Professional Documents

Culture Documents

TROUBLESHOOTING TDS-11HP

Uploaded by

vegeta1984Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TROUBLESHOOTING TDS-11HP

Uploaded by

vegeta1984Copyright:

Available Formats

August,2008 Rev0

TDS-11HP Troubleshooting Guide

1.0 HydraulicSystemPressureLow

1.1 Systempressurecannotbeobtainedthroughfollowinghydraulicsetupprocedure.

2.0 Shotpindoesnotengage.

3.0 Clampcylinderdoesnotactuate.

4.0 Shotpinengagesbutclampcylinderdoesnotactivate.

Symptoms/Problems

5.0 Clampcylinderdoesnotrelease.

6.0 Standjumpdoesnotfunction.

7.0 RLAdoesnotrotate.

8.0 Linktiltdoesnotmovetodrill/mouseholeposition.

9.0 Linktiltdriftbacktowellcenterfromdrill/mousehole.

10.0 Drillpipeelevatordoesnotreachmousehole/derrickmanposition.

11 0 I B O P does not operate 11.0 I.B.O.P.doesnotoperate.

12.0 Oilpumplossalarmison.

13.0 Hydraulicelevatorswillnotfunction.

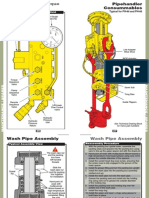

Setup/AdjustmentGuides

Hydraulicmanifoldsolenoididentification.

Hydraulicsystempressuresetup.

Hydraulicsystemmanifoldidentification.

Shotpincircuitsetupprocedure.

Gearoilpump/pressureswitchsetup.

Counterbalance / Stand Jump Adjustment Counterbalance/StandJumpAdjustment.

Standjump/Clampcircuitisolationprocedure.

BlowerPressureswitchadjustment.

CharlieEwing TedA.Jones

Whenyouoverrideadirectionalvalve,youbypassthesafetyinterlockwhichcanresultin

PROBLEM POSSIBLECAUSE REMEDY DETAILS

1.0

HydraulicSystem

PressureLow

Counterbalancemodevalveleft

inshutdown/rigupposition.

Counterbalancemodevalve

swithcedtoRUN

uncontrolledmovementoftopdrivecomponents,possiblycausingseriousinjuryordeath.

NohydraulicA/Cmotorrotation

/rotationbackwards

ConfirmA/Cmotorisrotating

clockwisebylookingintofan

endofmotor.

Flexiblecouplingisdamaged. Replacetheflexiblecoupling.

Hydraulicfluidlevellow

Fillhydraulicresevoirtoproper

level(middlesightglass)

Fillresevoirwith

counterbalancemode

switchinshutdown

ReliefvalvesRV1orUV1outof

adjustment.

Testpressuresandrelief

valves.Adjustasrequired

Refertohydraulicsystem

setupprocedure

1.1

Systempressure

cannotbeobtained

through following

EitherRV1orUV1valves ReplacebothRV1andUV1

Afterreplacement,follow

hydraulic system setup

1.1

throughfollowing

hydraulicsetup

procedure.

inoperative. valves.

hydraulicsystemsetup

procedure.

Hydraulicflowbleedingbackto

resevoirthroughauxiliarycircuit.

Isolatepressurelineson;

Counterbalalance,pipe

grabber(clamp)

Refertoauxiliarycircuit

isolationsection.

grabber(clamp)

Badhydraulicpump replacehydraulicpump

Removehydraulicaux.

circuitisolation,follow

hydraulicsystemsetup

procedure.

Installpressuregaugeat

2.0

Shotpindoesnot

engage.

SolenoidvalveSV5isnot

operating

Manuallyverifyfunctionof

SV5,ReplaceSV5ifnecessary

portB5onshotpinassy.

ManuallyfunctionSV5

untilshoppinrestson

faceofgear.Pressure

shouldbe400psi.

Ifpinfiresmanually,

check for proper voltage checkforpropervoltage

andsignalatSV5

reliefvalvefaultyoroutof

adjustment(400psi).

verifyreliefvalvepressures,

replacereliefvalve

Refertoshotpincircuit

setupprocedure.

clampengagepressureswitch

faulty

verifyfunctionalityofclamp

engagepressureswitch

pressureswitchis

normallysettoclose

(electrically)at1500psi.

shotpinmotorfaulty,not

rotating

RefertoSection(7.0)RLAwill

notrotate rotating notrotate

3.0

Clampcylinderdoes

notactuate.

Shotpinnotengaged

refertosection2.0"shotpin

willnotengage"

Nopressureorreducedpressure TestpressuresCPonclamp

Ifnopressureisindicated

attestportCPonclamp

maniforld replace Check

attheclampcylinder. manifold.

maniforld,replaceCheck

ValveCV5onclamp

manifoldandrecheck.

Toprovidehighpressure

totheclampcircuit,

pressure at C5 must be

Cylinderisdamaged.

Inspectcylinderandrepairor

replace.

pressureatC5mustbe

2,000psiandG5mustbe

lessthan100psi.Ifthis

conditionismet,pressure

atCPshouldincrease

fromlessthan100psito

higherthan2,000psi.If

not,checktheplumbing,

rotatinglinkadapter,and

clampcylinder.

Whileclamping,pressureatCR

shouldbe2.7timesthepressure

atCP.Whenthediescontact

thepipe,pressureatCRshould

belessthan100psi.Ifthe

pressuredoesnotfade,check

valveCNECforcontamination.

CleanorrepairCNECvalve.

If no pressure is indicated

4.0

Shotpinengagesbut

clampcylinderdoes

notactivate.

CheckValveCV5isfaultyor

sticking

CheckpressureattestportCP

(systempressure).Replace

valveCV5

Ifnopressureisindicated

attestportCPonclamp

maniforld,replaceCheck

ValveCV5onclamp

manifoldandrecheck.

Cartridgeand/orcheckvalveon removevalves,clean,checkfor

clampmanifoldisfaultyorstuck trashandreplace.

clampcylinderleakingby replaceclampassy.

testportCPonclamp

assy.Willnotreadsystem

pressureifcylinderis

leakingby.

5 0

Clampcylinderdoes

Control valve SV5 is stuck replace SV5

5.0

p y

notrelease

ControlvalveSV5isstuck replaceSV5

Clampcylindercartridgevalves

faultyorstuck

removevalves,clean,checkfor

trashandreplace.

valvesarelabeledas

CNECandCOFAon

hydraulicschematic

hydrauliclineatportB5

onmainhydraulic

manifold must be

InlineflowcontrolatPortB5on

mainmanifoldpluggedorstuck.

Replaceinlineflowcontrol,

removeandcleanotherwise

manifoldmustbe

removedtoaccessflow

controlvalve.Flow

controlvalveIStheboss

fitting.

LogicCartridgeLC5faultyor

stuck

ReplaceLC5atmainmanifold

stuck

6.0

Standjumpdoesnot

function.

SolenoidvalveSV9isnot

operating.

withguageconnectedatport

CB,manuallyfunctionsolenoid

andcheckforpressureto

increaseby200psi.Test

electricalandhydraulic

i R l i

Ifstandjumpfunctions

manually,eithersolenoid

isdefective,ornosignal

tosolenoidvalve.

refertocounterbalance/

d j operation.Replaceorrepair

asapplicable.

standjumpsetup

procedure.

CartridgevalvePCCisnot

properly set or operating.

adjustorreplacePCC

Refertocounterbalance/

standjumpsetup

properlysetoroperating.

procedure.

ReliefvalveSJRisnotproperly

setoroperating.

adjustorreplaceSJR.

Refertocounterbalance/

standjumpsetup

procedure.

Counterbalancecylinder Testcylinderandrepairor

damaged.Sealleaks. replaceseal.

Prechargeonthe

counterbalanceaccumulatoris

low.

Chargethecounterbalance

accumulatorto900psi.

7.0

RLAdoesnotrotate Systempressureislow refertosection1.0

SolenoidValveSV2/SV3is

inoperativeorhasnoelectrical

signal

ManuallyfunctionSV2/SV3

andcheckforelectricalsignal.

Replaceifdefective.

IfRLAdoesnotrotate

whenSV2isfunctioned

manually,hookhydraulic

testguagestomotortest

portsonshotpinand

checkfor1600psi.inboth

ddirections.

IFnopressureatmotor,

checkreliefvalvesfor

obstruction,replaceSV2.

IFpressureispresent,

replacehydraulicmotor

(shot pin)

Shotpinhydraulicmotor

damaged

replacehydraulicmotoror

shotpinassy.

(shotpin)

Whenyouoverridea

directionalvalve,you

bypassthesafety

interlockandtopdrive

componentsmove,

possiblycausingserious

Shotpinisengaged/clampnot

retracted

refertosection5.0

h i l i f d i

injuryordeath.

Mechanicalinterference. Inspectandrepair.

TDScontrolsystem

interlockwillnotallow

linktiltengaged functionlinktiltfloat

RLAtorotateleftorright

withlinktiltengaged.

FunctionlinktiltFLOATto

clearinterlock.

Whenyouoverridea

8.0

Linktiltdoesnotmove

todrill/mousehole

position.

SolenoidvalveSV7orSV6isnot

shifting.

manuallyverifyfunctionof

solenoidvalves,checkfor

electricalsignal

Whenyouoverridea

directionalvalve,you

bypassthesafety

interlockandtopdrive

componentsmove,

FloatsolenoidSV8stuckinopen

verifynoelectricalsignalto

SV8whennotassigned,or

position valvespoolisfreebymanually

functioning

cylinder/sbad,defectiveseals,

leakingby

test,replaceleakingsealsor

cylinders

Runloadholdingvalve

dj t t f ll

9.0

Linktiltdriftbackto

wellcenterfrom

drill/mousehole.

LoadholdingreliefvalvesCB1,

CB2onlinktiltmanifoldareout

ofadjustment,stuckopen,or

contaminated.

Adjustorreplacetheload

holdingreliefvalve.

adjustmentfully

clockwise,thenfully

counterclockwise.

Pressureatlinktilt

manifoldTPshouldread

+1500psi.

Ch k l i i

PressureatB8onmainmanifold

doesnotdecaytolessthan100

psi.

Replacethepilottoopen

checkvalvesCV1,CV2onlink

tiltmanifold.

Checkvalvepositionscan

beswappedtoconfirm

defectiveorstuckcheck

valve.

Pilottoopencheckvalveisstuck

openorcontaminated.

Replacethepilottoopen

checkvalve.

seeabove

Faultylinktiltcylinderseal. Replacethefaultycylinder.

10.0

Drillpipeelevator

doesnotreachmouse

hole/derrickman

position.

Linkclampincorrectlyadjusted.

Adjustlinkclampto27.5

inchesfrominsidetopofbale

eyetocenterofbaleclamp.

11.0

I.B.O.P.doesnot

operate

SolenoidValveSV4faultyorno

electricalsignal

ReplacefaultySV4orrepair

electricalconnection

12.0

Oilpumplossalarmis

on.

testforoilpressureatoilpressureswitchtestport.Pressureshouldread11+psi.

Oilleveltoolow. Addoil.

Oilviscositytoolow

changeoiltooilspecifiedin

lubemanagementprogram

Excessiveoilviscosity. Loweroilviscosity.

Oilpressureswitchisoutof

adjustment.

Adjustpressureswitchtotrip

atlessthan10psi.

Refertogearoilpumpset

upprocedure. adjustment. atlessthan10psi. upprocedure.

Faultymotor.Intermittent

operation.

Replacemotor.

Oilpumphydraulicmotor

failure.

Replacemotor.

Faultyfixeddisplacementpump.

CheckpressureatPF.Replace

pump if pressure is low.

Refertogearoilpumpset

up procedure. pumpifpressureislow. upprocedure.

Lowhydraulicfluidinreservoir. Addhydraulicfluid.

Gearspraynozzlemissing. Replacespraynozzle.

13.0

Hydraulicelevators

willnotfunction

Quickdisconnetspluggedor

dirty

check/cleanhydraulicquick

disconnects

Hydraulicsolenoidfaultyorno

electricalsignal

checkforelectricalsignal

(24v),replacesolenoidas

needed.

elevatormanifoldhydraulic

sequencingvalveoutof

adjustment,contaminated,bad

adjustvalve,replaceif

defective

runvalvefullyclockwise,

thencounterclockwise4

1/2turnstoset.

IFelevatorsdonot

function,replace

defective sequencing defectivesequencing

valve.

STAND JUMP

SOLENOID

BRAKE

SOLENOID

ROTATING LINK

ADAPTER

LFT/RGT

I.B.O.P. CLOSE

SOLENOID

TORQUE

WRENCH

CLAMP

SOLENOID

LINK TILT FLOAT

SOLENOID

LINK

TILT/DRILL

MODE

SOLENOID

(BOTTOM OF

MANIFOLD)

PORT (A5)

HOSE

(SHOT PIN

RETRACT)

HYDRAULIC COUNTERBALANCE

VALVE:

SHUT DOWN/RUN/RIG UP

(SWITCH SHOWN IN RUN

POSITION)

SystemPressuresetup

ProcedureTDS11HP

byHelmerich&Payne

LocatereliefvalveRV1andremovecap.AdjustRV1counterclockwisetoits p j

minimumsetting.

LocateunloadingvalveUV1andremovecap.AdjustUV1fullyclockwiseto g p j y

itsmaximumsetting.

LocatetestportP

InstalltestgaugeattestportP

WithTDShydraulicmotorrunning,turnRV1clockwisewhile

observingthetestgaugeriseto2200psi.Securejamnutandput

protectivecoverbackon. p

(Whileadjustingthevalve,verifyalinearrelationshipbetween

turningtheadjustmentscrewandobservingthepressuregauge.)

AdjustunloadingvalveUV1counterclockwiseuntilthepressure

starts falling The pressure will start cycling at this point Observe startsfalling.Thepressurewillstartcyclingatthispoint.Observe

severalunloadcyclestodetermineunloadpressure.Adjustthe

settingofUV1asrequiredtoa2000psiunloadpressure.Secure

jamnutandinstallprotectivecover.

TDS11Hydraulicsystem

manifoldidentification.

TestportA4.measurestheopenpressure.

Pressureshouldread500psi.(Thepressurewill

readsystempressureforapproximatelyone

minute after assigning IBOP open ) then it minuteafterassigningIBOPopen.)thenit

shouldfallto500psi.Thisisthetimingcircuit

thatprotectsIBOPcrankrollersfromcontinued

excessiveforce.

Testportsatclampmanifold.Youcanmeasureopen

andclosepressure.

ThisisreducingvalveAR5.WithagaugeintestportC5thepressureis

adjustedwithAR5to1000psi.Thiskeepsaconstantpressureonthe

clamp close circuit A reduced pressure at AR5 will result in slow clamp clampclosecircuit.AreducedpressureatAR5willresultinslowclamp

retractiontimes.

ThesearetheCLAMP/GEAROILandIBOPpressureswitches.There

aretestportsoneach.

Clampswitchsetat1500psi

Gear oil set at 10 psi Gearoilsetat10psi

IBOPsetat1500psi

TestportP.Install3000psigaugeheretomonitorsystempressure.

Properpressurewillbe2000psifallingto@1700psithenloadingback

to2000psiafter@20seconds.Arapidcycletimeof10secondsorless

isproblematicandmostofthetimearesultoflowsystemaccumulator

pressure.

Typicalgearoilpressureof21psi.Switchsettoalarmat10psi.

Gearoilpumphydraulicmotor.

Threepositionswitchinrigup.Thiswillextendthecounterbalance

cylinders.

ThreepositionswitchmustbeinSHUTDOWNANDtheTDShydraulicpump

MUSTbelockedoutbeforeanyhydrauliclinesareremoved.(thisdoesnot

i l d li ) includetestgaugelines.)

ThisisPCC,apressurereducing/relievingvalveforthecounterbalancecircuit.

WithagaugeconnectedattestportCBthepropersettingwillbe1450psi.

TestportCB

ThisisRV2.Itisthereliefvalveforthehydraulicmotorturningthe

gearoilpump.Withthepressurelinetothegearoilpumpplugged

andagaugeconnectedtotestportPFthepropersettingis400psi.

ReliefvalveRV1andtestportP.Correctpressure2000psifallingto@1700psi.

P

RV1

ReliefvalveSJR.Withagaugeconnected g g

totestportB9ANDstandjumpassigned

adjustto200psi.

SJR

UnloadingvalveUV1.SeeSettingupsystempressuredocument.

GaugeconnectedattestportP.Thegaugeshowsthepressurefalling

from2000psi.

Ampmeterconnectedtohydraulicpumpmotor.Thisprocedureis

part of setting up the hydraulic pump compensator With UV 1 partofsettingupthehydraulicpumpcompensator.With UV1

fullyclockwiseyourotateRV1increasingpressureobservedat

testportPtheampsshownshouldpeakasthepressurepasses

through800psi.

Illustratestheaboveslide.

Underthiscapisthecompensatingvalve.Itshouldbefactorypreset

and no adjustment necessary andnoadjustmentnecessary.

Compensatingvalve

T t t L/T if ld Thi i f th DRILL iti TestportonL/Tmanifold.ThisoneisfortheDRILLposition.

Ifyoulookcloselyyoucanseetheflowcontrolvalvethat

hoseB5connectsto.ThisvalveISdirectional,the

direction IS stamped on the valve This valve will cause directionISstampedonthevalve.Thisvalvewillcause

theclampnottoreleaseifpluggedormalfunctioning.

LoadholdingvalveforLinkTiltDrill.Whenlinktiltdrillisselected

thelinkswilltraveltothedrillposition,oncetherethepressurewill

risetosystempressure.Whenthedrillerremoveshisfingerfrom

the screen the pressure will fall to the load holding valve set point thescreen,thepressurewillfalltotheloadholdingvalvesetpoint.

Adjustthisvalvecounterclockwisetoincreasethepressureand

clockwisetodecrease.(oppositefromthenormalvalve.)

Ifyoudonothavesufficientpressurethelinkswilldriftbackto

wellcenterwhenthedrillerremoveshisfingerfromthescreen.

LoadholdingvalveforLinkTiltTILT.Adjustthesame

as the drill valve. asthe drill valve.

Linktilttilttestport.ConnectgaugeherewhensettingTiltpressure. p g g g p

GaugeconnectedtoshotpintestportB5,reliefvalveto

be adjusted to 400 psi beadjustedto400psi.

WithgaugeconnectedattestportonRLAmotormanifoldadjustreliefvalveopposite

ofthegauge.Correctpressureshouldbe1700psi.

NOTE:beforethisadjustmentcanbemadetheshotpin(andclamp)mustbeengaged

to lock the gear. tolockthegear.

Repeattheprocedureforoppositedirection.

TDS11ShotPinandClampSetup

Procedure.

Thepurposeofthisprocedureistolimittheamountofforcetheshotpinexertsonthering

gear.

TheadjustmentatAR5willspeeduporslowdowntheretractionoftheclamponcethe j p p p

commandisgiventorelease.

BeawarethatthecompleteROTATINGLINKADAPTORASSEMBLYANDBAILS/ELEVATORSWILLROTATEWHENTHEDRILLERASSIGNSCLAMP

ENGAGE!BEABSOLUTLYCERTAINTHATALLPERSONELLARECLEAROFANYPINCHPOINTSDURINGTHISPROCEDURE!

Assignthreepositionvalvetorun.TurnonTDShydraulics.

LocatetestportB5onshotpinbody.Connect3000psigauge.

HavedrillerassigntorquewrenchENGAGE.Becertainthattheshotpinstalls

onthefaceoftheringgear.

Adjustreliefvalveto400psi.

LocatetestportC5andinstall3000psigauge.

LocateReducingvalveAR5.WithTDShydraulicson

andclampreleasedadjustreducingvalveto1000psi.

SetupProcedureforGearOil

Pump/PressureSwitch

Toolsneeded:Hydraulicpressuretestingkitw/060psigauge,03000psigauge,

l i 5/32 ll h 9/16 bi i h 7/8 bi i multimeter,5/32allen wrench,9/16combinationwrench,7/8combination

wrench,anda8(1/2)JICcapandplug.5/8combinationwrench,anda

flathead/Philipsheadscrewdriver.

Locatelubeoilpressureswitch

LocateRV2pressurereducingvalveandPF

portonhydraulicmanifold,andthePFtest

portonhydraulicmanifold.

Removethecoveronthelubeoilpressure

switchandlocatetheblueandpurplewires.

Installthe060psigaugeonthetestporton

thepressureswitch.

: EngageTDShydraulicmotorandobservethepressureonthegauge.Onceitachievesmaximumpressure,

th lti t t if ti it b t th bl d l i U th 9/16 h t b k usethemultimetertoverifycontinuitybetweentheblueandpurplewires.Usethe9/16wrenchtobreak

thejamnutonRV2.Usethe5/32allen wrenchtoturnthepressurereducingvalve(RV2)counterclockwise

untilyouobserve10psionthegauge.Onceyouachieve10psi,backthesetscrewoffoftheadjustablebrass

nutlocatedinthepressureswitch.Observethatthemultimeterhaslostcontinuitybetweentheblueand

purplewires.Usethe5/8wrenchtoturnthebrassnutuntilyouachievecontinuity.Resetthesetscrewand p p y y

reinstallthecoveronthepressureswitch.

LO/TOTDS,LocatethePFportonthemanifoldandremovethelinewitha7/8wrench.

Use the JIC fittings to cap and plug the line and port. Install the 03000psi gauge on the UsetheJICfittingstocapandplugthelineandport.Installthe0 3000psigaugeonthe

PFtestport(locatedbetweensolenoidsnexttothePFbossport).Reenergizethe

hydraulics.Usethe5/32allen wrenchandturnRV2clockwiseuntilyouachieve400psi.

Onceyouachieve400psi,resetthejamnutonRV2andturnoffthehydraulics.LO/TO

TDS d i t ll th h d li li t th PF t th if ld TDSandreinstallthehydrauliclinetothePFportonthemanifold.

SetupProcedureforGearOilPump/PressureSwitch

Toolsneeded: Hydraulicpressuretestingkitw/060psigauge,03000psigauge,multimeter,

5/32allenwrench,9/16combinationwrench,7/8combinationwrench,anda8(1/2)JICcap

andplug.5/8combinationwrench,andaflathead/Philipsheadscrewdriver.

Step1:Locatelubeoilpressureswitch,RV2pressurereducingvalve,PFportonhydraulic

manifold,andthePFtestportonhydraulicmanifold.

Step2:Removethecoveronthelubeoilpressureswitchandlocatetheblueandpurplewires.

Installthe060psigaugeonthetestportonthepressureswitch.

Step3:EngageTDShydraulicmotorandobservethepressureonthegauge.Onceitachieves

maximumpressure,usethemultimetertoverifycontinuitybetweentheblueandpurplewires.

Usethe9/16wrenchtobreakthejamnutonRV2.Usethe5/32allenwrenchtoturnthe

pressurereducingvalve(RV2)counterclockwiseuntilyouobserve10psionthegauge.Onceyou

achieve10psi,backthesetscrewoffoftheadjustablebrassnutlocatedinthepressureswitch.

Observethatthemultimeterhaslostcontinuitybetweentheblueandpurplewires.Usethe

5/8wrenchtoturnthebrassnutuntilyouachievecontinuity.Resetthesetscrewandreinstall

thecoveronthepressureswitch.

Step4:LocatethePFportonthemanifoldandremovethelinewitha7/8wrench.UsetheJIC

fittingstocapandplugthelineandport.Installthe03000psigaugeonthePFtestport(located

betweensolenoidsnexttothePFbossport).Reenergizethehydraulics.Usethe5/32allen

wrenchandturnRV2clockwiseuntilyouachieve400psi.Onceyouachieve400psi,resetthejam

nutonRV2andturnoffthehydraulics.LO/TOTDSandreinstallthehydrauliclinetothePFport

onthemanifold.

Counterbalance adjustment Counterbalanceadjustment

Assignthreepositionswitchtorun.

LocateTestportCBandinstall3000psigauge.

LocatePressurereducing/relievingvalvePCC,removeprotectivecapandloosenjam

nutand.TurnTDShydraulicson.AdjustPCCasrequiredto1450psi.(OnTDS11HPthe

setting is 1450 ) settingis1450.)

OnTDS11SAsthepressuresettingwillbe1600psi.(FLEX2sandretrofits.)

WhileobservingthepressurehavethedrillerassignSTANDJUMP.The

pressureshouldincreaseby200psi.Ifadjustmentisnecessary,locaterelief

l SJR d dj il i i b i d valveSJRandadjustuntilcorrectpressureincreaseisobtained.

Standjump/Clampcircuit

isolationprocedure

Lock out TDS hydraulic pump Assign three position LockoutTDShydraulicpump.Assignthreeposition

switchtoShutdown.

Afterallpressurehasbledoff,remove

COUNTERBALANCEpressurelinefromdrillers

sidecylinder.Plugandcapbothends

h h d l l k d d h WithTDShydraulicpumplockedoutandthree

positionswitchinshutdown.Afterpressure

hasbledoff,removeclampsupplyandreturn

linesandinstallcapsandplugs. p p g

Adjustment Procedure for Blower Pressure

Switch - TDS11HP

1) Assign the Top Drive to ON. Blowers should come on.

2) Remove the cap on the Pressure Switch for the Blower.

3) Follow Directions on the inside of the cap.

4) Adjust Large Brass nut (using a 5/8 open end wrench) out until the alarm

is no longer present. (This may take a couple of attempts to get desired

setting.)

Note: Do not handle or touch the small plunger!

5) Once that the alarm is no longer present we need to disconnect the blower

tube at the junction box and verify that the alarm is present.

Note: Blowers must be on during this test.

6) Install Tube after alarm verification test is complete.

7) Replace cap for the Pressure Switch and re-tie wire as necessary.

You might also like

- 2 - Canrig Top Drive Rig Crew TrainingDocument104 pages2 - Canrig Top Drive Rig Crew TrainingDiego Fabian Ruiz Vacaflor89% (9)

- AXON 005 Drilling Products Top Drives BrochureDocument16 pagesAXON 005 Drilling Products Top Drives BrochureJuan Pablo Villazon Richter100% (1)

- Bomba National 12-P-160Document6 pagesBomba National 12-P-160Hugo VillcaNo ratings yet

- DQ450DBZ Top Drive Device User's ManualDocument73 pagesDQ450DBZ Top Drive Device User's ManualHala Dawod100% (1)

- Washpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)Document12 pagesWashpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)osvaldoNo ratings yet

- Foot Throttle ROSS HILLDocument2 pagesFoot Throttle ROSS HILLmadaba723504No ratings yet

- LCI Rig ComponentsDocument33 pagesLCI Rig ComponentsJuanVela100% (1)

- Tesco HCI Operacion Guide PDFDocument90 pagesTesco HCI Operacion Guide PDFluis sarmientoNo ratings yet

- 166-31590 Manual BaylorDocument54 pages166-31590 Manual BaylorJairo Peña100% (5)

- LEWCO DirectDrive Top Drive (AD00176)Document4 pagesLEWCO DirectDrive Top Drive (AD00176)eefunnNo ratings yet

- RS Land Pressure Control Equipment Brochure-876650150Document19 pagesRS Land Pressure Control Equipment Brochure-876650150corsini999No ratings yet

- Pumps Selection LectureDocument59 pagesPumps Selection Lectureshicardinal100% (2)

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document226 pages400 Bad Request 400 Bad Request Nginx/1.2.9ranid303086% (7)

- Top Drive Level I Course IntroductionDocument31 pagesTop Drive Level I Course IntroductionGiezy Daniela Velasquez Hernandez100% (2)

- TDS Manual-TescoDocument33 pagesTDS Manual-TescoQAMAR ALI KHAN100% (1)

- TDS 11saDocument1 pageTDS 11saMohamedAbdel-Rahman100% (1)

- Drawworks MaintenanceOK enDocument46 pagesDrawworks MaintenanceOK envichusega_809319337100% (1)

- Installation and Trouble Shooting Manual: Top Drive Drilling EquipmentDocument48 pagesInstallation and Trouble Shooting Manual: Top Drive Drilling EquipmentAlejandro HernadezNo ratings yet

- Top Drives CanrigDocument8 pagesTop Drives Canrigthought001No ratings yet

- 7838 Brake Care and OperationDocument54 pages7838 Brake Care and OperationMarutpal Mukherjee100% (1)

- MAS 7500 Operation Manual Bearing Clearance LimitsDocument2 pagesMAS 7500 Operation Manual Bearing Clearance Limitsmohamed salem100% (1)

- TDAS11 Training ManualDocument266 pagesTDAS11 Training Manualmiguel.pereiraNo ratings yet

- OWI 1000 DrawworksDocument54 pagesOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- Can Rig LWCV Actuator ManualDocument58 pagesCan Rig LWCV Actuator ManualAhmed Magd100% (2)

- TDS-Maintenance ManualDocument51 pagesTDS-Maintenance ManualAlejandro Hernadez100% (2)

- Manual Top Drive Tds 11sa InternetDocument64 pagesManual Top Drive Tds 11sa InternetRichard More67% (6)

- Catalogo - Ge752 - Curvas PDFDocument61 pagesCatalogo - Ge752 - Curvas PDFjuanpnuss100% (1)

- Equipment RecordDocument12 pagesEquipment Recordjesus alfonso fragozo calderonNo ratings yet

- Torque TDS4 Pocket Guide-2 PDFDocument5 pagesTorque TDS4 Pocket Guide-2 PDFHaridev50% (2)

- BPM TDS Maintenance ManualDocument45 pagesBPM TDS Maintenance ManualAnonymous MxwCc467% (3)

- Top Drive SystemDocument8 pagesTop Drive SystemianherzogNo ratings yet

- Training Manual PDFDocument400 pagesTraining Manual PDFcarlospais2100% (3)

- Tds 11 Troubleshooting Guide Elect.Document1,110 pagesTds 11 Troubleshooting Guide Elect.FSTNo ratings yet

- Top Drive Solutions d392001277 MKT 001Document12 pagesTop Drive Solutions d392001277 MKT 001JINDAL100% (2)

- Planos Top Drive TDS11 Ideal PDFDocument890 pagesPlanos Top Drive TDS11 Ideal PDFpablo100% (3)

- 6923 PDFDocument5 pages6923 PDFMEHDINo ratings yet

- TDS1000AInstallationManual 03May28AbridgedDocument20 pagesTDS1000AInstallationManual 03May28Abridgedbwd104No ratings yet

- Electric House Manual: Top Drive Drilling EquipmentDocument22 pagesElectric House Manual: Top Drive Drilling EquipmentAlejandro HernadezNo ratings yet

- Top Drive SpecificationDocument4 pagesTop Drive SpecificationDya PratamaNo ratings yet

- Canrig TD 4 Inch Actuator ManualDocument42 pagesCanrig TD 4 Inch Actuator ManualAshrafNo ratings yet

- Traveling Equipment Anti-Collision System Tac-Ii ManualDocument66 pagesTraveling Equipment Anti-Collision System Tac-Ii ManualAlex RamirezNo ratings yet

- Tds-11sa - Top DriveDocument64 pagesTds-11sa - Top DriveRuben Dario Conde Leon100% (1)

- 1000012667-PIB Shot PinDocument3 pages1000012667-PIB Shot PinAdrian CantaragiuNo ratings yet

- ZJ70DBS Drilling Rig Electrical Drive and Control System (VFD) DrawingDocument260 pagesZJ70DBS Drilling Rig Electrical Drive and Control System (VFD) DrawingKapil Tiwari100% (1)

- Canrig torque wrench specificationsDocument16 pagesCanrig torque wrench specificationsaris4silveyraNo ratings yet

- SEC6 Partes y PlanosDocument380 pagesSEC6 Partes y PlanosJohn Suarez100% (1)

- Product Bulletin No.: TDS-03-16 Release Top Drive Drilling SystemDocument8 pagesProduct Bulletin No.: TDS-03-16 Release Top Drive Drilling Systemahmedsaid85No ratings yet

- Bentec FormationDocument73 pagesBentec FormationMohammed teggarNo ratings yet

- SCR Unit Chapter 3Document48 pagesSCR Unit Chapter 3stashkinvalriy100% (2)

- Omron SCR OperationDocument106 pagesOmron SCR OperationOmabdotarek OmabdotarekNo ratings yet

- Sec6 PDFDocument424 pagesSec6 PDFAlex Ramirez100% (1)

- TDS-11SA Lubrication and Maintenance GuidelinesDocument1 pageTDS-11SA Lubrication and Maintenance GuidelinesEduardo Vilela RomeroNo ratings yet

- User Manual: Mechanical WashpipeDocument60 pagesUser Manual: Mechanical WashpipeIvan Villarreal LopezNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Hydraulic System TroubleshootingDocument9 pagesHydraulic System TroubleshootingSantos Quiñones ParimangoNo ratings yet

- 992G HYD TroubleshootingDocument9 pages992G HYD TroubleshootinglisahunNo ratings yet

- TroubleshootingDocument7 pagesTroubleshootingg665013No ratings yet

- AttTesting and AdjustingDocument8 pagesAttTesting and Adjustingchanlin100% (1)

- 416C, 426C, 428C, 436C and 438C Hydraulic System TroubleshootingDocument10 pages416C, 426C, 428C, 436C and 438C Hydraulic System TroubleshootingJose Antonio SalasNo ratings yet

- Control valve functions guideDocument39 pagesControl valve functions guideAstrit StratiNo ratings yet

- Breaker KOM PDFDocument50 pagesBreaker KOM PDFnamduong368100% (5)

- High Pressure Gas Piping BOM 12-11-19Document3 pagesHigh Pressure Gas Piping BOM 12-11-19MELVIN MAGBANUANo ratings yet

- July 2015 Master Plumber Terms Included PDFDocument5 pagesJuly 2015 Master Plumber Terms Included PDFLoren ViejayNo ratings yet

- Accessories: Spare Parts and AccessoriesDocument1 pageAccessories: Spare Parts and AccessoriesHafiz Muhammad Azeem NoorNo ratings yet

- Gambar Desain IPAL 5m3Document4 pagesGambar Desain IPAL 5m3alwiyaniNo ratings yet

- Repair ListDocument36 pagesRepair ListRizky SkrillexNo ratings yet

- Mramco Sample CylinderDocument1 pageMramco Sample Cylinderi.q.francisco.danielmoraNo ratings yet

- NB-27 - 2012 A Guide For Blowoff VesselsDocument1 pageNB-27 - 2012 A Guide For Blowoff VesselsOleg ShkolnikNo ratings yet

- 1 Linear ActuatorsDocument34 pages1 Linear ActuatorsSai KrishnaNo ratings yet

- Darcys LawDocument44 pagesDarcys LawRoman Lazarescu100% (1)

- Barksdale Controls Valves RegulatorsDocument42 pagesBarksdale Controls Valves Regulatorsuldarico lozanoNo ratings yet

- WILO SE-Group (En) - ISO 9001 Valid Until April 2024Document7 pagesWILO SE-Group (En) - ISO 9001 Valid Until April 2024kristo kalangNo ratings yet

- Non Moving TURBINEDocument44 pagesNon Moving TURBINERaja RamNo ratings yet

- Nuclear power plant valve data sheetsDocument7 pagesNuclear power plant valve data sheetspoojarimayurNo ratings yet

- Inventory Listing of Plumbing and Welding SuppliesDocument4 pagesInventory Listing of Plumbing and Welding SuppliesZaki Rizqi FadhlurrahmanNo ratings yet

- 24 - Southern Cross - Iso Pump - 100 X 65 - 200 - 1500 - 3500 RPMDocument1 page24 - Southern Cross - Iso Pump - 100 X 65 - 200 - 1500 - 3500 RPMHazim HazimNo ratings yet

- Feed Water SystemDocument18 pagesFeed Water SystempajriramadhanNo ratings yet

- Technical Information: Loop Flushing ValveDocument8 pagesTechnical Information: Loop Flushing ValveanandsubbiahNo ratings yet

- PT and Fittings Exam 4Document7 pagesPT and Fittings Exam 4Panitan MungsongNo ratings yet

- Manual de Partes CAT 10K-423-843Document421 pagesManual de Partes CAT 10K-423-843Zonis Taller7No ratings yet

- Practice Problems (Pumps Agitation)Document1 pagePractice Problems (Pumps Agitation)Lin Xian XingNo ratings yet

- Pipe Network Analysis PDFDocument3 pagesPipe Network Analysis PDFmichol2014100% (2)

- Cheng Fluid Systems, Inc. - Pump CavitationDocument3 pagesCheng Fluid Systems, Inc. - Pump CavitationjpalauguillemNo ratings yet

- Sistema Fire PumpsDocument44 pagesSistema Fire PumpsMohamadIbnuHassanNo ratings yet

- Peerless Pump UL FM (1) Hai An-B - M 250Hp PDFDocument1 pagePeerless Pump UL FM (1) Hai An-B - M 250Hp PDFViệt Đặng XuânNo ratings yet

- Pump TroubleshootingDocument54 pagesPump TroubleshootingM.nour El-dinNo ratings yet

- Control hydraulic motor and cylinder speeds with Webtec's variable priority flow dividersDocument8 pagesControl hydraulic motor and cylinder speeds with Webtec's variable priority flow dividersMichael DavenportNo ratings yet

- MSI-001280-GA-001 Skid Mounted Batch MixerDocument1 pageMSI-001280-GA-001 Skid Mounted Batch Mixerkiranvar13100% (1)

- Listado de Valvulas: Item Descripcion Cant Und Unit. Usd Total UsdDocument1 pageListado de Valvulas: Item Descripcion Cant Und Unit. Usd Total UsdPabloNo ratings yet