Professional Documents

Culture Documents

Wps 316L SMAW+GTAW R00

Uploaded by

Richard PeriyanayagamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wps 316L SMAW+GTAW R00

Uploaded by

Richard PeriyanayagamCopyright:

Available Formats

C

D

QA/QC

AL JALHAMI CONT. & Trad. Co.

Page 1 of 2

AL KHAFJI, K.S.A

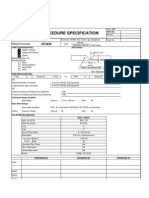

WELDING PROCEDURE SPECIFICATION (WPS) Date: 18/05/2014

Welding procedure specification no. QC/WPS/08 Revision no. 0 Date 18/05/2014

Supporting PQR no. Revision no. Date

Welding process GTAW+SMAW Type(s) MANUAL

CODE: ASME IX API 1104 AWS D1.1 Others (ASME B31.3,B31.4)

BASE METALS (QW-403)

P. No. 8 Group no. 1 to P. No. 8 Group no. 1

Specification type and grade A312, TP316/316L or EQUIVALENT

To specification type and grade A312, TP316/316L or EQUIVALENT

Or

Chemical Analysis and Mech. Prop.

To Chemical Analysis and Mech. Prop.

Thickness Range:

Base Metal Groove 1.5mm 21.94 mm Fillet Unlimited

Pipe Dia. Range Groove All Fillet Unlimited

Other Deposited Weld metal thickness range: GTAW: Max. 8.4mm, SMAW: Max. 13.54mm

JOINTS (QW-402)

Joint Design Single bevel, V, J, or U groove

Backing Gas backing Type Argon, 99.9%

Details

A 35 2

B 10.97

C 1.5 0.5

D 3.2 0.8

FILLER METALS (QW-404)

F. No. GTAW: 6, SMAW: 4 Other None A. No. 8 Other none

Spec No. (SFA) GTAW: 5.9, SMAW: 5.4

AWS No. (Class) ER316L / E316-16

Size of filler metals GTAW: 2.4mm, SMAW: 2.4mm & 3.2mm

Electrode flux (class) N/A

Consumable insert

N/A

TECHNICAL APPROVAL

Prepared by

Al JALHAMI CONT. & TRAD. CO.

Approved by KJO(AGOC/KGOC)

Signature Signature

Date Date

A

B

All Dimensions are in mm

QA/QC

AL JALHAMI CONT. & Trad. Co.

Page 2 of 2

AL KHAFJI, K.S.A

WELDING PROCEDURE SPECIFICATION (WPS) Date: 18/02/2014

POSITION (QW-405) POST WELD HEAT TREATMENT (QW-407)

POSITION(S) or groove All Positions Temperature range None

Welding progression Up Down Time range N/A

position(s) of Fillet All Positions Heating rate N/A cooling rate N/A

PREHEAT (QW-406) GAS (QW-408)

Preheat Temp. min. 10C Shielding gas(es) Argon

Interpass Temp. max. 250C % composition

(mixtures)

99.9%

Preheat maintenamce N/A Flow rate lp

Gas backing 5 10 lpm

Trailing shielding gas

composition

N/A

* Gas purging should be done until hot pass is completed

TECHNIQUE (QW-410)

String or Weaving Bead Root: String, Fill/Cap: Weave Max. weave width 3 times of core wire dia.

Orifice or Gas Cup Size N/A

Initial And Interpass Cleaning Brushing and/or Grinding

Method of Back Gouging N/A

Oscillation N/A

Contact Tube to Work Distance N/A

Multiple or Single Pass (Per Side) Multiple

Multiple or Single Electrodes Single

Travel Speed (Range) 90 120 mm/min

Peening N/A

Other N/A

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC DC Polarity GTAW : EN, SMAW: EP

AMPS (range) 90 to 180 Amps Volt(range) 15 - 35 Volts

Tungsten electrode size and type 2.4 mm, EWTH - 2% Thoriated

Mode of metal transfer for GMAW N/A

Electrode wire feed speed range N/A

Weld

Layer

Process

Filler

metal

Current Volt

range

Travel

speed

(mm/min)

Other

Class Dia. (mm) Type Amp

Root GTAW ER70S-2 2.4 DCEN 80-115 15 - 20 90 - 120

Hot GTAW ER70S-2 2.4 DCEN 95-120 18 - 27 90 - 120

Fill SMAW E316-16 3.2 DCEP 90-120 23 - 35 70 - 90

Cap SMAW E316-16 2.4 DCEP 70-120 20 - 32 100 -120

You might also like

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- Saudi Aramco Piping QC Inspector Sample Interview QuestionsDocument6 pagesSaudi Aramco Piping QC Inspector Sample Interview QuestionsRichard Periyanayagam100% (3)

- Wps For SS 304Document3 pagesWps For SS 304MuraliKrishna87% (23)

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- Wps SawDocument2 pagesWps Sawdevendrasingh2021100% (6)

- Quality Control QuestionerDocument31 pagesQuality Control QuestionerKaukab Imam88% (42)

- Sa 516 GR 70 WPSDocument5 pagesSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- WPS PQR-01Document9 pagesWPS PQR-01Ranjan Kumar0% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- WPS MigDocument3 pagesWPS MigAJOJOY00960% (5)

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline SungahidNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamNo ratings yet

- WpsDocument6 pagesWpsabhishek198327No ratings yet

- Wps Gtaw Monel b127 b164Document2 pagesWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- WPSDocument2 pagesWPSJuli Agus50% (2)

- Piping Inspector QuestionsDocument10 pagesPiping Inspector QuestionsRichard Periyanayagam100% (1)

- Passat No. 13/1: Comfort System, With Alarm SystemDocument16 pagesPassat No. 13/1: Comfort System, With Alarm SystemLuix TiradoNo ratings yet

- The Principles of Pulp Washing - PdfaDocument9 pagesThe Principles of Pulp Washing - Pdfashabi049No ratings yet

- DC Rectifier - OrionDocument12 pagesDC Rectifier - OrionLimbagaNo ratings yet

- Enzymes and Effects of PHDocument4 pagesEnzymes and Effects of PHSeph Cordova50% (2)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- WPS GmawDocument2 pagesWPS Gmawasikur100% (6)

- Wps 316L Gtaw R00Document3 pagesWps 316L Gtaw R00Richard Periyanayagam100% (3)

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)Senthil KumaranNo ratings yet

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNo ratings yet

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Sample WPS SMAW Stainless SteelDocument7 pagesSample WPS SMAW Stainless Steeldaemsal100% (4)

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- PQR SAW ProcessDocument1 pagePQR SAW Processdevendrasingh202133% (3)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- PWPS - GTSM-73 Rev-ADocument5 pagesPWPS - GTSM-73 Rev-AVimin PrakashNo ratings yet

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- SS312 Type310Document4 pagesSS312 Type310Vimin PrakashNo ratings yet

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- Welding Procedure Specification: Technip KT India LimitedDocument5 pagesWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- Des QC 8505 Ab 08Document3 pagesDes QC 8505 Ab 08Touseef RafiqueNo ratings yet

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Document24 pagesPrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNo ratings yet

- WPS - 004Document12 pagesWPS - 004MAT-LIONNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Request For Inspection: Saudi Aramco Project Inspection Division Inspection DepartmentDocument1 pageRequest For Inspection: Saudi Aramco Project Inspection Division Inspection DepartmentRichard Periyanayagam100% (1)

- Some Imp NotesDocument5 pagesSome Imp NotesRichard PeriyanayagamNo ratings yet

- Twi India Cswip Fee 2017Document4 pagesTwi India Cswip Fee 2017kamal100% (1)

- Piping Engineer 2019Document2 pagesPiping Engineer 2019Richard PeriyanayagamNo ratings yet

- Piping Engineer 2019Document8 pagesPiping Engineer 2019Richard PeriyanayagamNo ratings yet

- What Is QualityDocument3 pagesWhat Is Qualitysubhash kumar1958100% (2)

- PT Request28janDocument3 pagesPT Request28janRichard PeriyanayagamNo ratings yet

- Yearly Prayer TimesDocument2 pagesYearly Prayer TimesRichard PeriyanayagamNo ratings yet

- Aramco Questions. Coating & WeldingDocument1 pageAramco Questions. Coating & WeldingRichard Periyanayagam100% (1)

- Cause Effect Analysis PDFDocument1 pageCause Effect Analysis PDFRichard PeriyanayagamNo ratings yet

- Daily Fit-Up/Welding Inspection ReportDocument7 pagesDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamNo ratings yet

- Request For Inspection: Rfi No: Abis-Mech-Yr/72Document7 pagesRequest For Inspection: Rfi No: Abis-Mech-Yr/72Richard PeriyanayagamNo ratings yet

- Cleartrip Flight E-TicketDocument1 pageCleartrip Flight E-TicketRichard PeriyanayagamNo ratings yet

- 26jan Prodn ReportDocument23 pages26jan Prodn ReportRichard PeriyanayagamNo ratings yet

- Abdullah A. Al Barrak & Sons Co.: Inspection Work Sheet (IWS) For Monomer and Polymer AreaDocument1 pageAbdullah A. Al Barrak & Sons Co.: Inspection Work Sheet (IWS) For Monomer and Polymer AreaRichard PeriyanayagamNo ratings yet

- (If Applicable) : NON Conformance Report/ Corrective Preventive Action RequestDocument1 page(If Applicable) : NON Conformance Report/ Corrective Preventive Action RequestRichard Periyanayagam100% (1)

- Safco Welding SummryDocument148 pagesSafco Welding SummryRichard PeriyanayagamNo ratings yet

- Welders Continuity Nov.23 NEWDocument79 pagesWelders Continuity Nov.23 NEWRichard PeriyanayagamNo ratings yet

- Appendix B - InsulationDocument9 pagesAppendix B - InsulationWaseem YounisNo ratings yet

- Pmirequest 11febDocument8 pagesPmirequest 11febRichard PeriyanayagamNo ratings yet

- Daily Fit-Up/Welding Inspection ReportDocument7 pagesDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamNo ratings yet

- QC Masterlist HadeedDocument8 pagesQC Masterlist HadeedRichard PeriyanayagamNo ratings yet

- Qa/Qc Dossier Qa/Qc Dossier: VOL: 1 - 5 VOL: 2 - 5Document3 pagesQa/Qc Dossier Qa/Qc Dossier: VOL: 1 - 5 VOL: 2 - 5Richard PeriyanayagamNo ratings yet

- Exit LetterDocument1 pageExit LetterRichard PeriyanayagamNo ratings yet

- Application 4of4Document1 pageApplication 4of4Richard PeriyanayagamNo ratings yet

- 6.5exit Letter PDFDocument1 page6.5exit Letter PDFRichard PeriyanayagamNo ratings yet

- DAY Monday Tuesday Wednesday Thursday Friday: Hinigaran National High SchoolDocument10 pagesDAY Monday Tuesday Wednesday Thursday Friday: Hinigaran National High SchoolHelen LaurelNo ratings yet

- Working of Steam Turbine Learn EngineeringDocument4 pagesWorking of Steam Turbine Learn EngineeringWahid HusainNo ratings yet

- Modulation Reviewer For ECEDocument171 pagesModulation Reviewer For ECEianneanNo ratings yet

- Amyuni PDF ConverterDocument22 pagesAmyuni PDF ConverterMikeyarnoldNo ratings yet

- Important RCC Questions-Short and LongDocument15 pagesImportant RCC Questions-Short and LongmailjoelsamuelNo ratings yet

- KSB KWP: Non-Clogging Centrifugal PumpsDocument12 pagesKSB KWP: Non-Clogging Centrifugal PumpsalfredNo ratings yet

- Base Plate and Anchor Rod DesignDocument2 pagesBase Plate and Anchor Rod DesignKannan MurugesanNo ratings yet

- Auto Plin Schema Zapojeni Prepinace Autronic As 101Document28 pagesAuto Plin Schema Zapojeni Prepinace Autronic As 101Tom TalicniNo ratings yet

- A Primer On Spray Drying Chemical Engineering Nov09Document7 pagesA Primer On Spray Drying Chemical Engineering Nov09Hikmah Triana HadiNo ratings yet

- Software Engineering EconomicsDocument4 pagesSoftware Engineering Economicsazam_rasheed50% (2)

- Gopez Wood Craft Spot Rep Feb 06, 2022Document2 pagesGopez Wood Craft Spot Rep Feb 06, 2022Eller-Jed Manalac MendozaNo ratings yet

- Makalah Program PDFDocument10 pagesMakalah Program PDFIvanFolkNo ratings yet

- Free Gear Calculator - KHK GearsDocument5 pagesFree Gear Calculator - KHK GearslawlawNo ratings yet

- Sec1 1 1Document2 pagesSec1 1 1rajfmc100% (1)

- FORM Inspection Test Plan MMPDocument8 pagesFORM Inspection Test Plan MMPRicky Stormbringer ChristianNo ratings yet

- Cored Wires - ESAB - OK TubrodDocument87 pagesCored Wires - ESAB - OK TubrodElias KapaNo ratings yet

- LY IR9000 BGA Rework Station User GuideDocument4 pagesLY IR9000 BGA Rework Station User GuidemariabaccaroNo ratings yet

- Power Tool Switches: Catalog 1308650 Issued 1-01Document18 pagesPower Tool Switches: Catalog 1308650 Issued 1-01Gamal AhmadNo ratings yet

- Grinding Polishing: Kiesow Dr. BrinkmannDocument36 pagesGrinding Polishing: Kiesow Dr. BrinkmannChoice OrganoNo ratings yet

- Maryland Institute of Technology and Management, Jamshedpur Theory of Machine-Module: IIIDocument12 pagesMaryland Institute of Technology and Management, Jamshedpur Theory of Machine-Module: IIISourabh PradhanNo ratings yet

- CS 450 Assignment 5 SolutionsDocument3 pagesCS 450 Assignment 5 Solutionshidrovo3589No ratings yet

- 122Document10 pages122Bayangan HatiNo ratings yet

- Basics of CT and PTDocument15 pagesBasics of CT and PTanamika1690% (1)

- Behringer EPR900 Powered Speaker SchematicsDocument14 pagesBehringer EPR900 Powered Speaker SchematicsJimNo ratings yet

- Pds Microstran LTR en LRDocument2 pagesPds Microstran LTR en LRthaoNo ratings yet

- Tabl Navegacion Aqua SignalDocument4 pagesTabl Navegacion Aqua SignalNelson Aguirre BravoNo ratings yet