Professional Documents

Culture Documents

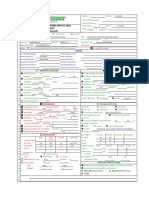

API 674 Pump Data Sheet

Uploaded by

Eason Ng100%(2)100% found this document useful (2 votes)

3K views5 pagesengineering

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentengineering

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

3K views5 pagesAPI 674 Pump Data Sheet

Uploaded by

Eason Ngengineering

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 5

JOB NO. ITEM NO.

PURCHASE ORDER NO.

SPECIFICATION NO.

RECIPROCATING PUMP (API 674-2ND) REVISION NO. DATE

DATA SHEET PAGE 1 OF 5 BY

SI UNITS

1 APPLICABLE TO: PROPOSAL PURCHASE AS BUILT

2 FOR UNIT

3 SITE NO. OF PUMPS REQUIRED

4 SERVICE SIZE AND TYPE

5 MANUFACTURER SERIAL NO.

6 NOTE: INDICATES INFORMATION TO BE COMPLETED BY PURCHASER BY MANUFACTURER

7 GENERAL

8 NO. MOTOR DRIVEN OTHER DRIVER TYPE

9 PUMP ITEM NO'S PUMP ITEM NO'S

10 MOTOR ITEM NO'S DRIVER ITEM NO'S GEAR ITEM NO'S

11 MOTOR PROVIDED BY DRIVER PROVIDED BY GEAR PROVIDED BY

12 MOTOR MOUNTED BY DRIVER MOUNTED BY GEAR MOUNTED BY

13 MOTOR DATA SHEET NO. DRIVER DATA SHEET NO. GEAR DATA SHEET NO.

14

OPERATING CONDITIONS LIQUID

15 CAPACITY @ PT (m/h): TYPE OR NAME OF LIQUID

16 @ MAXIMUN VISCOSITY @ MINIMUM VISCOSITY PUMPING TEMPERATURE (C): COMPRESSIBILITY %

17 DISCHARGE PRESSURE (kPa)(BARG): NORMAL MAXIMUM MINIMUM

18 MAXIMUM MINIMUM SPECIFIC GRAVITY MAXIMUM MINIMUM

19 SUCTION PRESSURE (kPa)(BARG): SPECIFIC HEAT Cp (kJ/kg C)

20 MAXIMUM MINIMUM VISCOSITY (cp) MINIMUM MAXIMUM

21 DIFFERENTIAL PRESSURE (kPa)(BARG): CORROSIVE/EROSIVE AGENTS

22 MAXIMUM MINIMUM CHLORIDE CONCENTRATION (PPM)

23 NPSH AVAILABLE (m) WITHOUT ACCELERATION HEAD H

2

S CONCENTRATION (PPM)

24 ACCELERATION HEAD (APP G) NET LIQUID TOXIC FLAMMABLE OTHER

25

PERFORMANCE SITE AND UTILITY DATA

26 RATED CAPACITY (m/h) LOCATION INDOOR OUTDOOR

27 NPSH REQUIRED (m) HEATED UNHEATED UNDER ROOF

28 PISTON SPEED (m/h) ELECTRICAL AREA CLASS GROUP DIV

29 DISPLACEMENT (m/h) WINTERIZATION REQ'D TROPICALIZATION REQ'D

30 VOLUMETRIC EFFICIENCY (%) SITE DATA

31 MECHANICAL EFFICIENCY(%) RANGE OF AMBIENT TEMPS: MIN/MAX / C

32 kW @ MAXIMUM VISCOSITY UNUSUAL CONDITIONS

33 kW @ RELIEF VALVE SETTING DUST FUMES SALT ATMOSPHERE

34 MAXIMUM ALLOWABLE SPEED (RPM) OTHER

35 MINIMUM ALLOWABLE SPEED (RPM) UTILITY CONDITIONS

36 PINION SHAFT (RPM) ELECTRICITY DRIVERS HEATING CONTROL SHUTDOWN

37 HYDRAULIC kW BRAKE kW VOLTAGE

38 FOR DIRECT-ACTING PUMPS: HERTZ

39 DRIVE GAS PHASE

40 GOVERNOR TYPE COOLING WATER INLET RETURN DESIGN MAX

41 INLET PRESSURE (kPa)(BARG) TEMPF MAX

42 INLET TEMPERATURE (C) PRESS.(kPa)(BARG) MIN

43 EXHAUST PRESSURE (kPa)(BARG) SOURCE

44 STALL PRESSURE (kPa)(BARG) INSTRUMENT AIR MAX MIN

45 GAS CONSUMPTION (kg/kW-h) PRESSURE (kPa)(BARG)

46

APPLICABLE SPECIFICATIONS

47 API 674 POSITIVE DISPLACEMENT PUMPS-RECIPROCATING

48 GOVERNING SPECIFICATION (IF DIFFERENT)

49 REMARKS:

50

51

06/95 SHT 1 OF 5 API674SI.XLS REV 0

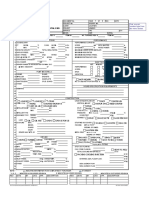

JOB NO. ITEM NO.

RECIPROCATING PUMP (API 674-2ND) REVISION NO. DATE

DATA SHEET PAGE 2 OF 5 BY

SI UNITS

1 CONSTRUCTION

2 ANSI

3 LIQUID END: (2.7.1.1 THROUGH 2.7.1.4) NOZZLES SIZE RATING FACING LOCATION

4 SIMPLEX MULTIPLEX PLUNGER LIQUID SUCTION

5 DUPLEX NO. OF CYLINDERS PISTON LIQUID DISCHARGE

6 SINGLE ACTING HORIZONTAL REMOVABLE LINERS GAS INLET

7 DOUBLE ACTING VERTICAL NO LINERS GAS EXHAUST

8 VALVES PER CORNER: GLAND FLUSH

9 NUMBER AREA (mm) VELOCITY (m/h) DRAINS

10 SUCTION OTHER

11 DISCHARGE OTHER

12 VALVE TYPE: DISC WING 2'BLE PORTED BALL OTHER

13 MATERIALS

14 PART LIQUID END ASTM NO. GAS END

15 CYLINDER

16 LINER

17 PISTON OR PLUNGER

18 PISTON RINGS

19 PISTON ROD

20 VALVES/VALVE SEATS

21 GLAND

22 THROAT BUSHING

23 PACKING

24 LANTERN RING

25 BOLTING

26 OTHER

27 OTHER

28 LIQUID END LUBRICATION PACKING

29 PACKING LUBE LIQUID END GAS END VALVE ROD

30 FLUSH SOURCE NO. OF RINGS

31 LUBRICATOR MAKE SIZE OF RINGS

32 SIZE NO. OF FEEDS OTHER

33 PRESSURE RATINGS QA INSPECTION AND TEST

34 LIQUID GAS COMPLIANCE WITH INSPECTORS CHECK LIST

35 CYLINDER CYLINDER CERTIFICATION OF MATERIALS

36 MAXIMUM PRESSURE (kPa)(BARG) FINAL ASSEMBLY CLEARANCES

37 MAXIMUM TEMPERATURE (C) SURFACE AND SUBSURFACE EXAMINATIONS

38 HYDROSTATIC TEST PRESS. (kPa)(BARG) RADIOGRAPHY

39 OTHER ULTRASONIC

40 DRIVE MECHANISM MAGNETIC PARTICLE

41 DIRECT COUPLED V-BELT OR COG GEAR LIQUID PENETRANT

42 COUPLING MANUFACTURER CLEANLINESS PRIOR TO FINAL ASSEMBLY

43 SOLEPLATES BASEPLATE SKID HARDNESS OF PARTS, WELDS & HEAT AFFECTED ZONES

44 BY PUMP MANUFACTURER SUITABLE FOR EPOXY GROUT FURNISH PROCEDURES FOR OPTIONAL TESTS

45 EXTENDED FOR TESTS REQ'D W/T OBS

46 SUBPLATES BY PUMP MANUFACTURER HYDROSTATIC X

47 DRAIN-RIM DRAIN-PAN PERFORMANCE

48 LEVELING PADS SUITABLE FOR COLUMN MOUNTING NPSH

49 OTHER

50 REMARKS:

51

06/95 SHT 2 OF 5 API674SI.XLS REV 0

JOB NO. ITEM NO.

RECIPROCATING PUMP (API 674-2ND) REVISION NO. DATE

DATA SHEET PAGE 3 OF 5 BY

SI UNITS

1 POWER FRAME CONTROLS

2 MAXIMUM FRAME RATING: TYPE: SIGNAL:

3 kW @ RPM MANUAL REMOTE PNEUMATIC

4 MAXIMUM PRESSURE RATING(kPa)(BARG) AUTOMATIC LOCAL ELECTRONIC

5 CRANKSHAFT MATERIAL CAPACITY CONTROL:

6 NO. OF MAIN BEARINGS FLOW BYPASS VARIABLE SPEED COMBINATION

7 TYPE OF MAIN BEARINGS ONLY ONLY

8 INTERNAL GEARS YES NO VENDOR FURNISHES CS GOVERNOR & VALVE

9 GEAR RATIO VENDOR TO FURNISH CONTROL PANEL

10 GEAR SERVICE FACTOR FREESTANDING ON UNIT OTHER

11 POWER END LUBRICATION: TACHOMETER REQUIRED TYPE

12 TYPE SPLASH POSITIVE PRESSURE GRAVITY OTHER PURCHASE REQUIREMENTS

13 OIL PUMP: NAMEPLATE UNITS U.S. CUSTOMARY SI

14 MAIN VENDOR REVIEW FURNISHED PROCESS PIPING

15 AUXILIARY

16 DRIVEN BY VENDOR REVIEW PIPING DRAWINGS

17 OIL FILTER: VENDOR FURNISHED PULSATION SUPPRESSION DEVICES

18 TYPE MAKE VENDOR FURNISHED RELIEF VALVE

19 FILTRATION SIZE MODEL INTERNAL EXTERNAL

20 OIL COOLER RELIEF VALVE SETTING (kPa)(BARG)

21 TYPE LIQUID-FILLED PRESSURE GAUGES REQUIRED

22 SIZE TECHNICAL DATA MANUAL REQUIRED

23 DRIVERS MAXIMUM SOUND PRESSURE LEVEL dBA

24 MOTOR @ m dBA

25 MANUFACTURER OVERSIZE NOZZLE MATING PARTS BY VENDOR

26 TYPE QUENCH-TYPE GLANDS REQUIRED

27 FRAME NO. PROVIDE PACKING COLLECTION CHAMBER

28 CONSTANT SPEED PROVIDE LANTERN RING PURGE

29 VARIABLE SPEED SIZE

30 kW RPM OIL HEATER CONNECTION REQUIRED

31 VOLTS PHASE DISTANCE PIECE COVERS

32 HERTZ SERVICE FACTOR SAFETY LOUVERED SOLID

33 ENCLOSURE GUARDS WEATHER COVERS

34 COVERS

35 STEAM TURBINE ADDITIONAL OIL SYSTEM ITEMS

36 OTHER (SEE SEPARATE DATA SHEETS) FLOW PRESSURE TEMPERATURE

37 GEAR REDUCER

INDICATOR GAUGES GAUGES

38 REQUIRED STRAINER OTHER

39 MANUFACTURER

40 MODEL OIL HEATER REQUIRED

41 TYPE STEAM ELECTRIC

42 SERVICE FACTOR MECHANICAL LUBRICATION REQUIRED

43 RATING MINIMIM DESIGN METAL TEMPERATURE C

44 V-BELT OR CHAIN DRIVE GEARS COMPLY WITH API 613 API 677

45 REQUIRED API 671 COUPLINGS AND GAUGES REQUIRED

46 NO. OF BELTS PREPARATION FOR SHIPMENT

47 SIZE OF BELTS DOMESTIC EXPORT EXPORT BOXING

48 CHAIN DETAILS OUTDOOR STORAGE MORE THAN 6 MONTHS

49 TOTALLY ENCLOSED GUARD WEIGHTS (kg)

50 SLIDE RAILS FOR ADJUSTMENT PUMP BASE GEAR DRIVER

51

06/95 SHT 3 OF 5 API674SI.XLS REV 0

JOB NO. ITEM NO.

RECIPROCATING PUMP (API 674-2ND) REVISION NO. DATE

DATA SHEET PAGE 4 OF 5 BY

SI UNITS

1 PULSATION SUPPRESSION DEVICES FOR RECIPROCATING PUMPS(CONTD) SERVICE

2 THESE SHEETS TO BE FILLED OUT FOR EACH SERVICE AND /OR STAGE STAGE NO.

3 APPLICABLE TO: PROPOSAL PURCHASE AS BUILT

4 FOR/USER

5 SITE/LOCATION AMBIENT TEMPERATURE MIN/MAX / C

6 PUMP SERVICE NUMBER OF PUMPS

7 PUMP MFG. MODEL/TYPE

8 SUPPRESSOR MFG.

9 NOTE: Data Completed Purch. By Pump/Supp. Mfg. w/Proposal By Mfg(s) after order By Mfg(s)/Purchaser as Applicable

10 GENRAL INFORMATION APPLICABLE TO ALL SUPPRESSORS

11

12 TOTAL NUMBER OF SERVICES AND /OR STAGES

13 AMSE CODE STAMP STATE/COUNTRY/PROVINCE OF CODE AND REGULATIONS APPLY

14 OTHER APPLICABLE PRESSURE VESSEL SPEC. OR CODE

15 RADIOGRAPHY (X-RAY OF WELDS): NONE SPOT 100% IMPACT TEST SPECIAL WELDING REQUIREMENTS

16 SHOP INSPECTION OUTDOOR STORAGE OVER 6 MONTHS SPECIAL PAINT SPEC

17

18 DESIGN APPROACH: 1 W/SIMPLIFIED MANUAL ANALYSIS OF PIPING SYSTEM

19 HYDROTEST WITNESS 2 ACOUSTIC SIMULATION STUDY

20 OBSERVE STUDY TO BE WITNESSED: YES NO

21

22 OPERATING AND SUPPRESSOR DESIGN DATA

23 PUMP DATA, THIS SERVICE OR STAGE ONLY NUMBER OF CYL. INTERNAL PASSAGES

24 NOTES:

25 BORE DIA mm STROKE mm RPM

26 PUMP VALVE DATA

27 TYPE LIFT mm WEIGHT g

28 SPRING PRELOAD N SPRING RATE LIFT AREA

29 FULL PROJECTED AREA EFF. FULL LIFT AREA

30 LIQUID HANDLED -SEE DATA SHEET PG. 1 NORMAL OPERATING

31 CORR. PRESENT (DESCRIBE)

32 SPECIFIC GRAVITY

33 COMPRESSIBILITY%

34 OPERATION N PARALLEL W/

35 PUMP MANUFACTURER'S RATED CAPACITY GPM

36 LINE SIDE OPERATING PRESSURE INLET (kPa)(BARG) DISCHARGE (kPa)(BARG)

37 OPERATING TEMP WITHIN SUPRESSORS INLET C DISCHARGE C

38 ALLOWABLE PRESSURE DROP THROUGH SUPPRESSORS P (kPa)(BAR) % P (kPa)(BARG) %

39 INLET SUPPRESSOR DISCHARGE SUPPRESSOR

40 COMBINATION INLET SUPP SEPARATOR/INTERNALS YS. NO / YS. NO / YES NO

41 NO. (QTY) OF INLET &DISCH. SUPP. PER STAGE

42 ALLOWABLE PEAK-PEAK PULSE @ LINE SIDE NOZZLE (kPa)(BARG) % (kPa)(BARG) %

43 ALLOWABLE PEAK-PEAK PUSLE @ CYL FLANGE NOZZLE (kPa)(BARG) % (kPa)(BARG) %

44 MIN. REQ'D WORKING PRESSURE & TEMPERATURE

45 NOTE: After design, the actual Mawp & temp are to be determined (kPa)(BARG) @ C (kPa)(BARG) @ C

46 based on the weakest component and stamped on the vessel.

47 The actual Mawp is to be shown on pg. 5 line 11 and on the U1A

48 Forms.

49

50

51

06/95 SHT 4 OF 5 API674SI.XLS REV 0

JOB NO. ITEM NO.

RECIPROCATING PUMP (API 674-2ND) REVISION NO. DATE

DATA SHEET PAGE 5 OF 5 BY

SI UNITS

1 PULSATION SUPPRESSION DEVICES FOR RECIPROCATING PUMPS (CONT'D) SERVICE

2 THESE SHEETS TO BE FILLED OUT FOR EACH SERVICE AND/OR STAGE STAGE NO.

3 CONSTRUCTION REQUIREMENTS & DATA INLET SUPPRESSOR DISCHARGE SUPPRESSOR

4 BASIC MATERIAL REQUIRED, CS, SS, ETC.

5 ACT.MAT.,ASTM OR SA DESIGNATION SHELL/HEAD / /

6 SPECIAL HARDNESS LIMITATIONS Rc YES NO SHELL & HEADS WELDS SHELL & HEADS WELDS

7 CORROSION ALLOW. (mm) REQUIRED mm mm

8 WALL THICKNESS, (mm) SHELL/HEAD mm/ mm mm/ mm

9 NOM. SHELL DIA x OVERALL LGTH. mm/VOL.m x mm/ m x mm/ m

10 PIPE OR ROLLED PLATE CONSTRUCTION PIPE ROLLED PLATE PIPE ROLLED PLATE

11 ACT MAX ALLOW. WORKING PRESS AND TEMPERATURE (kPa)(BARG) @ C (kPa)(BARG) @ C

12 MAX EXPECTED PRESSURE DROP D P, (kPa)(BAR)% LINE PRESS D P (kPa)(BAR) / % D P (kPa)(BAR) / %

13 WEIGHT, kg EACH kg kg

14 INSUL NUTS & ALLOW. FOR INSULATION REQUIRED YES NO YES NO

15 EXPECTED P-P PULSE @ LINE SIDE CYL FLG, % LINE PRESS

16 BASED ON FINAL SUPPRESSOR DESIGN % / % % / %

17

18 SUPPORTS, TYPE/QUANTITY

19 CONNECTION REQUIREMENTS & DATA

20 LINE SIDE FLANGE, SIZE RATING/FACING/TYPE

21 PUMP FLANGE(S),QTY: SIZE RATING/FACING/TYPE

22 FLANGE FINISH, SPECIAL (SPECIFY)

23 PER ASME 16.5

24 INSPECTION OPENINGS REQUIRED YES NO BLINDED YES NO BLINDED

25 SPEC. QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING

26 *QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING

27 VENT CONNECTIONS REQUIRED YES NO YES NO

28 SPEC. QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING

29 *QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING

30 DRAIN CONNECTIONS REQUIRED YES NO YES NO

31 SPEC. QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING

32 *QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING

33 PRESSURE CONNECTIONS REQUIRED YES NO YES NO

34 SPEC. QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING

35 *QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING

36 TEMPERATURE CONNECTIONS REQUIRED YES NO YES NO

37 SPEC. QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING

38 CYL NOZZLE MAIN BODY

39 *QTY, SIZE, 6000 LB NPT CPLG, FLG TYPE & RATING

40

41

42 OTHER DATA AND NOTES

43 PUMP MFG'S SUPP. OUTLINE OR DRAWING NO.

44 SUPPRESSOR MFG'S OUTLINE OR DRAWING NO.

45 NOTES* = AS BUILT

46

47

48

49

50

51

06/95 SHT 5 OF 5 API674SI.XLS REV 0

(kPa)

You might also like

- API 675 Data Sheet SIDocument2 pagesAPI 675 Data Sheet SIhappale2002100% (3)

- API 610 11th Ed DatasheetDocument13 pagesAPI 610 11th Ed DatasheetHatem ShawkiNo ratings yet

- (API 674-2nd) Reciprocating PumpDocument6 pages(API 674-2nd) Reciprocating PumpadistiNo ratings yet

- API STD 676-2009 - Hoja de RequisiciónDocument28 pagesAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroNo ratings yet

- Api 618 4th Ed Si DatasheetsDocument17 pagesApi 618 4th Ed Si Datasheetshmshawki100% (5)

- Pump DatasheetDocument10 pagesPump DatasheetPaulusIwan100% (1)

- 674 Reciprocating Pump DatasheetsDocument6 pages674 Reciprocating Pump DatasheetsAKSHEYMEHTANo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Document17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNo ratings yet

- 04 - Data Sheet - Mech Seals-Cipf Inj PumpDocument3 pages04 - Data Sheet - Mech Seals-Cipf Inj Pumpisaac2408No ratings yet

- API 676 Datasheet PDFDocument6 pagesAPI 676 Datasheet PDFPierre Norris0% (1)

- API 675 Pump DatasheetDocument2 pagesAPI 675 Pump DatasheetArun CPNo ratings yet

- Centrifugal Pump Data Sheet InsightsDocument1 pageCentrifugal Pump Data Sheet Insightspkitchen25No ratings yet

- SEO-OPTIMIZED TITLEDocument3 pagesSEO-OPTIMIZED TITLEwado11No ratings yet

- API 610 Data Sheet 1 PDFDocument6 pagesAPI 610 Data Sheet 1 PDFSuresh Kumar MittapalliNo ratings yet

- 610 10th Ed Datasheets (SI)Document11 pages610 10th Ed Datasheets (SI)sjois_hsNo ratings yet

- Specification Datasheet For Instrument Air Compressor PackageDocument5 pagesSpecification Datasheet For Instrument Air Compressor PackageBarata RendengNo ratings yet

- Intro To TBE For PumpDocument2 pagesIntro To TBE For PumpMuhammad RidhwanNo ratings yet

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 pagesData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNo ratings yet

- STD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureDocument27 pagesSTD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureNikunj KNo ratings yet

- Globe Valve1 DatasheetDocument1 pageGlobe Valve1 DatasheetobumuyaemesiNo ratings yet

- Native Data Sheet Asme b73.1Document4 pagesNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- Controlled Volume Pump (Api 675-2Nd) Data Sheet U.S. Customary UnitsDocument3 pagesControlled Volume Pump (Api 675-2Nd) Data Sheet U.S. Customary UnitshamedNo ratings yet

- (0152) 4664-MSP-001 - API610 Centrifugal PumpsDocument6 pages(0152) 4664-MSP-001 - API610 Centrifugal PumpsSixto Gerardo Oña AnaguanoNo ratings yet

- FPD 1034 e PDFDocument923 pagesFPD 1034 e PDFBenicio Joaquín Ferrero Brebes75% (4)

- 01SA0S02Document5 pages01SA0S02raobabar21No ratings yet

- Mechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraDocument5 pagesMechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraAhmad RifaiNo ratings yet

- 01NC0B02Document4 pages01NC0B02raobabar21No ratings yet

- API Reciprocating Pump TheoryDocument31 pagesAPI Reciprocating Pump TheoryFidezuri Yemen80% (5)

- Spec For Centrifugal Pumps - APIDocument12 pagesSpec For Centrifugal Pumps - APIjowar100% (1)

- TSV and PSV PDFDocument5 pagesTSV and PSV PDFMetoo ChyNo ratings yet

- Instrument Air Supply: ManualDocument34 pagesInstrument Air Supply: ManualHugoNo ratings yet

- CPT Performance Curves ISO 50Hz 60Hz enDocument255 pagesCPT Performance Curves ISO 50Hz 60Hz enEfosaUwaifoNo ratings yet

- vs1 DatasheetDocument22 pagesvs1 DatasheetMojtabaNo ratings yet

- API 619 (97) PD CompressorsDocument118 pagesAPI 619 (97) PD CompressorsMuhammadAwais100% (1)

- BE-WI-248-01-F19 Datasheet Breather ValveDocument3 pagesBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloNo ratings yet

- bb1 DatasheetDocument14 pagesbb1 DatasheetMojtabaNo ratings yet

- Senior Flexonics Expansion JointsDocument93 pagesSenior Flexonics Expansion JointssunethbabuNo ratings yet

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Document5 pagesSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNo ratings yet

- Equipment data sheet specificationsDocument15 pagesEquipment data sheet specificationsArieWBNo ratings yet

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzNo ratings yet

- ISO 9906 pumps hydraulic performance tests gradesDocument1 pageISO 9906 pumps hydraulic performance tests gradesAhmed SaedNo ratings yet

- Process Design P-001Document39 pagesProcess Design P-001Yohanes Silaen100% (1)

- Data Sheet FOR Centrifugal Pump: Page 1 of 3Document3 pagesData Sheet FOR Centrifugal Pump: Page 1 of 3ThiênSứBanPhúcNo ratings yet

- API 610 DatasheetDocument7 pagesAPI 610 DatasheetagusnnnNo ratings yet

- Centrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si UnitsDocument15 pagesCentrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si Unitsf09aiNo ratings yet

- Vacuum PresentationDocument277 pagesVacuum Presentationavinashpatil2408100% (2)

- Review of BPV XIII 2021Document32 pagesReview of BPV XIII 2021Dan Tompkns100% (2)

- Api 676 UsDocument2 pagesApi 676 UsAbhai Gupta100% (1)

- Hoja de Datos API-674Document5 pagesHoja de Datos API-674texwan_No ratings yet

- Reciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsDocument10 pagesReciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsÆmanuel J Silva100% (1)

- API 674 Pump Data SheetDocument5 pagesAPI 674 Pump Data SheetFahmi AtriadiNo ratings yet

- Api 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetDocument22 pagesApi 674,2Nd Edition: Reciprocating Pump Data Sheet Revision Record SheetmaruthigabbitaNo ratings yet

- Centrifugal Pump Api-610 Data Sheet Mks Units: Operating Conditions Site and Utility Data (Cot D)Document12 pagesCentrifugal Pump Api-610 Data Sheet Mks Units: Operating Conditions Site and Utility Data (Cot D)sahrilbayunirosidikNo ratings yet

- Api 673 SiDocument11 pagesApi 673 Situtuionut100% (1)

- Controlled Volume Pump - SI Units - Non ColoredDocument2 pagesControlled Volume Pump - SI Units - Non ColoredDayo IdowuNo ratings yet

- DATA SHEET MULTIPHASE PUMP REV0 BornermanDocument5 pagesDATA SHEET MULTIPHASE PUMP REV0 BornermanJessika López100% (1)

- HD Api610Document5 pagesHD Api610Venkat RanganNo ratings yet

- PROJECT UNITS DATA SHEETDocument7 pagesPROJECT UNITS DATA SHEETHatem ShawkiNo ratings yet

- API 675 pump specification sheetDocument2 pagesAPI 675 pump specification sheetAKSHEYMEHTANo ratings yet

- Turboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP CompDocument6 pagesTurboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP ComptutuionutNo ratings yet

- Casio G-Shock 5562 ManualDocument9 pagesCasio G-Shock 5562 ManualEason NgNo ratings yet

- 153 152 151 150 148 146 ASME PCC1-Bolted Joint Integrity Presentation 1Document17 pages153 152 151 150 148 146 ASME PCC1-Bolted Joint Integrity Presentation 1Eason NgNo ratings yet

- API 510 Sample QuestionsDocument10 pagesAPI 510 Sample Questionsbichibtech1No ratings yet

- API 579 Fitness For Service, Current State of TechnologyDocument61 pagesAPI 579 Fitness For Service, Current State of TechnologyEason Ng100% (2)

- BMW-Price-List-20170706 PDF Asset 1499233595444Document1 pageBMW-Price-List-20170706 PDF Asset 1499233595444Eason NgNo ratings yet

- API 6D Valve Test PressureDocument1 pageAPI 6D Valve Test PressureEason NgNo ratings yet

- API 510. Daily Exam-1 (Closed Book)Document6 pagesAPI 510. Daily Exam-1 (Closed Book)DAMIAN ALEJANDRO100% (1)

- Api 510 Practice Exam B (150 Questions) : Design Temp Test TempDocument45 pagesApi 510 Practice Exam B (150 Questions) : Design Temp Test Temperagorn100% (2)

- API 574 Piping Inspection Guide for Visual Checks, Thickness Tests & Pressure ExamsDocument8 pagesAPI 574 Piping Inspection Guide for Visual Checks, Thickness Tests & Pressure ExamsEason NgNo ratings yet

- API 6A Type 6B & 6BX FlangesDocument31 pagesAPI 6A Type 6B & 6BX FlangesEason NgNo ratings yet

- Fike Pressure Relief Product GuideDocument5 pagesFike Pressure Relief Product GuideEason NgNo ratings yet

- API 5L - Summary PDFDocument3 pagesAPI 5L - Summary PDFEason Ng0% (1)

- Xist PDFDocument2 pagesXist PDFAgustin Gago LopezNo ratings yet

- Sony Home Audio VideoDocument14 pagesSony Home Audio VideoEason Ng100% (1)

- Asme b16.48 Steel Line Blanks (1997)Document35 pagesAsme b16.48 Steel Line Blanks (1997)Eason NgNo ratings yet

- 2016 IDC Course CalendarDocument2 pages2016 IDC Course CalendarEason NgNo ratings yet

- Penetrant TestingDocument43 pagesPenetrant TestingVineet JeswaniNo ratings yet

- TDP InfoDocument7 pagesTDP InfoEN LeedNo ratings yet

- S-0701-PE Chief Engineer's ReportDocument2 pagesS-0701-PE Chief Engineer's ReportThiet Pham100% (1)

- RAM StudyDocument12 pagesRAM StudyputelNo ratings yet

- Hilti Te70 PDFDocument13 pagesHilti Te70 PDFSIVARAMANJAGANATHAN100% (1)

- GP080-120VX Folleto Comercial - CompressedDocument16 pagesGP080-120VX Folleto Comercial - CompressedhiabyyNo ratings yet

- 2 - W 220 Genset & Datasht PDFDocument80 pages2 - W 220 Genset & Datasht PDFshahin gholamiNo ratings yet

- (DOL) Motor Starter: Instructions For Direct-On-LineDocument3 pages(DOL) Motor Starter: Instructions For Direct-On-LineVenkata Suresh MandavaNo ratings yet

- Reciprocating Engine Overhaul ProceduresDocument4 pagesReciprocating Engine Overhaul ProceduresCapNo ratings yet

- Caterpillar Cat 216B3 Skid Steer Loader (Prefix PWK) Service Repair Manual (PWK00001 and Up)Document28 pagesCaterpillar Cat 216B3 Skid Steer Loader (Prefix PWK) Service Repair Manual (PWK00001 and Up)rpoy9396615No ratings yet

- D Sars 0017924Document7 pagesD Sars 0017924Richardo JuarezNo ratings yet

- Ash HandlingDocument12 pagesAsh HandlingKhemant OdNo ratings yet

- Data TWD1643 GEDocument17 pagesData TWD1643 GEVolvo Truck100% (3)

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document30 pagesTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkNo ratings yet

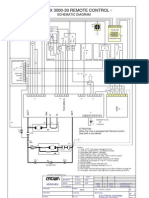

- SX 3000-30 REMOTE CONTROL SCHEMATIC DIAGRAMDocument8 pagesSX 3000-30 REMOTE CONTROL SCHEMATIC DIAGRAMAngela ZMNo ratings yet

- Irregularities in Indicator Diagram - Marine Engineering Study MaterialsDocument6 pagesIrregularities in Indicator Diagram - Marine Engineering Study MaterialsRavi Viknesh100% (1)

- Caterpillar Engine 2Document4 pagesCaterpillar Engine 2fahmi wibowoNo ratings yet

- How To Replace Fuel Filter Assembly On Toyota Vios Gen 2 - YouTubeDocument1 pageHow To Replace Fuel Filter Assembly On Toyota Vios Gen 2 - YouTubeJun TumananNo ratings yet

- Hss 3200 App Iss 2.3 07 11Document58 pagesHss 3200 App Iss 2.3 07 11Luis Carlos80% (5)

- Cat Electronic Technician 2019C v1.0 Product Status ReportDocument9 pagesCat Electronic Technician 2019C v1.0 Product Status ReportAndy A.S.No ratings yet

- EIL Standard Specification PDFDocument107 pagesEIL Standard Specification PDFkalaiNo ratings yet

- RX50Document519 pagesRX50Vinícius FerrazNo ratings yet

- Digifant MP 4.0Document30 pagesDigifant MP 4.0victorvicvicNo ratings yet

- Catalog of Replacement Parts: CL44e AND CL54e Series DishwashersDocument40 pagesCatalog of Replacement Parts: CL44e AND CL54e Series DishwashersAndres RiveraNo ratings yet

- Ducati WiringDocument7 pagesDucati WiringRyan LeisNo ratings yet

- BacklashDocument6 pagesBacklashvishnuNo ratings yet

- Universal MotorDocument4 pagesUniversal MotorarunNo ratings yet

- Catalogue Pièces de Rechange Spare Parts Catalogue: Ref: 15 18 311 0FDocument17 pagesCatalogue Pièces de Rechange Spare Parts Catalogue: Ref: 15 18 311 0Ffird100% (1)

- Carrier 40mphaq12xa3 Article 2478185340526029 en SMDocument48 pagesCarrier 40mphaq12xa3 Article 2478185340526029 en SMWilliam TayNo ratings yet

- 7.1 - en-US - 2022-04 - BRK - Flygt Basic Repair KitDocument52 pages7.1 - en-US - 2022-04 - BRK - Flygt Basic Repair KitFernando ChavesNo ratings yet

- Vibratingfeeder 150211110459 Conversion Gate01Document18 pagesVibratingfeeder 150211110459 Conversion Gate01ManekGorisNo ratings yet