Professional Documents

Culture Documents

Vvitnes Ed: Kotlli/Ri Fni/Lex LTD V.K.J

Uploaded by

DrManoj Kumar Sharma0 ratings0% found this document useful (0 votes)

9 views1 pageAIPUR-13 ACCEPTANCE test REPORT Size of pipe 90 mm IS: 4985:2000 Class ill pressure 6kgf / cm2 Total pipes J OGSmeterslll68 piees Date eftesting07 &OU)3.20l4 Batch no, Tests Required value NO.Qf observed value.

Original Description:

Original Title

Scan Doc0015

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAIPUR-13 ACCEPTANCE test REPORT Size of pipe 90 mm IS: 4985:2000 Class ill pressure 6kgf / cm2 Total pipes J OGSmeterslll68 piees Date eftesting07 &OU)3.20l4 Batch no, Tests Required value NO.Qf observed value.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageVvitnes Ed: Kotlli/Ri Fni/Lex LTD V.K.J

Uploaded by

DrManoj Kumar SharmaAIPUR-13 ACCEPTANCE test REPORT Size of pipe 90 mm IS: 4985:2000 Class ill pressure 6kgf / cm2 Total pipes J OGSmeterslll68 piees Date eftesting07 &OU)3.20l4 Batch no, Tests Required value NO.Qf observed value.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

[

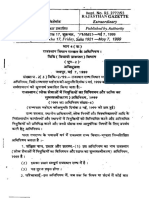

KOTlLi\RI FNi\LEX LTD

E-206., ROAD NO.J O, V.K.J . AREA J AIPUR-13

ACCEPTANCE TEST REPORT

Size of pipe 90 mm IS: 4985:2000

Class ill

Pressure 6kgf/cm2

Total pipes J OGSmeterslll68 piees

Date eftesting07 &OU)3.20l4

Batch no,

Tests Required value

NO.Qf

Observed value

Remarks

Samples

1 Pipe Ends Cleanly cut &reasonably

Square O.K Pass

2

~~

Short term hydraulic W hen- subject to Internal

.. ." -. .--. -- -- .. - --- -.-

test at hydrostatic pressure of 2NQS No cracks or swelling observed P ass

27C _+1 C 25. 14J (g1cnl the pipe shall at 25.3Kg1cm

2

,

not burst during the test ,

period of 1hour

,

'3 Visual Inspection Should be Gray coloured

:.

a) Colour Clean &smooth Gray Pass

b) Finish free from defects OK

c) Visual defects Square &free from sharp OK,

d} End jfnish edges OK

~ Density The density of the pipe

1.42; ~AJ, 1.43, 1.45, 1.42, 1.40

...

shall be with ill1,40to SNos L40,IAI Pass

1.46.

5 External Resistance Pipe sample shall not

Blows at 0 C +_ I C fracture or crack through 3Nos No Crack Pass

(Impact) its complete wall thickness

6 Reversion test Length of pipe approx 2.82,3.23, 3.21,2.85, 3.3S,

At 150C+_2 C 200+ 20 mm shall not alter 8Nos 3.25,3.41,2.85 Pass

inlenl$ more than 5%

7 Vacate Softening Vacate Softening 82'C, SfC, 82'C, arc, 82'C,

Temperature Temperature shall not be 8NQS sac, 84C, 82'<; P ass

less than 800C

s

Supplanted Ash Supplanted ash contents

contents shall not exceed 11% 2Nos 8.92% 9.65% Pass

vVITNESSED

+

You might also like

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- API 510 Open Book Q&ADocument138 pagesAPI 510 Open Book Q&AMohammed Shakil25% (4)

- Api 598Document13 pagesApi 598SurachaiAumongkolNo ratings yet

- Data Sheet For Tank Radar Gauge RTG 3920 - Level MeasurementDocument2 pagesData Sheet For Tank Radar Gauge RTG 3920 - Level MeasurementAndrei HorhoianuNo ratings yet

- Pages From Specs2009V2Document6 pagesPages From Specs2009V2Soni JitubhaiNo ratings yet

- API 510 PC 20 31 Aug05 Final Exam OpenDocument4 pagesAPI 510 PC 20 31 Aug05 Final Exam OpennikafiqNo ratings yet

- API 570 Open Book (26-02-18)Document5 pagesAPI 570 Open Book (26-02-18)Mahmoud Alwasif100% (1)

- Ashirvad Pipes Pvt. LTD.: Test Report of Upvc Agri Pipes As Per Is 4985:2021Document6 pagesAshirvad Pipes Pvt. LTD.: Test Report of Upvc Agri Pipes As Per Is 4985:2021mohd shiraz100% (1)

- Pipe Line Hydraulic Calculation: By: M. KhosravyDocument12 pagesPipe Line Hydraulic Calculation: By: M. KhosravyAnyanele Nnamdi FelixNo ratings yet

- A Report Is About: University of Duhok College of Engineering Civil. Eng. Department Soil Mechanics LaboratoryDocument10 pagesA Report Is About: University of Duhok College of Engineering Civil. Eng. Department Soil Mechanics Laboratoryفؤ ادNo ratings yet

- Hydrostatic Testing ProceduresDocument2 pagesHydrostatic Testing Proceduresomar sadiqNo ratings yet

- Data Sheet Insulating JointDocument4 pagesData Sheet Insulating Jointblacx_rzkyNo ratings yet

- 510 PC Oct04 Qar-Mid Open PSJDocument7 pages510 PC Oct04 Qar-Mid Open PSJCss SfaxienNo ratings yet

- Api 510 QDocument25 pagesApi 510 QShyam Singh100% (1)

- Mechanical Q1Document8 pagesMechanical Q1Ahmed HaridiNo ratings yet

- Api 510 Q&a-2Document32 pagesApi 510 Q&a-2Mohammed ShakilNo ratings yet

- SIS BOOK 2 - 3rd RevisionDocument201 pagesSIS BOOK 2 - 3rd RevisionHamza Alam100% (1)

- The Location Markers Required by ASME V Are Required To Appear As Radiographic ImagesDocument6 pagesThe Location Markers Required by ASME V Are Required To Appear As Radiographic ImagesSadiq KhattakNo ratings yet

- Ki NG Do M o F Thai L And: EDI CT OF GovernmentDocument26 pagesKi NG Do M o F Thai L And: EDI CT OF GovernmentsuosvannakNo ratings yet

- API 570 Atual Exam 2015Document38 pagesAPI 570 Atual Exam 2015أحمد صبحى100% (4)

- Api 570 Exam D (50 Open Book Q & A)Document38 pagesApi 570 Exam D (50 Open Book Q & A)Shaalan Ali100% (2)

- Gujarat 2014Document19 pagesGujarat 2014Anudeep Chittluri100% (1)

- API 510 Exam Q.bank-V VVV ImportantDocument138 pagesAPI 510 Exam Q.bank-V VVV ImportantJeganeswaranNo ratings yet

- Gas Pipeline Blowdown TimeDocument3 pagesGas Pipeline Blowdown Timeankur2061No ratings yet

- Kenwood TS-520 SE Service ManualDocument11 pagesKenwood TS-520 SE Service ManualYayok S. AnggoroNo ratings yet

- Api650 Questionn°03 Open Book ResponseDocument2 pagesApi650 Questionn°03 Open Book ResponsekorichiNo ratings yet

- 10) Api 510 Day 2Document206 pages10) Api 510 Day 2hamedNo ratings yet

- OVSOL Evacuated-Tube CollectorDocument7 pagesOVSOL Evacuated-Tube CollectorTanveer ShaikhNo ratings yet

- Problemas de YacimientosDocument2 pagesProblemas de YacimientosDaniel McflyNo ratings yet

- BMC 1100 & 1300 Workshop ManualDocument324 pagesBMC 1100 & 1300 Workshop ManualMichael Carnell93% (15)

- API 570 Flash CardsDocument13 pagesAPI 570 Flash CardsSarathiraja Sekar100% (5)

- API 653 PREPARATION/ Question N°10 Close BookDocument8 pagesAPI 653 PREPARATION/ Question N°10 Close BookkorichiNo ratings yet

- LA Type Test ReportDocument35 pagesLA Type Test Reportashwani2101No ratings yet

- Problem # Mark Earned Grade 1 10 2 12 3 18 4 20 60: Wüa 'É (Tåxw Ta TçàtüDocument10 pagesProblem # Mark Earned Grade 1 10 2 12 3 18 4 20 60: Wüa 'É (Tåxw Ta Tçàtükakajssh yhsusuaiwNo ratings yet

- Chapter - 1 Criteria For Selection of PVC Pipe Line-As Per Guideline of Technical CommitteeDocument21 pagesChapter - 1 Criteria For Selection of PVC Pipe Line-As Per Guideline of Technical CommitteeMehta MalayNo ratings yet

- Seamless Pipes - API 5L Grade X65 PSL 2Document2 pagesSeamless Pipes - API 5L Grade X65 PSL 2shiv kr dubeyNo ratings yet

- 1 - Classification of CasingDocument68 pages1 - Classification of CasingnabiNo ratings yet

- API-570 Final Exam QuestionsDocument26 pagesAPI-570 Final Exam QuestionsAndiappan Pillai88% (26)

- API 5L PRACTICE QUESTIONS - Doc r2Document4 pagesAPI 5L PRACTICE QUESTIONS - Doc r2Mhd Ebal100% (2)

- API 620 Tank CalculationsDocument11 pagesAPI 620 Tank CalculationsPrashant Malve64% (11)

- JOC 1978 StillDocument3 pagesJOC 1978 Stillentity8No ratings yet

- Piping Code ComparisonDocument5 pagesPiping Code ComparisonAndy Hakim83% (6)

- Choosing A Line Size and Wall ThicknessDocument20 pagesChoosing A Line Size and Wall Thicknessxion_mew2No ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- An Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesFrom EverandAn Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Electric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesFrom EverandElectric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesNo ratings yet

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Hindu Astrology 1Document45 pagesHindu Astrology 1api-26502404100% (2)

- Jataka Alankar Jyotish HindiDocument116 pagesJataka Alankar Jyotish HindiRakesh SoniNo ratings yet

- Rapsar RuleDocument4 pagesRapsar RuleDrManoj Kumar SharmaNo ratings yet

- Rajasthan Service Rule Part 1stDocument381 pagesRajasthan Service Rule Part 1stKrishan Kumar SharmaNo ratings yet

- Government of Rajasthan Finance Department (Rules Division) Notification No.F.1 (5) FD (Rules) /2008 Jaipur, Dated: Subject: Amendment in Rajasthan Service Rules, 1951Document4 pagesGovernment of Rajasthan Finance Department (Rules Division) Notification No.F.1 (5) FD (Rules) /2008 Jaipur, Dated: Subject: Amendment in Rajasthan Service Rules, 1951DrManoj Kumar SharmaNo ratings yet

- Cuspal Interlink Astrology: Life Long LifeDocument6 pagesCuspal Interlink Astrology: Life Long LifeDrManoj Kumar Sharma100% (1)

- General Notes of AstrologyDocument5 pagesGeneral Notes of AstrologyDrManoj Kumar SharmaNo ratings yet

- Rapsar ActDocument10 pagesRapsar ActDrManoj Kumar SharmaNo ratings yet

- General Financial and Accounts Rules: Government of RajasthanDocument64 pagesGeneral Financial and Accounts Rules: Government of RajasthanDrManoj Kumar SharmaNo ratings yet

- Quality Manual SampleDocument16 pagesQuality Manual SampleDrManoj Kumar Sharma100% (1)

- Corrected Map by IkbalDocument4 pagesCorrected Map by IkbalDrManoj Kumar SharmaNo ratings yet

- Book of Forms CPWADocument168 pagesBook of Forms CPWAkhan_sadi0% (2)

- GFR IIDocument131 pagesGFR IIDrManoj Kumar SharmaNo ratings yet

- Procedure For CompetenceDocument6 pagesProcedure For CompetenceDrManoj Kumar Sharma100% (1)

- Salary TheoremDocument8 pagesSalary TheoremDrManoj Kumar SharmaNo ratings yet

- ISO 17025:2017 Document Kit For Testing LaboratoryDocument2 pagesISO 17025:2017 Document Kit For Testing LaboratoryDrManoj Kumar Sharma100% (1)

- Iso-Iec-17025 ComparisionDocument1 pageIso-Iec-17025 ComparisionDrManoj Kumar SharmaNo ratings yet

- Ghalib... (In Hindi)Document36 pagesGhalib... (In Hindi)api-19771339No ratings yet

- Cocktail SnacksDocument36 pagesCocktail SnacksRuchi MahajanNo ratings yet

- Quality Manual SampleDocument16 pagesQuality Manual SampleDrManoj Kumar Sharma100% (1)

- MathemagicDocument10 pagesMathemagicAbhilash AgrawalNo ratings yet

- Ajhoon Chet Ghawar - OSHODocument629 pagesAjhoon Chet Ghawar - OSHOALPESH KOTHARINo ratings yet

- PronunciationDocument56 pagesPronunciationpapino72100% (4)

- 010 Anand GangaDocument81 pages010 Anand GangadvsNo ratings yet

- Answer Key: (Jee Advance) Paper-2Document14 pagesAnswer Key: (Jee Advance) Paper-2DrManoj Kumar SharmaNo ratings yet

- Exercise On GLP: What Are The Two Main Goals of The GLPS?Document2 pagesExercise On GLP: What Are The Two Main Goals of The GLPS?Manoj Kumar SharmaNo ratings yet

- Indian BreadDocument25 pagesIndian Breadmarisepim9110No ratings yet

- Mock TailsDocument27 pagesMock Tailsvishnu7755No ratings yet

- Answer Key: (Jee Mains)Document17 pagesAnswer Key: (Jee Mains)DrManoj Kumar SharmaNo ratings yet

- On GLPDocument80 pagesOn GLPManoj Kumar Sharma100% (2)