Professional Documents

Culture Documents

Shell Min T: Element Thickness, Pressure, Diameter and Allowable Stress

Uploaded by

jithin.rjn40550 ratings0% found this document useful (0 votes)

32 views1 pageThe document provides calculations for mechanical design of a LOX backup vaporizer shell replacement. It calculates the required thickness, maximum allowable working pressure, and maximum allowable pressure for different sections of the shell based on internal pressure, material properties, and ASME code requirements. The minimum required thickness was determined to be 1.5 mm for all sections to meet the code minimum. The maximum allowable working pressure was calculated to be 0.103 MPa with the limiting factor being the design pressure.

Original Description:

head and shell minimum thickness for vessel

Original Title

Minimum Thickness

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides calculations for mechanical design of a LOX backup vaporizer shell replacement. It calculates the required thickness, maximum allowable working pressure, and maximum allowable pressure for different sections of the shell based on internal pressure, material properties, and ASME code requirements. The minimum required thickness was determined to be 1.5 mm for all sections to meet the code minimum. The maximum allowable working pressure was calculated to be 0.103 MPa with the limiting factor being the design pressure.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views1 pageShell Min T: Element Thickness, Pressure, Diameter and Allowable Stress

Uploaded by

jithin.rjn4055The document provides calculations for mechanical design of a LOX backup vaporizer shell replacement. It calculates the required thickness, maximum allowable working pressure, and maximum allowable pressure for different sections of the shell based on internal pressure, material properties, and ASME code requirements. The minimum required thickness was determined to be 1.5 mm for all sections to meet the code minimum. The maximum allowable working pressure was calculated to be 0.103 MPa with the limiting factor being the design pressure.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

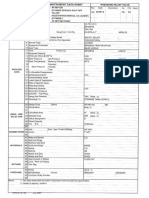

MECHANICAL DESIGN CALCULATIONS FOR LOX BACKUP VAPORIZER

LIKE TO LIKE SHELL REPLACEMENT OF LOX 110-EX-062 A/B

PV Elite 2014 Licensee: DOHA PET. CONST. CO. LTD., QATAR

FileName : VEN-28442-LOX-5-12-0001 Rev

Internal Pressure Calculations :

Step:

3

2:10p Dec 10,2014

17

Element Thickness, Pressure, Diameter and Allowable Stress :

|

| Int. Press |

Nominal | Total Corr|

Element | Allowable |

From| To | + Liq. Hd | Thickness | Allowance |

Diameter | Stress(SE)|

|

|

MPa

|

mm

|

mm

|

mm

|

MPa

|

--------------------------------------------------------------------------10| 20|

0.1214 |

8.0000 |

... |

2134.0 |

115.15 |

20| 60|

0.1214 |

12.000 |

... |

2134.0 |

97.875 |

60| 90|

0.1214 |

6.0000 |

... |

2134.0 |

97.875 |

90| 100|

0.1214 |

12.000 |

... |

2134.0 |

97.875 |

100| 120|

0.1214 |

8.0000 |

... |

2134.0 |

115.15 |

Element Required Thickness and MAWP :

|

|

Design |

M.A.W.P. |

M.A.P. |

Minimum |

Required |

From| To |

Pressure | Corroded | New & Cold | Thickness | Thickness |

|

|

MPa

|

MPa

|

MPa

|

mm

|

mm

|

---------------------------------------------------------------------------10| 20|

0.10342 |

0.63285 |

0.65079 |

6.00000 |

1.50000 |

20| 60|

0.10342 |

1.08778 |

1.10572 |

12.0000 |

1.50000 |

60| 90|

0.10342 |

0.53367 |

0.55161 |

6.00000 |

1.50000 |

90| 100|

0.10342 |

1.08778 |

1.10572 |

12.0000 |

1.50000 |

100| 120|

0.10342 |

0.63285 |

0.65079 |

6.00000 |

1.50000 |

Minimum

0.103

0.552

MAWP: 0.103 MPa , limited by: DESIGN (user specified)

Internal Pressure Calculation Results :

Provided t

head min t

ASME Code, Section VIII, Division 1, 2013

Elliptical Head From 10 To 20 SA-240 304L at 110 C

Longitudinal

Joint: Full Radiography per UW-11(a) Type 1

Circumferential Joint: Full Radiography per UW-11(a) Type 1

Material UNS Number:

S30403

Required Thickness due to Internal Pressure [tr]:

= (P*Do*Kcor)/(2*S*E+2*P*(Kcor-0.1)) per Appendix 1-4 (c)

= (0.121*2134.0000*1.000)/(2*115.15*1.00+2*0.121*(1.000-0.1))

= 1.1235 + 0.0000 = 1.1235 mm

Note: The thickness required was less than the Code Minimum, therefore

the Code Minimum value of 1.5000 mm per UG-16 will be used.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 0.018 MPa

= (2*S*E*t)/(Kcor*Do-2*t*(Kcor-0.1)) per Appendix 1-4 (c)

= (2*115.15*1.00*6.0000)/(1.000*2134.0000-2*6.0000*(1.00-0.1))

= 0.651 - 0.018 = 0.633 MPa

Maximum Allowable Pressure, New and Cold [MAPNC]:

shell min t

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Cone Design Tool: Pressure Vessel Engineering LTDDocument1 pageCone Design Tool: Pressure Vessel Engineering LTDkedubhajjiNo ratings yet

- Grade Slab ACI-150thkDocument7 pagesGrade Slab ACI-150thkMUTHUKKUMARAM100% (1)

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- 003-Heat ExchangerDocument299 pages003-Heat ExchangerVijayshanker GuptaNo ratings yet

- Vessel Design CalculationDocument54 pagesVessel Design CalculationPohn Myint Han50% (2)

- Report SPeaDer BarDocument24 pagesReport SPeaDer BarMochammad Shokeh100% (2)

- How To Review PV Elite Design Report PDFDocument9 pagesHow To Review PV Elite Design Report PDFprocess process100% (1)

- 111 - CT-NCT Spec-Dec, 2012Document27 pages111 - CT-NCT Spec-Dec, 2012SURJIT SINGHNo ratings yet

- Vessel CalculationDocument106 pagesVessel CalculationBhadresh PatelNo ratings yet

- Engineering Example CalculationDocument78 pagesEngineering Example Calculationkae kaeNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Report Pipe RackDocument16 pagesReport Pipe RackMochammad ShokehNo ratings yet

- Sample4 PVEliteDocument66 pagesSample4 PVEliteSourav Hait100% (1)

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanNo ratings yet

- PV Elite Heat Exchanger CalculationsDocument99 pagesPV Elite Heat Exchanger CalculationscbousmuNo ratings yet

- MESC-SPE-77-312-Fugitive Emission Production Testing PDFDocument25 pagesMESC-SPE-77-312-Fugitive Emission Production Testing PDFjithin.rjn4055No ratings yet

- Air Receiver Sample CalcDocument49 pagesAir Receiver Sample CalcBrian Edwin RodriguezNo ratings yet

- PV EliteDocument6 pagesPV ElitevikrantgulhaneNo ratings yet

- Sample Pipe Stress ReportDocument15 pagesSample Pipe Stress Reportpipinguser100% (4)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Base Ring and SkirtDocument8 pagesBase Ring and Skirtduazo2009No ratings yet

- R1 VE-J061-D-E201 REV-1 Earthing Design Calculation 271010Document10 pagesR1 VE-J061-D-E201 REV-1 Earthing Design Calculation 271010S Manohar100% (1)

- PV Elite ResultDocument18 pagesPV Elite ResultVeny MartianiNo ratings yet

- Tutorial Pressure VesselDocument19 pagesTutorial Pressure Vesseltahseenahsan100% (1)

- PRV SizingDocument28 pagesPRV Sizingjithin.rjn4055No ratings yet

- Rotating Drum CalculationDocument12 pagesRotating Drum Calculationمحمد أزها نو الدينNo ratings yet

- Design CalcDocument308 pagesDesign CalcPeja Jusoh100% (1)

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Document8 pagesPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Sample4 SpreadsheetDocument21 pagesSample4 SpreadsheetTrishul Nath Pallay100% (1)

- So2 BlowerDocument1,647 pagesSo2 Blowersgupta_615796No ratings yet

- Asme b31g Calculation Eml-4Document3 pagesAsme b31g Calculation Eml-4GRANRICKY100% (4)

- Torisperical - Element ThicknessDocument6 pagesTorisperical - Element ThicknessVipul GandhiNo ratings yet

- PV Elite Vessel Analysis Program: Input DataDocument9 pagesPV Elite Vessel Analysis Program: Input DataAhmed Ammar YasserNo ratings yet

- Element Thickness 2Document20 pagesElement Thickness 2Vipul GandhiNo ratings yet

- Element Thickness 3Document24 pagesElement Thickness 3Vipul GandhiNo ratings yet

- 500L - MIXING TANK - N4-SMT-03 (MP1), N4-SMT-04 (MP2) - Ellipsoidal DishDocument8 pages500L - MIXING TANK - N4-SMT-03 (MP1), N4-SMT-04 (MP2) - Ellipsoidal Dishprakash KaleNo ratings yet

- Element ThicknessDocument10 pagesElement ThicknesskhairulakbarNo ratings yet

- PV Elite Vessel Analysis Program: Input DataDocument90 pagesPV Elite Vessel Analysis Program: Input DatajahiranazriNo ratings yet

- PV Elite 2012 R1 Licensee: Pressure Filename: 102 Horz Tank - Internal Pressure Calculations: Step: 3 7:29P Oct 5,2012Document7 pagesPV Elite 2012 R1 Licensee: Pressure Filename: 102 Horz Tank - Internal Pressure Calculations: Step: 3 7:29P Oct 5,2012isaacalvareztejanoNo ratings yet

- DC S3-1301 REV.0 OriginalDocument93 pagesDC S3-1301 REV.0 OriginalPeja JusohNo ratings yet

- PV Elite Vessel Analysis Program: Input DataDocument30 pagesPV Elite Vessel Analysis Program: Input DatachampNo ratings yet

- A085hydraulicactuators PDFDocument2 pagesA085hydraulicactuators PDFCesar PomposoNo ratings yet

- Sump TankDocument65 pagesSump TankAgus MarpaungNo ratings yet

- How To Review PV Elite Report: (Specific To Forbes Marshall)Document9 pagesHow To Review PV Elite Report: (Specific To Forbes Marshall)thomas_v501925No ratings yet

- Cone of Vapour SeparatorDocument100 pagesCone of Vapour SeparatorDeepikaNo ratings yet

- (1. Earthquake Analysis Results Per ASCE 7Document20 pages(1. Earthquake Analysis Results Per ASCE 7ankitNo ratings yet

- SM4319PSK Datasheet PDFDocument11 pagesSM4319PSK Datasheet PDFban4444No ratings yet

- Control ValveDocument22 pagesControl Valvesantoshsapan25No ratings yet

- 9810 Chassis 13310-01-02 Manual de ServicioDocument0 pages9810 Chassis 13310-01-02 Manual de Serviciomauito27No ratings yet

- MV Capacitor and Voltage Divider DsDocument4 pagesMV Capacitor and Voltage Divider DsCristiano BruschiniNo ratings yet

- CK Report STEEL Design Calculations From STAADDocument299 pagesCK Report STEEL Design Calculations From STAADNeeraj DubeyNo ratings yet

- C A E S A R I I Vers 4.50 Jul 2,2010 0:20:58 Jobname: F:/SORIN P/TUR-G017/TERMOFICARE-G017 Licensed To: User Id: 1 1Document29 pagesC A E S A R I I Vers 4.50 Jul 2,2010 0:20:58 Jobname: F:/SORIN P/TUR-G017/TERMOFICARE-G017 Licensed To: User Id: 1 1irinaNo ratings yet

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter Specificationsjimbo2032No ratings yet

- Makkah PSM2 Suction SideDocument4 pagesMakkah PSM2 Suction Sideniyamat89No ratings yet

- 5433 080Document3 pages5433 080Ваня БойкоNo ratings yet

- PV Design Calc3Document6 pagesPV Design Calc3evrim77No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Jithin Kottarakkara (Truss, Board, Shingles Work)Document5 pagesJithin Kottarakkara (Truss, Board, Shingles Work)jithin.rjn4055No ratings yet

- Bathroom ListDocument2 pagesBathroom Listjithin.rjn4055No ratings yet

- Installation Instructions Use and Care Information Instructions D'installation Utilisez Et D'entretienDocument36 pagesInstallation Instructions Use and Care Information Instructions D'installation Utilisez Et D'entretienjithin.rjn4055No ratings yet

- ISO-designated Steel GroupsDocument6 pagesISO-designated Steel Groupsjithin.rjn4055No ratings yet

- Classification: Internal UseDocument10 pagesClassification: Internal Usejithin.rjn4055No ratings yet

- Safety and Relief Products: Kunkle Models 40R/40Rl Sentinel Relief ValvesDocument2 pagesSafety and Relief Products: Kunkle Models 40R/40Rl Sentinel Relief Valvesjithin.rjn4055No ratings yet

- Shand & Jurs-94160Document5 pagesShand & Jurs-94160jithin.rjn4055No ratings yet

- Babbitt-Chainwheels SpecificationsDocument2 pagesBabbitt-Chainwheels Specificationsjithin.rjn4055No ratings yet

- Fives Nordon - Expansion Joints LeafletDocument2 pagesFives Nordon - Expansion Joints Leafletjithin.rjn4055No ratings yet

- Afr/Afx: External Temperature Sensing ValveDocument2 pagesAfr/Afx: External Temperature Sensing Valvejithin.rjn4055No ratings yet

- Online Permit PanchayatDocument1 pageOnline Permit Panchayatjithin.rjn4055No ratings yet

- mesc-74-001-CARBON STEEL PIPE (AMENDMENTS API 5L) PDFDocument7 pagesmesc-74-001-CARBON STEEL PIPE (AMENDMENTS API 5L) PDFjithin.rjn4055No ratings yet

- Limitorque GearboxDocument36 pagesLimitorque Gearboxjithin.rjn4055No ratings yet

- Data Sheet-Shut Off Valve InstrumentDocument1 pageData Sheet-Shut Off Valve Instrumentjithin.rjn4055No ratings yet

- 762 VITO Interface Material Request FormDocument4 pages762 VITO Interface Material Request Formjithin.rjn4055No ratings yet

- Moment of Inertia API 650Document1 pageMoment of Inertia API 650jithin.rjn4055No ratings yet

- JQP Development Progress Status On 21st June 2016Document4 pagesJQP Development Progress Status On 21st June 2016jithin.rjn4055No ratings yet

- IMI Z+J Isolation ValveDocument4 pagesIMI Z+J Isolation Valvejithin.rjn4055No ratings yet

- Tension 3.5 in Normal Running CCL CalculationDocument1 pageTension 3.5 in Normal Running CCL Calculationjithin.rjn4055No ratings yet

- Moment of Inertia API 650 PDFDocument140 pagesMoment of Inertia API 650 PDFjithin.rjn4055No ratings yet