Professional Documents

Culture Documents

950H Wheel Loader Valve Lash Adjusting

Uploaded by

Timotije TimoticCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

950H Wheel Loader Valve Lash Adjusting

Uploaded by

Timotije TimoticCopyright:

Available Formats

950H Wheel Loader J AD00001-UP (MACHINE) POWERED BY C7 Engine(SEBP5422 - 01)/Basic Search

https://127.0.0.1/...b/sisweb/fulltext/fulltextheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[14.7.2014 15:29:27]

Product: WHEEL LOADER

Model: 950H WHEEL LOADER JAD

Configuration: 950H Wheel Loader JAD00001-UP (MACHINE) POWERED

BY C7 Engine

Testing and Adjusting

C7 Engines for Caterpillar Built Machines

Media Number -SENR9939-17 Publication Date -01/01/2010 Date Updated -06/01/2010

i02634218

Engine Valve Lash - Inspect/ Adjust

SMCS - 1102-025

To prevent possible injury, do not use the starter to turn the

flywheel.

Hot engine components can cause burns. Allow additional

time for the engine to cool before measuring valve

clearance.

This engine uses high voltage to control the fuel injectors.

Disconnect electronic fuel injector enable circuit connector

to prevent personal injury.

Do not come in contact with the fuel injector terminals

while the engine is running.

Note: Valve lash is measured between the rocker arm and the bridge for the inlet valves. Valve lash is

measured between the rocker arm and the valve stem for the exhaust valve. All of the clearance

measurements and the adjustments must be made with the engine stopped. The valves must be fully

closed.

Valve Lash Check

An adjustment is not necessary if the measurement of the valve lash is in the acceptable range. Adjust the

valve lash while the engine is stopped. The range is specified in Table 1.

Table 1

Inlet Valves Exhaust Valves

Shutdown SIS

Previous Screen

950H Wheel Loader J AD00001-UP (MACHINE) POWERED BY C7 Engine(SEBP5422 - 01)/Basic Search

https://127.0.0.1/...b/sisweb/fulltext/fulltextheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[14.7.2014 15:29:27]

Valve Lash Check (Stopped

Engine)

0.38 0.08 mm (0.015 0.003

inch)

0.64 0.08 mm (0.025 0.003

inch)

TC Compression Stroke 1-2-4 1-3-5

TC Exhaust Stroke

(1)

3-5-6 2-4-6

Firing Order 1-5-3-6-2-4

(2)

( 1 )

360 from TC compression stroke

( 2 )

The No. 1 cylinder is at the front of the engine.

If the measurement is not within this range adjustment is necessary. See Testing And Adjusting, "Valve

Lash And Valve Bridge Adjustment".

Illustration 1 g01320108

Cylinder and Valve Location

(A) Exhaust valve

(B) Inlet valves

Valve Lash and Valve Bridge Adjustment

950H Wheel Loader J AD00001-UP (MACHINE) POWERED BY C7 Engine(SEBP5422 - 01)/Basic Search

https://127.0.0.1/...b/sisweb/fulltext/fulltextheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[14.7.2014 15:29:27]

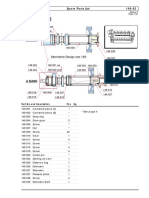

Illustration 2 g01109236

(1) Exhaust rocker arm

(2) Inlet valve bridge

(3) Rocker arm adjustment screw locknut for the exhaust rocker arm

(4) Rocker arm adjustment screw for the exhaust rocker arm

Table 2

Valve Lash

Valves Dimension of Gauge

Inlet

0.38 0.08 mm (0.015 0.003 inch)

Exhaust

0.64 0.08 mm (0.025 0.003 inch)

Adjust the valve lash while the engine is stopped.

1. Put the No. 1 piston at the top center position on the compression stroke. Refer to Testing and

Adjusting, "Finding Top Center Position for No. 1 Piston".

Table 3

TC Compression

Stroke

Inlet Valves Exhaust Valves

950H Wheel Loader J AD00001-UP (MACHINE) POWERED BY C7 Engine(SEBP5422 - 01)/Basic Search

https://127.0.0.1/...b/sisweb/fulltext/fulltextheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[14.7.2014 15:29:27]

Valve lash 0.38 0.08 mm (0.015 0.003

inch)

0.64 0.08 mm (0.025 0.003

inch)

Cylinders 1-2-4 1-3-5

2. Adjust the valve lash according to Table 3.

a. Lightly tap the rocker arm at the top of the adjustment screw with a soft mallet. This will ensure

that the lifter roller seats against the camshaft's base circle.

b. Loosen the adjustment locknut.

c. Place the appropriate feeler gauge between rocker arm and the valve bridge. Then, turn the

adjustment screw in a clockwise direction. Slide the feeler gauge between the rocker arm and

the valve bridge. Continue turning the adjustment screw until a slight drag is felt on the feeler

gauge. Remove the feeler gauge.

d. Tighten the adjustment locknut to a torque of 30 7 Nm (22 5 lb ft). Do not allow the

adjustment screw to turn while you are tightening the adjustment locknut. Recheck the valve

lash after tightening the adjustment locknut.

3. Remove the timing bolt and turn the flywheel by 360 degrees in the direction of engine rotation. This

will put the No. 6 piston at the top center position on the compression stroke. Install the timing bolt in

the flywheel.

Table 4

TC Exhaust

Stroke

(3)

Inlet Valves Exhaust Valves

Valve lash 0.38 0.08 mm (0.015 0.003

inch)

0.64 0.08 mm (0.025 0.003

inch)

Cylinders 3-5-6 2-4-6

( 3 )

Position for No. 1 cylinder

4. Adjust the valve lash according to Table 4.

a. Lightly tap the rocker arm at the top of the adjustment screw with a soft mallet. This will ensure

that the lifter roller seats against the camshaft's base circle.

b. Loosen the adjustment locknut.

c. Place the appropriate feeler gauge between rocker arm and the valve bridge. Then, turn the

adjustment screw in a clockwise direction. Slide the feeler gauge between the rocker arm and

the valve bridge. Continue turning the adjustment screw until a slight drag is felt on the feeler

gauge. Remove the feeler gauge.

d. Tighten the adjustment locknut to a torque of 30 7 Nm (22 5 lb ft). Do not allow the

adjustment screw to turn while you are tightening the adjustment locknut. Recheck the valve

lash after tightening the adjustment locknut.

5. Remove the timing bolt from the flywheel after all adjustments to the valve lash have been made.

Reinstall the timing cover.

950H Wheel Loader J AD00001-UP (MACHINE) POWERED BY C7 Engine(SEBP5422 - 01)/Basic Search

https://127.0.0.1/...b/sisweb/fulltext/fulltextheaderinfoframeset.jsp&calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp[14.7.2014 15:29:27]

Copyright 1993 - 2014 Caterpillar Inc.

All Rights Reserved.

Private Network For SIS Licensees.

Mon Jul 14 15:28:21 UTC+0200 2014

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ThermoKing Yanmar Overhaul Manual TK353ModelRD1Document53 pagesThermoKing Yanmar Overhaul Manual TK353ModelRD1liudnas0091% (11)

- Engine Family Names PDFDocument21 pagesEngine Family Names PDFAlvaroNo ratings yet

- Anillos EmdDocument2 pagesAnillos EmdHANSELL MIRANDA ALVA100% (1)

- 05-Hose Assembly Tools PDFDocument18 pages05-Hose Assembly Tools PDFqwureyquweryNo ratings yet

- 05-Hose Assembly Tools PDFDocument18 pages05-Hose Assembly Tools PDFqwureyquweryNo ratings yet

- CAT Hose Coupling Guide PDFDocument32 pagesCAT Hose Coupling Guide PDFTimotije Timotic0% (1)

- 950H Wheel Loader JAD00001-UP Pilot Oil AccumulatorDocument7 pages950H Wheel Loader JAD00001-UP Pilot Oil AccumulatorTimotije TimoticNo ratings yet

- Marine Engine-WP12 Series: General SpecificationsDocument2 pagesMarine Engine-WP12 Series: General SpecificationsDolfin YohanesNo ratings yet

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 08-14 - Cylinder HeadDocument6 pagesD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 08-14 - Cylinder HeadMANUALESNo ratings yet

- Dd15 FaultDocument19 pagesDd15 FaultSs100% (1)

- Introduction To Automobile EngineeringDocument8 pagesIntroduction To Automobile EngineeringSaurabh AwacharNo ratings yet

- DL650K9Document187 pagesDL650K9Juan Abraham AjpopNo ratings yet

- Inlet and Exhaust Valve Springs - Remove and InstallDocument10 pagesInlet and Exhaust Valve Springs - Remove and InstallMbahdiro KolenxNo ratings yet

- Perkins Parts BookDocument54 pagesPerkins Parts BookKoppertPower83% (23)

- Thermo Fluids Ime-241L Lab Report: Prof. DR Salman Habib Hassan Ali Butt 2017-IM-39Document19 pagesThermo Fluids Ime-241L Lab Report: Prof. DR Salman Habib Hassan Ali Butt 2017-IM-39Mahrukh ChaudharyNo ratings yet

- VTEC - Wikipedia PDFDocument54 pagesVTEC - Wikipedia PDFThakker Vraj JasaniNo ratings yet

- 950H - Ajuste de Luz de VálvulasDocument4 pages950H - Ajuste de Luz de VálvulasRenato Assis da Silva100% (2)

- U4 - Four Stroke EngineDocument47 pagesU4 - Four Stroke EnginePhước Vinh NguyễnNo ratings yet

- Escuela Superior Politécnica de Chimborazo: Autor Nivel: Fecha: Asignatura Motores de Combustión Interna Docente: TemaDocument19 pagesEscuela Superior Politécnica de Chimborazo: Autor Nivel: Fecha: Asignatura Motores de Combustión Interna Docente: TemaKassy AndradeNo ratings yet

- Motores GMDocument50 pagesMotores GMWilson Bueno100% (1)

- Manual de Partesz225 PDFDocument209 pagesManual de Partesz225 PDFManuel GuevaraNo ratings yet

- Catalogo de Partes Motores CATDocument10 pagesCatalogo de Partes Motores CATLuis Panti Ek100% (2)

- Ecs 2GDDocument29 pagesEcs 2GDImam DedyNo ratings yet

- Camshaft V32: Wärtsilä 32 Spare Parts List 148-02Document4 pagesCamshaft V32: Wärtsilä 32 Spare Parts List 148-02Toster902No ratings yet

- Hydraulic Cylinder Front OutriggerDocument2 pagesHydraulic Cylinder Front OutriggerHamed SaeedyNo ratings yet

- Detroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00aDocument20 pagesDetroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00anguynthanhlongNo ratings yet

- Tabla de Bujias Champion 20234Document82 pagesTabla de Bujias Champion 20234alexander ortizNo ratings yet

- Volvo June 2016 New Monthly Releases PV776-K-D12D Engine TOCDocument4 pagesVolvo June 2016 New Monthly Releases PV776-K-D12D Engine TOCM Morn ZawNo ratings yet

- Case 504 BDT Large Main TorquesDocument1 pageCase 504 BDT Large Main Torquesducatiss900No ratings yet

- Honda Price ListDocument527 pagesHonda Price ListAakash NNo ratings yet

- Engine Bearing: Website Email Tel: Fax: 0086-577-86755433 0086-577-86755422Document27 pagesEngine Bearing: Website Email Tel: Fax: 0086-577-86755433 0086-577-86755422Суханов КонстантинNo ratings yet

- DDR Extract Aug12Document516 pagesDDR Extract Aug12rajesh_talwar_3No ratings yet

- BT 50Document8 pagesBT 50manuelmanrique100% (1)

- CRI Pump & ControllerDocument5 pagesCRI Pump & Controllereko sunaryo100% (1)