consists of a mixture of cleaning solution concentrate and water, the limits in Table 5 apply to the resulting cleaning product. Solar offers various cleaning solutions that that when properly mixed as a cleaning product, comply with both on-crank and on-line requirements of Table 5. These are available through the Solar Service Parts support network and part numbers are listed in Table 6. Three different types of cleaning solutions are available, each in either concentrate or ready mixed solutions: 5.2.1 Solar Gas Turbine Cleaner No. 1 Petroleum solvent based solution is the most effective type for cleaning oil and Carbon based fouling. However, local environmental regulations may require special treatment of the waste from on-crank cleaning. Disposal is not typically a consideration for on-line cleaning because the cleaning product is combusted completely in the turbine. 5.2.2 Solar Gas Turbine Cleaner No. 2 - This biodegradable type of solution is formulated with natural solvents and detergents and is generally less effective than pretroleum based solution. Warming solution to approximately 30C (86F) and allowing longer soak time can improve effectiveness.

Specification No. ES 9-62 Table 5. Requirements for Cleaning Product Used in Ingestive Cleaning of Solar Engines Max. Limits for On-Crank Solutions 105 ppmw 100 ppmw ASTM D512 ASTM D3559 ASTM D3373 ASTM D857, D858, D1068, D1688 ASTM D3605 ASTM D511 ASTM D482 ASTM D93 ASTM D 1293 100 ppmw 2 ppmw 2 ppmw 10 ppmw Max. Limits for On-Line Solutions 1.9 ppmw 1.9 ppmw 40 ppmw 0.70 ppmw 0.35 ppmw 3.8 ppmw

Test Method Sodium + Potassium Fluorine Chlorine Lead Vanadium Iron, Tin, Silicon, Aluminum, Copper, Manganese, Phosphorus Calcium + Magnesium Ash Flash Point PH ASTM D1428

100 ppmw 0.25 wt. % >140oF 6-9

3.8 ppmw 0.01 wt. % >140oF 6-9

Table 6. Solar Cleaning Solutions for On-Line and On-Crank Cleaning Maximum Strength Volume Ratio (Water:Cleaning Solution) 4:1

SOLAR PRODUCT NAME Solar Gas Turbine Cleaner No. 1 (Petroleum Solvent Based) Concentrate Solar Gas Turbine Cleaner No. 1 (Petroleum Solvent Based) Ready-To-Use Solar Gas Turbine Cleaner No. 2 (Natural Solvent Water Based) Concentrate Solar Gas Turbine Cleaner No. 2 (Natural Solvent Water Based) Ready-To-Use Solar Gas Turbine Cleaner No. 3 (Non-Solvent Water Based) Concentrate Solar Gas Turbine Cleaner No. 3 (Non-Solvent Water Based) Ready-To-Use

SOLAR P/N P/N 701690C2 (6.5 gal) P/N 701691C2 (55 gal) P/N 701696C2 (6.5 gal) P/N 701697C2 (55 gal) P/N 701688C2 (6.5 gal) P/N 701689C2 (55 gal) P/N 701694C2 (6.5 gal) P/N 701695C2 (55 gal) P/N 1011634 (6.5 gal) P/N 1011635 (55 gal) P/N 1011636 (6.5 gal) P/N 1011637 (55 gal)

Full Strength 4:1 Full Strength

4:1 Full Strength

Specification No. ES 9-62 5.2.3 Solar Gas Turbine Cleaner No. 3 This biodegradable type of solution is formulated with natural detergents and is generally less effective than solutions containing solvents. Warming solution to approximately 30C (86F) and allowing longer soak time can improve effectiveness. 5.3 EMULSIFIED KEROSENE/WATER SOLUTIONS - An emulsified mixture of kerosene and water or diesel fuel and water may be used for on-crank cleaning only. This mixture is formulated by mixing diesel fuel per MIL-F-16884 and water per Table 3 with an emulsifier per MIL-D-16791 (Type II) such that a homogenous, sprayable solution is formed. The mixing ratio shall be according to that recommended by the emulsifier manufacturer, but limited such that the combined diesel/kerosene and emulsifier content does not exceed 10% by volume of the final mixture. 5.4 ABRASIVE CLEANING Abrasive cleaners, such as Carboblast, walnut shells, pecan shells or rice, are not recommended for use in Solars gas turbines. Use of abrasive cleaners can cause plugging of cooling air passages in nozzles and blades, resulting in loss of cooling air and thermal degradation of the component. Abrasive cleaners may also have a detrimental effect on compressor coating.

You might also like

- Diagram Elektrik StarletDocument4 pagesDiagram Elektrik Starletunggul99100% (3)

- Chapter 11Document30 pagesChapter 11ta.ba100% (1)

- Taurus 60 Generator Set TrainingDocument6 pagesTaurus 60 Generator Set Traininghzq1eNo ratings yet

- Es2184d - Cleaning and Flushing of Hydraulic Systems & ComponentsDocument9 pagesEs2184d - Cleaning and Flushing of Hydraulic Systems & Componentsferfilho100% (2)

- Encyclopedia of Chemical Processing and Design. 69 - Supplement 1Document277 pagesEncyclopedia of Chemical Processing and Design. 69 - Supplement 1steamboatpirate80% (15)

- CENELEC - TR 50404-2003 Electrostatic-Code of Practice For The Avoidance of Hazards Due To Static ElectricityDocument82 pagesCENELEC - TR 50404-2003 Electrostatic-Code of Practice For The Avoidance of Hazards Due To Static Electricityjosethompson100% (5)

- 3c841 Bumi Unit 1Document725 pages3c841 Bumi Unit 1Jacob Mbang100% (1)

- GTUA 2001 Report PDFDocument243 pagesGTUA 2001 Report PDFMijail David Felix Narvaez100% (2)

- PMR - CPP Solar Turbines Taurus - 70 Driven Compressor Set PackagesDocument15 pagesPMR - CPP Solar Turbines Taurus - 70 Driven Compressor Set PackagesAceh NyakponNo ratings yet

- Maintenance SolarDocument17 pagesMaintenance Solardilo001100% (3)

- Centaur 50: Gas Turbine Generator SetDocument2 pagesCentaur 50: Gas Turbine Generator SetAdylNo ratings yet

- IplDocument392 pagesIplRanjan Shankar100% (2)

- Boroscopeo Turbina PDFDocument9 pagesBoroscopeo Turbina PDFegr00No ratings yet

- Dew-Point Curves of Natural Gas. Measurement and ModelingDocument6 pagesDew-Point Curves of Natural Gas. Measurement and Modelingreclatis14No ratings yet

- Freezing and MeltingDocument5 pagesFreezing and Meltingapi-361123151No ratings yet

- ES9-62 Ingestive Cleaning PDocument9 pagesES9-62 Ingestive Cleaning PIfran Sierra100% (1)

- Industrial Resources, Inc.: Solar Taurus 60 Gas TurbineDocument28 pagesIndustrial Resources, Inc.: Solar Taurus 60 Gas TurbineIsabel PaixaoNo ratings yet

- Manual Taurus 60 Turbina Parte 1Document71 pagesManual Taurus 60 Turbina Parte 1Edgar SeguaNo ratings yet

- E0430 Commissioning ManualDocument58 pagesE0430 Commissioning Manualczekjo100% (2)

- Solar Turbine Operation Manual 2Document368 pagesSolar Turbine Operation Manual 2Pong KrubNo ratings yet

- Supplementary Data Gas TurbineDocument17 pagesSupplementary Data Gas Turbinegiang0% (1)

- Anti Surge ControlDocument1 pageAnti Surge ControlyvesfireNo ratings yet

- Service Bulletin Solar Turbines AccesoryDocument3 pagesService Bulletin Solar Turbines AccesoryJONATHAN100% (1)

- C10518078 PDFDocument20 pagesC10518078 PDFJessica ChandlerNo ratings yet

- Vdocument - in Centaur 40Document83 pagesVdocument - in Centaur 40José RosarioNo ratings yet

- ES2098 Accpet Test Req Rev AbDocument101 pagesES2098 Accpet Test Req Rev Abverat81100% (1)

- Power Borescope Unit 1Document41 pagesPower Borescope Unit 1Mohammed YusufNo ratings yet

- IOPTC PLC4TurbineDocument4 pagesIOPTC PLC4TurbineStarlightbrightNo ratings yet

- Tips For InspectionDocument31 pagesTips For Inspectionali morisyNo ratings yet

- ROTALIGN-Ultra Operating-Instructions ALI-209.855!01!09 2.06 GDocument165 pagesROTALIGN-Ultra Operating-Instructions ALI-209.855!01!09 2.06 GDon Freeman100% (1)

- Part List Turbinas Taurus 70 Modulo IVDocument440 pagesPart List Turbinas Taurus 70 Modulo IVPSI para su informaciónNo ratings yet

- Centaur 50 Generator Set Preliminary Product SpecificationDocument89 pagesCentaur 50 Generator Set Preliminary Product SpecificationDAVIS VELASQUEZ100% (1)

- Vol IV Spare Part Illustration PDFDocument305 pagesVol IV Spare Part Illustration PDFgiang100% (3)

- CHP in New York State CHP in New York State CHP in New York State CHP in New York StateDocument23 pagesCHP in New York State CHP in New York State CHP in New York State CHP in New York StateftriwahyudiNo ratings yet

- GEK 97310 GEK 97310 Addendum I Addendum IDocument32 pagesGEK 97310 GEK 97310 Addendum I Addendum IJacky WuNo ratings yet

- Manual Mto 1203 - 5,6 MWDocument98 pagesManual Mto 1203 - 5,6 MWAgustin BaratcabalNo ratings yet

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document10 pagesTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robinyNo ratings yet

- Lampiran 1 Standar InspectionDocument7 pagesLampiran 1 Standar InspectionFitra SNo ratings yet

- 3 U 141 SogDocument228 pages3 U 141 SogGAS PLANTNo ratings yet

- Solar Mars 90 Gas Turbines BrochureDocument86 pagesSolar Mars 90 Gas Turbines BrochureKian TecNo ratings yet

- Se Brochure Dresser Rand Steam Turbines 2021Document24 pagesSe Brochure Dresser Rand Steam Turbines 2021Irfan FatahilahNo ratings yet

- Solar Turbine Operation Manual 3Document16 pagesSolar Turbine Operation Manual 3Pong KrubNo ratings yet

- Rolls-Royce Industrial AvonDocument7 pagesRolls-Royce Industrial AvonRiswan SaputraNo ratings yet

- Borescope Inspection Gas Turbien Generator Taurus 60Document38 pagesBorescope Inspection Gas Turbien Generator Taurus 60vamcodong100% (2)

- MCO2 SP300 8011 SP2 8007 Operationmanual enDocument49 pagesMCO2 SP300 8011 SP2 8007 Operationmanual encengiz gunesNo ratings yet

- Saturn - Russia 12MW Gas TurbineDocument22 pagesSaturn - Russia 12MW Gas Turbinedndudc100% (1)

- February 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsDocument4 pagesFebruary 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsKarim MuhammedNo ratings yet

- Service Bulletin: PurposeDocument3 pagesService Bulletin: PurposejussmeeeNo ratings yet

- Saturno 20Document80 pagesSaturno 20r_chulin100% (1)

- 5.0-111c-Turbine Package Grounding PracticesDocument10 pages5.0-111c-Turbine Package Grounding Practiceswili_ab8040No ratings yet

- Peppers Catalogue PDFDocument64 pagesPeppers Catalogue PDFStone123456789No ratings yet

- Peppers Catalogue GlandsDocument28 pagesPeppers Catalogue GlandsVlad Andronache100% (1)

- Vol IV Illustrated Part ListDocument460 pagesVol IV Illustrated Part ListmargaretramosNo ratings yet

- Rotor End of Life InspectionDocument26 pagesRotor End of Life InspectionJJNo ratings yet

- InstallationOperationMaintenance 3600 enDocument110 pagesInstallationOperationMaintenance 3600 enStaman1988No ratings yet

- 3c841 Bumi Unit 2Document707 pages3c841 Bumi Unit 2Jacob MbangNo ratings yet

- Centauro 40, Centauro 50 y Taurus 60 Gas TurbineDocument54 pagesCentauro 40, Centauro 50 y Taurus 60 Gas Turbinebarcaza_13No ratings yet

- Fuel Flexibility in Conventional and Dry Low Emissions Industrial Gas TurbinesDocument30 pagesFuel Flexibility in Conventional and Dry Low Emissions Industrial Gas TurbinesHenrik13No ratings yet

- Es2290 Rev L FinalDocument39 pagesEs2290 Rev L FinalLeidy Alejandra Urquijo Pastrana100% (1)

- 4 - Inspection - Interval - Extension W5015DA PDFDocument12 pages4 - Inspection - Interval - Extension W5015DA PDFEDBNo ratings yet

- Manual Caja Lufkin NF2019DDocument46 pagesManual Caja Lufkin NF2019DLuis Romero100% (1)

- Gas Turbine MaintenanceDocument3 pagesGas Turbine MaintenanceMohamed NawarNo ratings yet

- San Diego Lean 6 Sigma Solar Turbines PDFDocument91 pagesSan Diego Lean 6 Sigma Solar Turbines PDFarmin heidariNo ratings yet

- 04 Ingestive Cleaning Es9 62 Rev L PDF 180309185003Document10 pages04 Ingestive Cleaning Es9 62 Rev L PDF 180309185003slam12125No ratings yet

- Astm D-6439-2005Document29 pagesAstm D-6439-2005MasNo ratings yet

- Project Standards and Specifications Crude Desalter Systems Rev01Document6 pagesProject Standards and Specifications Crude Desalter Systems Rev01muhammad_asim_10No ratings yet

- Softmap InstallationDocument1 pageSoftmap Installationreclatis14No ratings yet

- Softmap 30 DDocument29 pagesSoftmap 30 Dreclatis14No ratings yet

- GPA 2145-09 Rev 1 GEQ GHV Summary FactorsDocument1 pageGPA 2145-09 Rev 1 GEQ GHV Summary Factorsreclatis14No ratings yet

- Appliation Example Hydrate InhibitionDocument21 pagesAppliation Example Hydrate Inhibitionreclatis14100% (1)

- Caete 2014Document10 pagesCaete 2014sukanyagggNo ratings yet

- Comparative Simulation Study of Gas Phase Propilene PDFDocument12 pagesComparative Simulation Study of Gas Phase Propilene PDFreclatis14No ratings yet

- Propylenepropane Separation Swing Adsorption Using 13X ZeoliteDocument17 pagesPropylenepropane Separation Swing Adsorption Using 13X Zeolitereclatis14No ratings yet

- HP's Petrochemical Processes 2005Document209 pagesHP's Petrochemical Processes 2005Ennecyr Pilling Pinto100% (1)

- Ammonia Flooded EvaporatorDocument3 pagesAmmonia Flooded Evaporatorreclatis14100% (1)

- Aspen ProcessBrowser V10 ECR00226248 ReleaseNotesDocument4 pagesAspen ProcessBrowser V10 ECR00226248 ReleaseNotesreclatis14No ratings yet

- Ammonia Flooded EvaporatorDocument3 pagesAmmonia Flooded Evaporatorreclatis14100% (1)

- AspenPolymersUnitOpsV8 4 UsrDocument544 pagesAspenPolymersUnitOpsV8 4 UsrKRenblog100% (1)

- Zhu 2015Document10 pagesZhu 2015reclatis14No ratings yet

- Hysys - Thermodynamics Best Practice Guide For Upstream & MidstreamDocument42 pagesHysys - Thermodynamics Best Practice Guide For Upstream & MidstreamPablo Maximo100% (1)

- AVCA Workflow V9Document11 pagesAVCA Workflow V9reclatis14No ratings yet

- Bently Nevada Day - Bolivia - 3500 PDFDocument21 pagesBently Nevada Day - Bolivia - 3500 PDFreclatis14No ratings yet

- AspenPolymersPropertiesV8 0 UsrDocument253 pagesAspenPolymersPropertiesV8 0 Usrreclatis14No ratings yet

- Costa 2011Document18 pagesCosta 2011reclatis14No ratings yet

- AIChE Journal Volume 49 Issue 10 2003 (Doi 10.1002/aic.690491017) A. S. Reginato J. J. Zacca A. R. Secchi - Modeling and Simulation of Propylene Polymerization in Nonideal Loop ReactorsDocument13 pagesAIChE Journal Volume 49 Issue 10 2003 (Doi 10.1002/aic.690491017) A. S. Reginato J. J. Zacca A. R. Secchi - Modeling and Simulation of Propylene Polymerization in Nonideal Loop Reactorsreclatis14No ratings yet

- Bently Nevada Day - Bolivia - 3500 PDFDocument21 pagesBently Nevada Day - Bolivia - 3500 PDFreclatis14No ratings yet

- Nik Nad Daf 2013Document13 pagesNik Nad Daf 2013reclatis14No ratings yet

- Saheb Del Far 2012Document8 pagesSaheb Del Far 2012reclatis14No ratings yet

- Far Joo 2011Document7 pagesFar Joo 2011reclatis14No ratings yet

- Somche 2014 - 2 - 2015 - 048 - 061Document15 pagesSomche 2014 - 2 - 2015 - 048 - 061reclatis14No ratings yet

- Granato 2007Document7 pagesGranato 2007reclatis14No ratings yet

- Du 2015Document15 pagesDu 2015reclatis14No ratings yet

- Alsha Iban 2009Document15 pagesAlsha Iban 2009reclatis14No ratings yet

- Quiz Science HeatDocument3 pagesQuiz Science HeatlinaNo ratings yet

- Sihi Lem 90 - 125 - 150 DetailsDocument4 pagesSihi Lem 90 - 125 - 150 DetailsElmer RchNo ratings yet

- Science TestDocument2 pagesScience TestJeist HideNo ratings yet

- 3.types of Fluids - Properties of Fluids and SelectionDocument3 pages3.types of Fluids - Properties of Fluids and SelectionAnya CooperNo ratings yet

- Reservoir Fluid PropertiesDocument28 pagesReservoir Fluid PropertiesSafwan NasirNo ratings yet

- Antacid - Film Canister LabDocument2 pagesAntacid - Film Canister LabTanish bossNo ratings yet

- Sodium Percarbonate DecompositionDocument10 pagesSodium Percarbonate DecompositionaleksovNo ratings yet

- BearingDocument11 pagesBearingThanh Luan NguyenNo ratings yet

- Redlich-Kister EquationDocument6 pagesRedlich-Kister EquationVatsal ShahNo ratings yet

- Pharmaceutical AerosolsDocument54 pagesPharmaceutical Aerosolsabdullah2020No ratings yet

- University of Cambridge International Examinations International General Certificate of Secondary EducationDocument20 pagesUniversity of Cambridge International Examinations International General Certificate of Secondary EducationKim Yen GohNo ratings yet

- APPENDIX SLB PUMP-dirotasiDocument60 pagesAPPENDIX SLB PUMP-dirotasiadhitya suzari putraNo ratings yet

- 1Document6 pages1Kuo Garol SarongNo ratings yet

- Laboratory Investigation of Enhanced Light-Oil Recovery by CO /flue Gas Huff-n-Puff ProcessDocument9 pagesLaboratory Investigation of Enhanced Light-Oil Recovery by CO /flue Gas Huff-n-Puff Processjrluva096No ratings yet

- CH 23 Thermal Questions - KEYDocument3 pagesCH 23 Thermal Questions - KEYShe DilNo ratings yet

- Surface TenaiomDocument27 pagesSurface TenaiomBishnu PoudelNo ratings yet

- 07061-Company brochureCZ - ENG - Full PDFDocument72 pages07061-Company brochureCZ - ENG - Full PDFJan PaloučekNo ratings yet

- Phy CHP 4 f4 Revision 1Document5 pagesPhy CHP 4 f4 Revision 1Alexandra ChiengNo ratings yet

- Persian Gum and Xanthan GumDocument11 pagesPersian Gum and Xanthan GumIoana PeptănaruNo ratings yet

- BS en 12595-2014Document22 pagesBS en 12595-2014dipakNo ratings yet

- Leak Calc (Autoguardado)Document9 pagesLeak Calc (Autoguardado)ca_perez75No ratings yet

- Changes in Matter: Department of Mathematics and ScienceDocument20 pagesChanges in Matter: Department of Mathematics and ScienceAsru RojamNo ratings yet

- HCHEM Notes Specific Heat Capacity 3 2Document21 pagesHCHEM Notes Specific Heat Capacity 3 2leimendozaschoolNo ratings yet

- 19xl 3pd PDFDocument38 pages19xl 3pd PDFDione SilvaNo ratings yet

- Material Chap 7Document24 pagesMaterial Chap 7chemicaly12No ratings yet

- Two - Phase Line Sizing GelamDocument5 pagesTwo - Phase Line Sizing GelamElias EliasNo ratings yet

- Advanced Well TestingDocument91 pagesAdvanced Well TestingBendali MehdiNo ratings yet