Professional Documents

Culture Documents

Other Mill Powers

Uploaded by

sempatik721Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Other Mill Powers

Uploaded by

sempatik721Copyright:

Available Formats

16 10 2014

Other Mill Powers

The Mining Grinding Office

Thu, 16 October 2014, 18:38:07 UTC

Main Home

Home Mining

Tools Calculators

Grinding Technology

Links

www.themininggrindingoffice.com

All rights reserved 2012-2014 The Mining Grinding Office

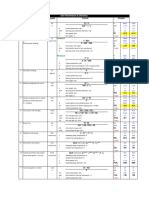

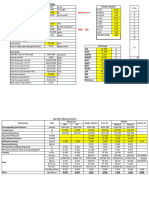

Other Power Formulas

1

Introduction:

- This paper intends to describe the different methods to calculate the power of a ball mill.

- Two methods will be presented here:

1) Bond formula

2) Hogg and Fuerstenau formula

Bond Formula:

- The Bond power formula is the following:

Where:

Pb is the power by ton of balls at the shaft in kW/ton,

D is the internal mill diameter in m,

J is the volume load (filling degree) in % and

Vcr is the percentage of the critical speed.

- If the mill is with grate discharge, the formula must be multiplied by 1,08.

- A correction factor called Ss must be applied for mills with a diameter higher than 3,3m:

Where:

Ss is the ball size factor in kW/t and

dm is the maximum ball diameter in mm.

And the formula for these mills is:

- To get the absorbed power of the mill at terminals, it is necessary to multiply by the tonnage of balls and to

correct with the transmission and motor efficiency factors.

Hogg and Fuerstenau Formula:

- The Hogg and Fuerstenau power formula is the following:

Where:

P is the power at the shaft in kW,

D is the mill's internal diameter in m.

L is the useful length in m,

Vcr is the percentage of the critical speed,

app is the apparent density of the charge in t/m3,

J is the volume load (filling degree) in % and

La is the lifting angle of the charge gravity center with the vertical line.

- app is given by the following formula:

Where:

BC is the tonnage of the ball charge in tons,

M is the tonnage of material between the balls (intersticial) and

http://www.thecementgrindingoffice.com/mining/othermillpowers.html

1/2

16 10 2014

Other Mill Powers

M is the tonnage of material between the balls (intersticial) and

Vch is the volume taken by the ball charge in m3.

M is given by the following formula:

Where:

bmat is the bulk density of the material in t/m3

J is the volume load (filling degree) in %,

D is the mill's internal diameter in m and

L is the useful length in m.

- To get the absorbed power of the mill at terminals, it is necessary to correct with the transmission

and motor efficiency factors.

www.themininggrindingoffice.com

All rights reserved 2012-2014 The Mining Grinding Office

Calculators are available here:

All rights reserved 2012-2014 The Mining Grinding Office

http://www.thecementgrindingoffice.com/mining/othermillpowers.html

Go back to the top

2/2

You might also like

- HPGRSim Openpractica1Document83 pagesHPGRSim Openpractica1Aldo PabloNo ratings yet

- Study of The Grinding Balls Distribution Inside The MillDocument2 pagesStudy of The Grinding Balls Distribution Inside The Millsempatik721No ratings yet

- Ball Mill Volume LoadingDocument2 pagesBall Mill Volume LoadingThaigroup CementNo ratings yet

- 1.4878 Eng PDFDocument3 pages1.4878 Eng PDFRoberto_PrrNo ratings yet

- Thermos Design of Rotary Kiln For Reduction of Radiation Losses-10Document17 pagesThermos Design of Rotary Kiln For Reduction of Radiation Losses-10Madhav Krishna MNo ratings yet

- Mechanical OperationDocument116 pagesMechanical OperationNomee PatelNo ratings yet

- Effect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierDocument51 pagesEffect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierNam HuynhNo ratings yet

- Coal Mill Ball Interlocks-V0.0Document11 pagesCoal Mill Ball Interlocks-V0.0Junaid MazharNo ratings yet

- Hopper Heating Design GuideDocument4 pagesHopper Heating Design GuideBadukwangNo ratings yet

- Fundamental analysis of ACC Ltd and India's cement industryDocument5 pagesFundamental analysis of ACC Ltd and India's cement industryDevika SuvarnaNo ratings yet

- Ball Mill Sizing CalculatorDocument6 pagesBall Mill Sizing CalculatorHoàng HùngNo ratings yet

- Executive Summary: Delhi Pollution Control CommitteeDocument26 pagesExecutive Summary: Delhi Pollution Control CommitteeparthNo ratings yet

- Better Burner Specifications PDFDocument4 pagesBetter Burner Specifications PDFAbdul HayyeNo ratings yet

- Comparison of Different Methods For Enhancing Reactivity of Pozzolans PDFDocument6 pagesComparison of Different Methods For Enhancing Reactivity of Pozzolans PDFArtemia Loayza ArguellesNo ratings yet

- Paper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit DesignDocument13 pagesPaper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit Designcuberbill1980No ratings yet

- 09.work Instruction For Operation of Additive Ball MillDocument9 pages09.work Instruction For Operation of Additive Ball MillRahul VermaNo ratings yet

- Waste CFB CombustionDocument15 pagesWaste CFB CombustionmihugirNo ratings yet

- Ball Top Size Diameter CalculationDocument1 pageBall Top Size Diameter Calculationsempatik721100% (1)

- Low NOx Burners in High Temp SerDocument21 pagesLow NOx Burners in High Temp SerIman Akbari100% (1)

- In VoluteDocument3 pagesIn Voluteds693No ratings yet

- Importance of Dedusting Pipe LayoutDocument4 pagesImportance of Dedusting Pipe LayoutManoj ThakurNo ratings yet

- AFR Profile 2003 GuidelinesDocument13 pagesAFR Profile 2003 Guidelinesshani5573No ratings yet

- 4 MPDocument33 pages4 MPSyed Shahzaib ShahNo ratings yet

- Cement Kiln Installed Capacity Calculation MethodsDocument2 pagesCement Kiln Installed Capacity Calculation Methodsemad sabriNo ratings yet

- Heat BalanceDocument33 pagesHeat BalanceIrshad Hussain100% (2)

- AG and SAG Mill Circuit Selection and Design by SimulationDocument22 pagesAG and SAG Mill Circuit Selection and Design by Simulationbob2341No ratings yet

- Lime - Reactivity - WC2014 - 01 PDFDocument7 pagesLime - Reactivity - WC2014 - 01 PDFAlbertNo ratings yet

- New AG/SAG mill model for scale-up and optimisationDocument9 pagesNew AG/SAG mill model for scale-up and optimisationJuanOlivaresNo ratings yet

- The Future of ComminutionDocument15 pagesThe Future of ComminutionAngel LopezNo ratings yet

- Flow Conversion To Normal Meter Cube Per HourDocument2 pagesFlow Conversion To Normal Meter Cube Per HourIrfan AhmedNo ratings yet

- Waste Heat Recovery System For Cement PlantDocument6 pagesWaste Heat Recovery System For Cement PlantandrowreganNo ratings yet

- An Overview of Single Stage Autogenous and Semiautogenous Grinding MillsDocument12 pagesAn Overview of Single Stage Autogenous and Semiautogenous Grinding Millsjosesejo123No ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatorsriramNo ratings yet

- Mill Calculation: Plant: Date: Mill: VisaDocument2 pagesMill Calculation: Plant: Date: Mill: VisaThaigroup CementNo ratings yet

- Annexure 1 Mass Flow RajashreeDocument3 pagesAnnexure 1 Mass Flow RajashreeKenny RuizNo ratings yet

- Clinker Cooler Queching Best PracticeDocument1 pageClinker Cooler Queching Best PracticeShukor AzNo ratings yet

- Ercom Brief ProfileDocument57 pagesErcom Brief ProfileKarthik DhayalanNo ratings yet

- Kiln Eval Line IDocument1 pageKiln Eval Line IRaji SuriNo ratings yet

- Transformations E.12Document36 pagesTransformations E.12Dilnesa EjiguNo ratings yet

- A Critical Review of SAG Mill Design ProceduresDocument3 pagesA Critical Review of SAG Mill Design ProceduresAbhay BodhmageNo ratings yet

- StanexDocument2 pagesStanexSamehibrahemNo ratings yet

- Performance metrics and operational data from a cement kiln over 72 hoursDocument1 pagePerformance metrics and operational data from a cement kiln over 72 hoursElwathig BakhietNo ratings yet

- Solids flow modes and hopper design principlesDocument14 pagesSolids flow modes and hopper design principlesHogar Belo HorizonteNo ratings yet

- A Comparison of The Bond Method For Sizing Wet Tumbling Mills With A Size Mass Balance Simulation ModelDocument14 pagesA Comparison of The Bond Method For Sizing Wet Tumbling Mills With A Size Mass Balance Simulation ModelJavier Enrique Toro YentzenNo ratings yet

- Ball Mill Design - CompressDocument6 pagesBall Mill Design - CompressSuresh VedalaNo ratings yet

- Find similar insulating brick to SkamolDocument1 pageFind similar insulating brick to SkamolpsaayoNo ratings yet

- Pyro System - Control Loops V0.0Document2 pagesPyro System - Control Loops V0.0Junaid MazharNo ratings yet

- MBT CalculatorDocument2 pagesMBT Calculatorsempatik721100% (1)

- 2012 - Design, Fabrication and Commissioning of RDF PDFDocument72 pages2012 - Design, Fabrication and Commissioning of RDF PDFHilmi Gazali TvkNo ratings yet

- Calculation of Max. Ball Size: Plant: Mill Nr. Mill SizeDocument1 pageCalculation of Max. Ball Size: Plant: Mill Nr. Mill SizeAbul QasimNo ratings yet

- Conveyor Design Stockpile Volume FormulasDocument1 pageConveyor Design Stockpile Volume FormulasmetkarchetanNo ratings yet

- Flow Through Converging and Diverging NozzlesDocument4 pagesFlow Through Converging and Diverging NozzlesDhinasuga DhinakaranNo ratings yet

- Influence of The Clinker SO3 On The Cement CharacteristicsDocument1 pageInfluence of The Clinker SO3 On The Cement Characteristicsroshan_geo078896No ratings yet

- BELT FEEDER Preliminary Dimension IngDocument29 pagesBELT FEEDER Preliminary Dimension IngoscarjofkNo ratings yet

- Raw Grinding Ball Mill Interlocks-V0.0Document2 pagesRaw Grinding Ball Mill Interlocks-V0.0Junaid MazharNo ratings yet

- Upgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L SmidthDocument7 pagesUpgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L Smidthmail2quraishi3084No ratings yet

- Torque Density of PM MotorsDocument7 pagesTorque Density of PM MotorsDantam RaoNo ratings yet

- Experimental Analysis On Multi Hole Nozzle Jet Pump: Jagadeshwar Kandula, M Vijay KumarDocument6 pagesExperimental Analysis On Multi Hole Nozzle Jet Pump: Jagadeshwar Kandula, M Vijay KumarIJMERNo ratings yet

- FLUID MECHANICS AND MACHINERY EXAM REVIEWDocument1 pageFLUID MECHANICS AND MACHINERY EXAM REVIEWnarayananx5No ratings yet

- Novel Idea of Optimizationof PCP System at Different Stages of CBM Well LifeDocument14 pagesNovel Idea of Optimizationof PCP System at Different Stages of CBM Well Lifemohit narayan100% (1)

- B 408Document10 pagesB 408Chris GrahamNo ratings yet

- CycloneDocument17 pagesCyclonesempatik721No ratings yet

- 06 Heating CoolingDocument20 pages06 Heating Coolingsempatik721No ratings yet

- 06 Heating CoolingDocument20 pages06 Heating Coolingsempatik721No ratings yet

- RDF Feeding For Kilns 2014Document164 pagesRDF Feeding For Kilns 2014sempatik721No ratings yet

- Design and Validation of High-Energy Impact TesterDocument10 pagesDesign and Validation of High-Energy Impact TesterorlandompsilvaNo ratings yet

- Ball MillDocument14 pagesBall MillISLAM I. Fekry95% (20)

- Experience With The SIMULEX Cement Plant Training SimulatorDocument7 pagesExperience With The SIMULEX Cement Plant Training SimulatorDiego MorenoNo ratings yet

- Ball Charge DesignDocument12 pagesBall Charge DesignRaul LoaizaNo ratings yet

- LF Cue Cost 3 SeattleDocument25 pagesLF Cue Cost 3 SeattlejnmanivannanNo ratings yet

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Principles of Ball Mill GrindingDocument12 pagesPrinciples of Ball Mill Grindingaghilif0% (1)

- Tromp Curve ExampleDocument3 pagesTromp Curve Examplesempatik721100% (4)

- Study of The Grinding Balls Distribution Inside The Mill 2Document3 pagesStudy of The Grinding Balls Distribution Inside The Mill 2sempatik721No ratings yet

- Fuel and Clinker WeighingDocument20 pagesFuel and Clinker Weighingsempatik721No ratings yet

- HPGR Faq PDFDocument9 pagesHPGR Faq PDFfran01334No ratings yet

- The Mining Grinding Office: Main Home Home Mining Tools Calculators Grinding Technology LinksDocument2 pagesThe Mining Grinding Office: Main Home Home Mining Tools Calculators Grinding Technology Linkssempatik721No ratings yet

- Ball Top Size Diameter CalculationDocument1 pageBall Top Size Diameter Calculationsempatik721100% (1)

- Particle Size Distribution - RepresentationDocument4 pagesParticle Size Distribution - Representationsempatik721No ratings yet

- US Meshs Vs Microns TableDocument1 pageUS Meshs Vs Microns Tablesempatik721No ratings yet

- The Mining Grinding Office: Other Power FormulasDocument2 pagesThe Mining Grinding Office: Other Power Formulassempatik721No ratings yet

- Grinding MediaDocument4 pagesGrinding Mediasempatik721No ratings yet

- Blaine Apparatus ProcedureDocument7 pagesBlaine Apparatus ProcedureVivek Pandey100% (3)

- Mill Speed RecommendationsDocument1 pageMill Speed Recommendationssempatik721No ratings yet

- BALL NOSE MILLS FINISHING CUTSDocument3 pagesBALL NOSE MILLS FINISHING CUTSsempatik721No ratings yet

- The Mining Grinding Office: Other Power FormulasDocument2 pagesThe Mining Grinding Office: Other Power Formulassempatik721No ratings yet

- Media Charge - Linear Wear - Ball MillsDocument5 pagesMedia Charge - Linear Wear - Ball Millssempatik721No ratings yet

- KasaDocument1 pageKasasempatik721No ratings yet