Professional Documents

Culture Documents

Manual Chiyoda Ing Basica

Uploaded by

Engr Tahir UL Haq0 ratings0% found this document useful (0 votes)

327 views209 pagesfree

Original Title

52686859 Manual Chiyoda Ing Basica

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfree

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

327 views209 pagesManual Chiyoda Ing Basica

Uploaded by

Engr Tahir UL Haqfree

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 209

@CHIVODA fencer

ENGINEERING MANUAL

FOR

BASIC DESIGN PACKAGE

OCTOBER 1987

CHIYODA CHEMICAL ENGINEERING & CONSTRUCTION cO., LTD.

YOKOHAMA JAPAN

Q@CHIVODA tesncaets

Introduction

The design package is defined as:

- the package of design specifications and drawings

prepared in the planning and engineering work for a

project

The design package is classified into 2 types:

a. Basic Design Package (Process Design Package)

b. Engineering Package

The package is prepared by plant owner, Process licensor, or

engineering contractor and is included in bid package or

contract document for the base of the project works.

Therefore, preparation of design package is in accordance with

contractor assignment plan for the project from basic plan

through construction. In case turn key contract is applied

and one contractor covers overall construction project from

basic design to construction, no design package is prepared in

general.

In case licensed process is included, basic design package is

supplied by licensor, and typical licensor's design package is

UoP's Schedule "A" Package which is composed of the

followings.

- process flow diagram

- preliminary P & I diagram

- preliminary plot plans

- equipment specifications

- instruments specifications

- material specifications

- process manuals

© REWCAL EXGINEETING

‘torsmcroncama

To complete the plant meeting with requirements within planned

schedule, it is required to complete the package with through

understanding of overall project execution plan including

contractor assignment plan and contract type.

All design and engineering conditions of the plant are given

by the Basic Design Requirement (BDR) and Basic Engineering

Design Data(BEDD). Basic design and engineering procedure

covering process plant, utility plant and off site facilities

is typically summarized as attached. From this procedure,

major activities and their output information is clarified,

and contents of design package and information to be filled

are explained.

© CHIYODA toss

Procedure for Basic Design / Engineering

Engineering Procedure for Process Design

Input pata Activity Output Tnformation

Proceas Design Requirement | 1, Process Design Development | === Process Study Report

2. Basic Process Design ===> Basic Process Design Package

Basic Engineering Design

Data: 3, Detailed Proceas Design +Process Design Package

*Design Report

+Operating Instructions

+Analytical Instructions

+Performance Guarantee Figure

4, Review of Downstream

Activities

SGRey ass VOOAII®

© cHvOdA ceenssT

Process Design Development

(1)

(2)

(3)

(4)

(5)

Process flow diagram

development

Calculation of preliminary

material and heat balances

(including pressure balance)

Preliminary design of

equipment

Estimation of plant costs

and manufacturing costs

Evaluation and selection of

alternative designs

Q@CHIVODA raceme

Basic Process Design

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Establishment of design

criteria

Establishment of design

procedure

Finalization of process

flow arrangement

Calculation of heat and

material balances

Design of unit operations

Waste flow arrangement

Selection of construction

materials

Estimation of requirements

for catalysts and chemicals

Detailed Process Design

a

(2)

@

(4)

(3)

(6)

a

(a)

Preparation of specifica-

tions for:

(a) Reactors

() Columns.

(c) Drums

Preparation of duty sreci-

fications for:

(a)

(>)

(c) Heat exchangers

(4) Air-cooled heat

exchancers

(e) Fired heaters

(2) Vacuum equipment

(g) Miscellaneots equipment

Preparation of duty speci-

fications for packaged units

Estimation of pressure

balance

Utility flow arrangement

Estimation of utility

consumption rates

Preparation of specifica—

tions for ranges of

instruments and control

valves

Desien of safety facilities

xs and blowers

a

(10)

(11)

a2

aay

(14)

(15)

ae)

(17)

Development of process

requirements for utility

header diagrams and plow

plans

Preliminary desion of

equipment

Estimation of manufacturing

costs

Compilation of process

desion package

Pr

Pi

paration of operating

lesephy

Compilation of éesign report

Preparation of operating

instructions

Preparation of analytical

instruction

Establishment of performance

guarantee figures

@CHVODA texszeT

qa

(2)

Q

a)

(5)

(6)

(7)

(a)

BASIC DESIGN REQUIREMENTS FOR PROCESS DESIGN

BASIC DESIGN REQUIREMENTS FOR PROCESS DESIGN

Performance requirements, such as:

(a) Plant capacity

(b) Production rate

(c) Operation factors

(4) Quality and quantity of feedstocks and products

Basic functions of each process unit

Boundary conditions, including definitiofis of the functional

and physical interfaces between all process units

Applicable regulatory requirements, including environmental

ones

Waste disposal requirements, such as for air pollution,

water source pollution, malodors, waste oil, tar, pitch, and

sludge

Special design considerations

Operational requirements

Guarantee requirements

Q@CHIVODA coc

@

(2)

a

4)

(5)

(6)

a

BASIC ENGINEERING DESIGN DATA FOR PROCESS DESIGN

BASIC ENGINEERING DESIGN DATA FOR PROCESS DESIGN

Codes and regulations

Mumbering systems for:

(a) Documents

(b) Units and equipment

Units of measure

Utility data

(a) Utility conditions at the battery limit and on the

Process side

(b) Design conditions

Utility cost data

Economic criteria

Special design data, such as:

(a) Essential chemical and physical properties of all

materials handled

(b) Corrosion protection requirements, material selection

guides, and other special requirements

(c) Testing laboratory data and methods of interpretation

arr

BASIC ENGINEERING FOR.

AcrivsTY

oureur

1, Proce dsien packane compti

o

®

°

o

o

©

®

co

a

«2

a3

4)

as)

06)

“

an

a

0)

a

@

23)

Process deteption

Block Mow alata

joe low diagram

erin and en Balance with seem

fats sheet

Enlmated presure balance

Estnated tty sammary

Luly flow plan

Cataya requirements

Ceres sequvemes

Material section pide with dingame

Equlpoent Index

De sheets for packed columns, trys,

eal exchangers, Ted healers, air-cooled

heat exchange, pumps, compress,

ower, and vacuum eaulpment

Speciation sheets for eohumns and drum

for spelt equipment

‘Skeleton drawings for special equipment

Process date fot pacaged unite

‘Proce data for contol vies snd

Safty and ele rae

‘Addons! information for dersoplng the

PAL diagrams, wlty Dow agri, end

ot pins

Operating philosophy If mecesary

Operating instruetlons

Ault lsrvetions

Review proces devin package

Prepare P aT claus showin

(1) Major equipment

2) Nala proces tee

(2) Uility tines seated to te process

(4) Line size

6) Insrumentaton seated to the proces

(6) Innsation requirements

Prepare an equpment Jit

repre the aren plot plane

Prepare the tne

Estimate line seg

Fle the (cllowing te on the da

specldeavion sees

sheets and

(1) Axpliabie coder and repultons

2) Villy conditions :

(2) Design temperatures and premures

(4) Comodon stowancee

(5) Norte schedule teed on proces

(6 Freiminary pump and comprewor heeds

)Rebeving caput OF safety andre ales

(8) Inasetion mpectnton

repare & summary of estimated wtlty requlrmente

‘Prepare ity header dag

Prepare moot tit

1 Eoginerng PHAR for proces unite

®

o

“

°

©

o

o

”

0

ap

imma of eimsted ety conumtion

Duta sheets for pecked columns, tray

exchanger, fied heater, air-cooled heat

‘exchange, pumps, compres, bower,

fd vacuum equpment

Spedation sheets for columns and drums

Safty and relief valve data set

Equlpment it

‘Arex pot plane

Ln date sheet

PAL dapane

Summary of estimated tity seqicements

Vy header dagrme

Motor tit

eeeese vOOAIHI®

PROCESS DESIGN

AcTiysTY.

1 Review basle deslan requlrewents for the following Items:

2) Dean basis for each

(2) Relation simone waits

8) Utility condition

(4) Special design requirements

rocess ult

2. Request process design of process unite

ourrur

Basie Design Requirements,

|

‘ary oeauspuswe3 9

‘SENG OME

UTILITY AND OFF-SITE SYSTEM PLANNING

weur act curr

Tae ewig doen ae 1. Prepay baa daa flow: ‘ui or bate ereeering of ef-e and

wees

(Pant block flow dagen

(1) Mant Bock flow digram

2) Gensel plot plan with route pln)

‘Process dein prokaae 2) Capecey of offi (cer

(®) Gener pot plan (with route plan)

(©) Heaardous aren dation (2) Haaadous aes clasiiction

(4) Plant opertion pattern

es (8) Oftante ete deagn baer

(uit stad report)

o

7 (0) Pan Mode sae St

pestered

eeceeeeeeeeee: (@) Blowdown and disposal criteria

a p peanrepaner

pear factors ae

ee © yen de vm ih ety

(1) Prepare break down and displ eters (4) UUity sdematle Now

(2) Prepwe schematic Bow ©) Uiaty summary set

LERSTSeRs VOOAIHD@)

4. Luly sem planing

(1) Prepare tty temale Now diagrame

(2) Sosy tity seguireme

(2) Sty wy balance

(4) Study emerneney backup system of willy fallen

(9) Study stet-vp condition of wlity feces

. (6) Prepare tity design beer

ineur

BASIC ENGINEERING FOR OFF-SITE FACILITIES-1

acniviry

‘ovrrut

Date for base erieeing of off-site and

facies

1, sbi bale dein requlrements

o

°

feder-t

For mate ieeving and product shipping fac

(9) Governing code ond reulton

()Esabish design beset

(o) Prepac schematic flow agen for mate

teernng and product shippl Folie

(2) Exabah speciasequlrements for unlosdng and

towllng

ond snd taliond rap, hydronrele

©

For sore fatty

(6) Governog code and seaton

(Ewen design aver

°

hematle low dagram for storage

(eeity

(0) Evtabiih spect cequhements for storm felity

For bending fulity

(0) Gorening coe and re

(8) Esb deen bees

(0, Prepare ehamatle Now ciayrim for blending

fealty

(8) Bstabioh special requleements for Blending eclty

repuation of engiowesng packages for offsite

Bae deen rqulements for material

ecering and product shipping Ton

(1) Design toes

(2) Sehematle Now dlagram forthe material

reerng and product shila Toles

) Related documents and drawings for

nets seceng and product shipping

Trees

Dace dein requlements for sorae Feit

(1) Daten bees

(2) Schematle Now diagram for sora

fealty

se dei regulrmente for Bending fc

(1) Desan tare

(2) Schiematle Now diagram for blending

fey

sugenses VOOAIHD @)

meur

BASIC ENGINEERING FOR OFF-SITE FACILITIES-1

{(Continaed )

acriviry

Enwinering package for off-site faliiea-1

comprsng:

1. Paelty dveripton

21. Proce flow sheet or schematic system

Ainge Cth seam date)

P&L diaram

ley ender darame

Line date sheet

4

5

6, Egulpment tt

7, Date eeatfpeciation sheet

1, Enimated tity regulements

9. Enimsted chembalsrqulrements

0. Enimated amount of water

| Aven plot plan

12, Motor it

12, Other documents and denwings for off-te

freituert

2. Reve off

feces

enginering puckaten on follwing Heme

o

o

o

o

“

©

o

o

o

9)

an

an

a

Feeity detrption

roses Now sheet of sche

(sith soem date)

ow dlagren

PAL dig

Unity Header

Line date seat

Equipment tt

Date sheetSpecifation sheet

(Complete the date sheet and speciation sheet

lth necentry date fr iting work)

Eatnated ity requreents

CSommarice uty requirements

summery sheet)

Balmated chemicals requlements

ated amount of waves

he waity

Ares pot

Motor tt

Other documents and denwlags for off-ate

faater-1 .

Buc entinerng pachaae for off-site

facer-1

a

Material reeteag nd product sipping

facie

Storage ecites

Blending feces

“MUTTON LLSHOS 8 VOOAHO@®

nana NAR

iNruT

BASIC ENGINEERING FOR OFF-SITE FACILIT

(Continued )

acniviry

ourrur

Date for bate engineering of off-at and

lly facies

@) For

o

cy

o

©

© For

«

»

() For

© Fo

o

o

ate tetment and dingo fa

Governing code tnd rensation

Prepare block flow ginram for waste Ueatment

and digoet facie

stb deen bases

(Summaries waste trom prose unite, off-ate

faci, uty uellies and there

(1) Released material property eitein

stabi petal requirements

aa

ety

Estblih fcaion plan and srvtare eguremes

sab deg bee

(© Machinury maintenance shop

(W) Electrical equipment maintenance shop

(G1) rarument maintenance shop

bortory

Esteblih design bess

ution .

stb tat of tangs

Estsblih bane’ dvian requkemente for bulge

(0 Appliction

(Apparatus

(Uy Number of men and sex

0 Bavipment

(0) Ale conditioning

2, Requetprepuaion of eagivering packages for off-site

(echoes

Desc dein regiments (or wate treatment

snd ipo fetes

(1) lock Now dns for waste westment

snd depo fete

(2) Deven bees

(Summary of weate

() Reteaed matedel property sites

(©) Special requlremente

Bosc deign requirement for mntenance

Facity

(1) Location plan and sruturerequlrements

for malntnance fcty

(2) Design baer”

(9) Machinry maintenance shop

(©) het equipment maltenance shop

(© Inerument maintenance shop

Basle desien reglremente for Iborsony

Design bale

Base deen requirements for bung

(0) Butngs tae

(©) Desan baie

“UN TAOUIMUSNODE voOoAHO@

meee NS

BASIC ENGINEERING FOR OFF-SITE FACILITIES

Enginesrog packages for offsite faciis-t1

comprising

1. Faeiy desrpion

2. Process Now sheet (with ateam data)

6 Eaulpment list

7. Date seetfpeciaton shoot

3. Enimated tty regulrements

9. Ealated squiements of chemical, cata

descents tnd pecklog

10. Estimated amount of water

1. Are plot plan

12, Other docoments and

fee

lng for off-te

2 Review off-site enpnerng package 8 following items

(1) Pacty deseiption

(2) Process flow sheets (with stream dete)

©) PAT deme

(8) Uulty Header dageeme

(5) Line date sheat

(6) Eaulpment ist

(Date sheatipctation sheet

(Complete the date sheet ad speciation sheet

wth neceiay date or ratiog work)

(8) Eatimated ty equements

(Sammare ullity requrements In the ty

‘emmy set)

(9) Exist requirement

esccante tnd packing

(10) Estimated amount of waste

(Feed back to wists Wesiment and dapat

‘gulrements)|

‘Aes plot plan

(12) Other documents and drawings fr oftte

feeder

chen, calle,

nglocering paces for off-site fates

1, Fare Blowdown faety

2. Fine gh Fey

3. Waste weatment and disor feces

4. Malaenance fectites

5. Latontony

6. Balings

soamguaess WOOAIHD @)

eur,

ASIC ENGINEERING FOR UTILIY FACILITIES

acnviny,

‘ourrur

Date for base engineering of off-site and

ly cite

Eneineviog packaes ar offsite failtie-t

nginetsog packages for oti

comprising

1. Feely deetption

uty ender dagrme wth team

2

3. PAL dignme

4. Line date sheet

Eaulpment tt

6. Date shestapecication sheet

7, Edimated ity summary

8. Esimsted vequtement of chemical, packing,

9, Exinated amount of wiser

10, Aree plot plan

11, Phetrieal one fine diarant for power

‘ecelring and distbutlon plan

1. Entbih base deen resiements

o

oe

°

o

o

2. Request pi

Goveming cose and repulsion

Review uility rehematic ow Jagam propted on

he tity sytem planning

Review estinated wilty summary prepsed on the

ily system planing

Prepare motor tt

stb deren bao

on of enginetig package for

ty eciie

3. Relew

nd complete lity engineering pockage at

following Heme

0

a

°

o

o

©

”

Facitydesripton

Uutlty eader

P&T diagram

‘Line date sheet

Equipment at

Date shectepdtenton shet

(Complete the dats seat pod petition sheet

vith neceasary date for ming work }

Estimated uty ermmary

Evimated requirements of chemi, racking, ee,

Eatimated amount of wastes (fed back to phase

3c)

Motor et

‘Aves pit plan

Elect one Sine igre for power receing

tnd diatabution plan

ase design requirements fr uty fale

(1) Ui schematic Now igre

2) Extimated vty summary

©) Motor et

(0) Design baer

Engineering packages for wttyfeciten

IQ

Ant

soya

ae

INPUT

FINALIZATION OF PLANT BASIC ENGINEERING

ACTIVITY,

oureur,

Engineering packages for process units

Engineering packages for off=ate

faclitier-t

‘Engineering packages for off-site

Review and Moai general enginering date

(1) Plant description

(@) Pant block flow diagram

() Overt plant

(4) General plot plant

(8) Hazardous ares clasiication

(6) Estimated wilty summary

7) List of estimated cremics

requirements

5, catalysts, packing

(8) Motor tet

@) BEDD

(00) Project standard specification

2, Compile engineesing package for project

Engineering packste for project

1. General

(Plant description

(2) Plant block flow diagram

2) Overall plant start-up

instructions

(4) General plot pt

(3) Hazardous ares clarification

(6) Estimated tity summary

(1) List of estimates chemicals,

catalyst, packing. requirements

(8) Motor Ii

@) EDD

(10) Project standard specification

2. Engineering package for process units

3. Engineering package for off-site

‘acilies=1

4. Engineering package for off-site

faciities-IT

5S. Engineering package for utility

facies

Suess VOOAIHI@®

@CHIVODA S.cRE%

PROCESS DESIGN CHECKLIST

The process engineer should check the following items to optimize

engineering work:

1. How do the various alternatives compare as attributes of a

good process?

(2) Simple:

. Minimum number of reactions

. Minimum number of unit operations

. No complicated equipment which might cause costly

repairs and shutdowns

. Generally simple reactions

. Easy to control

(2) Adaptable:

+ Can utilize available equipment

. Adaptable to a wide range of production volumes

(3) Reliable:

. No inherent factors which likely would cause a

breakdown

. Stability of yield, equality, and other operations

(4) Economical:

. Most profitable

. Has other nonspecified attributes which will assure

long-range profitability

. Little capital investment required

4

«

®

(3)

(6)

a

can

a)

(2)

(3)

mw

o)

(6)

m

(a)

(9)

(10)

au

az)

EMAL eNGHEER

SConsTRuETORGLATD.

Safe:

+ Moderate operating conditions

. All the safety precautions are specified

Adequate:

A complete process — no loose ends

. The areas of doubt are known and the risks evaluated

; Product quality and quantity are adequate

Expandable:

+ Cost and capital savings will be realized by expansion

. Larger units are feasible

separation be carried out more easily by:

Evaporation (employing multi-effect or film processes,

or thermosiphon or forced circulation)?

Diffusion?

Simple distillation?

Fractional distillation (azeotropic or solvent)?

Drying (flash, freeze, spray, drum, or kiln)?

Gas absorption?

Adsorption (employing carbon, alumina, silica gel, or a

molecular sieve)?

Extraction (liguid-liguid or liguid-solids)?

Filtration (centrifugation)?

crystallization?

Entrainer distillation (steam)?

Condensation?

®

a3)

(4)

(15)

as)

a7

ot)

ag)

(20)

(21)

‘SMA, ESRI

‘Sconsrucronca Ta

Sublimation?

High-vacuum distillation?

Decanting?

Hydraulic separation?

Settling?

Ion exchange?

Dust or mist collection (cyclones or filters)?

Screening?

Other methods?

can more favorable chemistry be gained by using:

mM

(2)

Q)

“

(3)

(6)

(oD)

(8)

(9)

(io)

an

(12)

a3)

aa

as)

Nitration?

jAmination by reduction (by aminolysis)?

Halogenation?

Diazotization and coupling?

Sulfonation?

Oxidation?

Hydrogenation?

Alkylation?

Esterification?

Hydrolysis?

Polymerization?

Dehydrogenation?

Dehydration?

Reforming?

Cracking?

®

a6)

(27)

(ag)

CEMA, CNET

‘SConstmocroneo.T.

Catalysts?

Vapor phase reactions?

Other reactions?

4. Is there any different method for reacting as in:

a

@)

@)

4)

(5)

(6)

5. Can

m

(2)

(3)

4)

A fractionation column?

A plug-flow reactor?

‘The vapor phase?

An extraction column?

A continuous process?

A fluid bed?

any of the operations advantageously be:

Eliminated?

Combined?

Simplified?

Rearranged?

6. Should the order of the reactions (unit operations) be

changed by:

a)

@Q)

a)

(4)

(5)

Purifying while reacting?

Transporting while reacting or treating?

Flash drying while transporting solids?

Simultaneously cooling and concentrating while lowering

the pressure?

Employing a pipeline neutralizer?

© ao

1.

12.

13.

14.

as.

16.

17.

18.

Would dividing the reactions (unit operations) help?

For example, by:

(1). Series operation to promote efficiency?

(2) Employing stage reactors?

Would continuous (or batch) flow processing help?

Will the type of agitation effect the process?

Can the temperature requirements be realized by employing

ordinary cooling water instead of chilled water?

Can steam at normal pressure be used?

Should the number of recycle streams be reduced?

Should buffer storage be provided or eliminated?

Should these factors be checked?

(2) Temperature sensitivity?

(2) Ease of handling?

(3) Pumpability?

(4) Agitation characteristics?

(5) Fouling of heat transfer surfaces?

(6) Phase changes?

(7) Solids precipitation?

(8) Decomposition?

How will yield, conversion, and quality vary with operating

time, temperature, pressure, and concentration?

What will be the consequences of water in the system?

Will the disposal of hazardous by-products, the recovery of

solvents, residues, etc., pose a problem?

Should a dry run be made?

19.

20.

2.

22.

23.

24.

2s.

26.

27.

28

29.

30.

a1.

MAL ENEMEER

‘SeonstucTonen

Will the effect of contaminant buildup in the reactions be

considered?

What will be the effect of the construction materials on the

process yield, conversion, and quality?

Will the skin temperature of the heating surfaces cause

decomposition?

Will the skin temperature of cooling surfaces cause unwanted

condensation of water or precipitation?

Are saturated solutions involved which will cause blockages

when in contact with cold walls, valves, and flanges?

How will an upset in one operation affect another?

Will the intermediate or product deteriorate in series oper-

ations?

Under what conditions may the process be shutdown?

(2) For a short time?

(2) For a long time?

Should the need for pumps be eliminated?

(1) Use gravity flow

(2) Use pressure transfer

(3) Use air life

Should liguids be transported instead of solids?

Will the effect of contaminant or chloride buildup as a

corrosive agent be considered?

Are the data and correlations for chemical and physical

Properties reasonably accurate and applicable?

Are any of the following toxic?

(1) Raw materials?

32.

33.

(2)

a

4)

Are any of the following unstabli

am

(2)

a)

@

ema enc

‘SCONSTRETONCD LT.

Intermediate?

Products?

Residues?

Raw materials?

Intermediates?

Products?

Residues?

Should these factors be checked?

a

(2)

@)

(4)

(5)

(6)

m

(8)

9)

(10)

Bulk densities?

Temperature sensitivity?

Foaming characteristics?

Ease of handling?

Crystal size distribution?

Pumpability?

Agitation characteristics?

Scaling or fouling of heat transfer surfaces?

Solids precipitation?

Decomposition?

@ cHIVODA snssEs

ADDITIONAL INFORMATION NECESSARY FOR DEVELOPING

P & I DIAGRAMS, UTILITY HEADER DIAGRAMS, AND PLOT PLANS

1, Start-up and shutdown requirements, such as equipment to be

by-passed

2. ‘The number of sampling points

3. Safety considerations, including blowdown and drainage systems

4. Chemical cleaning requirements

$. Tight shutoff requirements for valves

6. Chemical injection devices

7. Regeneration and decoking requirements

8. Special notes required to define the following piping or

equipment arrangement:

+ Two-phase flow line ‘1

@

3)

. Slurry flow line

+ Gravity flow line

+ Piping length (for pipeline neutralizer)

. Seal height or depth

+ Elevations (of sloped or symmetrical piping)

9. Steam, hot water, or brine tracing

Notes:

(1) Because of a large pressure drop in a two-phase flow after

flashing, it is advisable that the control valve be located

near the feed nozzle

(2) Short-radius elbows are prohibited in slurry piping

(3) The length of piping shall be minimal, without loops or

pockets

ree exci

‘SconstmUCTON Ca TD

Engineering Package for Project

EMAL ENGINEERING

‘AcovsmcToN cn TO

ENGINEERING PACKAGE FOR PROJECT

INTRODUCTION

An engineering package includes technical documents that are

necessary for engineering work,

These documents include project standard specifications and

@rawings, and furnish the following:

(1) General information on the project, including the scope

of work

(2) Descriptions of site conditions, climatic conditions, and

utility conditions

(3) Design information and requirements

(4) Specific design data (or specification sheets) and

drawings based on the process design

The contents of different engineering packages will be es-

sentially identical, whether the project is a grass roots

refinery, petro-chemical complex, or simply a process unit or

facility. However, the contents of an engineering package may

be modified during the engineering stage.

Q@CHIVODA tesneerat

2.

TYPICAL CONTENTS OF ENGINEERING PACKAGES FOR PROCESS UNIT

Engineering packages for process wits contain the following:

(1) Design basis

(2) Description of process

(3) Block flow diagrams

(4) Process and utility flow diagrams

(5) Material and heat balances

(6) Estimated pressure balance

(7) Estimated utility summary

(8) Requirements for catalysts and chemicals

(9) Equipment list

(10) Plot plans

(1) P & I diagrams

(12) Utility header diagrams

(13) Equipment data or specification sheets

(14) Routing plans

(18) Hazardous area classifications

(16) One-line diagrams

(17) Motor list

(18) Basic instructions for plant operation and analysis of

products

(19) Individual specifications

Q@CHIVODA teense

REQUIREMENTS FOR PROCESS UNITS

3.1

3.4

DESIGN BASIS

The design basis of the unit and facility is outlined and

described with the through-put or flow rates, properties,

specifications, and battery limit conditions for the

feedstocks and products.

DESCRIPTION OF PROCESS

A description is given of the process flow throughout the

process unit and the function of major equipment, such as

chemical reactions, separation techniques, and selection

of solvents and catalysts. Flow circuit interfaces are

shown according to the process flow diagrams or process

flow schematics. A description is also given of the

feedstock and the products leaving the process unit, with

quantities.

BLOCK FLOW DIAGRAMS

The block flow diagrams are schematics showing unit

design capacities, their interfaces, flow rates, operating

temperatures and pressures, and other critical data.

They indicate whether connections between units are

direct, or intermediate storage is required.

PROCESS AND UTILITY FLOW DIAGRAMS

The diagrams show the major lines, and equipment and

control loops according to Subsection 3.2. Major operating

Q@CHIVODA tssnemsts

3.5

coaditions, such as pressures, temperatures, and heat

duties for heat transfer equipment, are indicated. when

several operations must be considered, data is furnished

for all operating conditions and an indication of which

condition should be the design basis.

MATERIAL AND KEAT BALANCES

Material and heat balances are shown on the stream data

sheet for principal streams that are identified numerically.

The stream data sheet indicates the flow quantities,

physical data, and chemical compositions of fluids.

If the design provides for different operations, a separate

stream data sheet may be prepared for each operation.

Each sheet is designated as operation A, operation 8,

etc.

ESTIMATED PRESSURE BALANCE

The estimated pressure balance throughout the process

unit is for normal and special operating conditions, such

as start-up, shut-down, and regeneration.

ESTIMATED UTILITY SUMMARY

The estimated plant utility requirements are tabulated

for normal and intermittent use, based on the requirements

for each piece of equipment. The total consumption rates

for all utilities are summarized, and any special require-

ments for start-up, shut-down, etc., are specified.

e& Lome

3.8 REQUIREMENTS FOR CATALYSTS AND CHEMICALS

The estimated requirements for catalysts and chemicals

are for the initial inventory, makeup, and replacement.

Quantities are per day or year.

3.9 EQUIPMENT LIST

The equipment list is a summary of all major equipment

and specifies the following:

(1) Ttem number

(2) Number required, including spares

_@) Equipment name

(4) Major specifications, such as dimensions, capacity,

type, materials of construction, and design pressure

and temperature

3,10 PLOT PLANS

3.10.1 General Plot Plan

The general plot plan shows the layout of process

units, utility facilities, and off-site facilities.

3.10.2 Area Plot Plans

Area plot plans show the preliminary layout and

extent of each unit or facility. They are

normally reviewed and finalized during the

engineering stage for cost estimation.

Q®CHIVODA 8.25%

3.11

3,12

P_& I DIAGRAMS

P & I diagrams are generally developed and finalized

during the engineering stage of cost estimation. They

are based on the results of equipment rating activities,

hydraulic calculations, and, if available, vendors’

data. The following are shown on the drawings:

(1) All equipment, including spare equipment

(2) All process lines, including start-up, shut-down,

flare, and blowdown lines, with preliminary sizes

(3) All utility connections to equipment and process

lines

(4) Major process and utility valves, including type

designations

(5) All process control instrumentation, including

control valves

(6) Special instructions and requirements for the

engineering stage of cost estimation

(7) Piping stream data (such as name of fluid, flow

rate, properties, design temperature and pressure)

UTILITY HEADER DIAGRAMS

Utility header diagrams relate to the utility flow

diagrams. The following utility lines are drawn according

to the equipment layout plan:

(1) Freshwater, boiler feedwater, seawater, cooling

water, and steam condensate

Q@CHIVODA tasnserets

3.13

(2)

@)

«)

(5)

High pressure, medium pressure, and low pressure

steam

Oil, gas and other fuels

Plant air, instrument air, etc.

Inert gases, such as nitrogen

EQUIPMENT DATA OR SPECIFICATION SHEETS

3.13.1 General Information

The equipment data or specification sheet for

each item of equipment prescribes the operating

requirements or specific requirements and features

to be considered in the design and selection of

the equipment. Designation and equipment numbers

are given. Equipment internals may be shown for

a clear understanding of the working of the

equipment. Heat transfer equipment, pumps,

compressors, etc., operating in parallel or in

series are shown as one equipment item.

3.13.2 Specification Sheet for Columns, Drums and

Reactors

Operating and design conditions and metallurgy

requirements are described on the sheet. A

sketch shows the locations of nozzles, manholes,

handholes, instruments, etc. The sketch also

gives specifics for internal components, such

Q@CHIVODA seenseces:

3.13.3

3.13.4

as number of trays, type of tray, packed sections,

entrainment separaters, and vortex breakers.

For columns, tray loadings are given. Detailed

tray design calculation are not normally furnished.

For reactors and vessels, a jacket or internal

heat transfer equipment is specified if required.

Heat Exchanger Data Sheet

Operating and design conditions are specified

for the handled fluids, such as flow rates,

inlet and outlet pressures and temperatures,

heat duties, fouling factors, metallurgy, and

the general mechanical arrangement. when

required, cooling or vaporization curves are

furnished.

Pump Data Sheet

Operating and design conditions are specified

for the pumped fluid; such as flow rate, design

temperature, preliminary inlet and outlet

pressures, viscosity, and vapor pressure. Other

data includes:

(1) Special metallurgical and mechanical design

requirements

(2) Recommendations for type of pump and driver,

and sparing arrangements

(3) Estimated horsepower

3.13.5

3.13.6

CEMCAL ENGINEER

‘SconstmucTON Ca.

Compressor and Blower Data Sheet

Operating and design conditions are specified

for the handled fluid, such as flow rate,

design temperature, preliminary inlet and outlet

pressures, *and molecular weight.

Recommendations are made for the type of compressor

river, and sparing and control arrangements.

Estimated horsepower may be given

Fired Heater Data sheet

Operating and design conditions are specified

for the handled fluid, such as flow rate,

preliminary inlet and outlet temperatures and

pressures, and physical properties. The heat

duty, limiting transfer rates, allowable pressure

drop, and recommended tube material and its

corrosion allowance are described. Special

requirements from the process design data are

included, such as whether vertical or horizontal

tubes, tube sizes, number of passes, and firing

arrangements.

Q@CHIVODA teense

3.14

3.13.7 Special Eouipment

Special process equipment, such as packaged

units, dryers, filters, agitators, desuperheaters,

vacuum generation units, and catalyst loading

and withdrawal facilities, are described if

required. Duty specifications are furnished

with data for similar equipment.

3.13.8 Instrumentation

Process data for control valves and flowmeters

specifies the various operating conditions for

the handled fluids. Data furnished includes

flow rates, preliminary inlet and outlet temper

atures and pressures, and physical properties.

Lists of instruments are also furnished.

ROUTING PLANS

Routing plans are based on the general plot plan and

indicate the type of installation. The following plans

are drawn

(1) Piping routing plans showing utility distribution

piping, interconnecting piping, cooling water

lines, firewater lines, etc.

(2) Cable routing plans

(3) Sewer and flare blowdown routing plans

(4) Road and maintenance access plans

3.15

3.17

3.18

3.19

Crem. ENE

‘covsmucTONC TO

HAZARDOUS AREA CLASSIFICATIONS

Hazardous area classifications are determined by reference

to the plot plans and standard specifications. They

facilitate selection of equipment and facilities, and

plant safety. The classifications are reviewed and

finalized during the engineering stage for cost estimation.

ONE-LINE DIAGRAMS

One-line diagrams show the principles of the electric

power receiving, distribution, ané protection systems.

They are the basis of engineering activities concerning

cost estimation.

MOTOR LIST

The motor list gives item numbers, service names, and

estimated outputs.

BASIC_INSTRUCTIONS FOR PLANT OPERATION AND ANALYSIS

Op probUCcIS.§ SSCS

General instructions for start-up and shutdown procedure,

and the method of analysis are described.

INDIVIDUAL SPECIFICATIONS

Individual specifications specify the special requirements

and design information for specific equipment and packaged

units.

Q@CHIVODA raises

4. ‘TYPICAL COMPONENTS OF UTILITY AND OFF-SITE FACILITIES

Generally, utility and off-site facilities are consisting of

the following:

a

(2)

@)

«@)

(5)

(6)

(7)

Utility facilities

Material receiving and product facilities

Storage facilities

Product blending facilities

Flare and blowdown facilities

Wastewater treatment and waste disposal facilities

Fire fighting facilities

Maintenance shop

Laboratory facilities

Buildings

Ancillary facilities

5. REQUIREMENTS FOR UTILITY AND OFF-SITE FACILITIES

5.2

DIILITY FACILITIES

(1) Description of process or facility features

(2) P & T diagrams showing major line sizes, or simplified

flow diagrams with blanks for vendors' work

(3) Area plot plans and elevations

(4) Individual specifications and requisitions

(5) Equipment list, data sheets, and specification

sheets (without ratings)

(6)

(o2)

(3)

CrEeAL eNoIEERNE

‘RcoxsTUCTONCRITO.

Summary of estimated utility requirements and

chemical requirements

One-line diagrams for electric power receiving,

distribution, and protection systems

Utility header diagrams showing major line sizes and

line data sheets

5.2 MATERIAL RECEIVING AND PRODUCT SHIPPING FACILITIES

5.3

am

(2)

3)

(4)

(5)

Description of process and facility features

P & I diagrams (showing major line sizes) and line

data sheets

Equipment list with major specifications

Design requirements for truck gantry yard, railroad

arrangement, jetty, sea berth, etc.

Area plot plan of unloading and loading facilities

STORAGE FACILITIES

a)

(2)

Q@)

(4)

P & I diagrams (showing major line sizes) and line

data sheets

Area plot plan of material storage yard

Design requirements for storage tanks

Equipment list, data sheets, and specification

sheets (without ratings)

Q@CHIVODA tence

5.4

5.6

PRODUCT BLENDING FACILITIES

mM

@)

3)

P & I diagrams (showing major line sizes) and line

data sheets

Equipment list, data sheets, and specification

sheets (without ratings)

Area plot plan

FLARE AND BLOWDOWN FACILITIES

@

(2)

(3)

4)

P & I diagrams (showing major line sizes), line data

sheets and simplified flow diagram of blowdown

header

Equipment list, data sheets, and specification

sheets (without ratings)

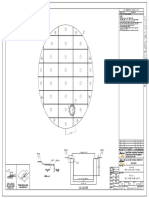

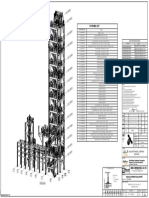

Skeleton drawings of flare stacks

Area plot plan

WASTEWATER TREATMENT AND WASTE DISPOSAL FACILITIES

qa)

(2)

@)

«)

Description of process and facility features

Block flow diagram (with material and heat balances

for subcontracted unit) or P & I diagrams (with

major line sizes) and line data sheets for Chiyoda

designed unit

Area plot plans and elevations

Equipment list, data sheets, and specification

sheets (without ratings)

@cHvoda sooner:

Socorro

oO

(6)

Summary of utility requirements and chemical require-

ments

Individual specifications and requisitions

FIRE FIGHTING FACILITIES

a

(2)

a)

4)

P&I diagrams for fire fighting facilities, showing

the firewater main, main fire foam piping, firewater

pumps, fire alarms and detectors

Fire fighting equipment list, with quantities and

major specifications

Fire fighting equipment layout, including hydrants,

sprinklers, alarms, and detectors

Typical drawings of fire fighting equipment, such as

air foam piping around tanks

MAINTENANCE SHOP

qa)

(2)

Qa)

Layout drawing of maintenance shop and warehouse,

with major specifications for buildings

List of maintenance tools, machine tools, and vehicle

tools

Classified summary of craftsmen required

LABORATORY FACILITIES

a)

List of laboratory equipment and apparatus, including

furniture and, if requested, reagents

5.10

5.11

recA. enc.

‘ooxsmucroncn Ta

(2) Layout drawing of laboratory, with major speci-

fications for buildings

(3) Estimated manning schedule for laboratory

(4) Specific requirements for the laboratory, such as

individual waste disposal or utility supply systems

BUILDINGS

(1) Drawing of each building, showing layout of rooms

and equipment, and major specifications for buildings

(2) Wiring and plumbing routing plan for each building

(3) Parking lot and garden plan for buildings

(4) Estimated utility consumption rates with time schedule

(5) “List of furniture and, if necessary, specifications

for major items

ANCILLARY FACILITIES

ay

Computer

(a) Punction and flowchart

(b) Programming and coding features

(c) List of accessories, and layout of computer and

accessories

(€) Specifications for the computer room

(2)

a)

“)

(3)

rena NGA

‘ScoxsTmuCTON CTO

Telecommunications

(a) Overall wiring diagram for communications

system, including interface with public utility

facilities

(b) Paging equipment and telephone lists with

layout drawings

Plant and building lighting

(a) Design, illumination level for each area or

building

(b) Lighting fixture list

Security system

(a) Specifications for gates and fencing

(b) Plan showing patrol route, location of keybox,

and alarm

(c) Wiring diagram for alarm system

Welfare

(a) Garden plan

(b) Description of medical facilities

(c) Layout drawing of dining room and kitchen, and

description of sizes, facilities, etc.

(a) Layout drawing of playground

Q®CHIVODA sse.sere

Data Sheets

@ CHIvonA sean

BASIC PROCESS DESIGN

This involves the development of the process scheme, first concestually

(i.e., the arrangement of process steps) and then in sufficient detail

to establish saterial ond energy balances. In doing this, several

8 are usually examined to ensure that the plant can handle

design ca:

all of the expected feed stocks and-required products in the range of

capacities likely during the life of the plant. This is generally

handled be a series of computer simulations.

‘The products of the basic process desim are as follows:

(1) Process design criteria including product yields, specifications,

ete.

(2) Process flow diagrams indicating

operating conditions, process strean characteristics, basic

erial and energy balances,

instrumentation, etc.

(3) Process duty specification, basic material specification for

process equipment

(4) Site of major equipment such as reactor, fractionator, ete. and

requirenents for detailed desig development

(5) Specifications and quantity recuirement for catalyst, chemicals

and wtiliti,

Refer to the following appendices ("Form Sheet"):

o®

Q@O@GOO@O@)

G@ee@e

8ee@

@)

63)

(4)

()

@® cuivona sess see

DETAILED PROCESS DESToY

This involves the develounent of basic process design information into

@ successful operating plant. The flow scheme is expanded and P&I

@isgrams are developed. The process engineers size or specify all the

equipment, piping, instruments, etc., and review the purchased items

of equipment, leyout of piping, plot plan and plant operability.

‘Throughout all of this work, the process engineer aust eaintain

liaison with the client, and ensure that the proper interpretation and

implemention of local engineering and environmental codes is nade.

This follows through the development of the project and into a success-

ful starting.

‘The products of the detailed process design are as follow:

(1) Equipment list

(2) Equipment data/specification sheet including vessel sizing and

tray hydraulic design

(3) Utility balance summary data sheet

(4) Line design data/specification sheet including line hydraulic

design

(5) Safety valve design data/specification sheet

(6) Data/specification and requisition sheet for packaged unit

(7) Preliminary plot plan and elevation

(8) P&I diagrams

(9) Utility header diagrans

(lo) Instructions for plant operation

Refer to the following appendices ("Form Sheet"):

380802089898 ow

7288S ® 8 @ G OG =/»)

>

ie Shs

URES ati

ro

es

i

a

wor [tome] Pemwure | orney | Enieipy | Vinay

-

te [oatemta | warm? | toning

“oN 00

‘ON aor

LLL

EI

da

“ENGI

SRgess3 VOOAIHI@)

(v) I33HS Vivo Wvae1s

aH]

a]

Aa]

st

ENT

aaa

aH |

lavnl © 1 ©

ian

>

2

°

3

‘ates; (0) @ Tora tow, © Ligula have, © _Vevor ohare, @ sola, (0) Waver () pram @)_wate (L) phew =

‘

Buea a Raa aes

ESBS VOOAIHD@)

(@) 4335S VLVO Wv3uLS

sooaihe See cee le Reage

seem nore oeree

conpormne | Mw aa has

aay tea ST]2 lea

‘nee Sa Wet eae 3}3/8/"|*

Flow Rate kam i ee ee : ‘|

=n a a

Tenses % eee 3

esmare woentn

ic tein? a al

$8 /2/ElE

ee Ce Ce a13/6/8/8

2 x1pusdey

@CHIVODA secksste

Appendix J

HEAT EXCHANGER DATA SHEET

7

‘CLIENT sev] > 1 @ 1 @ wang

ogee MADE

Tle HKD] icHKD,

108 0 fw a

Doc Xo. ZT [pare DATE]

eee a tee

See — ee

* ear mores et Same That

* [stn

: Perera py Ta

a area Ter ee

va aaa ioe eae

Bea [

" eevee tower Garcon

‘a =

Sea eae ma

roe rh

" [Seen Pew Re ven

” [Conwing Tonmeenr a t

* [Conese Fee ron

° estore ma

* pea, deseo a ; ; 7

* [tweoy tsarveer cele i 7 7

3 ooo Sr Unie maeel 7 7 ;

© rnemet conection rasone | ET? 7 7 7

2 erat Peas fot a Seg dos i

* ew sso =a]

* reson ctor mm |

* an reve Uns =

®lm oer aioe

———— =

= Temata]

Sonar On Pet Ta Beas ul

Tone Svat Geb Argue | SEES

Sf eee ares wa eee :

a) eS 7 =o

2-1 = a =o

ae go = ior

hl coo ore 1 Closes —Cnemnaner

Notes _Anieched Date Tine

@CHIYODA SSeS

seeeceeeunteeeseeeunta

Appendix #

AIR-COOLED HEAT EXCHANGER DATA SHEET i

‘CLIENT

PROJECT

TITLE

JOB NO.

Doc NO.

Tree

Gose/Reguion

Tiinavens

REV |

BY

SHED)

VD |

[parE |

>

OFenes baie

Petormance per Tram

Liauis Flow Rave

‘Seam Flow Race

Obereting Teoereture

‘Obereing Premare

Viceury, Weuie/ Vener

Goecitie Het, Uquie/Vener

Welocey Umiarion

Feulog Aesicance Read

‘Gan Terenure

Denson Prema

Tipe of Brive

Gonwot at Fan Pech

ueror

Tne

ne

ne

Conerel_et Fen S000

wr om ca

wr mm Ga

Drea

Cacroreranie)

Dive (Caewsoie

Oye

Cavremaie)

‘elemta, Buen Prone

=

Q@CHIVODArsKseess

Appendix 5

FIRED HEATER DATA SHEET i}

ADE]

CLIENT BY {th IMADE:

itt Exot Tete

JOB NO. jarvo | JAPYD

ae (egos [pal ipa

‘Sece

Tee Citron Tose Olverieal Tube

Caae/Reqintion

ae er Hester Sarton

Wate Flow Rew

Vener & Ges Flow Ante

ule Grainy

‘emiey, _Uua/Veoor & Got

Vices, Uaula/Venor & Gar

Thermal Conguctviey Ugula/Vaper

Totaewar Weient of Vapor & Gar

aula Flow Ree

‘Vener & Gas Flow Rave

aula Graney

Gemaey, _Wiauia/Veoer & Gee

i

4

:

3

‘Tremal Conauciviy, Uavia/Veper

‘Moleeuar Walght of Vesor & Ge

‘Atewsbie Premute Sree

‘Fouling Resiance Ree'e

‘Alewaoie Flex Genny (Aveoes!

Tye

Preeire © Heese

CHIYODA 23.23%

srr. Appendix 6

(PUMP DATA/ SPECIFICATION SHEET

C.HYDRAULIC TURBINE DATA/ SPECIFICATION SHEET 4

.

cuENnt REV] > | > [MADE

PRO) T_T BY 0

TT

JOB NO.

DOC NO. ae

Tee Ne |

=

oe Ticenrifuesi Ghoary Grows CProperioning Cousin

«[ Sescie Reauirement Biverieat Sumo Set Priming

‘No, Requires (Ine. Spare) No. of Spare n

Cede/ Relation Guesce os

rive Type for Operation Dow _Otwone

Driver Tyee for Soere Dwowr Owing

Loerton Dlowoor — Cazardous Aree Cass

of Pie Deen =

Operation [Creanat __Clseries warn

[Dawe stat Dawe stop Cremote star

+3] Operation Gane

14 cia Name

181 ora de to Canter or om

Erotve ue 12 em | Parc Size te 7 i

Harmful or Toxie due

181 Pumping Temperature Normal ©

= Seeciie Grey OPT

Vinconity OFF ?

‘veoor Prewure @°T alert

Freezing Point %

‘By proceas_enginecr

8

‘Vapor Volume % @Exhauw for Hyaraulie Turbine

‘Capacity, MinimurNormal/Maxirum ma] 7 al (ese

Section Prewure, Normel/Meximum ‘alent 7 7 7

iter Pre id

itera! Heed =

al

>

a

‘25]_acnarge Premure, Normai/taximum ‘alert 7 Z 7

2a[ PSH Aveilble m

»|

‘Laud Hone Power i t

Maar, Cant / moet [Sat or Material Coe

Nez (oeston, _ Suction/Oncnrae r

Counting Tyee Towers Cvenonee_OGer

‘Cooling Plan or Plan Code

‘Seal Toe / Seal Coat Ticiena Ciechanical 7

Flushing Plon or Pan Coos

Exwrnat Fling Lia) Temo.'G / Prem. Kalen G : 7

Elecrie Power He ver

‘uve. Steer SuB0y Gre Gwe Ou 6. alerts

‘Exhwon Steam Return Time OP Claw, Ocongensin

ty project engineet

@®cu oa oc Appendix 7

COMPRESSOR & BLOWER DATA SHEET Cy

cuENT BEV D 1 @ [Mans

PROJECT By | (cH

TITLE HKD

JOB NO. : laPvDy rv

OC No. (71 bare ipaTE|

No. Aaguiea (Ine. Soarai/No. ot Soere

Tleereritueet Citectorocatng

‘coae/Reguinton |

Deter Otureine ¢

Draroine

river Troe for Onertion

ecaion

ee Hanae

Motacuir weione

‘aio of Soecite eet (Co/Gv) @ Suction _(Refeeren

Comerenibity Factor @ Suction (Reference)

‘GorrotanrGronon Gheracrernice

Nm mGt, 1 eon)

‘mine Suction)

‘Section Tenoerure =

Suction Premure teenta

(henerge Temperature (Reterenee) =

Dlaenarge Frans

‘ittrenia|Promure er

Comprewion Aasie

umber of Steeee (Reverenceh

‘Aalavetic Power (Reference) =|

Mareratg, Cane or Gyineee

‘Geoacey Conerol Seem

ringer Gbrieation

elet vane Set Premare wwente

lees Power

Live Steer S08017

Exheuwt Stew Reva

‘Ger Composition rel

eerseeeeeree

{rey x0.

SERVICE ou

FID =

> case No. :

= Name I

= verating Temperature (0.7.) !

= Viscosity @ 0.7. i

= Vapor Press. @ 0.7. 1

= Density @ 0.7. f

i

{

i

I

i

Tors Flow Rave

[cies prensa ries te

tated Flow Bate es

Buena sie 7

= Suction Eauipasnt -

— Press. @ Suc. Equip. Tera

[7 nn Stasie Hoa Tepe

= Pipe Friction Pe

7 ie

Be

= Filter

}

T

= Net Suc. Press. (1) |

= Discharge Zouipment > =

= Press. @ Dis. Equin.

= Static Head

= Pipe Friction

= Filter

= Dis. Press. Req'd (2)

PUKP DIFF. PRESS. (=(2)=(1))

DIFR. HEAD

‘OTHERS

= Pu a .

= Pump Hydraulic Horsesower

= Estimated ett.

= Estimated Brake lorsepower

= Wax. Suc. Press,

Tax. Shut“off Press.

= Min. Cont. Flow Req'd-@ Process

PIPING AND EQUIPMENT DIAGRAM.

2 mole Fab

= Tisi

UII,

Appendix ?

(CUSTOMER :

308 NAM

408 No. ;

oCUM. No.

SHEET No.

PUMP CALCULATION SHEET

PUMP CALCULATION SHEET _

I

i

i

T

i

=

T

J

i

T

i

— ©

Line 0 Qo

Nomina i a 3 =

6

2

5 s

a

2 a2

7 e

Bd

aa

Ess

5R5

as aed

als

== 3

2

‘

\

Ae etree ieee

: JOB NO.

DOC NO, + (7)

ESTIMATED PRESSURE BALANCE SHEET MADE BY.

niet & Queer Sureen No. of Eaviomert

‘Coeratng Tersereure =

S| oevaiey er

| veser Prema wens

Flow Aw @ niet Tm | wi

‘Start Point Pramare twents

Fina Point Premure twente |

niet |

Minimum State Premwre keer?

Gre keen!

‘vent

vert

ever

tarenta |

weer |

ewer?

wen? |

teen

hve

‘een

‘even!

een

avert

Few ewer

Outer Peau © O° wert

‘iterates Pee O- Oe ©-O teen

Nowe: NPS Avalianig (ml = 10 1 -OVO®

aula none Power wi = 372 x 10° OO

Bane

REVISIONS ———T ase

cuent se

PROJECT TITLE > sexs 1D D1 beck} —

a { =

JOB NO. z i area

DOGUMENT NO a =

SHEET NO: oF oare care

EQUIPMENT NO

CHIYODA

CHEMICAL ENGINEERING & CONSTRUCTION CO, LTD,

DESIGN INFORMATION

[seance |

cut Off Line

Appendix //

REMARKS:

T

{

I

L

I

I

I

i

I

MARK|SIZE | SERVICE | QUANT. | RATING

NOZZLE _SCHEOULE

DESIGN CONDITIONS.

HO! ReaUineD eee GeT

CODE GOVERNED,

OPERATING PRESS. @ TEMP___kg/em®G 9 __

DESIGN PRESS. O TEMP, ko/em? 6 @__&

STRESS RELIEVING

RAIOGRAPHING

VOINT EFFICIENCY SHELL ___% HEAD %

CORROSION ALLOWANCE SHELL _mm.HEAD___mn|

NING.

TEST PRESS, HYDROSTATIC. kg/emi G

PNEUMATIC, koemG

HAMMER, ie gems

MATERIALS SHELL

HEAD.

SUPPORT.

INTERNALS,

INSULATION MATERIAL.

THICKNESS

@CHIVODA2e8e%

Appendix +2

PACKED COLUMN DATA SHEET oi

rev] OT OTS

CLIENT :

PROJECT 7

mm D|

JOB NO. VD,

DOC NO.: C7) pate

Peexee Secon

Veoor Flow Rate tem

eoer Boneh

asta Bera wre

‘awia Vinconey

‘aula Sertace Tenwion eynien

Minimom Race we % of Daign Ree

‘Marimom Flooe Pastor

‘lewsola Prewure Oreo ow Secon mnie

“Goereting Temperature

‘Speratng Promure Twente

Packos mole

Facies volume Ed

Tree

‘Nominal Sie x Thx mat

Bulk Onetey teins

auis eenbeter

ald Gown Pine T

Mis Eiminetor [ove

wig Men Yorn No, oe eeu

Toe of Mit Glimineror

Monee ot Peeing

jae Cow

Nowe

: ee

Q@CHIYGDA terete

Appendix w

TRAY DATA SHEET eae)

CLIENT Rev] D1 D | S MADE

PROJECT By | MADE

TITLE KO [__cHKD]

JOB NC. favol larvol

OC NO. eet PATE! yATEL

tam No. i]

‘Service

t

2

3 [Try Seaton (Try No, From ToplBonom)

4 [Poets Tray We.

8 [No.of Tavs in Section

‘

1

8

9

Fluid Name

Vapor Flow Rate ah

Vapor Dena aim?

Vapor Viscosity 2 | i t

to| Uauid Flow Ane woh

| Ligeia Denaey ‘elem

12| Casi Vincoiey ¢ i [

13 | Gaus Surtees Torsion olen

14[ Minimum Race ar % of Onsign Rate T

15|_ Foaming Tendency (Syitem Factor) i T

16| Maximum Flood Factor t t

11] Atom Fomre Oros pe Ty mae 5

18| Cowrning Tenowrstre =] 1

13|_Ooemiog Pemure ‘went T 1

20| Type ot Tow T 1

21| Tow Iniae Oise (Rete om] 1 i

22 Tray Sover Retrence in | i

al Ne. of Fume Retereee i 1

2u| acionabi War Tava Gre Ove One [Ove One [ove One

25|_Wes Hole Tn Che [Ove Che [Ove Gre |G Ya One

[Gene Gye Cre | Oye One [Cv Gre | C¥e One

ala 1 i i 1

a) [Thekres inducing Gorenon Alona am] 1 i i

|” Frew covoson Aloweres on 1

20 er 7

2] § 5 [Thee inuaig Conesion Alowenoe om] T

Tota! Conenion Alowance on |

Gast Hevea i i

Tasis nade Ome =i i 1

Tene

2

i

i

:

See See eos

FORM 101 €

<

CHIYODA

(CHEMICAL ENGINEERING & CONWTRUCTION CO-LTD.

TRAY PERFORMANCE CHART

Appendix “#

Se eeeeeee

mee ba

a

SERVICE

‘ON 900

‘ON aor

1,

soul0ud

‘INITIO

‘

ee oe :

a 7 — 8

z

Regeneration Mathod ase = ae |e Z

Container Form = fe 2

aa Seen | nace 4

a i as 2

| senutncore a 7 :

Type a a 7

5 | nomen o1wrane om Z

[sme sno =e Tee e|3

i . a = Pe

i 5 Soeg eeele

Gontsiner Ferm o 7 IS

Note; Ka

— eagles

= alSlzlgle

‘ (cee : sae -

WOOAIHI @)

‘wr wosmausee

ANON WMO

$7 Xi puaddy

Gomena ae]

CHEMICALS REQUIREMENTS C7)

WO LOTS Mae

cunt

PeOeCt eee eeee ees fo Mae

TITLE i |cHKD

JOB NO. [avo [ano

DOC NO. (71 fare are

| | |

( | |

| i | i

| |

1

ryt

LL

1 |

| { at

HET

hele

| |

Vdd

tid |

7 7

| |

| mel

| | | | |

| | | | |

|

Lit || |

1] leiztalalsiei | geile | ‘|

a sR)" /¢ | | |

Faigle |] | x4 | | |

g | I

i i | |

j |

‘ | |

i |i i | | |

i i } | } i i i j

5 g $

a 3} | 2g] (42/3 Lal fg

Electric Power Foal ‘Steam water 8 3 38 £ @

‘rm Ho femtce woe [vor nventa | tetemta | tofemta gS "As =

=a ers East net a ect ao 3

oe | i

— - F

[sea sla 2 #

a mi

— 4

— 5

5

- es d

- §

_ - | - fe 5

: : : : 5

a es 2

- = | ~ =

: — z

5

a ia a Weel 2

oe LF ] FASE *

— == | — lel =

oo t | 7 TTT fel

— a ES

| >:

er el

{Bl Fa coonpion etd or nt Pag fo z aaiagg] |:

ae e a 3 18/318 | 818 2

x

S

mc tai 1400 © SSS

FORM DAL 002 ME CHIYODA Appendix 7?

(CHEMICAL ENGINEERING & CONSTRUCTION €O..LTD. |

EQUIPMENT LIST zi

CLIENT APF

cH

PROJECT

TITLE

Form

peoy

308 No, EQUIPMENT LIST

PROJECT TITLE ITEM :_ COLUMN & DRUK

FQurMeny Ne, SHE

TEM. SERVICE THe DIMENSION — | INTERNAL

NUMBER MATE

L

MARE

DATE

Revision Ey

‘cum

APD

vwercir con | oR | msutation [TA] cove | race oF

Tags. [ewe aCe en

ow [ae [RES | 7

AREA

m | 4 cc)

Appendix /?

_ APPROVED

+, CHECKED

PREPARED

Guin | pexvery| |

PAGE No.

wc eves

Form

108 No. EQUIPMENT LIST

PROJECT TITLE FEM: _DRUM

lequrseevt| Ne, DIMENSION sH

TEM SERVICE TE INTERNAL | OD X TL.

NUMBER REGO] (mum) wan

Appendix 20

ea APPROVED

DATE 4 :

BY, (eae “vieuecxen’ {

ERD T ‘PREPARED

“APvD.

DESIGN PAINT

TION F

conpisons *| INSULA | paiNt.| cope | rm

at | om [enscr] 2e |S [ao | ee

| wercer tow

ee

‘86 | act [ocr

|

PAGE NO.

@CHIYODA tesa

Form 230

108 No, EQuipMeENT List

PROJECT TITLE

ITEM :_HEAT EXCHANGER

EQUIPMENT No. DIMENSION surFace| xa

me SERVICE Tie (um) AREA |-—

‘NUMBER z0D} Pat) * (ik) (oot) | SHEL

ME eens

APPROBED BY:

CHECKED BY:

PREPARED BY:

tat [ewaexe|_DESIGN conpmTions INSULATION PAINT |

AREA

rune | wows [ss [es ]es las} es

|

{

ts. [oss [rs | cy

WEIGHT PRESS Ga/en®G]_TEMP(°c) | THKNS (mm) | AREA (a?) |

Me saoves

308 No. EQUIPMENT LIST

PROIECT TITLE ITEM :__AIR-COOLED HEAT EXCHANGER

eourrMeny) No. | TYPE oF DIMENSION ‘BARE

ITEM SERVICE oF coal ae

wo earr | BuNDLE | Tame

ae feiceen) ae wind | LeNcTH te)

Appendix 22

APPROVED. BY:

REVISION cic ee

PREPARED BY

WeIcHT | DESIGN | DESIGN MOTOR TE

o

press. | Tew. touvess| oF

ey xw | pore | vor DELIVERY

|

|

PAGE NO,

Form

ion he EQUIPMENT LIST

PROJECT TITLE ITEM ;__FIRED HEATER

Jequtement| Ne. DESIGN Flow | iter

TE SERVICE TPE HEAT DUTY are | Tew

NUMBER |Reqo} (Kaif) orgs) c

Appendix 23

aE

um TSTsTarTs amore F,

revision [iP St : a

a at —————

a = - Spngranen ° ay:

const] MOY T nme | caw |. na oF | noor | omar] Taw

tear | TRESS ALLOW TURE oF Nores

ct | ASS |waveniat} “om |ctamaers| pass | ray | peuivery

i

PAGE NO.

mis ewer

JOB No. EQUIPMENT LIST

PROJECT TITLE ITEM : PUMP & DRIVER

fouuenn| Ne. DESIGN CONDITIONS

TEM SERVICE Te

NUMBER lrecr capqcrrr [DOF press] HEAD

tetra es o

came | corae | ata)

‘WEIGHT | POWER

pote] vout

materiat! bd

|

|

PAGE NO.

o equlement usr

monet nme Tra <_oupasson

Fava ve WE

ITEM SERVICE TYPE FLOW RATE uw

oa peo alin a

Appendix ov

be Se TS TST Simon ar

; _

vensoy Tet cick ay:

= a:

Sm + Fnepanen ay

imme ERATURE

as TEAPERATURI MATERIAL esmuuateo | wvstarten | weicer | tae oF

rower” | “rows veo

pace | sucr. [ orscx. | case | ER] TOME om | focuveny

PAGE No.

Form 390

Project Title EQUIPMENT List

Job No, Item:

—

Equipment No. nee

Item Service of Type

Number Regd & Capacity

MH tous st cas sore

Appendix 2é

|

|

HEL

|

F

33/184

th

®cn

Crewe. NGIEERI

A CINSTAUETON C.D,

COLUMN SPECIFICATION SHEET

Appendix

y

cunt mT ® a

roy

TITLE, KD} HK}

JOB NO. : yD VDI

boc Ne i bate

a Sane

a

ses

-

eter eaves Poe fame

Soa

ais

[ree ior—ipeatsroroe ee

ae ao :

es

Ss

—

Sea eT ae

[ares hone oe

a

Sa =

SESE ae ao ee

ae a ee

_

[THean ee _—

TRAY/NTERNAL

‘surronT

NOZZLE FLANGE

NECK

(ea

BOLT & NUT: ERT. iNT.

SS ee

TRSULATION: = |

TIRE FROOF YES RO

[ wetcitr: enserion |

GPERATION =

FULL WATER a

ACCESSORIES SUPPLIED BY WANUFACTURER

LADDER & PLATFORM CLIPS, PIPE SPRT. CLIPS

DAVIT, LIFTING LUG, CORROSION GAGE POINT.

INTERNAL LADDER (SHELL, SKIRT) EARTH PIECE,

ANCHOR BOLTS, TEMPLATE

@®cuvoparsasees

Appendix 27

DRUM SPECIFICATION SHEET (A) cy

nev | © 1 TS Iwan

one BY IMADE

TITLE fea! [enKD|

JOB NO, laPvD| laPvD)

Doc No. i DATE [DATE]

2 EEK. REMARKS

2 [service

3 [No REQD,

* r

10 T

" [ARK] sige | SeRvice | ory | RATING

" NOZZLE SCHEDULE,

* OPERATING CONDITION

= FLUID

a (ea eee gio

jepess 2 fet

2 TEMP. =

a [uqu pensery ri

u TOTAL VOLUME, 5

= NORMAL Liquid HOLD UF = me

» ‘CONTROL RANGE REQUIRED

" DESIGN CONDITION

2 ‘CODE/REGULATION

‘DESIGN PRESS. & TEMP, = x

TEST PRESS. YOROSTATION "agente

____ PNEUMATIC! gle?

‘CORROSION _ALLOWANCE ‘=m

POST WELD HEAT TREATMENT CODE, YER NO

RADIOGRAPHING : FULL.SFOT _8.NO. CODE

JOINT EFF. SHELL %,HEAD

MATERIAL

}——_____wareniag

SHELL:

psig

HEAD

jee

"TRAY/INTERNAL

SUPPORT :

| SNORE reac eee

NECK

a

BOLT & NUT=EXT, iN

INSULATION: am

FIRE PROOF: YES_NO

WEIGHT: ERECTION rm

(OPERATION i

FULL WATER P

‘ACCESSORIES SUPPLIED BY MANUFACTURER

LADDER & PLATFORM CLIPS, PIPE SPRT. CLIPS”

DAVIT, LIFTING LUG, CORROSION GAGE POINT.

INTERNAL LADDER (SHELL, SKIRT), EARTH PIECE,

ANCHOR BOUTS, TEMPLATE

0

ue

@®cuiyopa exxee" Appendix 27

DRUM SPECIFICATION SHEET (B) ce

cuswr mT

Royse

prope

y08 no

oe NO.

en mane

ae

t t

heanel sae | — wanes Terrase

ee

aera

Less rr

Cee

(ies pees

Seneca 7

Hota the ers ———.7 "=

eset Sonar

SaaS

[iene meee

TEST PRESS. HYDROSTATIC gem

ee =

‘POST WELD HEAT TREATMENT : CODE, YES.NO

RADIOGRAPHING : FULL, SPOT &, NO, CODE

JOINT EFF. SHELL HEADS.

MATERIAL

‘SEL

C2

aTRAY TERNAL sionainananen aera naa

SUPPORT,

GATE

NECK

CT

BOUT & NUT TEXT er,

INSULATION: mm

TIRE PROOF: YSN

[Fweicit: ERECTION ie

‘OPERATION i

FUL WATENSincinEcccnctortseg:

"ACCESSORIES SUPPLIED BY MANUFACTURER

LADDER & PLATFORM CLIPS, PIPE SPRT. CLIPS,

DAVIT, LIFTING LUG, CORROSION GAGE POINT,

INTERNAL, LADDER (SHELL, SKIRT), EARTH PIECE,

®cu oecanermes

DRUM SPECIFICATION SHEET (C)

Appendix yo

a wT STSTS

FROIEET. 7 =

108 xo 0

oe Ne ;

«Pena aa

: Fe

ie i

. i:

—_,

Bees euNeureNsess

beesege

MARK| Size | seRvice | QTY | RATING

NOZZLE SCHEDULE

GPERATING CONDITION

uD.

|pREss eee

a

(Cetquie pensny rr

[Foran vouwe et

NORWAL LIQUID HOLD UF = il

(CONTROL RANGE REQUIRED

‘DESIGN CONDITION

‘CODE/REGULATION

DESIGN PRESS. & TEWP. ere a =

‘TEST PRESS, HYDROSTATIC rrencall

[eee rena ccc omc pee]

“CORROSION ALLOWANCE. ‘am

POST WELD HEAT TREATMENT CODE, VES.NO

RADIOGRAPHING FULL, SPOT NO, CODE

JOINT EFF, :SHELL §. HEAD 3,

MATERIAL

‘SHELLS

HEAD.

‘TRAY INTERNAL

‘SUPPORT,

NOZZLE FLANGE

NECK

GASKET

BOLT & NUTIEXT INT.

TRSULATION a

FIRE PROOF: YES NO

WEIGHT: ERECTION 7

‘OPERATION, rm

FULL WATER kt

"ACCESSORIES SUPPLIED BY WANUFACTURER

LADDER & PLATFORM CLIPS, PIPE SPRT. CLIPS

DAVIT, LIFTING LUG. CORROSION GAGE. POLNT,

INTERNAL LADDER (SHELL, SKIRT), EARTH PIECE,

ANCHOR BOLTS. TEMPLATE

ve EAGER

BONSTRUCTEN CAT

®cuvo

Appendix v7

DRUM SPECIFICATION SHEET (D) :

REV

CLIENT ey OTe

PROJECT

TITLE

J08 NO. vO)

oc No. ee

1 [rerre: 7 Tey FAW

2 | Seavies

3 [HO REQD: =

x |

” GPERATING CONDITION REMARKS

» [uD

a0 [Ress, wate

a [rem €

x [Liguip DeNsiry im

TOTAL VOLUME =

NORMAL LIQUID HOLD UP ri

‘CONTROL RANGE REQUIRED.

DESIGN CONDITION

‘CODE/REGULATION IT

DESIGN PRESS. & TEMP alee ae a iene

TEST PRESS. HYDROSTATIC! as Ty te

PNEUMATIC MalemG 1

CORROSION ALLOWANCE a

POST WELD HEAT TREATMENT “CODE, VES_NO (ana i

RADIOGRAPHING. FULL.SPOT ___%, NO, CODE [ce

JOINT EFF. SHELL & HEAD, je T

MATERIAL lee T

SHELL fale t

HEAD. MARK SIZE | SERVICE 7 OFY_ RATING

SUPPORT NOZZLE SCHEOULE!

INTERNAL, WeiGnT emery m7

NOZZLE FLANGE: (OPERATION ma

NECK FULL WATER ie

GASKET ACCESSORIES SUPPLIED BY _WANUFACTURER

Bout a NUT LADDER & PLATFORM CLIPS, PIPE SPRT. CLIPS,

INTERNAL LADDER, CORROSION GAGE POINT,

INSULATION Tm] ANCHOR (OR SETTING) BOLT, SLIDING PLATE.

rpms ewcnceRIG

STATION.

®cnivo

Appendix y2

+ DRUM SPECIFICATION SHEET (E)

RV] O_O | O Mave

CLIENT + .

one BY | i MADET

TITLE a HKD] HKD

J0B NO. z hevo| |_| APvD

DOC NO. ATE] {| iDATE]

1 [meno T iY nan

2 [senvice

3 [No. REO®: J —

a

2 ‘SRERATING CONDITION Renan

x eae

» =

ta

a TT

NORMAL LIQUID HOLD UP aie

CONTROL RANGE REQUIRED

DESIGN CONOITION

ObE/REGULATION I T

DESIGN PRESS TEMP ewe ieee [me

TEST PRESS. HYDROSTATIC md 1

PNEUMATIC ens i

CORROSION ALLOWANCE. = 1 1

POST WELD HEAT TREATMENT CODE, VES NO t

RADIOGRAPHING : FULL, SPOT 9 NO, CODE t

TOIT EFF. SHELL "8, HEAD, : Las]

MATERIAL 1 ese]

SHEL | fee)

HEAD hank! SE | _senwice —Qrv | aaTine

SUPPORT NOZZLE SEHEDULE

INTERNAL WET Ewe 7

NOZZLE FLANGE OPERATION Me

NECK FULL WATER Me

case "ACCESSORIES SUPPLIED BY MANUFACTURER

BOLT & NUP LADDER & PLATFORM CLIPS, PIPE SPRT, CLIPS

INTERNAL LADDER, CORROSION GAGE POINT,

TRSULATION Tm] amcor (on SETTING) BOLT, SLIDING PLATE.

EARTH riECE

Q@CHIVODA Fess:

Appendix vJ

COLUMN

Q COLUMN speciFICATION SHEET

REV] D | | O MADE

oe val si] MADE’

TERE. lcnKD: (CHRD.

lapvD| lArvo

Z [bATE! [paTE|

1 EMAAR

+ [SERvice

2 [ Ro. REO®:

+ 1 t

’ |

» 1 t

a [ee 1

2 T |

“ t

* 1

* 1

® fwamel size | senvice [av | —aarine

WozzLe SCHEDULE

SPERATING CONDITION

or)

TRESS Teas

TEM, =

Liguip BENE war

(prorAtvor ae

NORWAL CIQUID HOLS UF me

CONTROL RANGE REQUIRED

DEsGH CONOTTION

cone REGULATION

DESIGN PRESS. 4 TEMP een

"FEST PRESS, HYDROSTATIC Ee

PREUMATIC ware

CORROHON ALLOWANCE 7 =

Tost WELD HEAT TREATMENT TCODE, YES_NO

RADIOGRAPHING FULL, POT @.NO, CODE

JOINT EFF_:SHEIi—§. MEAD "=.

TaTeRia

HEAD

TRAY TERNAL

surront

NOZzLE FLANGE

NECK

CASE

BOLT & NUTIERT, os

REULATION =

FIRE PROOF! vis wo

WEIGHT. ERECTION m3

OPERATION m3

FULL WATER 7

TGECESSORIES SUPPLIED BY MANUFACTURER

LADDER & PLATFORM CLIPS, PIPE SPAT. CLIPS;

DAVIT, LIFTING LUG, CORROSION GAGE POINT,

a

> CHEMICAL ENGINEERING

@CHIYODA sees (Ono

eee |

SHELL AND TUBE HEAT EXCHANGER SPECIFICATION SHEET cy

CUENT pe 1 O11 S huaor [ees

PROJECT HKD |

TITLE jenn] 0D |

JOB NO. rArvD] |

DOC No. C7) Pa dil it

(eae Taste array Ova Une Tent

ate. Citerizeneat Ui vernicat Na. of Traine ‘Surt Train =]

*[eenrae Ts Perr a

a eae Seal Bae Tans Se

| ee oe ieee eee

{] Prmnene

Sooo a

de vr sen 1

we Teva m2 T

“fe i 1

OE [eam = i t

«| 8 [uate "esr at t

tu] § [Soeetie teat Ue.tvaec! nesitee E]

ta| § [Peron Gonactiviy te vet “keaton T

ad

| & [ineerromare wwe |

0[ E [pee rateareoea mat 7 7

a. 8| _ [Premure Oreo (allow Gameut) wien 7 I z

| _ [reste nears Rosine’ woth} i

3] [rerenemreer a a rae =

| [remornee bone Tame aa ier

: a SFE Sara By REST ae

| Tube Rich mim SP PSE Yane tyne Chin Oe

| Tv Ghinw Weta

o Bettie Seacing (Cancer) sifie Spacing mm Impingement Protection Cl¥w UNe

af 4 [inter Nessie av? ‘Shea Enerance av Kolm Shot exit ov? wena]

| & | FubeTubeneee Joine T ‘Shel Sige Tube Siw

5 [Sra | Dewon Pressure igen t

[mare 3 I

Bicommoos i |

5 | crannel Cover ‘Tbe of Cieening Coeres Overencs Cohence Onenei

5 | Rosina eee Ee TeerenenAtoweand na i

E [aire Fiengetoarr ar Thesioweonine (rw Cia Che [Gran Giver Che

3 [Roasts Fienge (S.5/7-57 |[Poroweia Het Tresmnent [ves UNe Lkoae Live Uno Ueeae]

£ [Retenee NerseTe i

a :

8 rane inner 7

Requivtion Thresces Cannactions Tien” CNet Aton Clatiow Chee Aton |