Professional Documents

Culture Documents

Soil Mechanics and Foundations by Dr. B.C. Punmia - Ashok Kumar Jain - B.C. Punmia - Arun Kr. Jain

Uploaded by

PawanKumar75%(24)75% found this document useful (24 votes)

45K views53 pagessoil mechanics for engineers

Original Title

Soil Mechanics and Foundations by Dr. B.C. Punmia- Ashok Kumar Jain- B.C. Punmia- Arun Kr. Jain

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsoil mechanics for engineers

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

75%(24)75% found this document useful (24 votes)

45K views53 pagesSoil Mechanics and Foundations by Dr. B.C. Punmia - Ashok Kumar Jain - B.C. Punmia - Arun Kr. Jain

Uploaded by

PawanKumarsoil mechanics for engineers

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 53

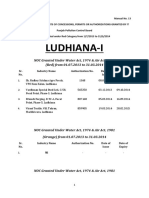

780 SOIL MECHANICS AND FOUNDATIONS

R=2R, -+:(27.3)

where R is measured below the high flood level (HFL).

Scour level = H.F.L. = R =HF.L. =2R, (27.4)

‘The grip length is taken as $R below the scour level according to the code of

practice of the Indian Roads Congress and as $4 in Railway practice. This means that

the depth of foundation should be at least 1}.8 below HFL according ta IRC code, and

LR below HEL according to Railway practice . It is further recommended. that the minimum

depth of embedment below the scour level should not be less than 2.0 m for piers and

abutment with arches and 1.2 m for piers and abutments supporting other types of superstructure.

According to Terzaghi and Peck, the ultimate bearing capacity can be determined

from the following expression:

Or= Oy + 2nRf, Dy 27.5)

Qp = aR? (1.2 CNe + yDy Ny + 0.67RNy) + oe(27.6)

where Ne, Nye N,=Terzaghi's bearing capacity factors

radius of well

Dy= depth of well (depth of foundation)

Jr= average skin friction

27.4, FORCES ACTING ON A WELL FOUNDATION

In addition to the self-weight and buoyancy, a well carries the dead load of the

super-structure, bearings pier and is liable to the following horizontal forces :

(®) bracking and tractive effort of the moving vehicles.

(ii) force on account of resistance of the bearings against movement due to

variation of temperature,

(ii) force on account of water current,

(i) wind focres,

() seismic forces,

(vi) earth pressure,

(vii) centrifugal forces.

‘The magnitude, direction and point of application of all the above forces can be

found under the worst possible combinations and they can be replaced by two horizontal

forces, P and @ and a single vertical foree W as shown in Fig. 27.3.

P= Resultant of all horizontal forces in the direction across the pier.

Q= Resultant of all horizontal forces in the direction along the pier.

W-=Resultant of all vertical forces.

The analysis is done on the following assumptions (Banerjee and Gangopadhyay, 1960);

WELL FOUNDATIONS 78k

1. The well is acted upon by an uni-

directional horizontal force P in a direction across

the pier.

2. The well is founded in sandy stratum.

3, The resultant unit pressure on soil at

any depth is in simple proportion to horizontal

displacement,

4. The ratio between contact pressure and

corresponding displacement is independent of the

pressure.

5. The co-efficient of vertical subgrade

reaction has the same value for every point

of surface acted upon by contact pressure.

The analysis that follows is that suggested

by Banerjee and Gangopadhyay (1960).

27.8. ANALYSIS OF WELL FOUNDATION

1, Horizontal soil reactions. When a rigid

well, embedded in sand, starts moving parallel FIG. 27.3. FORCES ON A WELL.

to its original position, under the action of a

horizontal force P, it transforms the soil on

one side to passive state of plastic equilibrium and the other side into active state. Assuming

that the well movement p, is sufficient to mobilise fully the active and passive earth pressure,

‘the resultant unit pressure at a depth z below the surface

is given by pray. 2(Kp~ Ke) 27.1)

where y= unit weight of soil

K,. K, = co-efficient of passive

and active earth pressure, and depend

upon the angle of internal friction §,

and angle of wall friction 8.

Let p be the load per unit arca

of vertical surface of sand and p be

the corresponding displacement. Assum-

jing that p, is the displacement required

to increase the value of resultant unit

pressure form zero to p,, we have.

ape -

Pray pr te tp Kay

+-(27.8)

FIG. 27.8. EFFECT OF WALL MOVEMENT.

788 ‘SOIL MECHANICS AND FOUNDATIONS:

6, Evaluation of moment M, produced by P,

D

- Pe py ae = ML apt “

Ma = f" m5, (- Dy) fdz =i, (GD' - 4D, D+ Di) (27.19)

7. Evaluation of vertical reaction R : Modulus of vertical subgrade reaction is

ee

°

where p= vertical deflection of soil corresponding to vertical reaction P = o%

Ba Bit

R=2 pdr =2 koa de

° °

or B=KBp +e(27.20)

8. Evaluation of moment M, produced at the base due to vertical soil reaction p

‘The rotation of the well is also resisted by a moment M, acting at the base on

account of the downward deflection of the toc and upward deflection of the heel. Fig.

27.8 shows the rotation of the base, with displacement p, at the ends. Let p be the

deflection at a distance x from the centre O of the base.

—

FIG. 27.8 ROTATION OF BASE.

But Ps

= pr (27.21)

This moment acts in clockwise direction for the present case of Fig. 27.5 (a).

9, Evaluation of Pp, on the basis of maximum soil pressure

If no plastic flow is allowed in the soil, horizontal soil reaction p at any depth

Must not exceed (PJms for that depth, given by

(Pada = 1 (Kp ~ Ka) «(27.22)

209 oc

Be ky ~ Ke) 27.23)

WELL FOUNDATIONS: 789

is in contact with soil and the remaining portion is only held by skin friction, A three-point

support of the cutting edge resting on a log may be assumed for design purposes. The

load coming on the cutting edge is uncertain as a considerable part of it is borne by

skin friction. Another factor of uncertainty is in regard to the effective depth of the well

curb, since the entire well acts as a deep girder to resist torsion and bending. Since the

load is occasional, working stress upto 99% of yield stress may be penmitted. The well

curb has also to withstand stress due to sand blows, as well as due to light blasting

required when boulder obstructs the sinking of the well

Cutting edge. The cutting edge should have as sharp an angle as practicable for

knifing into the soil without making it too weak to resist the various stresses induced by

boulders, blows, blasting, etc. An angle to the vertical of 30°, or a slope of 1 horizontal

to 2 vertical has been found satisfactory in practice. In concrete caissons, the lower portion

of the cutting edge is wrapped with 12 mm steel plates which are anchored to the concrete

by means of steel straps. A sharp vertical edge is generally provided along the outside

face of the caisson. Such an edge facilitates the rate of sinking and prevents air leakage

in the case of pneumatic casissons.

Steining thickness. The thickness of steining is designed in such a way that at all

stages the well can be sunk under its own weight, as the need for weighting with kentledge

takes time and retards progress considerably, For a circular well with outer diameter D

and thickness ¢ of the steining, we have

Self-weight per unit height = x(D- 1p

Skin friction force per unit weight = xD 1

where p= unit weight of concrete or masonry of the steining

r= unit skin friction

Equating the two, we get 1(D-itp= "Dy

ol, afi 4a)

Bla 1-H | «(27.46)

It will be seen from this equation that for a given value of skin friction, the steining

thickness comes out to be less with increasing value of diameter of the well. This is,

however, contrary to the usual practice of providing greater thickness of steining with increasing

diameter of the well as given in the following table :

From which

D (outside diameter of well) t (steining thickness)

3m 0.75 m

sm 1.20 m

7m 2.00 m

This is so because large diameter wells are taken deeper and the skin friction increases

with depth. Moreover, for deeper wells, water is invariably met with and the effective

self-weight is reduced by buoyancy in the portion of the well below water level, and hence

larger steining thickness is required.

™m ‘SOIL MECHANICS AND FOUNDATIONS

use of phaweah Jhams is effective. When power winches are available clayey strata can

also be successfully excavated with the help of big grabs having tempered steet teeth,

‘As the well sinks deeper, the skin friction on the sides progressively increases. To

overcome the inreased skin friction and the loss in weight of the well due to buoyancy,

additional loading known as kensledge is applied on the well.

Pumping out the water from inside the well is effective in sinking of well under

certain conditions. Pumping should be discouraged in the initial stage. Unless the well has

gone deep enough or has passed through a ring of clayey strata so that chances of tilts

and shifts are minimised during this process. Complete dewatering should not be allowed

when the well has been sunk to about 10 m depth. Sinking thereafter should be done

by grabbing, chiselling, applying Kentledge and using gefignite charges. Only when these

methods have failed, dewatering may be allowed upto depressed water level of 5 m and

not more.

On certain occasions a well is struck up and normal method of keniledge and dredging

fail co sink it further. In such a case frictional resistance developed on its outer periphery

is reduced considerably by forcing jet of water on the outer face of the well around.

This method is effective in case the well is being sunk in sand strata.

4. Tilts and Shifts. The primary aim in well sinking is to sink them straight and

at the correct position, Suitable precautions should be taken to avoid tilts and shifts, Also

proper records of tilts and shifis should be maintained and measure should be taken to

Counter-act tills and shifts. The precasutions to avoid tilts and shifts are as follows:

1. The outer surface of the well curb and steining should be as regular and smooth

as. possible

2. The radius of curb should be kept 2 to 4 cm larger than the outside radius

of well steining.

3. The cutting edge of the curb should be of unifrom thickness and sharpness since

the sharper edge has a grater tendency of sinking than a blunt edge.

4. The dredging should be done uniformly on all sides in a circular well and in

both pockets of a twin well. The tilts and shifts of well, if any, must be carefully checked

and recorded. The correct measurement of the tilts at any stage is pethaps one of the

most important field observations required during well sinking.

As soon as tilt exceeds 1 in 200, the sinking should be supervised with special

care and rectifying measures should be immediately taken, Any of the following measures

can usefully be employed to counteract the tillts in the well during sinking operations :

(® Regulation of grabbing. Unequal dredging causes tilts and hence if higher side

is grabbed more by regulating the dredging, the tilt can be rectified (Fig. 27.12. (a)].

This method is not very effective when the well has been sunk to a great depth. In that

case, a hole in the steining of the well is made on the higher side, and by hooks, the

rope of the grab is pulled towards higher side to the maximum possible extent (Fig. 27.12

(O)]. The hole is made near the ground level. The well may be dewatered if possible

and open excavation on the higher side is carried out.

77 SOIL. MECHANICS AND FOUNDATIONS

In larger size wells to be sunk to great depths, eccentric loading may be as much

as 400 to 600 tonnes with an eccentricity of 3 to 4 m. In such a case a welded frame

bracket is used as shown in (Fig. 27.12 ()].

(iii) Water jetting or digging pit outside the higher side of the well. In this method,

water jet is forced on the outer faces of the well, towards the higher side so that skin

friction is reduced towards the higher side, The method if used alone is not very effective

but provides a contributory effect if used with other methods.

(iv) Excavation under the cutting edge. A filled well generally. refuses to straighten

on account of unbroken stiff strata on the higher side of the well. In such a case, the

well is dewatered, if possible and safe, an open excavation is done below the cutting edge

of the higher side. If dewatering is unsafe, divers should be sent to loosen the strata,

(*) Providing temporary obstacles below the cutting edge. In some cases wooden.

sleeper pieces are put temporarily below the cutting edge of the well on the lower side

to avoid further tilt of the well while various expedients are being tempted to rectify the

tilt [Fig. 27.12 (d)]. Hooking the cutting edge on the lower side of the well with the

help of the steel wire rope, pulled, and kept strained by steam which also has a similar

effect (Fig, 27.12 (c)].

() Pulling the well. This method is effective only in early stages of sinking, The

well is pulled towards the higher side by placing one or more steel ropes round the well with

vertical sleepers packed in between to distribute the pressure over larger areas of well

steining. The pulling of ropes may be carried out by winches [Fig. 27.12 (/].

(vii) Strutting the well. This method is used to avoid any further increase in the

tilt of the well rather than reetifying it. The well is strutted on its tilted side with suitable

logs of wood. The well steining is given covering plate to distribute pressure. The other

ends of the logs rest against firm and non-yielding base by driving piles ete. Wood pieces

are kept ready to be inserted and fixed in the gaps caused by the tilts of the well being

rectified

(viii) Pushing by jacks. The well may be pushed by force applied by hydraulie or

mechanical jack on the tilled side of the wells.

27.9. PNEUMATIC CAISSONS

Pneumatic caissons are closed at the top and open (during construction) at the bottom,

‘The essential fearure of a pneumatic caisson is that compressed air is used to exclude or remove

water from the working chamber at the bottom, and the excavations are thus carried out

in dry conditions. The method of construction of pneumatic caisson is similar to that for

‘open caissons (wells) except that the working chamber is kept air tight. In order that sub-soit

water may not enter the working chamber, the pressure of air in the shaft is kept just

higher than that of the water at that depth, However, the maximum pressure is limited

from the considerations of health of persons who work inside the chamber. Normally, the

tolerable air pressure under which a man can work is limited to 3.5 kg /cm’,

Let h be the height of water, at any stage of working. Then ait pressure p required

to exclude water is given by

796 SOIL MECHANICS AND FOUNDATIONS

inside the well. The air lock may rest on rubber seals just above the cutting edge. The

number of air locks may vary from one to three. Generally, two ait locks are used —

one for sending men inside and the other for moving the excavated material with the help

of a much bucket and hoisting rope.

3. Afier properly placing the air lock in position, so that direct air entry is scaled,

water is pumped out from the bottom and air pressure is gradually increased so that fresh

water docs not enter the working chamber.

4. Labourers are then sent down to the working chamber, through the appropriate

air lock. In order to prevent leakage of air, arrangement of double gates is provided.

‘The person enters the first gate, where pressure is atmospheric. The first door is closed

and pressure is gradually increased to make it equal to the one in the working chamber.

‘The height of working chamber is kept about 2 m, with proper lighting arrangement. Air

is supplied through the air inlet pipe connected to an air compressor.

5. Excavation is carried out in the working chamber by the labourers sent down

through air lock. The excavated material is sent up through the muck buckets lifted up

by a hoisting rope operated by winch drum, through the air lock. In order to assist sinking,

air pressure may be reduced for a short while. Sometimes, explosives may be employed

in which case it is essential to make arrangements for the immediate removal of fall fumes.

6. When the caisson bottom has reached the desired level, concrete seal (or plug)

is made by concreting upto the underside roof of the working chamber. Sufficient air pressure

is maintained to force the concrete against the bottom surface till it hardens.

7. Ait locks are removed, well is filled with sand or water (or even kept empty).

The well cap is then formed on its top as usual.

28

Machine Foundations

28.1, SOIL DYNAMICS

Soil dynamics is defined as that constituent part of soil mechanics which deals with

soil under dynamic conditions. It studies the effect of forces on soil in any way associated

with causing motions in soil as well as with the mutual dynamic interaction of the foundation

and soil (Sumikis, 1969). Most of the motions encountered in soil dynamics work are those

of vibration, plane linear motion, motion brought about by impact, shock, clastic waves,

and seismic action of geophysical forces.

‘The design of foundations of turbines, motors, generators compressors, forge hammers

and other machines, having a rhythmic application of unbalanced forces require special knowledge

of theory of harmonic vibrations. Inertial forces of rotating elements of machines contribute,

besides their static loads, additional dynamic loads. The machinery vibration influences adversely

the foundation supporting soil by densifying it which may in turn, casue differential settlement

of soil and foundation.

28.2. THE MASS SPRING SYSTEM

In soil dynamics problems, the analysis may be conveniently carried out by a single

equivalent mass supported by a perfectly elastic system — the soil being replaced by the

spring. Fig. 28.1 shows mass-spring system (or spring-

mass system), in which the weight W=mg may be

associated with the weight of the vibrating vibrator

or foundations. ‘The elastic spring represents the real

soil support. Such a system has six degrees of freedom,

and has thus six natural frequencies.

Free-Vibrations, Let the mass spring system

be set to vibration by an external force which is

then removed. The system will continue to oscillate

indefinitely with the same frequency and amplitude

if extemal force or internal friction is absent. The

time for one complete oscillation of the mass is

called the free period and the distance up or down |

from the equilibrium position is called the amplitude. FIG. 28.1. MASS-SPRING SYSTEM

7)

798 SOIL. MECHANICS AND FOUNDATIONS,

Fig. 28.2 (a) shows a simple spring with a spring constant & kg/m. When a weight

W is attached to it (without any vibrations), it extends by an amount 5, (Fig. 28.2 (b)].

‘The static deflection 6, of the apring is given by

wW

k

b= (28.1)

oe,

equim

potion

(a)

FIG. 28.2. FREE VIBRATIONS.

If the the spring mass system is pulled down, by an external force, by a maximum

distance Zn OF A, (called the amplitude), and then released, the whole system vibrates

with a certain frequency. Let z be the displacement of the mass at any instant, with respect

to the equilibrium position, the force F, in the spring (t) is then given by

Fs=k (85+ 2) = kbs + kz = W kz ++(28,2)

The force acts in the opposite direction to the motion at any instant. The gravity

force W acts downward. Hence when the motion is downward, the net downward force

is equal to WL-(W+4z) 7. This must be equal to mass x acceleration, Hence, we get

W dz

W-(W+k)=— —

wet S

W dz

= 4 k=0 228.3

or eat ( a)

which is usually written as mi +k =0 =-(28.3)

where

= mass of the vibrating body = W/g

# = acceleration

Eq. 28.3 is called the equation of motion, which is similar to the following standard

equation of motion

t+odz=0 (28.4)

where @q= natural frequency of the system.

Comparing Eqs. 28.3 and 28.4,

MACHINE FOUNDATIONS: 799

or n= VE = Vi tad/sec (28.5)

If f, is the natural frequency of the system in cycles per second, we have

on_d

Oat ake ‘,

fo 50-3 Vip syelesisec. wos(28,6)

28.3. VIBRATING SPRING-MASS SYSTEM WITH DAMPING

If the spring mass system be provided with

dash-pot, having ¢ as the damping factor and focsntrcosseitcit

2 is the velocity of the vibrating sytsem at any

instant, the force in the dash-pot, opposite the motion,

will be equal to 2.

Hence the equation of the motion will be

WL-(W+k:) t= t = mi

me teeth =0 (28.7)

Comparing this with the standard equation

for damping vibrations

i 42nt +o} 2-0 (28.8) w

c

we pet -£ (28.9)

FIG. 28.3. VIBRATING SPRING-MASS

SYSTEM WITH DAMPING

or On=

m

Eq. 28.8 is the standard differential equation which can be solved by putting

eel! te Cne! i) P= OM Le iti) ..28.10.a)

Putting these in Eq. 28.7, we get

me eC ERC! bad «(28.10

or me +arA+k=0

c ey _(k

-£2V(5) -(4) =-neVn—on (28.11)

-n+Vit- oF and hye-n-Vit-of

‘Three cases may arise from Eq. 28.11 :

Case (i) Real, if >on

Case (if) Zero, if n= 02

Case (iii) Imaginary or complex if 2° < 0?

h

Hence

Case (ii) gives a value of = A=-n=

800 ‘SOM. MECHANICS AND FOUNDATIONS

Eq. 28.11 for case (if) reduces to e-'=0, indicating that for this condition there

will be no oscillation, but only a rapid retm back to the equilibrium position of the

mass [Fig.28.4 (b)]. The value of ¢ for this condition is called critical damping <,.

ce = 2m y x -amk ---(28.12)

For case (i), the radical is real (#?>0g) , and ¢22Vmk.

¢.afiey 4)

Hence from (i), wl e eee (ae -(a) « (28,13)

Eq. 28.13 shows that z is not a periodic function of time. Therefore, the motion,

when 2?—o}>0 is not a vibration, because it can only approach the equilibrium position

at (+, However, the viscous resistance is so pronounced that the weight set in motion

from its equilibrium does not vibrate but creeps gradually back to the equilibrium position

at time infinity (Fig. 28.4 (@)]. For case (iii) when n (8) Case (i}n? = op

28.8. Also, the sum or dif- z

ference of these two solutions mul-

tiplied by any constant is also a

solution :

C '

Glare) oft.

(28.15 a)

G ty geet

Slerteer)

(28.15 5)

where C, and C, are constants.

‘Substituting the values of

4, and 2, from Eq. 28.14, and

See gye FIG. 28.4. TIME DISPLACEMENT CURVES FOR

simplifying, we get DAMPED VIBRATIONS.

a

and 2

(©) Case (ii) n’ <0,"

n= Ce" sin wet and t=O: 008 oy t

Summation of z,+z,=z renders the general solution of Eq. 28.8 in the following form.

MACHINE FOUNDATIONS 01

rae" [C, sin agt + C; cos wy] (28.16)

‘The quantity in the bracket represents the simple harmonic motion of the case of

vibration without damping while &” is the damping term. Fig. 28.4 (c) shows the time

displacement curve for this ease. The peroid T of the damped vibration is given by

on ___ie 3

T= oe Volar +(28.17)

‘The term og is called the frequency of damped vibrations,

a= Vog -

28.4, FORCED VIBRATIONS

Forced vibrations of a system are generated and sustained by the application of an

external periodic movememt of the foundation of the system, Forced vibrations constitute

the most important type of vibration in machine foundation design, We shall consider the

case of forced vibrations with damping. Generally, for oscillating machinery (where the

machinery vibrates because an unbalanced rotational force exists), the force can be expressed

as a sine or cosine function, such as Fysin az, The equation of motion for such a case

may be writen as

sj ..(28.18)

mi’ + ch + kz = Fosin of (28.19)

or e+ fer kA ox (29.19 ay

mmm

The solution of the above equation may be assumed in the following forms :

z= A cot or + Bsin at (28.20 ay

By successive differentiation, we obtain

£5 Aa sin af + Bo cos of (28.20 by

#' =~ Ao! cos wf ~ Bo’ sin or o-(28,20 ey

Substiuuing into Eq. 28.19 (a), we get

( Ae €0s wt - Bo* sin an) + (— Ao sin oF + Bo cos 01) + £ (4 00s wt + B sin oy = sin ot

(28.21)

Equating the co-efficient of sin or to both sides,

~Bo?-£4o+* po (28.22 a

m8

Similarly, equating the coefficients of cos ar to both sides,

-40*+£p04+£ 420 (28.22 BY

moo *

Solving Eqs. 28.22 (a) and (b) for co-efficients A and B, we get

sor SOIL MECHANICS AND FOUNDATIONS

Foca Fo (k = mos*)

A= -—__,.--_., (28.23 B=——_,, ——,,_ ...(28.23 5)

- mo’) + (Co)? ‘ ? (k= may + (CoP « )

Substituting these in Eq. 28.20 (a), we get the solution in the form

=Foco Fo(k - mo’) sin ot

=e ee ene (28.24)

Pe ea mae ea ee map “ORM

The equation represents the components due to forced vibrations with the period of

‘The frequency fo vibrations (in cycles per second) is given by

°

faq 28.25 a)

‘The natural frequency of vibration, as defined earlier, is given by

on= VX radians/see 28.25)

talk

and pefeg yt (28.25. ©)

Substiuting in Eq. 28.24,

- Fico Fy (k — mo’)

— hoe 2B. —Fotk=me) (28.26

Tay ee mee IF B26 and eT age” 20 #2826 PY

we get ret (6in§ cos oste0s 6 sin of)=2 sin (WF6) 28.27)

where the angle @ is termed as the phase angle between the exciting force and the motion

of vibrating mass.

Noting that these terms represent a pair of vectors which must be added to obtain

the displacement, the solution for the displacement due to the forced vibrations of Eq.

28.24 becomes

z= WP + Fosin (or + O) (28.28)

Substituting the values of A and B, and noting from Eq. 28.12 that

@nbe

cont Vek = 28.29 a) or k= EE (28.29)

we get if 1 sin (or +4) (28,30 a)

fh in (at + 4)

or Tee giph -.(28.30 6)

The maximum deflection ipa: is thus given by

MACHINE FOUNDATIONS 803

Fork

fa = A = eee +-(28.31)

© Vee fel (fy

ce” fn tn

But Bea, sstatic deflection of spring

A in |

== «(28.31 a)

ee Veet

& Sn Sn

where Az= Zmar = maximum dynamic deflection of the system.

Putting $= me == magnification factor or dynamic amplification factor

o 7

= frequency ratio damping ratio, we get

1 aot

= Qa 83)

Fig. 28.5 shows a plot between r Lege 4

the magnification factor and the fre-

io r(-Le 2) i

quency ratio rf f=) for vc

ous values of damping ratio

¢

s(-Z}

From Fig. 28.5, it is observed

that magnification factor suddenly

shoots up for the values of r between

0.6 to 1.5. Atr = 1, resonance occurs

for an undamped condition. Even

for damped conditions, the magni- F

fication factor (and hence the am-

plitude) is maxinyum at r< 1. Thus, 2

these curves show the effect of damp-

ing on shifting the frequency for ic

maximum amplification away from

Magnification factor

T

the natural foundation frequency. The oftrriit = lo

aim of the designer should be such Frequency ratio ¢

that the frequency ratio f/f, is either FIG, 28.5. AMPLITUDE FREQUENCY RELATIONSHIP

less than 0.6 or more than 1.5. How- FOR DAMPED FORCED VIBRATIONS.

ever, the frequency f of the machine is always constant, and a foundation engineer has

to manipulate the natural frequency f, of the machine foundation system by suitably proportioning

it,

MACHINE FOUNDATIONS 05.

-tf_t Vo

or Loa iam, In Ve, (28.34 B)

where Wy =weight of the vibrator, and

W,= weight of the apparent soil mass.

Unfortunately, the size of the co-vibrating body of soil cannot be determined exactly

as yet because it depends on frequency and is influenced by the size of the base area

of the vibrator (foundation) and by the elastic properties of the soil (spacing).

‘We shall consider here three methods of determining the natural frequency of foundation

soil system : (1) Barken's method, (2) Balakrishna Rao's method, (3) Pauw's method.

28,7. BARKEN’S METHOD

Barken suggested the following equation for the natural frequency of system

on= Sut =(28,35 a)

where C,= co-efficient of elastic uniform compression of soil

A-=contact area of foundation with soil

m= mass of machine plus foundation.

The amplitude of displacement is given by

F

aan)

where — 4e= no = maximum. displacement

Fy

=-(28.35. 8)

xciting force ; r= frequency ratio =

5

The above formulae for natural frequency takes no account of the mass of soil vibrating

with the foundations.

Barken gave the following equation for the co-efficient of elastic uniform compression

of soil, obtained from the solution of theory of elasticity problem concerning the distribution

of normal stresses under the base contact area of a rigid plate :

El

Cu = 1.13 +-(28.36)

re e830

where E= Young's modulus of soll; 1 = Poisson's ratio

Thus, C, depends not only on elastic constants £ and je but also on size of the

base contact area of foundation. The co-effeicient C, changes in inverse proportion to the

square root of the base area of the foundation

Coy A

a N = (28.37)

Table 28.1 gives the recommended value of C, for A= 10m*, for various soils.

806 SOIL MECHANICS AND FOUNDATIONS

TABLE 28.1. RECOMMENDED DESIGN VALUES OF THE CO-EFFICIENT OF

ELASTIC UNIFORM COMPRESSION C, (BARKEN, 1962)

Permissible load on soll under | Coefficient of elastie uniform

Soit actfon of satic toad only compression Cu Cogn)

group (eg em?)

Weak soils (clays and silty clays

sand, in a plastic state, clayey. and silly

sands; also soils of categories I and I up to 15

with laminae of organic silt and of peat)

Soil of medium strength (clays and

clays with sand, close tothe plastic 15-35

sand)

Strong soils (clays and sity clays swith

sands of hard consistency; gravels and

gravelly sand, loess and loessial soils)

Rocks.

28.8. BULB OF PRESSURE CONCEPT

‘The calculations of natural frequency by Barken took no account of the mass of

soil vibrating. But the work done by DEGEBO indicates that when a vibrating load acts

on a soil, a certain mass of soil ranging from 4 to 5 times the vibratory load participates

in the vibration. Balakrishna and Nagraj (1960) proposed the bulb of pressure concept of

calculating the apparent mass of soil participating in the vibration. According to this, the

vibrating mass of soil is assumed to be contained by the boundary of a pressure bulb.

For the purpose of simplicity, the load acting on any surface is replaced by an equivalent

concentrated load acting at the mass centre of the original area, If y is the unit weight

of the soil in Ib/cu, fi., then according to the pressure bulb concept, the apparent mass

of the soil is the mass enclosed by the pressure bulb of intensity a, Ib/sq. ft. such that

=lyl «--(28.38)

For example, if the unit weight of soil is 110 Ib/cu.ft., the apparent mass of the

soil will be the mass of the soil contained by a pressure bulb of intensity 110 Ib/sq.

fi, From Boussinesq analysis, the vertical stress o, at a depth z and radial distance is

r=0 is given by

oars 2

2

Hence byl =o477s Me (28.39)

z

In the above equation fy} and W, are known,

Hence z=diameter of the pressure bulb is known,

. 4 fz), 4 [osmsm p

Weight W, of soil=3x(2) v-35|(S --(28.40)

It should be noted that Eq. 28.40 is nor dimensionally homogeneous, and is applicable

only in F.P.S. units, where W, and W, are in pounds and 7 is Ibsicu. ft

oe SOIL MECHANICS AND FOUNDATIONS

TABLE 28.2. VALUE OF fo AND Bi

‘Soil ype Ea (he /em* )

‘Clay, semi-solid 0.115 —0.23

‘Clay, stiff plastic OMS —0.23

Clay, weak plastic 14 — 28 115 —23 O15 — 0.23.

The spring constant for the truncated pyramid is calculated by first of all determining

the surface deformation 8 given by following infinite integral ;

ahi?

beg J @rajbtanmra htt a)

a 44

or anos eres --(28.44 )

a : ook, met

where pare) ssa sand “5 (28.45)

The equivalent soil spring constant & in the vertical plane is given by

_Py ti

k= 52 (by definition)

tlt Pf ___am ___

Kk Bb “g (l+m) (1m) (s+m)

If the base of foundation is circular, a truncated cone wil be considered in the place

of truncated prism, and the above expression will be modified as under :

1a I dm

1, —_a—_ o(2B4T.

k pe “5 (+ my(s +m) « »

ae ah

where m=" and s= 5

‘The values of k are determined by curves of Fig. 28.7 in which k is given by

the equation

k= $6) (for rectangular base) + (28.48)

b). «(28.48 a)

(28.46),

6 = diameter of the foundation.

and kat pon (for circular base of dit

For given values of a and £ ratios, 2 i detetmtied from the curves, amd thos

7

A is known. Then & is calculated from Eq. 28.38.

MACHINE FOUNDATIONS: 509

02 6

5

08 4

z z °

gi i

|

E §

59 20 fie

4 10

os

5.0 06

04

wos teosy as ese

td ob (0) or (Log soak)

i

a

FIG. 28.7. EQUIVALENT SOIL SPRING CONSTANT FOR HORIZONTAL SURFACE.

Pauw developed expression for apparent soil mass m; by equating the kinetic energy

of the effected zone to the kinetic energy of a mass assumed to be concentrated at the

base of the foundation. Following is final form of the expression :

m= Cm (where the factor Cy is read from Fig 28.8.) —...(28.49)

(Note. The above treatment is valid only if the machine foundation has only one

degree of freedom. i.¢., for the vibrations taking place in the vertical directon. In the

general case, however, the foundation may be considered as a mass having six degrees

of freedom, namely, displacments in the directions of the three coordinate axes and rotations

about each of these axes.)

After having determined the equiva-

lent spring constant k and apparent soil mass

‘m,, the natural frequency of oscillations,

and the amplitude of vibrations are deter-

mined from the following equations :

1 k

foe em,

(for lineal oscillation) (28.34 b)

and tmar = Ar

(Ey J +(% SF

+--(28.31) FIG, 28.8 DETERMINATION OF FACTOR Cm

MACHINE FOUNDATIONS au

A 23-7 Ber

% change in 4,-223"=" , 199-23

. “Teer =e

When =0,3, % change in A: =——-———5=23%

r Stange 1D T1330

When = r=2, — % change in A B35 %

Example 28.2, Assuming resonance to have occurred at the frequency of 22 cyclesisecond

in a vertical vibration of a test block, 1.0~ 1.0 = 1.0 m size, determine the coefficient

of elastic uniform in compression (C,). The weight of oscillator is 62 kg and the force

produced by it at 12 cycles per second is 100 kg. Also compute the maxinmun amplitude

in vertical direction at 12 eycles/second.

Solution. fon = Inf, = In X22 = 442

ibrator = &2 = 62. _

Mass of vibrator= = 557 = 6:3

Lx 1x 1x 2.40 x 1000

Mass of foundation block (concrete) = si = 244.7

im =6.34+244.7=251 5 A= contact area of foundations = 1 m*

Substituting these in the expression for ©,

On= ee ,we get (lax 22)=

or Cu= (440) (251) = 4.76 «108 kg/m?

Amplitude a

where Fy = total load produced in vertical direction = 100 kg

m= 251 5 @y=2n (2) =442 |

Ace 1 metres = 3 x 10 om.

251 (44x)* (1 - 0.3)

Example 28.3. The resonance of a test block 2 m x 1 mx J m occurred at

25 cyeles/sec in the vertical direction, The other data are as follows :

Weight of oscillator = 62 kg. Vertical unbalanced force = 0.5 tonnes. Unit weight of

Soil = 1.7t/m . Calculate the apparent mass of soit by Balakrishna Rao method.

0.4775 W, P?

Solution, From Eq, 28.40, Sy [287 Me P Ib

W, =total load in Ibs (é.e. weight of machine + foundation + unbalanced force)

Weight of foundation block = 2x 1 x 2.4 x 100 = 4800. kg

Weight of oscillator= 62 kg : Vertical unbalanced force = 500 kg

382 SOIL MECHANICS AND FOUNDATIONS

~ Total jy = $362 kg = 11,800 Ib ; y= 1.7 t/m'= 106 Ib/eu ft

4 0.4775 x 11800 FP? _

we=$ nao] A775 <8 = 21500 Ib = 9750 kg

9750 2

m= Zp 7 994 kg- seo%/m

Example 28.4, Design the foundation for a gas engine with a vertical cylinder and

vertically oscillating paris, for the following data:

1, Toral weight of engine = 4500 kg.

2. Speed of rotation = 260 rpm.

3. Unbalanced vertical force = 1 tonne

4. Base dimensions of the engine = 1m x25 m

5. Elevation of machine base above ground =1m

Weak silty sand exists to a depth of 0.5 m followed by a dense sand to a depth

of 6 m. The unit weight of moist sand is 1.7 1/ wm.

Solution. Let the size of the block be 1.5x3 m at the base of the machine, and

2x 3.5m at its bottom, Let the height of the concrete block be 2.0 m, so that it penetrates

1 m below the ground.

Weight of the block = 2x24 tomes =27.6 +

‘This is about 6 times the weight of machine, Hence satisfactory.

Total mass of machine and foundation, m, Bats

Let us first calculate the spring constant k.

G5 «3)+(2x3.5)

2

x 1000 = 3270 kg-sec’/m

Y y= 1.7 7m’ = 1700 kg/m

Now Assuming a=1 and taking b=2 m

1627 a ee

sees: F = 1.15

From Table 28,2, assume, B=4.6 x 10*kg/m'/m .

ab

From Fig, 28.7, when s=1.35 and Ze175, we se B

=2x 422x355

headnpadx oy 35

k= Bb'A = (4.6 x 109 (2) G.5) = 64.6 x 10° kg/m

,

‘The apparent soil mass is given by mo Ca

813 MACHINE FOUNDATIONS

From Fig. 28.8, When s=1.35 and 2=1.75, = A

Coe 1.1 3S w 1.98 and mm, = IOGY 1.95 «2670 kg- seem

Hence the natural iven by

is

LJ kta) 644 x10" .

I aeN Gam, "an ¥ 3267+ 2670 ~ 1% CPS 996 Tp.m.

‘The operating frequency of the machine is o =260 r.p.m.

© _ 260

aa 99g * 027

‘The amplitude of vibration is determined from

Fo

4e¢——

“NTT TRE aT

where © Fy=dynamic load = 1000 kg. Assume z =0.15

1000 1

ZIPP +412 64.4 x 10? x 0.97

64.4 x 10h

= 0.0016 cm

Reduction factor B= 1 -0.6 =

where b=} (2+2.5)=275 m ; z=depth below ground surface=1 m

L

Bel ~ 06 55 = 1-0.218 = 0.782

(Adma = 0.0016 x 0.782 = 0.00125 cm. Permissible amplitude by Rauch equation is

Ay (for f< 1800 r.p.m.)

= 534 = 0.0366" = 0.09 cm. Hence the foundation is safe.

28.10. DYNAMIC ANALYSIS OF BLOCK FOUNDATIONS

The methods of Pauw and Balakrishna Rao are based on the assumption that a certain

mass of soil participates in the vibration with the foundation, Barken’s method is based

on liner spring theory. The method neglects the effects of damping and participating soil

mass. Barken’s method is very much used in design offices. A summary of various formula

are given below :

1, Equation of Motion ; In the general case, the foundation may be considered

as a mass having six degrees of freedom—displacements in the three conordinate axes (x,

y, 2) and rotation about each of these axes (Fig. 28.9). The rotations about y, z and

x-axes are respectively known as rocking, yawing and pitching. Let us first consider the

816 SOIL MECHANICS AND FOUNDATIONS

3, Stiffness of elastic supports

(a) Soil base, The values of kr ky and ky for the elastic support of soil are

given by the following expressions :

For vertical motion » GA (28.66 a)

For horizontal (sliding) motion + ky= Cy A + (28.66 b)

For rocking motion : kay = Co ly (28.66. oh

‘Thus, knowing C,, the values of k, . &, and ko, can be computed .

(8) Elastic pads. If, however, the foundation block is supported on elastic pad

of comiact area A and thickness 1, then the values of the stiffiness factors are given by

the following expressions :

For vertical motion > k,= 58 (28.67 a)

For horizontal (sliding. motion): k= (28.67 6)

For rocking motion : bo, ~ Bit 228,67 3)

where £=modulus of clasticity of the pad meterial

G= shear modulus of the pad material.

(©) Steel spring. If the foundation sc —— 0

block is supported on steel spring with

d as the diameter of spring wire, D

as the diameter of spring coil, n as

the number of windings in each coil,

ft as height of each coil and G as the

shear modulus of the material, the stiffness

factors are given by the following ex-

a

—o—

pressions

For vertical motion,

1 Gad*

keke (28.68 @)

If there are N springs in the coil,

the resultant vertical stiffness will be

Niky,

For horizontal mation (stiding mo-

tion), 4

. 1 1 4

ke = ks | ———_—____—— 4

[ise | J

of 40 4s SSC

(28.68 BY to

FIG. 28.10 VALUE OF COEFFICIENT a.

819 MACHINE POUNDATIONS:

28.12. INDIAN STANDARD CODE OF PRACTICE FOR DESIGN OF

FOUNDATION FOR IMPACT TYPE MACHINES

‘The design requirements of the impact types machines, such as drop and forge hammers,

are different than those of the reciprocating type machines discussed above. IS : 2974

(Part I) ; 1966 covers the design requirements for the foundations of these heavy impact

type machines. Fig. 28.13 showns some typical sections of the foundations for these machines.

Definitions, (i) Anvil: Anvil is a base-block for a hammer on which material is

forged into shape by repeated striking of the tup. (if) Tup: Tup is a weighted block which

strikes the material being forged on the anvil. (iii) Foundation block : It is a mass of reinforced

concrete on which the anvil rests. (/v) Protective cushioning layer Goint J, ) : It is an

elastic cushioning of suitable material and thick-

ness provided between the anvil and the foun-

dation block in order to prevent bouncing

of anvil and creation of large impact stresses

and consequent damages to the top surface

of the concrete in the foundation block. (v)

Foundation support (joint J, ) = It is a support

for resting the foundation block. The block

may rest directly on ground or on a resilient

mounting such as timber sleepers, springs. cork

layer etc. The block may also be supported

on pile foundations.

Design Criteria (1) The stresses produced

at the time of impact in the foundation base

(soil, timber, sleeper, cork, spring elements

‘or piles) should be within 0.8 times allowable

static stresses.

(2) The design of the entire foundation

system should be such that the centres of

gravity of the anvil, and of the foundation

block, as well as the joints at which the (0) Foundation resting directly on soil

resultants of forces in the clastic joints i} “*

J, and Jy act, coincide with the line of Ts. oundation

. ° Elastic layer 4, Foundati

fall of the hammer tup. While determining

the centre of gravity of the foundation block,

the weight of the frame of the tp could

also be considered.

(3) The maximum vertical vibrational

amplitude of the foundation block should not

be more than 1.2 mm. In case of foundations

on sand below the ground water, the permissible

amplitude should not be more than 0.8 mm.

(¢) Foundatien resting of piles

FIG. 28.13, DIFFERENT TYPES OF FOUNDATION

SUPPORTS FOR IMPACT TYPE MACHINES.

PART VII

PAVEMENT DESIGN

29. DESIGN OF FLEXIBLE PAVEMENT

30. DESIGN OF RIGID PAVEMENT

31. STABILISATION OF SOILS

23)

Design of Flexible Pavement

29.

. INFRODUCTION : TYPES OF PAVEMENTS

‘A natural earth track is incapable of supporting modern wheel loads. A constructed

pavement is required on the top of the soil in order to distribute the wheel load efficiently

and to provide the necessary wearing surface. A pavement is, therfore, defined as a relatively

stable crust constructed over the natural soil for the purpose of supporting and distributing

the wheel loads and providing an adequate wearing surface. Depending upon the mode

of supporting and distributing loads, pavements are classified as fiexible, rigid and semi-flexible.

‘The flexible pavements consist of a relatively thin wearing surface built over a base

course and sub-base course, and they rest on compacted sub-grade. The flexible pavements

are able to resist only very small tensile stresses. In contrast to this, rigid pavements are

made up of Portland cement concrete and may or may not have a base course between

the pavement and the sub-grade. A rigid pavement can take appreciable tensile stresses

and is capable of bridging small weakness and depression in the sub-grade. A. semi-flexible

pavement is made of dry-lean concrete or soil cement, and possesses qualities intermediate

between the flexible and rigid pavements. A semi-flexible pavement possesses appreciable

flexural strength but its modulus of elasticity is considerably lower than that of concrete

The essential difference between rigid and flexible pavements is the manner in which

they distribute the load over the sub-grade. The design of a flexible pavement is based

on the principle that a surface load is dissipated by carrying it deep into the ground through

successive layer of granular materials. Hence the strength of a flexible layer is a result

of building up thick layers and thereby distributing the load over the sub-grade rather than

by the bending action. The thickness design of the flexible pavement is influenced primarily

by the strength of the sub-grade.

Because of its rigidity and high tensile strengh, a rigid pavement tends to distribute

the load over a relatively wide area of soil, and a major portion of the structural capacity

is supplied by the slab itself, For this reason, minor variations in sub-grade strength have

little influence upon the structual capacity of the pavement.

The rigid pavements are used for heavier Ioads and can be constructed over relatively

poor sub-grade such as black cotton or plastic soils, peat etc. However, since the load

is taken up by the bending action of the slab, uniform sub-grade support is the most

(825)

826 SOIL MECHANICS AND FOUNDATIONS.

essential condition for the satisfactory performance of rigid pavement. In the flexible pavements,

on the contrary, a high quality, well compacted sub-grade is essential.

29.2. STRUCTURAL ELEMENTS OF A FLEXIBLE PAVEMENT

A flexible pavement is usually built up in several layers as shown in Fig. 29.1,

each layer having a special function. Generally, the flexible pavement thickness consists

of three components : surfacing, base and sub-base course. The wearing course or surfacing

is the component. of. a pavement with which the wheels of vehicles are in actual contact.

The purpose of the wearing course,’made of bituminous material is to provide a smooth

riding surface that is resilient and will resist

pressure exerted by the tyres, It should be

flexible so that it will not fail if consolidation

of the subgrade or base course takes place.

A base course is defined as a layer

of granular material which lies immediatly

below the wearing surface of a flexible pave-

ment. A sub-base is a layer of material

between the base and sub-grade. Base course

and sub-bases are used under flexible pave-

“bases are | y SKA

ments primarily to increase the load supporting

capacity of the pavement by distributing FIG. 29.1. BASIC STRUCTURAL ELEMENTS

the load through a finite thickness of pavement. OF A FLEXIBLE PAVEMENT.

‘The base course lies close to the pavement

surface, and hence it. must possess high resistance to deformation in order to withstand

the high pressures imposed upon it. However, a sub-base can be of a lower quality,

‘The sub-grade is the foundation layer, the structure which must eventually support

all the loads which come on to the pavement. The performance of the pavement is affected

by the characteristics of the sub-grade. Desirable properties which the sub-grade should possess

are : strength, drainage, ease of compaction, permanencey of compaction, and permanency

of strength. The strength of the sub-grade is increased by compaction, or in some cases

by stabilisation. Stability of the sub-grade is influenced by soil texture, water content, density,

frost. action, shrinkage and swelling, and other climatic factors.

29.3. STRESSES IN FLEXIBLE PAVEMENT

1, Stresses in homogeneous mass ; We have seen in chapter 13 that the vertical

stress distribution on any horizontal plane at a depth z below the ground surface, duc

to a concentrated load takes the form of a bell-shaped surface, The maximum stresses occur

on the vertical plane passing through the point of load application. According to Boussinesq’s

analysis, the vertical stress a, at any point (r, 2) is given by

3P

++(29.1)

You might also like

- Arsenic Removal 1.2Document8 pagesArsenic Removal 1.2PawanKumarNo ratings yet

- Reservoir Storage CapacityDocument9 pagesReservoir Storage CapacityPawanKumarNo ratings yet

- C Volume I Part - 2Document75 pagesC Volume I Part - 2PawanKumarNo ratings yet

- Sieve AnalysisDocument2 pagesSieve AnalysisPawanKumar100% (1)

- Design of Steel StructuresDocument48 pagesDesign of Steel Structuressudhakarummadi87% (15)

- Project GroupsDocument2 pagesProject GroupsPawanKumarNo ratings yet

- Departmental Time-Table: Jan-April 2015Document1 pageDepartmental Time-Table: Jan-April 2015PawanKumarNo ratings yet

- Chapter 2ededDocument24 pagesChapter 2ededPawanKumarNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- RRC DVD No. 251: Yakshagana Dance TrainingDocument50 pagesRRC DVD No. 251: Yakshagana Dance TrainingJason MartinNo ratings yet

- NO Full Name Grade: Surabaya Math Contest ParticipantDocument10 pagesNO Full Name Grade: Surabaya Math Contest ParticipantYeni SuryaniNo ratings yet

- Trimsatika (Thirty Verses) of VasubandhuDocument4 pagesTrimsatika (Thirty Verses) of VasubandhuKelly MatthewsNo ratings yet

- Division of LongevityDocument5 pagesDivision of Longevityshree_laxminarayan9No ratings yet

- OB AssignmentDocument3 pagesOB AssignmentGirish TripathyNo ratings yet

- Indian Knowledge Systems: Past, Present & Future /TITLEDocument14 pagesIndian Knowledge Systems: Past, Present & Future /TITLEMahesh Daxini Thakker100% (1)

- The Raji Tribe of Uttrakhand in GlobaliDocument6 pagesThe Raji Tribe of Uttrakhand in GlobaliPiru JohnNo ratings yet

- AvalokitesvaraDocument10 pagesAvalokitesvaraJesus MarreroNo ratings yet

- 3VDocument4 pages3VShamsul Suzaimie Ahmad SukriNo ratings yet

- Huayan - The Jeweled Net of IndraDocument9 pagesHuayan - The Jeweled Net of IndrasengcanNo ratings yet

- Extra-Cocirricular ActivitiesDocument281 pagesExtra-Cocirricular ActivitiesS B JAIN INSTITUTE OF TECHNOLOGY MGMT. & RESEARCHNo ratings yet

- Muhurat For House On 11Document5 pagesMuhurat For House On 11Vejella PrasadNo ratings yet

- Derren Brown - Book - Pure EffectDocument9 pagesDerren Brown - Book - Pure EffectDayanandKambleNo ratings yet

- Punjab Steel CompaniesDocument503 pagesPunjab Steel CompaniesdheeruyadavNo ratings yet

- Shandilya Bhakti SutramDocument78 pagesShandilya Bhakti SutrambrijbasidasNo ratings yet

- Gr4 NotificationDocument24 pagesGr4 NotificationKiran KumarNo ratings yet

- Prakrta Rasa Aranya ChediniDocument299 pagesPrakrta Rasa Aranya Chediniaexb123No ratings yet

- Mantra of Vajrasattva for peace and enlightenmentDocument1 pageMantra of Vajrasattva for peace and enlightenmentbluzenadaNo ratings yet

- TAncAncient Indian Trees Depicted in Mayamatamrees Depicted in MayamatamDocument60 pagesTAncAncient Indian Trees Depicted in Mayamatamrees Depicted in MayamatamAshok Nene100% (2)

- The Vedic Samskaras and The Planets Influencing The Months of Pregnancy and The Development of Foetus - Pre Natal AstrologyDocument6 pagesThe Vedic Samskaras and The Planets Influencing The Months of Pregnancy and The Development of Foetus - Pre Natal AstrologyANTHONY WRITER100% (1)

- The Madras High Court On Tuesday Held That Devotees Cannot Be Denied Their Right To Worship at Any CostDocument2 pagesThe Madras High Court On Tuesday Held That Devotees Cannot Be Denied Their Right To Worship at Any Costmohammad asif abbasNo ratings yet

- VajrayanaDocument54 pagesVajrayanaTriyana DcNo ratings yet

- List of Power Tillers TestedDocument6 pagesList of Power Tillers TestedDEEPAK DOSADNo ratings yet

- Misson & Vission of AirtelDocument23 pagesMisson & Vission of AirtelrameshsonuNo ratings yet

- Ass AsDocument3 pagesAss AsMukesh BishtNo ratings yet

- Venkatesa SahasranaamamDocument296 pagesVenkatesa Sahasranaamamajiva_rts100% (6)

- Planets in The Tenth HouseDocument57 pagesPlanets in The Tenth HouseKrishna CH100% (1)

- Holiday Home Complete ListDocument17 pagesHoliday Home Complete Listajmermukhtar100% (1)

- Form 9Document95 pagesForm 9roshanNo ratings yet

- Principles and Practices of Management Assignment 1Document13 pagesPrinciples and Practices of Management Assignment 1Pragati MehndirattaNo ratings yet