Professional Documents

Culture Documents

Fallo de Fatiga

Uploaded by

Peio GilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fallo de Fatiga

Uploaded by

Peio GilCopyright:

Available Formats

Ken Youssefi

MAE dept., SJSU

1

It has been recognized that a metal subjected

to a repetitive or fluctuating stress will fail at a

stress much lower than that required to cause

failure on a single application of load. Failures

occurring under conditions of dynamic loading

are called fatigue failures.

Fatigue Failure

Fatigue failure is characterized by three stages

Crack Initiation

Crack Propagation

Final Fracture

Ken Youssefi

MAE dept., SJSU

2

Jack hammer component,

shows no yielding before

fracture.

Crack initiation site

Fracture zone

Propagation zone, striation

Ken Youssefi

MAE dept., SJSU

3

VW crank shaft fatigue failure due to cyclic bending and torsional stresses

Fracture area

Crack initiation site

Propagation

zone, striations

Ken Youssefi

MAE dept., SJSU

4

928 Porsche timing pulley

Crack started at the fillet

Ken Youssefi

MAE dept., SJSU

5

1.0-in. diameter steel pins from

agricultural equipment.

Material; AISI/SAE 4140 low

allow carbon steel

Fracture surface of a failed bolt. The

fracture surface exhibited beach marks,

which is characteristic of a fatigue failure.

Ken Youssefi

MAE dept., SJSU

6

This long term fatigue crack in a high quality component took a

considerable time to nucleate from a machining mark between the spider

arms on this highly stressed surface. However once initiated propagation

was rapid and accelerating as shown in the increased spacing of the 'beach

marks' on the surface caused by the advancing fatigue crack.

bicycle crank spider arm

Ken Youssefi

MAE dept., SJSU

7

Gear tooth failure

Crank shaft

Ken Youssefi

MAE dept., SJSU

8

Hawaii, Aloha Flight 243, a Boeing 737, an upper part of the plane's cabin

area rips off in mid-flight. Metal fatigue was the cause of the failure.

Ken Youssefi

MAE dept., SJSU

9

Cup and Cone

Dimples

Dull Surface

Inclusion at the bottom of the dimple

Ductile

Fracture Surface Characteristics

Shiny

Grain Boundary cracking

Brittle Intergranular

Shiny

Cleavage fractures

Flat

Brittle Transgranular

Beachmarks

Striations (SEM)

Initiation sites

Propagation zone

Final fracture zone

Fatigue

Mode of fracture Typical surface characteristics

Ken Youssefi

MAE dept., SJSU

10

Fatigue Failure Type of Fluctuating Stresses

a

=

max

min

2

Alternating stress

Mean stress

m

=

max

min

2

+

min

=0

a

=

max

/ 2

m

=

a

=

max

max

=

-

min

Ken Youssefi

MAE dept., SJSU

11

Fatigue Failure, S-N Curve

Test specimen geometry for R.R. Moore

rotating beam machine. The surface is

polished in the axial direction. A constant

bending load is applied.

Motor

Load

Rotating beam machine applies fully reverse bending stress

Typical testing apparatus, pure bending

Ken Youssefi

MAE dept., SJSU

12

The standard machine operates at an

adjustable speed of 500 RPM to

10,000 RPM. At the nominal rate of

10,000 RPM, the R. R. Moore machine

completes 600,000 cycles per hour,

14,400,000 cycles per day.

Bending moment capacity

20 in-lb to 200 in-lb

Ken Youssefi

MAE dept., SJSU

13

Fatigue Failure, S-N Curve

Finite life Infinite life

N < 10

3

N > 10

3

S

e

= endurance limit of the specimen

S

e

Ken Youssefi

MAE dept., SJSU

14

Relationship Between Endurance Limit

and Ultimate Strength

Steel

S

e

=

0.5S

ut

100 ksi

700 MPa

S

ut

200 ksi (1400 MPa)

S

ut

> 200 ksi

S

ut

> 1400 MPa

Steel

0.4S

ut

S

e

=

S

ut

< 60 ksi (400 MPa)

S

ut

60 ksi

24 ksi

160 MPa

S

ut

< 400 MPa

Cast iron

Cast iron

Ken Youssefi

MAE dept., SJSU

15

Relationship Between Endurance Limit and

Ultimate Strength

Aluminum alloys

S

e

=

0.4S

ut

19 ksi

130 MPa

S

ut

< 48 ksi (330 MPa)

S

ut

48 ksi

S

ut

330 MPa

Aluminum

For N = 5x10

8

cycle

Copper alloys

S

e

=

0.4S

ut

14 ksi

100 MPa

S

ut

< 40 ksi (280 MPa)

S

ut

40 ksi

S

ut

280 MPa

Copper alloys

For N = 5x10

8

cycle

Ken Youssefi

MAE dept., SJSU

16

Correction Factors for Specimens Endurance Limit

= endurance limit of the specimen (infinite life > 10

6

)

S

e

For materials exhibiting a knee in the S-N curve at 10

6

cycles

= endurance limit of the actual component (infinite life > 10

6

) S

e

N

S S

e

10

6

10

3

= fatigue strength of the specimen (infinite life > 5x10

8

)

S

f

= fatigue strength of the actual component (infinite life > 5x10

8

)

S

f

For materials that do not exhibit a knee in the S-N curve, the infinite

life taken at 5x10

8

cycles

N

S

S

f

5x10

8

10

3

Ken Youssefi

MAE dept., SJSU

17

Correction Factors for Specimens Endurance Limit

S

e

= C

load

C

size

C

surf

C

temp

C

rel

(S

e

)

Load factor, C

load

(page 326, Nortons 3

rd

ed.)

Pure bending

C

load

= 1

Pure axial

C

load

= 0.7

Combined loading

C

load

= 1

Pure torsion

C

load

= 1 if von Mises stress is used, use

0.577 if von Mises stress is NOT used.

S

f

= C

load

C

size

C

surf

C

temp

C

rel

(S

f

)

or

Ken Youssefi

MAE dept., SJSU

18

Correction Factors for Specimens Endurance Limit

Size factor, C

size

(p. 327, Nortons 3

rd

ed.)

Larger parts fail at lower stresses than smaller parts. This is

mainly due to the higher probability of flaws being present in

larger components.

For rotating solid round cross section

d 0.3 in. (8 mm) C

size

= 1

0.3 in. < d 10 in. C

size

= .869(d)

-0.097

8 mm < d 250 mm C

size

= 1.189(d)

-0.097

If the component is larger than 10 in., use C

size

= .6

Ken Youssefi

MAE dept., SJSU

19

Correction Factors for Specimens Endurance Limit

For non rotating components, use the 95% area approach to calculate

the equivalent diameter. Then use this equivalent diameter in the

previous equations to calculate the size factor.

d

equiv

= (

A

95

0.0766

)

1/2

d

d

95

= .95d

A

95

= (/4)[d

2

(.95d)

2

] = .0766 d

2

d

equiv

= .37d

Solid or hollow non-rotating parts

d

equiv

= .808 (bh)

1/2

Rectangular parts

Ken Youssefi

MAE dept., SJSU

20

Correction Factors for Specimens Endurance Limit

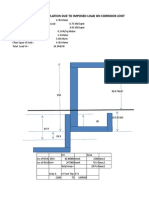

I beams and C channels

Ken Youssefi

MAE dept., SJSU

21

Correction Factors for Specimens Endurance Limit

surface factor, C

surf

(p. 328-9, Nortons 3

rd

ed.)

The rotating beam test specimen has a polished surface. Most

components do not have a polished surface. Scratches and

imperfections on the surface act like a stress raisers and reduce

the fatigue life of a part. Use either the graph or the equation with

the table shown below.

C

surf

= A (S

ut

)

b

Ken Youssefi

MAE dept., SJSU

22

Correction Factors for Specimens Endurance Limit

Temperature factor, C

temp

(p.331, Nortons 3

rd

ed.)

High temperatures reduce the fatigue life of a component. For

accurate results, use an environmental chamber and obtain the

endurance limit experimentally at the desired temperature.

For operating temperature below 450

o

C (840

o

F) the

temperature factor should be taken as one.

C

temp

= 1 for T 450

o

C (840

o

F)

Ken Youssefi

MAE dept., SJSU

23

Correction Factors for Specimens Endurance Limit

Reliability factor, C

rel

(p. 331, Nortons 3

rd

ed.)

The reliability correction factor accounts for the scatter and

uncertainty of material properties (endurance limit).

Ken Youssefi

MAE dept., SJSU

24

Fatigue Stress Concentration Factor, K

f

Experimental data shows that the actual stress concentration factor is not as

high as indicated by the theoretical value, K

t

. The stress concentration factor

seems to be sensitive to the notch radius and the ultimate strength of the

material.

(p. 340, Nortons 3

rd

ed.)

Steel

K

f

= 1 + (K

t

1)q

Notch sensitivity factor

Fatigue stress

concentration factor

Ken Youssefi

MAE dept., SJSU

25

Fatigue Stress

Concentration Factor,

q for Aluminum

(p. 341, Nortons 3

rd

ed.)

Ken Youssefi

MAE dept., SJSU

26

Design process Fully Reversed Loading for Infinite Life

Determine the maximum alternating applied stress (

a

) in terms of

the size and cross sectional profile

Select material S

y

, S

ut

Use the design equation to calculate the size

S

e

K

f

a

=

n

Choose a safety factor n

Determine all modifying factors and calculate the endurance

limit of the component S

e

Determine the fatigue stress concentration factor, K

f

Investigate different cross sections (profiles), optimize for size or weight

You may also assume a profile and size, calculate the alternating stress

and determine the safety factor. Iterate until you obtain the desired

safety factor

Ken Youssefi

MAE dept., SJSU

27

Design for Finite Life

S

n

= a (N)

b

equation of the fatigue line

N

S

S

e

10

6

10

3

A

B

N

S

S

f

5x10

8

10

3

A

B

Point A

S

n

= .9S

ut

N = 10

3

Point A

S

n

= .9S

ut

N = 10

3

Point B

S

n

= S

f

N = 5x10

8

Point B

S

n

= S

e

N = 10

6

Ken Youssefi

MAE dept., SJSU

28

Design for Finite Life

S

n

= a (N)

b

log S

n

= log a + b log N

Apply boundary conditions for point A and B to

find the two constants a and b

log .9S

ut

= log a + b log 10

3

log S

e

= log a + b log 10

6

a

=

(.9S

ut

)

2

S

e

b

=

.9S

ut

S

e

1

3

log

S

n

K

f

a

=

n

Design equation

Calculate S

n

and replace S

e

in the design equation

S

n

=

S

e

(

N

10

6

)

(

S

e

.9S

ut

)

log

Ken Youssefi

MAE dept., SJSU

29

The Effect of Mean Stress on Fatigue Life

Mean stress exist if the

loading is of a repeating or

fluctuating type.

Mean stress

Alternating

stress

a

S

e

S

y

Soderberg line

S

ut

Goodman line

Gerber curve

Mean stress is not zero

Ken Youssefi

MAE dept., SJSU

30

The Effect of Mean Stress on Fatigue Life

Modified Goodman Diagram

Mean stress

Alternating

stress

a

S

ut

Goodman line

S

y

S

y

S

e

Safe zone

C

Yield line

Ken Youssefi

MAE dept., SJSU

31

- S

yc

The Effect of Mean Stress on Fatigue Life

Modified Goodman Diagram

+

m

a

S

ut

Goodman line

S

y

Yield line

Safe zone

-

m

C

S

y

S

e

Safe zone

Ken Youssefi

MAE dept., SJSU

32

The Effect of Mean Stress on Fatigue Life

Modified Goodman Diagram

+

m

a

S

ut

Safe zone

-

m

C

S

y

Safe zone

S

e

- S

yc

Finite life

S

n

1 =

S

ut

m

+

Fatigue,

m

>0

Fatigue,

m

0

a

=

S

e

n

f

a

+

m

=

S

yc

n

y

Yield

a

+

m

=

S

y

n

y

Yield

n

f

S

e

1

=

S

ut

m

+

Infinite life

Ken Youssefi

MAE dept., SJSU

33

Applying Stress Concentration factor to Alternating

and Mean Components of Stress

Determine the fatigue stress concentration factor, K

f

, apply directly to

the alternating stress K

f

a

If K

f

max

<S

y

then there is no yielding at the notch, use K

fm

= K

f

and multiply the mean stress by K

fm

K

fm

m

If K

f

max

>S

y

then there is local yielding at the notch, material at the

notch is strain-hardened. The effect of stress concentration is reduced.

Calculate the stress concentration factor for the mean stress using

the following equation,

K

fm

=

S

y

K

f

a

m

n

f

S

e

1

=

S

ut

K

f

a

K

fm

m

+

Infinite life

Fatigue design equation

Ken Youssefi

MAE dept., SJSU

34

Combined Loading

All four components of stress exist,

xa

alternating component of normal stress

xm

mean component of normal stress

xya

alternating component of shear stress

xym

mean component of shear stress

Calculate the alternating and mean principal stresses,

1a

,

2a

= (

xa

/2) (

xa

/2)

2

+ (

xya

)

2

1m

,

2m

= (

xm

/2) (

xm

/2)

2

+ (

xym

)

2

Ken Youssefi

MAE dept., SJSU

35

Combined Loading

Calculate the alternating and mean von Mises stresses,

a

= (

1a

+

2a

-

1a

2a

)

1/2

2 2

m

= (

1m

+

2m

-

1m

2m

)

1/2

2 2

Fatigue design equation

n

f

S

e

1

=

S

ut

m

+ Infinite life

Ken Youssefi

MAE dept., SJSU

36

Design Example

R

1 R

2

10,000 lb.

6 6

12

D = 1.5d d

r (fillet radius) = .1d

A rotating shaft is carrying 10,000 lb force

as shown. The shaft is made of steel with

S

ut

= 120 ksi and S

y

= 90 ksi. The shaft

is rotating at 1150 rpm and has a

machine finish surface. Determine the

diameter, d, for 75 minutes life. Use

safety factor of 1.6 and 50% reliability.

Calculate the support forces, R

1

= 2500, R

2

= 7500 lb.

A

The critical location is at the fillet, M

A

= 2500 x 12 = 30,000 lb-in

a

=

Calculate the alternating stress,

Mc

I

=

32M

d

3

=

305577

d

3

m

= 0

Determine the stress concentration factor

r

d

= .1

D

d

= 1.5

K

t

= 1.7

Ken Youssefi

MAE dept., SJSU

37

Design Example

Assume d = 1.0 in

Using r = .1 and S

ut

= 120 ksi,

q (notch sensitivity) = .85

K

f

= 1 + (K

t

1)q = 1 + .85(1.7 1) = 1.6

Calculate the endurance limit

C

load

= 1 (pure bending)

C

rel

= 1 (50% rel.)

C

temp

= 1 (room temp)

C

surf

= A (S

ut

)

b

= 2.7(120)

-.265

= .759

0.3 in. < d 10 in. C

size

= .869(d)

-0.097

= .869(1)

-0.097

= .869

S

e

= C

load

C

size

C

surf

C

temp

C

rel

(S

e

) = (.759)(.869)(.5x120) = 39.57 ksi

Ken Youssefi

MAE dept., SJSU

38

Design Example

Design life, N = 1150 x 75 = 86250 cycles

S

n

=

S

e

(

N

10

6

)

(

S

e

.9S

ut

)

log

S

n

=

39.57

(

86250

10

6

)

(

39.57

.9x120

) log

= 56.5 ksi

a

=

305577

d

3

= 305.577 ksi

n =

S

n

K

f

a

=

56.5

1.6x305.577

= .116 < 1.6

So d = 1.0 in. is too small

Assume d = 2.5 in

All factors remain the same except the size factor and notch sensitivity.

Using r = .25 and S

ut

= 120 ksi,

q (notch sensitivity) = .9

K

f

= 1 + (K

t

1)q = 1 + .9(1.7 1) = 1.63

C

size

= .869(d)

-0.097

= .869(2.5)

-0.097

= .795

S

e

= 36.2 ksi

Ken Youssefi

MAE dept., SJSU

39

Design Example

a

=

305577

(2.5)

3

= 19.55 ksi

n =

S

n

K

f

a

=

53.35

1.63x19.55

= 1.67 1.6

d = 2.5 in.

Check yielding

n =

S

y

K

f

max

=

90

1.63x19.55

= 2.8 > 1.6 okay

S

e

= 36.2 ksi

S

n

=

36.20

(

86250

10

6

)

(

36.2

.9x120

) log

= 53.35 ksi

Ken Youssefi

MAE dept., SJSU

40

Design Example Observations

n =

S

n

K

f

a

=

56.5

1.6x305.577

= .116 < 1.6

So d = 1.0 in. is too small

Calculate an approximate diameter

n =

S

n

K

f

a

=

56.5

1.6x305.577/d

3

= 1.6 d = 2.4 in.

So, your next guess

should be between

2.25 to 2.5

M

max

(under the load) = 7500 x 6 = 45,000 lb-in

Check the location of maximum moment for possible failure

R

1 R

2

= 7500

6 6

12

D = 1.5d d

r (fillet radius) = .1d

A

M

A

(at the fillet) = 2500 x 12 = 30,000 lb-in

But, applying the fatigue stress conc. Factor of 1.63,

K

f

M

A

= 1.63x30,000 = 48,900 > 45,000

Ken Youssefi

MAE dept., SJSU

41

Example

A section of a component is shown.

The material is steel with S

ut

= 620 MPa

and a fully corrected endurance limit of

S

e

= 180 MPa. The applied axial load

varies from 2,000 to 10,000 N. Use

modified Goodman diagram and find

the safety factor at the fillet A, groove B

and hole C. Which location is likely to

fail first? Use K

fm

= 1

P

a

= (P

max

P

min

) / 2 = 4000 N

P

m

= (P

max

+ P

min

) / 2 = 6000 N

Fillet

r

d

= .16

D

d

= 1.4

4

25

=

35

25

=

K

t

= 1.76

Ken Youssefi

MAE dept., SJSU

42

Example

K

f

= 1 + (K

t

1)q = 1 + .85(1.76 1) = 1.65

Calculate the alternating and the

mean stresses,

a

=

P

a

A

=

4000

25x5

= 52.8 MPa K

f

1.65

m

=

P

m

A

=

6000

25x5

= 48 MPa

n

S

e

1

=

S

ut

m

+

Infinite life

Fatigue design equation

n = 2.7

n

180

1

=

620

52.8 48

+

Using r = 4 and S

ut

= 620 MPa,

q (notch sensitivity) = .85

Ken Youssefi

MAE dept., SJSU

43

Example

Hole

d

w

= .143

5

35

=

K

t

= 2.6

Using r = 2.5 and S

ut

= 620 MPa,

q (notch sensitivity) = .82

K

f

= 1 + (K

t

1)q = 1 + .82(2.6 1) = 2.3

Calculate the alternating and the

mean stresses,

a

=

P

a

A

=

4000

(35-5)5

= 61.33 MPa K

f

2.3

m

=

P

m

A

=

6000

30x5

= 40 MPa

n = 2.5

n

180

1

=

620

61.33 40

+

Ken Youssefi

MAE dept., SJSU

44

Example

Groove

r

d

= .103

D

d

= 1.2

3

29

=

35

29

=

K

t

= 2.33

Using r = 3 and S

ut

= 620 MPa,

q (notch sensitivity) = .83

K

f

= 1 + (K

t

1)q = 1 + .83(2.33 1) = 2.1

(35-6)5

Calculate the alternating and the

mean stresses,

a

=

P

a

A

=

4000

= 58.0 MPa K

f

2.1

m

=

P

m

A

=

6000

29x5

= 41.4 MPa

n = 2.57

n

180

1

=

620

58.0 41.4

+

The part is likely to fail at the hole, has the lowest safety factor

Ken Youssefi

MAE dept., SJSU

45

Example

F

a

= (F

max

F

min

) / 2 = 7.5 lb. F

m

= (F

max

+ F

min

) / 2 = 22.5 lb.

The figure shows a formed round wire cantilever

spring subjected to a varying force F. The wire is

made of steel with S

ut

= 150 ksi. The mounting

detail is such that the stress concentration could

be neglected. A visual inspection of the spring

indicates that the surface finish corresponds

closely to a hot-rolled finish. For a reliability of

99%, what number of load applications is likely to

cause failure.

M

a

= 7.5 x 16 = 120 in - lb M

m

= 22.5 x 16 = 360 in - lb

a

=

Mc

I

=

32M

a

d

3

=

32(120)

(.375)

3

= 23178.6 psi

m

=

Mc

I

=

32M

m

d

3

=

32(360)

(.375)

3

= 69536 psi

Ken Youssefi

MAE dept., SJSU

46

Example

C

load

= 1 (pure bending)

C

temp

= 1 (room temp)

Calculate the endurance limit

C

rel

= .814 (99% reliability)

C

surf

= A (S

ut

)

b

= 14.4(150)

-.718

= .394

A

95

= .010462 d

2

(non-rotating round section)

d

equiv

= A

95

/ .0766 = .37d = .37 x.375 = .14

d

equiv

= .14 < .3 C

size

= 1.0

S

e

= C

load

C

size

C

surf

C

temp

C

rel

(S

e

) = (.394)(.814)(.5x150) = 24.077 ksi

n

S

e

1

=

S

ut

m

+

n

24077

1

=

150000

23178.6

69536

+

n = .7 < 1

Finite life

S

n

1 =

S

ut

m

+

Find S

n

, strength for finite number of cycle

S

n

1 =

150000

23178.6

69536

+

S

n

= 43207 psi

Ken Youssefi

MAE dept., SJSU

47

Example

S

n

=

S

e

(

N

10

6

)

(

S

e

.9S

ut

)

log

43207 =

24077

(

N

10

6

)

(

24.077

.9x150

) log

N = 96,000 cycles

You might also like

- Fracture and FatigueDocument15 pagesFracture and FatigueZou JiaweiNo ratings yet

- Gear Force & StressDocument30 pagesGear Force & StressRanjeethkumar JalalNo ratings yet

- ME 322 - Partial notes – Part 4 (FatigueDocument70 pagesME 322 - Partial notes – Part 4 (FatigueNirmalya MishraNo ratings yet

- Fracture MechanicsDocument5 pagesFracture MechanicsShashishekarayya HiremathNo ratings yet

- Rayleigh Damping PDFDocument9 pagesRayleigh Damping PDFmattilandNo ratings yet

- Mechanical Springs: Exert Force. Provide Flexibility. Store or Absorb EnergyDocument68 pagesMechanical Springs: Exert Force. Provide Flexibility. Store or Absorb EnergyOtis Chu100% (1)

- md-8 Spring DesignDocument8 pagesmd-8 Spring DesignBharatiyulamNo ratings yet

- Fatigue Ch12Document87 pagesFatigue Ch12Bolaji Suberu100% (1)

- Unit IV Theories of Failure: Introduction: Due To Large Numbers of Examples of Compound Stresses MetDocument23 pagesUnit IV Theories of Failure: Introduction: Due To Large Numbers of Examples of Compound Stresses MetMohtasham NaeemNo ratings yet

- 7.IITD 2012 Theory of VibrationDocument9 pages7.IITD 2012 Theory of Vibrationlaith adnanNo ratings yet

- 1 ADocument27 pages1 AAtilio Suàrez BardellineNo ratings yet

- SpringsDocument7 pagesSpringsMd. Sazzad HossenNo ratings yet

- Spring DesignDocument26 pagesSpring DesignNeelkanth BenadeNo ratings yet

- Ansys Analysis-Trolley Beam 3T1Document13 pagesAnsys Analysis-Trolley Beam 3T1Ye Wint ThuNo ratings yet

- COMSOL Cohesive Zone DebondingDocument22 pagesCOMSOL Cohesive Zone DebondingAaqib AliNo ratings yet

- Fatigue FailureDocument22 pagesFatigue FailureHimanshu YadavNo ratings yet

- ME 550 Problem Sheet-03-Lift and DragDocument1 pageME 550 Problem Sheet-03-Lift and DragDeepak RajpurohitNo ratings yet

- Machine Design 4th Edn Norton PDFDocument1,269 pagesMachine Design 4th Edn Norton PDFhaiter paredes100% (1)

- Strain EnergyDocument34 pagesStrain EnergyPrakhar SrivastavaNo ratings yet

- 2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFDocument12 pages2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFvlad lupasteanuNo ratings yet

- Von MisesDocument8 pagesVon MisesAlex OliveiraNo ratings yet

- Strength of Material CE8395 - Formula and Short NotesDocument20 pagesStrength of Material CE8395 - Formula and Short Notesvijayan R100% (3)

- Keys & SplinesDocument51 pagesKeys & SplinesDr_M_Soliman100% (2)

- A Material Model For Flexural Crack Simulation in Reinforced Concrete Elements Using AbaqusDocument5 pagesA Material Model For Flexural Crack Simulation in Reinforced Concrete Elements Using AbaqusBala SubramanianNo ratings yet

- Fatigue PDFDocument8 pagesFatigue PDFflorinelvvNo ratings yet

- Fatigue Analysis of Leaf SpringDocument14 pagesFatigue Analysis of Leaf SpringylionkingxNo ratings yet

- Helical Spring Design - Static LoadDocument25 pagesHelical Spring Design - Static Loadjitinm007No ratings yet

- Deflection Calculation Due To Imposed Load On Corridor JoistDocument14 pagesDeflection Calculation Due To Imposed Load On Corridor JoistranjitNo ratings yet

- Dynamics Machine Vibration ProblemsDocument9 pagesDynamics Machine Vibration ProblemsnikhilasoknNo ratings yet

- SOM - AssignmentsDocument15 pagesSOM - Assignmentssatish448100% (1)

- 4 Failure CriteriaDocument43 pages4 Failure Criteriaali381No ratings yet

- Design Against Fluctuating Loads of Helical SpringsDocument29 pagesDesign Against Fluctuating Loads of Helical SpringsVikranth Deepak100% (1)

- In Axial Loading: Types StressDocument6 pagesIn Axial Loading: Types StressPaúlNinaquispeNo ratings yet

- Miners RuleDocument2 pagesMiners Ruleபிரபாகரன் ஆறுமுகம்No ratings yet

- Poisson'S Ratio Biaxial and Triaxial DeformationDocument8 pagesPoisson'S Ratio Biaxial and Triaxial DeformationRyan Jhay YangNo ratings yet

- Strength of LugDocument8 pagesStrength of LugnareniviNo ratings yet

- Subroutine For Cohesive ElementDocument41 pagesSubroutine For Cohesive ElementBhushanRaj100% (1)

- NCKU Advanced Mechanics Homework #1 Stress ProblemsDocument3 pagesNCKU Advanced Mechanics Homework #1 Stress ProblemsNaveen RajNo ratings yet

- 7 Christian Gaier Multi Axial Fatigue Analysis With The Fe Post Processor Femfat Utmis 2010Document50 pages7 Christian Gaier Multi Axial Fatigue Analysis With The Fe Post Processor Femfat Utmis 2010ashish38799100% (2)

- Spur Gear Design by IIT MadrasDocument28 pagesSpur Gear Design by IIT MadrasC.S.ABHILASHNo ratings yet

- Fatigue Strength PDFDocument11 pagesFatigue Strength PDFVinayak Rao100% (1)

- Lecture 4-Gears - General - 3-L-Spur ForceDocument28 pagesLecture 4-Gears - General - 3-L-Spur ForceAhmed Al SayedNo ratings yet

- Design For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringDocument22 pagesDesign For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringjonNo ratings yet

- NASTRAN Modeling of Composite Bonded Joint DelaminationDocument13 pagesNASTRAN Modeling of Composite Bonded Joint DelaminationAmbalam NandhuNo ratings yet

- C E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural NgineeringDocument27 pagesC E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural Ngineeringhend mahmoudNo ratings yet

- Assignment 2Document2 pagesAssignment 2just0% (2)

- Hertzian ContactDocument5 pagesHertzian ContactGanesh R NavadNo ratings yet

- Failure Analysis of Bolted Steel Flanges PDFDocument6 pagesFailure Analysis of Bolted Steel Flanges PDFmoha100% (1)

- Bevel GearDocument17 pagesBevel Gearparesh09No ratings yet

- Sample Past Paper CVEN2002Document6 pagesSample Past Paper CVEN2002Seanam DMNo ratings yet

- Finite Element Modeling To Verify Residual Stress in Orthogonal Machining PDFDocument124 pagesFinite Element Modeling To Verify Residual Stress in Orthogonal Machining PDF陳國父No ratings yet

- FEA Report PDFDocument24 pagesFEA Report PDFDanish JavedNo ratings yet

- CHAPTER 1 - Introduction To Shell TheoryDocument24 pagesCHAPTER 1 - Introduction To Shell TheoryDavid NashNo ratings yet

- Chapter 1 - Stress and StrainDocument72 pagesChapter 1 - Stress and StrainNazhan HaziqNo ratings yet

- Fatigue FailureDocument46 pagesFatigue Failurereek_bhat75% (4)

- Fatigue Failure AnalysisDocument37 pagesFatigue Failure AnalysisRohit MunaNo ratings yet

- Fatigue FailureDocument46 pagesFatigue FailureAhmad SalahNo ratings yet

- Ila 0601Document15 pagesIla 0601Florence CheangNo ratings yet

- Best simple PID tuning rulesDocument27 pagesBest simple PID tuning rulesstathiss11No ratings yet

- Sign Language - EnglishDocument1 pageSign Language - EnglishdinacaranNo ratings yet

- System Identification: Munther A. DahlehDocument29 pagesSystem Identification: Munther A. Dahlehdavid_29No ratings yet

- Pancha IntroDocument41 pagesPancha Introxmlsi100% (2)

- MATLAB Curve FittingDocument3 pagesMATLAB Curve FittingredpoptartNo ratings yet

- Learning Unit 2 - AbsorptionDocument68 pagesLearning Unit 2 - AbsorptionTshwarelo MahlakoaneNo ratings yet

- Distillation, Ponchon Savarit, ShahzadDocument30 pagesDistillation, Ponchon Savarit, ShahzadMahad ZahidNo ratings yet

- Thermal Ratcheting of A BeamDocument33 pagesThermal Ratcheting of A Beammilan44No ratings yet

- DIRECT SHEAR TEST TITLEDocument19 pagesDIRECT SHEAR TEST TITLESaid-Mansour MohamedNo ratings yet

- Problem 1 025Document6 pagesProblem 1 025Oscar SanchezNo ratings yet

- DSS Design of Steel BeamsDocument14 pagesDSS Design of Steel Beamsrashmi ashtekarNo ratings yet

- Fluid Mechanics Theory and DesignDocument158 pagesFluid Mechanics Theory and DesignWONG TSNo ratings yet

- EVMSU performance and selection dataDocument13 pagesEVMSU performance and selection dataAntonella EspinozaNo ratings yet

- Strength, Stiffness, Load Classifications, Stress and StrainDocument4 pagesStrength, Stiffness, Load Classifications, Stress and StrainMohammed ImranNo ratings yet

- Important Developments in Midas Gen Software From 2016-2021 For Filipino EngineersDocument92 pagesImportant Developments in Midas Gen Software From 2016-2021 For Filipino EngineersAlexander GatesNo ratings yet

- Hansen - Ha4a & Ha4asDocument1 pageHansen - Ha4a & Ha4asPepe GrilloNo ratings yet

- L&T Construction, Chennai G-O20002: Subarnarekha - Main Bridge SubstrcutureDocument7 pagesL&T Construction, Chennai G-O20002: Subarnarekha - Main Bridge SubstrcutureGopu RNo ratings yet

- Quiz 3Document8 pagesQuiz 3John Glenn Lausin MaticNo ratings yet

- FEModels of GFRP and CFRP StrengtheningDocument14 pagesFEModels of GFRP and CFRP StrengtheningCrystal SuriyaNo ratings yet

- The Concept of Hydroplaning of Commercial Vehicle On Wet RoadDocument3 pagesThe Concept of Hydroplaning of Commercial Vehicle On Wet RoadPrakash ShaktiNo ratings yet

- Kaplan TurbineDocument12 pagesKaplan Turbineanonymous anoNo ratings yet

- Seismic Design of Revetment For Second Specialized Terminal in Manzanillo, MexicoDocument7 pagesSeismic Design of Revetment For Second Specialized Terminal in Manzanillo, MexicoJiaer WuNo ratings yet

- Methods To Determine The Elastic Line: Description Learning Objectives/experimentsDocument3 pagesMethods To Determine The Elastic Line: Description Learning Objectives/experimentsDiego AvendañoNo ratings yet

- Sana Jafar PDFDocument6 pagesSana Jafar PDFPrateek NegiNo ratings yet

- Review of Available Approaches For Ultimate Bearing Capacity of Two-Layered SoilsDocument14 pagesReview of Available Approaches For Ultimate Bearing Capacity of Two-Layered Soilscvetan1983No ratings yet

- DissDocument190 pagesDissThomas MeierNo ratings yet

- Transfer Function ResponseDocument2 pagesTransfer Function ResponseAbdullah KutbiNo ratings yet

- Penberthy Jet Pump Application Guide AEDocument32 pagesPenberthy Jet Pump Application Guide AECookiemonNo ratings yet

- 4 Contacting EquipmentDocument40 pages4 Contacting EquipmentBiswa JitNo ratings yet

- Thermodynamics 1 LectureDocument57 pagesThermodynamics 1 LecturefabyunaaaNo ratings yet

- Thermodynamic Laws & Phase TransitionsTITLE Assignment 1: Thermodynamic ProblemsTITLE Temperature Measurement DevicesDocument2 pagesThermodynamic Laws & Phase TransitionsTITLE Assignment 1: Thermodynamic ProblemsTITLE Temperature Measurement DevicesSAUMYA MUNDRANo ratings yet

- API 571 Damage MechanismsDocument16 pagesAPI 571 Damage MechanismsTahseen Jwad100% (1)

- Chapter 3 Ref CyclesDocument74 pagesChapter 3 Ref CyclesBaakir KarkoshNo ratings yet

- Yuan2021 Article ParticleFiniteElementMethodImpDocument14 pagesYuan2021 Article ParticleFiniteElementMethodImpAhmed MabroukNo ratings yet