Professional Documents

Culture Documents

Case Study TPM Jet Airways

Uploaded by

Sanjay DomdiyaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study TPM Jet Airways

Uploaded by

Sanjay DomdiyaCopyright:

Available Formats

Vinod R Patel(2240)

Kaumil Shah(2246)

Chirag Vaghela(2258)

Ritin Maheta( 2222)

Hinshitsu Hozen : Focuses upon setting targets for

ensuring quality of products. These targets maybe

reduction in process failures, consumer complaints,

and retention time of row material and processed

materials.

Jishu Hozen : The first pillar of TPM; in Japanese, it

means autonomous maintenance. In JH, the workers

are taught that cleaning the machine helps into

discovering areas of equipment malfunctioning.

Kobetsu Kaizen : or Individual improvement, is to aim

at zero losses of all kinds, sixteen major kind of

losses are identified, their current level is calculated,

and goals are set for improvement in overall

equipment efficiency(OEE)

TPM is an innovative Japanese concept.

The origin of TPM can be traced back to 1951 when

preventive maintenance was introduced in Japan.

The concept of preventive maintenance was taken

from USA.

Nippondenso was the first company to introduce

plant wide preventive maintenance in 1960.

They were following preventive maintenance but also

autonomous maintenance added by the way of

modification of equipment while in preventive

maintenance hence its become a productive

maintenance which is maximizing the equipment

effectiveness to achieve the optimum life cycle cost of

equipment.

Maintenance : Maintenance is an initiatives that covers all

those operations such as monitoring , inspecting, adjusting,

repairing and / or doing whatever is necessary to keep a

machine, a facility, a piece of equipment or transportation

vehicle in the proper working conditions

Maintenance Management : Maintenance Management is

reviewing, planning,organising and controlling maintenance

activities such that the overall maintenance cost is the

minimum.

TPM : In TQM, the Total Productive Maintenance is an important and

effective tool for excellence. Total productive maintenance (TPM)

is keeping the current plant and equipment at its highest

productivity level through cooperation of all areas of the

organization. Generally, the first bridge to cross is to break

down the traditional barriers between maintenance and

production personnel so they are working together.

Jet airways engineering and maintenance facility was setup

in 1994 and progressively upgraded to carryout

maintenance up to C checks.

This is being further upgraded to D checks(Highest Level

of checks).

Jet Airways main engineering base is located at Mumbai

and its second base is Delhi with maintenance hanger

facility.

It also carries maintenance activities at its night halt

stations at Chennai, Kolkata and Bangalore.

Leased maintenance facility at Bangalore from HAL.

Its engineering team consists of highly qualified and

professional engineers, technicians and support staff .The

team has proved their competency by achieving the

highest dispatch reliability rate 99.2 % and above.

Its is basically divided in Three general category ;

1. Line maintenance : it is routine , scheduled

maintenance of air craft including pre-flight, daily

and overnight checks, and diagnostic and repairs.

2. C or phase 10 checks. : It is basically carries after 4800

flight hours, requires more eight days , it is more complex

inspection and servicing of air craft that require a longer

maintenance period. It is pre schedule agenda of major

overhauls defined in air crafts manual.

3. D Checks ( Heavy Maintenance) : This is major

maintenance work resulting un availability of air craft for

entire duration of such fiscal year.

Its maintenance procedure are regulated by

Directorate general of Civil Aviation(DGCA).

Regulations framed by DGC A are based on

international Civil Aviation Organization(ICAO)

Maintenance programme are based of Manufacturers

maintenance planning documents(MPD).

D type checks of Boing air craft approved by US

federal aviation Administration.

They have capability to carry out C type checks as per DGCA

norms.

Technical personnel are trained by its in-house training

programme and also by programmes offered by aircraft and

engine manufacturers.

Its quality control division overseas the compliance of all

airworthiness requirements and co-ordination with DGCA for

engineering activities.

Its engineering technical service division implements

modifications, determine work scope of repair and

maintenance and plan shop visits for engines and APUs.

Its engineering planning division forecasts long-term and

short-term maintenance activities and engaged in

optimization of resources and minimization of time required

for maintaining aircraft.

Its reliability section monitors components and analysis

defects of systems and components.

Power by the hour(PBTH) contract with Lufthansa

Techlink for the repair and maintenance of spares for

Boing fleet.

PBTH contract with Israel air craft industries Limited

for the maintenance of auxiliary power units(APU) for

boing 737-400, Classic aircraft

Contract with Honeywell International ,USA for the

repairs and overhaul of APUs in Boing-737,NG

aircraft.

PBTH contract with Hanover,GmbH, Germany for

engine condition monitoring and engineering services

for CFM 56-7 of Boing 737 NG.

In late 2006 ,Jet airways has purchased innovative,

web based maintenance tool-Maintenance

Performance Tool box (MPT) from Boing.

MPT is aviation industrys first set of productivity

tools designed to unify an airlines maintenance and

engineering operation from start to finish.

MPT gives airlines quick access to critical

maintenance information and ability to streamline the

potentially cumbersome process of customizing

online maintenance manuals, generates and

automatically track task cards.

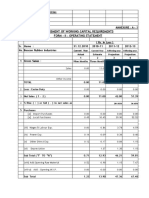

The cost of construction and maintenance of Hanger

is 690 million.

The construction of hanger is expected to reduce

maintenance cost and improve operational efficiency.

Costs of air craft maintenance ,APU, and engine

maintenance and repair are accounted for as

incurred, except such overhaul cost in respect of

engines/APU are covered by third party maintenance

agreement and accounted for an accordance with

such agreements.

From fiscal 2005, Jet airways has to implement AS-29

hence to consider expenditure of maintenance on

incurred basis which was earlier calculated on the

basis of hours flown.

Maintenance and repair cost decreased by

16.6 per cent from 1668 million to 1391

million for H1-2003.

This is primarily due to adopting new

accounting standard and discontinuation of

the accruals of certain provisions.

In just 10 years, Jet Airways has risen to be the

number one in India's domestic market with 50 Boing

737s and has started international services with

wide-body air craft.

The carrier has ordered one A330, twelve A 350s, and

ten 777s by 2009.

Jet Airways Chairman Mr. Naresh Goyal says airline

now has the critical mass in terms of size to launch

MRO company.

The company has announced plan to set up MRO

,collaboration with Lufthansa Techink.

1. A maintenance strategy involving creation of its own

MRO facilities has resulted in higher maintenance

costs for jet Airways compared to its new low-cost

rivals such as air Deccan, Spice jet and Indigo, Which

outsource their MRO. Discus..

2. Why would Lufthansa Technik be Interested in

helping Jet Airways establish its own MRO arm in

India ?

3. What steps should Jet Airways take to attract rivals in

India like Air Deccan,Spicejet,Indigo,etc.outiulize its

MRO service in place of their MRO to foreign

organizations ?

You might also like

- The Ultimate Step-By-Step Guide To Day Trading Penny StocksDocument66 pagesThe Ultimate Step-By-Step Guide To Day Trading Penny StocksAshleyHatcherNo ratings yet

- Basics of Aircraft Maintenance Programs For Financiers v1Document23 pagesBasics of Aircraft Maintenance Programs For Financiers v1Denilson Ribeiro100% (2)

- Fin 4150 Advanced Business Valuation Assignments Overview: Assignment 1: Class Preparation/Professionalism/ParticipationDocument21 pagesFin 4150 Advanced Business Valuation Assignments Overview: Assignment 1: Class Preparation/Professionalism/ParticipationEric McLaughlinNo ratings yet

- Veronica Atieno OpiyoDocument1 pageVeronica Atieno OpiyoChuck FenderNo ratings yet

- Project Report Indigo (Interglobe Aviation) AirlinesDocument13 pagesProject Report Indigo (Interglobe Aviation) AirlinesManik SharmaNo ratings yet

- Issue69 PDFDocument164 pagesIssue69 PDFsilvofNo ratings yet

- Inventory Management Assignment "World Class Manufacturing" Submitted To Sir Raja KhalidDocument15 pagesInventory Management Assignment "World Class Manufacturing" Submitted To Sir Raja KhalidFatimah KhanNo ratings yet

- Spicejet AirlinesDocument15 pagesSpicejet Airlinesshekhar_navNo ratings yet

- Module 01 - Special Economic Zone ActDocument42 pagesModule 01 - Special Economic Zone ActKyla Shmily GonzagaNo ratings yet

- Case Study in Aircraft MaintenanceDocument22 pagesCase Study in Aircraft MaintenanceMichael MitchellNo ratings yet

- Corporate Restructuring of Air India PDFDocument32 pagesCorporate Restructuring of Air India PDFgauri100% (1)

- Role of Management Information System in Tata MotorsDocument13 pagesRole of Management Information System in Tata MotorsPrasanna Dhanasekaran0% (1)

- Cat Logistics: Caterpillar Logistics Services, IncDocument17 pagesCat Logistics: Caterpillar Logistics Services, IncAnirudh VishnubhatlaNo ratings yet

- A Project Report Submitted in Partial Fulfillment Of: Master of Business Administration (MBA)Document39 pagesA Project Report Submitted in Partial Fulfillment Of: Master of Business Administration (MBA)Soma Chakraborty67% (3)

- Jet Airways MRO MarketDocument16 pagesJet Airways MRO MarketRajat AgrawalNo ratings yet

- 3a Maintenance ScheduleDocument13 pages3a Maintenance ScheduleWan Safwan100% (2)

- Managing Enterprise Content A Unified Content StrategyDocument385 pagesManaging Enterprise Content A Unified Content StrategyFrancisCharlesOcampo80% (5)

- RFP For Jet Airways v2Document17 pagesRFP For Jet Airways v2rahulalwayzzNo ratings yet

- Indian Airline Industry - Group1Document58 pagesIndian Airline Industry - Group1Shankho BaghNo ratings yet

- A Comparative Study On Indian Aviation Sector With Air India and Indigo Airlines Companies in IndiaDocument3 pagesA Comparative Study On Indian Aviation Sector With Air India and Indigo Airlines Companies in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Indigo Airlines Case StudyDocument5 pagesIndigo Airlines Case StudyDebottam BhattacharyyaNo ratings yet

- Balance Scorecard For Air IndiaDocument10 pagesBalance Scorecard For Air IndiaRyan HabaNo ratings yet

- Spice JetDocument4 pagesSpice JetPratik JagtapNo ratings yet

- Dmgs Dip 27092 FinalDocument11 pagesDmgs Dip 27092 FinalEsa BhattacharyaNo ratings yet

- Strategic Management of Jet AirwaysDocument23 pagesStrategic Management of Jet AirwaysApekshaNo ratings yet

- Branding Strategy and Market Share: A Case Study of Jet AirwaysDocument8 pagesBranding Strategy and Market Share: A Case Study of Jet Airwaysakshat mathurNo ratings yet

- Bombardier CaseDocument11 pagesBombardier CaseSamitRanjanNo ratings yet

- IndiaAirline Tejas Mar17Document21 pagesIndiaAirline Tejas Mar17Manoj JosephNo ratings yet

- Indian Airlines HR ProblemsDocument5 pagesIndian Airlines HR ProblemsPraveen Sah100% (2)

- Growth of Indian Aviation IndustryDocument6 pagesGrowth of Indian Aviation IndustrypriyankpmNo ratings yet

- INDIGO by Ravi ShahDocument38 pagesINDIGO by Ravi ShahRavi RanjanNo ratings yet

- Oligopoly in Oil Refinery IndustryDocument5 pagesOligopoly in Oil Refinery IndustryDokania Anish100% (2)

- Airbus Looking For MRO in IndiaDocument1 pageAirbus Looking For MRO in IndiaTabrez HassanNo ratings yet

- Indigo Airlines MarketingDocument15 pagesIndigo Airlines MarketingAbhiroop MukherjeeNo ratings yet

- Jet AirwaysDocument25 pagesJet AirwaysNaman AgrawalNo ratings yet

- Air IndiaDocument32 pagesAir IndiaPiyush KamraNo ratings yet

- Air IndiaDocument3 pagesAir IndiaZamora Enguerra EmmalyneNo ratings yet

- 7 P'S of Marketing Mix: Air IndiaDocument9 pages7 P'S of Marketing Mix: Air Indiadivyanshu ranjanNo ratings yet

- STP Spice JetDocument6 pagesSTP Spice JetPranky PanchalNo ratings yet

- Many Challenges On Indian EconomyDocument11 pagesMany Challenges On Indian EconomyHarikrishna Malla100% (1)

- Group 4 - ITC - Live ProjectDocument31 pagesGroup 4 - ITC - Live ProjectSyama kNo ratings yet

- Porters 5 Forces Presentation1Document8 pagesPorters 5 Forces Presentation1Tapan Shah100% (1)

- 412 - Indigo Airlines Case StudyDocument2 pages412 - Indigo Airlines Case Studyaman sharmaNo ratings yet

- Canon Executive SummaryDocument10 pagesCanon Executive SummaryIgel Gerard ManaloNo ratings yet

- Kingfisher AirlinesDocument14 pagesKingfisher AirlinesGaurav Patel50% (2)

- Marketing Management - II "Vistara": Group 03Document19 pagesMarketing Management - II "Vistara": Group 03Jasneet SinghNo ratings yet

- Air IndiaDocument12 pagesAir IndiaSathriya Sudhan MNo ratings yet

- Air IndiaDocument52 pagesAir IndiaAashish Gupta100% (1)

- SIA B - Case StudyDocument2 pagesSIA B - Case StudyDhanashree GharatNo ratings yet

- Presentation On Aviation IndustryDocument20 pagesPresentation On Aviation Industryaashna171No ratings yet

- Aviation Ancillary Services Question Bank Unit I Part B & C: Bba - 2 YearDocument4 pagesAviation Ancillary Services Question Bank Unit I Part B & C: Bba - 2 YearNambi RajanNo ratings yet

- Airport Strategic Planning Master Planning: An Exploratory Research ProjectDocument74 pagesAirport Strategic Planning Master Planning: An Exploratory Research ProjectUROOJ ARSHADNo ratings yet

- Jet AirwaysDocument4 pagesJet AirwaysKumar SachinNo ratings yet

- Strategic Management (IBM)Document22 pagesStrategic Management (IBM)AnilchaurasiyaNo ratings yet

- Jet AirwaysDocument25 pagesJet AirwaysTriptiNo ratings yet

- Job Description - Direct Entry PilotDocument2 pagesJob Description - Direct Entry PilotLucas NobreNo ratings yet

- Project Report On Jet Airways CitrixDocument9 pagesProject Report On Jet Airways CitrixvithanibharatNo ratings yet

- Executive SummaryDocument65 pagesExecutive Summaryakshay_kotkar_1No ratings yet

- Case: The North - South Airline: Far Eastern UniversityDocument17 pagesCase: The North - South Airline: Far Eastern UniversityEly CasugaNo ratings yet

- Greenville PPT Group 1Document22 pagesGreenville PPT Group 1Anushree GawadNo ratings yet

- Indian Airlines' HR ProblemsDocument8 pagesIndian Airlines' HR ProblemsAsif PatelNo ratings yet

- The Service Marketing Mix of A CompanyDocument9 pagesThe Service Marketing Mix of A CompanyMoinuddin Khan KafiNo ratings yet

- MISDocument13 pagesMISVaibhav ShahNo ratings yet

- Marketing Project Report On Measuring Success of New Product in Indian Auto Mobile Industry1Document66 pagesMarketing Project Report On Measuring Success of New Product in Indian Auto Mobile Industry1sneyadavNo ratings yet

- 03 - Boeing Group 7Document5 pages03 - Boeing Group 7kunal_thakur_250% (2)

- Employees Come FirstDocument4 pagesEmployees Come FirstLeonWilfanNo ratings yet

- Q3 - MOS AssignmentDocument2 pagesQ3 - MOS AssignmentAman AgarwalNo ratings yet

- Summary - RFQ - 23649 - PPL Tender DocumentsDocument9 pagesSummary - RFQ - 23649 - PPL Tender DocumentsAbuAbdullah KhanNo ratings yet

- Assessment of Working Capital Requirements Form - Ii: Operating StatementDocument17 pagesAssessment of Working Capital Requirements Form - Ii: Operating StatementAshok TiwaryNo ratings yet

- Assessment Task 2 InstructionsDocument15 pagesAssessment Task 2 InstructionsKira- SamaNo ratings yet

- Entrepreneurship Module No. - 7 - : Week 7: 1ST Quarter Marketing MixDocument7 pagesEntrepreneurship Module No. - 7 - : Week 7: 1ST Quarter Marketing MixAnnie S RejanoNo ratings yet

- Order Form - Swing Design Autumn 2014Document10 pagesOrder Form - Swing Design Autumn 2014Swing DesignNo ratings yet

- GE01 - Online Free Class Lecture Sheet PDFDocument40 pagesGE01 - Online Free Class Lecture Sheet PDFRefa- E- Alam 1110884030No ratings yet

- 7000 Word DissertationDocument4 pages7000 Word DissertationPsychologyPaperWritingServiceUK100% (1)

- Assignment MPU3223 - V2 Entrepreneurship September Semester 2021Document5 pagesAssignment MPU3223 - V2 Entrepreneurship September Semester 2021zainab ibrahimNo ratings yet

- YouTube Business - Cheat SheetDocument4 pagesYouTube Business - Cheat SheetChristian WagnerNo ratings yet

- Consultants IndiaDocument57 pagesConsultants IndiaAlok KumarNo ratings yet

- Viertola Wilma PDFDocument35 pagesViertola Wilma PDFPai RoroNo ratings yet

- PD Reissuancetawarruq Dec2018Document34 pagesPD Reissuancetawarruq Dec2018ELISSANUR SURAYA BINTI ARNAZ YUSRYNo ratings yet

- Engleski Jezik - IspitDocument610 pagesEngleski Jezik - IspitLeonarda PavićNo ratings yet

- Bike24 PDFDocument1 pageBike24 PDFAntonijVedernikovNo ratings yet

- Animation NC Ii: Technical Vocational and Livelihood (TVL) Information and Communication TechnologiesDocument18 pagesAnimation NC Ii: Technical Vocational and Livelihood (TVL) Information and Communication TechnologiesNiacinamide Demethiconol Cyclopentaxiloxane100% (1)

- Value Chain AnalysisDocument4 pagesValue Chain AnalysisnidamahNo ratings yet

- RBI Grade B 2021 Phase-I Memory Based Questions Papers - Quantitative AptitudeDocument10 pagesRBI Grade B 2021 Phase-I Memory Based Questions Papers - Quantitative AptitudelearningNo ratings yet

- ICN CPN CPA New Target Values For aPTTDocument4 pagesICN CPN CPA New Target Values For aPTTluisoft88No ratings yet

- Mock Questions PDFDocument6 pagesMock Questions PDFMadhuram SharmaNo ratings yet

- BST Notes 2023Document132 pagesBST Notes 2023Blablabla100% (1)

- Velaris North Unit 23H (200sqm)Document1 pageVelaris North Unit 23H (200sqm)Lean MeilyNo ratings yet

- Thesis On Humor AdvertisingDocument5 pagesThesis On Humor AdvertisingElizabeth Williams100% (2)

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Ér Kúñdäñ PåñðëýNo ratings yet