Professional Documents

Culture Documents

Fed-Batch Cultivation

Uploaded by

Saleha Shamsudin0 ratings0% found this document useful (0 votes)

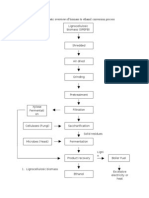

36 views14 pagesFed-batch cultivation involves intermittent or continuous feeding of nutrients to a bioreactor to supplement the reactor contents and control substrate concentration. There are three main operation modes - batch, continuous, and fed-batch. Fed-batch reactors allow control over substrate levels through intermittent or continuous feeding while maintaining a fixed or variable culture volume. Fed-batch bioprocesses have advantages like controllable conditions and avoidance of by-products, but require analysis of microorganisms and ability to precisely measure feed components.

Original Description:

Original Title

Fed-batch Cultivation

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFed-batch cultivation involves intermittent or continuous feeding of nutrients to a bioreactor to supplement the reactor contents and control substrate concentration. There are three main operation modes - batch, continuous, and fed-batch. Fed-batch reactors allow control over substrate levels through intermittent or continuous feeding while maintaining a fixed or variable culture volume. Fed-batch bioprocesses have advantages like controllable conditions and avoidance of by-products, but require analysis of microorganisms and ability to precisely measure feed components.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views14 pagesFed-Batch Cultivation

Uploaded by

Saleha ShamsudinFed-batch cultivation involves intermittent or continuous feeding of nutrients to a bioreactor to supplement the reactor contents and control substrate concentration. There are three main operation modes - batch, continuous, and fed-batch. Fed-batch reactors allow control over substrate levels through intermittent or continuous feeding while maintaining a fixed or variable culture volume. Fed-batch bioprocesses have advantages like controllable conditions and avoidance of by-products, but require analysis of microorganisms and ability to precisely measure feed components.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 14

Fed-batch

cultivation

Introduction

Chemical changes of a substrate

accomplished by selected

microorganisms

Microorganisms are bacteria, yeast,

and molds that feed on organic

materials

Food is required to grow

The reactor is the heart of any

fermentation

mode of operation

Batch reactor

Continuous reactor

Fed-Batch reactor

Batch reactor

Batch processes operate in closed

systems; substrate is added at the

beginning of the process and

products removed only at the end.

Continuous reactor

Bioreactors are operated

continuously in a few bioprocess

industries such as brewing,

production of bakers' yeast and

waste treatment.

Fed-Batch reactor

In fed-batch operation, intermittent

or continuous feeding of nutrients is

used to supplement the reactor

contents and provide control over

the substrate concentration.

Fixed volume fed-batch

The culture volume is maintained

constant by feeding the growth

limiting substrate or withdrawal of a

portion of the culture.

Variable volume fedbatch

the volume changes with the

fermentation time due to the

substrate feed.

Advantages and

disadvantages of the fedbatch reactors

The conditions are under the control

The production of by-products are avoided

Replacement of water loss by evaporation

Dealing with toxic substrate

No additional special piece of equipment is

required as compared with the batch

fermentation

There is opportunity to optimize product

synthesis

Disadvantages

It requires previous analysis of the

microorganism

The quantities of the components to

control must be above the detection

limits of the available measuring

equipment

The accumulation of non-producing or

low-producing variants may result

You might also like

- Types of Fermenters & Types of BioreactorsDocument24 pagesTypes of Fermenters & Types of BioreactorsMoaz Fiaz80% (5)

- Fermentation TechnologyDocument36 pagesFermentation TechnologyKoki KingNo ratings yet

- Bioreactors Or: FermentorsDocument4 pagesBioreactors Or: FermentorsRamya TeddyNo ratings yet

- Bioreactors LatestDocument34 pagesBioreactors LatestSyeda KazmiNo ratings yet

- Ass FoodDocument3 pagesAss FoodshftdinNo ratings yet

- Secondary MetabolitesDocument22 pagesSecondary MetabolitesStephen MooreNo ratings yet

- Bioreactor DesignDocument24 pagesBioreactor DesignVitra Wahyu PradanaNo ratings yet

- Fermentation: TechnologyDocument7 pagesFermentation: TechnologyfestagjakovaNo ratings yet

- Fermentation Types: 8 Types of Fermentations - Industrial BiotechnologyDocument12 pagesFermentation Types: 8 Types of Fermentations - Industrial BiotechnologyOdoemenem AnthonyNo ratings yet

- Modifying Batch and Continuous CultureDocument13 pagesModifying Batch and Continuous CultureRitika GeraNo ratings yet

- Fermentor TypesDocument33 pagesFermentor TypesFahad MukhtarNo ratings yet

- Kimia Pangan - Fermentasi Dan BioreaktorDocument53 pagesKimia Pangan - Fermentasi Dan BioreaktorHartati SNo ratings yet

- Industrial Biotechnology 1Document29 pagesIndustrial Biotechnology 1Abdul Al RajaNo ratings yet

- 18BT71 M1P2Document14 pages18BT71 M1P2Harshitha Gowda HarshiNo ratings yet

- Ch-3 Microbial BiotechDocument37 pagesCh-3 Microbial Biotechhamimmuhammedadem0579No ratings yet

- BiotechnologyDocument26 pagesBiotechnologyJ. DiroshikaNo ratings yet

- Basic Modes of Fermentation ProcessDocument16 pagesBasic Modes of Fermentation ProcessMahesh RamNo ratings yet

- FBR Bioreactor Advance CreDocument16 pagesFBR Bioreactor Advance CreFarisRazzakNo ratings yet

- 2.2 FED BATCH & Continuous Fermentation IIDocument36 pages2.2 FED BATCH & Continuous Fermentation IINixon Da Piedade CoutinhoNo ratings yet

- Batch and Fed-Batch FermentationDocument26 pagesBatch and Fed-Batch Fermentationnursadi12No ratings yet

- Bioprocess Technology 2022Document47 pagesBioprocess Technology 2022Sowjanya NekuriNo ratings yet

- Comparison of Batch Culture and Continuous Cultivation: SterilizationDocument3 pagesComparison of Batch Culture and Continuous Cultivation: SterilizationJulhamEfendiNo ratings yet

- Microbial CultureDocument5 pagesMicrobial CultureSaraniyaNo ratings yet

- Fermentation TechnologyDocument14 pagesFermentation TechnologyUmarNo ratings yet

- Specific Growth of Bakers Yeast in A Feed Batch SystemDocument52 pagesSpecific Growth of Bakers Yeast in A Feed Batch SystemDavid OjwangNo ratings yet

- Week 14 Industrial MicrobiologyDocument44 pagesWeek 14 Industrial MicrobiologyHerwanto ChrisTopel ManullangNo ratings yet

- Fermentation PresentationDocument23 pagesFermentation Presentationpisces_sanjeevNo ratings yet

- 4.the ProcessDocument77 pages4.the ProcessAnil MinhasNo ratings yet

- Fermentation Technology: The Fermentation Process Requires The FollowingDocument18 pagesFermentation Technology: The Fermentation Process Requires The FollowingSujan BoseNo ratings yet

- Fermentation TechnologyDocument32 pagesFermentation TechnologyPatel Divya DivyaNo ratings yet

- Reactor TypeDocument2 pagesReactor TypeAmir Hamzah50% (2)

- Bioconversion 2017-18Document112 pagesBioconversion 2017-18bagus sutrisnoNo ratings yet

- Industrial MCB (DR Etim)Document35 pagesIndustrial MCB (DR Etim)NAJAATU SHEHU HADINo ratings yet

- Bioreactor 2020 PPT PDFDocument76 pagesBioreactor 2020 PPT PDFAbrar Ali Sitab100% (3)

- Bios Era Part Ion 2Document10 pagesBios Era Part Ion 2Pooja Singh JainNo ratings yet

- Microbial Biomass ProductionDocument32 pagesMicrobial Biomass Productionpramudita nadiahNo ratings yet

- Bioreactor: ECH 3201 Biochemical EngineeringDocument26 pagesBioreactor: ECH 3201 Biochemical EngineeringWazif ZakwanNo ratings yet

- Fermentor: Krishna Priya.K Lecturer Dept. of MicrobiologyDocument140 pagesFermentor: Krishna Priya.K Lecturer Dept. of MicrobiologyneelNo ratings yet

- Batch Fermentation in Batch Fermentation, The Sterile Growth Medium Is Inoculated With The AppropriateDocument3 pagesBatch Fermentation in Batch Fermentation, The Sterile Growth Medium Is Inoculated With The AppropriateShanmugapriyaNo ratings yet

- Industrial FermentationDocument18 pagesIndustrial FermentationIram AnwarNo ratings yet

- Industrial BiotechnologyDocument8 pagesIndustrial Biotechnology6dnj28tfz6No ratings yet

- BioreactorDocument3 pagesBioreactorSTAFF JINNAH COLLEGENo ratings yet

- Fermenter TypesDocument23 pagesFermenter TypesPratishtha RawatNo ratings yet

- Fermentation For DummiesDocument12 pagesFermentation For DummiesShahfaraNo ratings yet

- Week 7 Types of Fermentation Part 3Document12 pagesWeek 7 Types of Fermentation Part 3fatima zafarNo ratings yet

- Visual Encyclopedia of Chemical Engineering Bioreactors: FermentersDocument13 pagesVisual Encyclopedia of Chemical Engineering Bioreactors: FermentersVanNo ratings yet

- Bio Reactor TypesDocument23 pagesBio Reactor TypesSundar SkNo ratings yet

- Bioprocess TechnologyDocument22 pagesBioprocess Technologyfabianosir321No ratings yet

- Fermentation: Shroff S.R. Rotary Institute of Chemical Technology (Srict)Document57 pagesFermentation: Shroff S.R. Rotary Institute of Chemical Technology (Srict)jeevalakshmanan29No ratings yet

- Characteristics of Microorganisms Used in Industrial MicrobiologyDocument62 pagesCharacteristics of Microorganisms Used in Industrial Microbiologyjaveriazia97No ratings yet

- Modes of FermentationDocument9 pagesModes of FermentationLouellaNo ratings yet

- Bioreactor (Introduction) Lec 1-2Document26 pagesBioreactor (Introduction) Lec 1-2mahi mridulaNo ratings yet

- G-3 The FarmcultureDocument23 pagesG-3 The Farmculturedeepansh sharmaNo ratings yet

- Joseph S. Alford: What Is A Bioprocess?Document8 pagesJoseph S. Alford: What Is A Bioprocess?rhabarberrhabarberNo ratings yet

- CH 28 Applied and Industril MicrobiologyDocument35 pagesCH 28 Applied and Industril Microbiologyramonlennon1980No ratings yet

- Fermenter Types and Their Kinetics-1Document15 pagesFermenter Types and Their Kinetics-1Hussain TaqiNo ratings yet

- Plant Antibiotic Production Through Plant Tissue Culture: Dushyant Kumar BSA-08-613Document12 pagesPlant Antibiotic Production Through Plant Tissue Culture: Dushyant Kumar BSA-08-613dushyantrockyNo ratings yet

- Industrial MicrobiologyDocument0 pagesIndustrial Microbiologymmoradi55100% (2)

- Organic Chemistry: Carbonyl Compounds IIDocument73 pagesOrganic Chemistry: Carbonyl Compounds IISaleha ShamsudinNo ratings yet

- A Comparison Between Simultaneous Saccharification and Fermentation and Separate Hydrolysis and Fermentation Using Steam-Pretreated Corn StoverDocument2 pagesA Comparison Between Simultaneous Saccharification and Fermentation and Separate Hydrolysis and Fermentation Using Steam-Pretreated Corn StoverSaleha ShamsudinNo ratings yet

- Aldehyde and Ketone ReactionsDocument12 pagesAldehyde and Ketone ReactionsSaleha ShamsudinNo ratings yet

- Quiz 1: A) With The Aid of The Diagram, Described The Characteristics of The FollowingDocument1 pageQuiz 1: A) With The Aid of The Diagram, Described The Characteristics of The FollowingSaleha ShamsudinNo ratings yet

- Continous Fermentation1Document38 pagesContinous Fermentation1Saleha ShamsudinNo ratings yet

- How Cells Grow in Continuous CultureDocument6 pagesHow Cells Grow in Continuous CultureSaleha ShamsudinNo ratings yet

- Experiment 1: To Study The Effect of High Pressure Steam Treatment On OPEFB As PretreatmentDocument5 pagesExperiment 1: To Study The Effect of High Pressure Steam Treatment On OPEFB As PretreatmentSaleha ShamsudinNo ratings yet

- House For SaleDocument1 pageHouse For SaleSaleha ShamsudinNo ratings yet

- Fig 1: Schematic Overview of Biomass To Ethanol Conversion ProcessDocument2 pagesFig 1: Schematic Overview of Biomass To Ethanol Conversion ProcessSaleha ShamsudinNo ratings yet

- Sealed EfbDocument1 pageSealed EfbSaleha ShamsudinNo ratings yet