Professional Documents

Culture Documents

30S316 H2S

Uploaded by

Vipin NairOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

30S316 H2S

Uploaded by

Vipin NairCopyright:

Available Formats

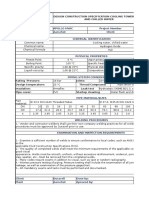

SPECIFICATION NUMBER: 30S316-H2S

SERVICE: ASME CLASS 300 HYDROGEN SULFIDE

STAINLESS STEEL) (21)

MAXIMUM HARDNESS: N/A

STRESS RELIEF: NO

HYDROSTATIC TESTING: YES (20)

MEETS CODE(S): ASME B31.3

COLOR: N/A

PHILTEX/RYTON SPEC

PHILTEX/RYTON COMPLEX PIPING SPECIFICATION

MINIMUM C/A: 0" (38)

MIN NDE: 100%

PRESSURE/TEMPERATURE

LIMITATIONS:

SIZE

&

FLANGES

(19) (30)

(1)(35)

ASME 300

FITTINGS

ELL, TEE,

RED, CAP

(1)

CPLGSINLINE

(1)

BRANCH

CONNECT

PIPE

NIPPLE

(5)

(17)(38)

BW /

SW

(5)

A182 F316/316L RF

SW PRF'D WN - SCH 40S

SE DO NOT USE

SW - A182 F316/316L 3000# PRF'D

SE - DO NOT USE

BW- A403 WP316/316L SCH 40S

SW - 182 F316/316L 3000#

SE - DO NOT USE

A182 F316/316L RF

WN PRFD / S0

WN SCH 10S

A403

WP316/316L

SCH 10S

XXXX

XXXX

XXXX

10

A182 F316/316L RF

WN PRFD / SO

WN SCH 10S

A403

WP316/316L

SCH 10S

XXXX

XXXX

XXXX

12

XXXX

14

XXXX

16

XXXX

DATE: 6/9/04

18

XXXX

20-24

XXXX

USE THE TABLE IN SECTION 3.6 OF THE APPPLICATION GUIDELINES

SIZE

SE

(5)

ASME CLASS 300 (NOT FOR CONTINUOUS

SERVICE BELOW - 150 )

(316

&

A312 TP316/316L

SE- DO NOT USE

SW- SCH40SSMLS

DO NOT USE

A312 TP316/316L

SCH 40S

SMLS

10

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

12

XXXX

14

XXXX

16

XXXX

18

XXXX

20-24

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

WELDOLET & BW ELBOLET 2 IN

WELDOLET & BW ELBOLET 3 IN 6 IN

SOCKOLET & SW ELBOLET

PLUGS, SOLID, ROUND HEAD

BUSHINGS

UNIONS

SWAGE NIPPLE FOR 2 IN PIPE

A312 TP316/316L

SCH 10S

EFW

A182 F316/316L SCH 40S

A182 F316/316L SCH - 10S

A182 F316/316L 3000#

A182 F316/316L (15)

A182 F316/316L (16)

SW -A182 F316/316L3000# FLANGES PRF'D

A403 WP316/316L SCH 80

A312 TP316/316L

SCH 10S

EFW

BOLTING MATERIAL

A193 B7M STUD WITH GREEN XYLON 1014 OR

1424 COATING. PRF'D

A 193 B8M CLASS II STUD BOLTS

NEVER MIX B7M & B8M.

NUTS

A194 2H HEAVY HEX NUTS WITH GREEN XYLON

1014 OR 1424 COATING PRF'D. USE COATED ONLY

WITH COATED BOLTS.

GASKETS

(1)CORRUGATED 316SS W/GRAPHITE PRFD. IDT WD-20, J

M CLIPPER ELASTOGRAPH, GARLOCK GRAPHONIC ALL

ACCEPTABLE.

(2)IN AREAS WHERE GRAPHONICS GASKETS WILL NOT

ACCOMMODATE FLANGE CAP USE SPIRAL WOUND 316 SS

WITH GRAPHITE FILL

(3)USE GRAPHONICS WITH NICKEL 200 AT RYTON

TUBING (1/2 & SMALLER)

SWAGELOK TUBING FITTINGS

THREAD COMPOUND

THERMOWELL CONNECTION

SMLS 316 STAINLESS STEEL ( .035 WALL)

316 STAINLESS STEEL

RECTORSEAL / GLADIATOR PASTE / VIRGIN TEFLON

PRFD

SOCKOLET / SW ELBOLET PRF'D or FLANGED

316 SS THERMOWELL PRF'D

Philtex/Ryton Mechanical Design Engineering must approve any exceptions to these specifications for any job on a case-by-case basis.

30S316-H2S

REV: 2

SPECIFICATION NUMBER: 30S316-H2S

SERVICE: Error: Reference source not found

DATE: 6/9/04

PHILTEX/RYTON COMPLEX PIPING SPECIFICATION

Valves listed below are preferred Consult the Phillips Engineering Standards for the other acceptable alternatives.

Orbit valves are considered a specialty item consult engineering.

SIZE

GATE

OS&Y

-1

BODY MATERIAL

TRIM MATERIAL

PACKING MATERIAL

BONNET CONSTRUCT

END CONNECTION

NOTES

A182 F316/316L (800#)

316 SS HF

GRAPHITE (23)

WELDED / BOLTED

FORMTEXT - B7M

W/2HM NUTS

FE

API 602 (6)

A182 F316/316L

316 SS HF

INCONEL X-750

FE

(800#)

CHECK

(14) (25)

BODY MATERIAL

TRIM MATERIAL

SPRING MATERIAL

END CONNECTION

NOTES

BUTTERFLY

FIRESAFE

API 607

API 609

(25)

BODY MATERIAL

TRIM MATERIAL

PACKING MATERIAL

END CONNECTION

NOTES

USE BALL VALVE

BALL

FIRESAFE

API 607

API 608

BODY MATERIAL

TRIM MATERIAL

PACKING MATERIAL

SEAT MATERIAL

END CONNECTION

NOTES

A182 F316/316L

316 SS

GRAPHITE (23)

GLASS FILL TEFLON

FE

PLUG

FIRESAFE

API 607

BODY MATERIAL

PLUG MATERIAL

SLEEVE MATERIAL

END CONNECTION

NOTES

GLOBE

BODY MATERIAL

TRIM MATERIAL

PACKING MATERIAL

BONNET CONSTRUCT

END CONNECTION

NOTES

OS&Y

(6)JAMESBURY 5300-313600XT

A351 CF8

316 SS

TEFLON

FE

A182 F316/316L (800#)

316 SS HF

GRAPHITE (23)

BOLTED

FE

A351 CF8

316 SS HF

GRAPHITE (23)

BOLTED- B7M W/2HM NUTS

FE

API 600

A351 CF8

316 SS

INCONEL X-750

FE

WATER

A351 CF8

316 SS

GRAPHITE (23)

FE

WAFER DOUBLE OFFSET (MIN.)

A351 CF8

316 SS

GRAPHITE (23)

GLASS FILL TEFLON

FE

JAMESBURY 5300-31-3600XT

A351 CF8

316 SS

TEFLON

FE

A351 CF8

316 SS HF

GRAPHITE (23)

BOLTED

FE

Notes:

(1) Use socket weld fittings except in areas where welding is not permitted.

(5) All first take-off piping thread nipples to 1 to first block valve shall be schedule 80 and stamped 80.

(6) Atmospheric vent and drain valves must be 1.

(14) Use only spring loaded check valves in vertical lines. Do not install any check valve with normal flow direction being down.

(15) No hexagonal head or hollowed out plugs allowed.

(16) Bushings to be a minimum of two size reductions. Use only on instruments takeoffs downstream of block valve.

(17) No all thread nipples allowed.

(19) Although one may be preferred over the other, slip-on flanges and weld neck flanges are interchangeable.

(20) If hydrotesting with water, the chloride content must be less than 250 ppm.

(21) Stainless steel 316L is acceptable substitutes for stainless steel 316.

(23)

Valves shall have die formed graphoil rings with braided graphite wiper ring top and bottom with corrosion inhibitor

(25) Equipment installed between flanges, i.e., wafer butterfly and check valves and some control valves, requires fire insulation or shielding of the flange bolts.

(30) Locate flanges in horizontal lines where possible.

(35) For slip-on flanges, leave a 1/4" gap on the back weld or drill an 1/8" hole from the backside to the bore for hydrogen gas to escape.

(38)

If C/A of 1/16" is needed, all screwed piping 1/2" - 1 1/2" shall be schedule 80 or 80S.

8 12

14 - 24

You might also like

- 60CSTL H2SDocument2 pages60CSTL H2SVipin NairNo ratings yet

- 15CSTL NaDocument3 pages15CSTL NaVipin NairNo ratings yet

- A2 1 16junDocument2 pagesA2 1 16junamitrai86No ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- Internal Normalization Piping Project Specification for Weakly Corrosive HydrocarbonsDocument1 pageInternal Normalization Piping Project Specification for Weakly Corrosive Hydrocarbonsliviu_dovaNo ratings yet

- A11Document1 pageA11liviu_dovaNo ratings yet

- Ep33411 b11Document9 pagesEp33411 b11salamrefighNo ratings yet

- Piping ComponentDocument19 pagesPiping Componentreach_arindomNo ratings yet

- Water SystemDocument9 pagesWater SystemArun GuptaNo ratings yet

- Eaton HansenKingDocument80 pagesEaton HansenKingKING COMERCIAL LTDANo ratings yet

- p128 22 PDFDocument3 pagesp128 22 PDFFernando CeballosNo ratings yet

- Chevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceDocument1 pageChevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceAldeline Sungahid100% (1)

- Spirax Sarco Ball Float PDFDocument12 pagesSpirax Sarco Ball Float PDFchanayireNo ratings yet

- 0 UltrastarDocument16 pages0 UltrastarGumersindo MelambesNo ratings yet

- 3., 4., & 9. RBXC Catalogue Local 2015Document16 pages3., 4., & 9. RBXC Catalogue Local 2015Nilesh RanadeviNo ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- D11Document1 pageD11liviu_dovaNo ratings yet

- Astm Nos For PipingDocument6 pagesAstm Nos For PipingJessica HerringNo ratings yet

- 3/2 Direct Acting Namur Solenoid Valve: FeaturesDocument2 pages3/2 Direct Acting Namur Solenoid Valve: Featureskuru_0125No ratings yet

- C 316SFeb2008Document2 pagesC 316SFeb2008Mano NegraNo ratings yet

- Valves & ControlsDocument16 pagesValves & ControlseborresonNo ratings yet

- 60 Series Tube Fitting 150123Document7 pages60 Series Tube Fitting 150123Nilesh MistryNo ratings yet

- Documents Plc150Document7 pagesDocuments Plc150Anonymous cuOIjrLINo ratings yet

- Purga Fondo BBV 980 A PDFDocument2 pagesPurga Fondo BBV 980 A PDFaugusto7777No ratings yet

- 6oilccopdngglobal2152008 Voll III 20piping 20 20 MechanicalDocument643 pages6oilccopdngglobal2152008 Voll III 20piping 20 20 Mechanicaldinesh2u85No ratings yet

- Horizontal Condensate Collection Manifold - FabricatedDocument2 pagesHorizontal Condensate Collection Manifold - Fabricatedkresimir.mikoc9765No ratings yet

- Class 61502 Carbon Steel Piping Design LimitsDocument10 pagesClass 61502 Carbon Steel Piping Design LimitsbalajivangaruNo ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- CS310ADocument4 pagesCS310Arabacet2923No ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Cat 4160-SC A00 ParkerDocument8 pagesCat 4160-SC A00 ParkerFabian Antonio RoldanNo ratings yet

- 11502Document9 pages11502balajivangaruNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- DNO Piping SpecificationDocument2 pagesDNO Piping SpecificationDurgesh GuptaNo ratings yet

- A17Document1 pageA17liviu_dovaNo ratings yet

- Valve Spirax Sarco 25P Ti-3-015-UsDocument2 pagesValve Spirax Sarco 25P Ti-3-015-Ussugesus100% (2)

- CAST STEEL GATE VALVES UNDER 40 CHARACTERSDocument4 pagesCAST STEEL GATE VALVES UNDER 40 CHARACTERSsghinausNo ratings yet

- Flange Selection GuideDocument11 pagesFlange Selection GuidebandithaguruNo ratings yet

- A09Document1 pageA09liviu_dovaNo ratings yet

- Ball ValveDocument12 pagesBall ValveIdabaNo ratings yet

- High-Tech Block & Bleed ValvesDocument20 pagesHigh-Tech Block & Bleed ValvesMayur PatelNo ratings yet

- Comprehensive Title for Piping Class Design DocumentDocument9 pagesComprehensive Title for Piping Class Design Documenteww08No ratings yet

- FT MedPress AutoclaveDocument12 pagesFT MedPress AutoclaveAymeeenNo ratings yet

- Autoclave Subsea Ball ValvesDocument20 pagesAutoclave Subsea Ball Valvesvp989No ratings yet

- Product TIRotameterEnged4Document8 pagesProduct TIRotameterEnged4gokulnathreddyNo ratings yet

- Catálogo Válvula DirecionalDocument20 pagesCatálogo Válvula DirecionalcristianoclemNo ratings yet

- Tyler Union CatalogDocument65 pagesTyler Union Catalognjsmith5No ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Cooling Tower and Chilled Water SpecificationDocument42 pagesCooling Tower and Chilled Water SpecificationEugen LupanNo ratings yet

- STD PipingDocument51 pagesSTD PipingRodrigo Iván Latorre AlmirallNo ratings yet

- Flanges, Gaskets, Nuts & BoltsDocument10 pagesFlanges, Gaskets, Nuts & BoltsJohnMerrNo ratings yet

- rc33026 D12-UscDocument7 pagesrc33026 D12-Usceww08No ratings yet

- Ball Float Steam Trap 1 PDFDocument3 pagesBall Float Steam Trap 1 PDFmaminzzzNo ratings yet

- Globe Control Valve Technical SpecificationsDocument16 pagesGlobe Control Valve Technical SpecificationsVinod KumarNo ratings yet

- STP CatalogueDocument37 pagesSTP CataloguemmkattaNo ratings yet

- Valves Pipe Fittings DimensionsDocument37 pagesValves Pipe Fittings DimensionstsoheilNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Input FileDocument10 pagesInput FileVipin NairNo ratings yet

- X-1-Estimating Tool - Rev 0Document10 pagesX-1-Estimating Tool - Rev 0Vipin NairNo ratings yet

- Blackjack Cheat Sheet PDF Color PDFDocument1 pageBlackjack Cheat Sheet PDF Color PDFVipin NairNo ratings yet

- Corsair 7 MIRs Feb 20 Feb 2717 NM 13 UsDocument1 pageCorsair 7 MIRs Feb 20 Feb 2717 NM 13 UsVipin NairNo ratings yet

- Steel Cals SimpleDocument53 pagesSteel Cals SimpleVashish RamrechaNo ratings yet

- Circuitization Project Workflow GuideDocument1 pageCircuitization Project Workflow GuideVipin NairNo ratings yet

- Stream Inspection Criteria FormDocument4 pagesStream Inspection Criteria FormVipin NairNo ratings yet

- DIY Cloth Face Covering Instructions PDFDocument3 pagesDIY Cloth Face Covering Instructions PDFnathanNo ratings yet

- 965 B10193 05,00Document1 page965 B10193 05,00Vipin NairNo ratings yet

- Texas MudHensDocument1 pageTexas MudHensVipin NairNo ratings yet

- Xref Lines Not in LCI DBDocument8 pagesXref Lines Not in LCI DBVipin NairNo ratings yet

- CUI Project ExchnagersDocument5 pagesCUI Project ExchnagersVipin NairNo ratings yet

- Static Head Calculation For B-31Document1 pageStatic Head Calculation For B-31Vipin NairNo ratings yet

- Terminal 3 Map2 - 2015 - R3 - tcm13-4102Document2 pagesTerminal 3 Map2 - 2015 - R3 - tcm13-4102Vipin NairNo ratings yet

- Management of Critical Process Equipment To Ensure It Is Designed and Installed Correctly, and That It Operates and Is Maintained ProperlyDocument2 pagesManagement of Critical Process Equipment To Ensure It Is Designed and Installed Correctly, and That It Operates and Is Maintained ProperlyVipin NairNo ratings yet

- Synthron Final Report1 PDFDocument17 pagesSynthron Final Report1 PDFVipin NairNo ratings yet

- Sphere MAWPDocument2 pagesSphere MAWPVipin NairNo ratings yet

- Vibration Related Failures of Small Bore AttachmentsDocument13 pagesVibration Related Failures of Small Bore AttachmentsJose PradoNo ratings yet

- LWN TablesDocument7 pagesLWN TablesVipin NairNo ratings yet

- Excel VBA For Dummies. BonusChapter02Document4 pagesExcel VBA For Dummies. BonusChapter02nick_giannNo ratings yet

- 05 Minor Moc SDR FormDocument23 pages05 Minor Moc SDR FormVipin NairNo ratings yet

- A-18 Top HeadDocument1 pageA-18 Top HeadVipin NairNo ratings yet

- PVElite Installation MethodDocument1 pagePVElite Installation MethodadnaniaziNo ratings yet

- Pressure Vessel MI Field TemplateDocument1 pagePressure Vessel MI Field TemplateVipin NairNo ratings yet

- Redlined DWGDocument1 pageRedlined DWGVipin NairNo ratings yet

- College Engineering Commencement TicketDocument1 pageCollege Engineering Commencement TicketVipin NairNo ratings yet

- E Battery TanksDocument8 pagesE Battery TanksVipin NairNo ratings yet

- Vintage Style Indonesian Geography Lesson For High School by SlidesgoDocument56 pagesVintage Style Indonesian Geography Lesson For High School by Slidesgoohd InstalasicontrolNo ratings yet

- About Version ControlDocument6 pagesAbout Version ControlMaria Kristina Cassandra HeukshorstNo ratings yet

- Center of Gravity and Shear Center of Thin-Walled Open-Section Composite BeamsDocument6 pagesCenter of Gravity and Shear Center of Thin-Walled Open-Section Composite Beamsredz00100% (1)

- Rescue Triangle PDFDocument18 pagesRescue Triangle PDFrabas_No ratings yet

- Tutorial 3Document2 pagesTutorial 3prasoon jhaNo ratings yet

- Policies and Regulations On EV Charging in India PPT KrishnaDocument9 pagesPolicies and Regulations On EV Charging in India PPT KrishnaSonal ChoudharyNo ratings yet

- 99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudDocument6 pages99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudPavankumar PuvvalaNo ratings yet

- IT SyllabusDocument3 pagesIT SyllabusNeilKumarNo ratings yet

- CH - 3Document3 pagesCH - 3Phantom GamingNo ratings yet

- The Bloodless GospelDocument7 pagesThe Bloodless GospelKJVNo ratings yet

- Indian Institute OF Management, BangaloreDocument20 pagesIndian Institute OF Management, BangaloreGagandeep SinghNo ratings yet

- Drypro832 PreInstallGude 0921YH220B 070627 FixDocument23 pagesDrypro832 PreInstallGude 0921YH220B 070627 FixRicardoNo ratings yet

- Choose the Best WordDocument7 pagesChoose the Best WordJohnny JohnnieeNo ratings yet

- Basic Calculus: Performance TaskDocument6 pagesBasic Calculus: Performance TasksammyNo ratings yet

- Denodo Job RoleDocument2 pagesDenodo Job Role059 Monisha BaskarNo ratings yet

- Electrophoresis and Fractionation of Wheat GlutenDocument14 pagesElectrophoresis and Fractionation of Wheat GlutensecucaNo ratings yet

- Youth, Time and Social Movements ExploredDocument10 pagesYouth, Time and Social Movements Exploredviva_bourdieu100% (1)

- Notes On The Life and Works of Jose Rizal - IncompleteDocument15 pagesNotes On The Life and Works of Jose Rizal - Incompleteblock_me_please50% (2)

- Body Scan AnalysisDocument9 pagesBody Scan AnalysisAmaury CosmeNo ratings yet

- Flexible AC Transmission SystemsDocument51 pagesFlexible AC Transmission SystemsPriyanka VedulaNo ratings yet

- Design and Analysis of Algorithms Prof. Madhavan Mukund Chennai Mathematical Institute Week - 01 Module - 01 Lecture - 01Document8 pagesDesign and Analysis of Algorithms Prof. Madhavan Mukund Chennai Mathematical Institute Week - 01 Module - 01 Lecture - 01SwatiNo ratings yet

- Principles of Cost Accounting 1Document6 pagesPrinciples of Cost Accounting 1Alimamy KamaraNo ratings yet

- Estwani ISO CodesDocument9 pagesEstwani ISO Codesनिपुण कुमारNo ratings yet

- January 2013 Igcse Timetable 22-06-2012Document2 pagesJanuary 2013 Igcse Timetable 22-06-2012Rizwanur RahmanNo ratings yet

- Hastrof Si Cantril. 1954. The Saw A Game. A Case StudyDocument6 pagesHastrof Si Cantril. 1954. The Saw A Game. A Case Studylandreea21No ratings yet

- LGFL Service GuideDocument24 pagesLGFL Service GuideThe Return of the NoiristaNo ratings yet

- English Skills BookDocument49 pagesEnglish Skills BookAngela SpadeNo ratings yet

- The Slave Trade and The British Empire An Audit of Commemoration in WalesDocument133 pagesThe Slave Trade and The British Empire An Audit of Commemoration in WaleslegoarkeologNo ratings yet

- Mba Project GuidelinesDocument8 pagesMba Project GuidelinesKrishnamohan VaddadiNo ratings yet