Professional Documents

Culture Documents

Important Considerations: Material of Construction

Uploaded by

hellopianoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Important Considerations: Material of Construction

Uploaded by

hellopianoCopyright:

Available Formats

Material of construction

Important considerations

Mechanical properties

Effect of high and low temperatures

Corrosion resistance

Cost?

Carbon and low alloy steels will oxidise rapidly at high temperatures and their

use is limited to temperatures below 50QC,

Chromium is the most effective alloying element to give resistance to oxidation, forming

a tenacious oxide film. Chromium alloys should be specified for equipment subject to

temperatures above 500C in oxidising atmospheres

The stainless steels are the most frequently used corrosion resistant materials in the

chemical industry.

To impart corrosion resistance the chromium content must be above 12 per cent,

and the higher the chromium content, the more resistant is the alloy to corrosion in

oxidising conditions. Nickel is added to improve the corrosion resistance in non-oxidising

environments.

Austenitic: 18-20 per cent Cr, > 7 per cent Ni,

austenitic stainless steels have greater strength than the plain carbon steels, particularly

at elevated temperatures

the austenitic stainless steels, unlike the plain

carbon steels, do not become brittle at low temperatures

Residence time calculations

You might also like

- 1 4713 4724 4742 4762Document4 pages1 4713 4724 4742 4762Ján KožičkaNo ratings yet

- Selective Hardening MethodsDocument47 pagesSelective Hardening MethodsvishnuNo ratings yet

- High Temperature CorrosionDocument2 pagesHigh Temperature CorrosionIlhamChaniefNo ratings yet

- Key Aluminum Nitride PropertiesDocument10 pagesKey Aluminum Nitride PropertiesMuhammad TanweerNo ratings yet

- High Alloy Cast IronsDocument4 pagesHigh Alloy Cast IronsHamid KhalilpoorNo ratings yet

- Seminar On Oxidation Resistant CoatingDocument18 pagesSeminar On Oxidation Resistant CoatingManoj IyengarNo ratings yet

- Mod 6 Materials and Hardware: Exam PointsDocument16 pagesMod 6 Materials and Hardware: Exam PointsKetanRaoNo ratings yet

- Bab 9 - Materials SelectionDocument106 pagesBab 9 - Materials SelectionFachry Hafidz AhmadiNo ratings yet

- CPHFD 011Document7 pagesCPHFD 011Napoleon DasNo ratings yet

- Ajp Module-2Document22 pagesAjp Module-2Naveen S BasandiNo ratings yet

- Materials For High Temperature High Pressure Applications andDocument28 pagesMaterials For High Temperature High Pressure Applications andDrVRKNo ratings yet

- Unit 4 Corrossion Protection MethodsDocument32 pagesUnit 4 Corrossion Protection Methods20pcha122 20pcha122No ratings yet

- SubhradipDocument10 pagesSubhradipGreatNo ratings yet

- Material at Low TemperatureDocument3 pagesMaterial at Low TemperatureGajendra GuptaNo ratings yet

- Duplex & Super Duplex InformationDocument7 pagesDuplex & Super Duplex InformationrajeshNo ratings yet

- Materials For Woven Wire Cloth.: Extensive As The Range of ApplicationsDocument12 pagesMaterials For Woven Wire Cloth.: Extensive As The Range of ApplicationsadrianioantomaNo ratings yet

- Stainless SteelDocument24 pagesStainless SteelsmrutiNo ratings yet

- SST PDFDocument48 pagesSST PDFpostguard64No ratings yet

- Material of ConstructionDocument43 pagesMaterial of ConstructionMohammed.abudi1996No ratings yet

- Chap-10 Materials and Fabrication SelectionDocument51 pagesChap-10 Materials and Fabrication SelectionSuprio KamalNo ratings yet

- Nature of MaterialsDocument20 pagesNature of MaterialsBALBIDO John LesterNo ratings yet

- Low Alloy Steel - An OverviewDocument10 pagesLow Alloy Steel - An OverviewhaharameshNo ratings yet

- AlloysDocument33 pagesAlloyshenryNo ratings yet

- Materi 1.7 Linepipe MaterialDocument45 pagesMateri 1.7 Linepipe MaterialPermana HasnoNo ratings yet

- Steels For Cryogenic and Low-Temperature Service - KEY To METALS ArticleDocument3 pagesSteels For Cryogenic and Low-Temperature Service - KEY To METALS Articlekumarpankaj030No ratings yet

- Austenitic Cast IronDocument2 pagesAustenitic Cast Ironkatchani123No ratings yet

- Materials and Processes For Agricultural and Biosystems EngineeringDocument17 pagesMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioNo ratings yet

- MMEN 120 - Surface HardeningDocument19 pagesMMEN 120 - Surface HardeningnattydreadfathelahNo ratings yet

- Material Selection Consideration For ReactorsDocument6 pagesMaterial Selection Consideration For ReactorsMiera Yushira YusoffNo ratings yet

- ElectroDocument14 pagesElectronvemanNo ratings yet

- AJM & NDT - Module - 2Document23 pagesAJM & NDT - Module - 2Naveen S BasandiNo ratings yet

- Most Common Steels Used in Process Piping Industry: A LiteratureDocument38 pagesMost Common Steels Used in Process Piping Industry: A LiteraturekarunaNo ratings yet

- Low Alloy Steels For Cryogenic ApplicationsDocument0 pagesLow Alloy Steels For Cryogenic ApplicationsidienNo ratings yet

- Stainless Chromium-Nickel-SteelsDocument26 pagesStainless Chromium-Nickel-SteelscesargamboaNo ratings yet

- GCE3135 AssignmentDocument10 pagesGCE3135 AssignmentBilal MishoryNo ratings yet

- ss304 NitridingDocument11 pagesss304 Nitridingvijayps.mechNo ratings yet

- Table 7.7 (Continued) : 7.3.12 Stainless SteelsDocument21 pagesTable 7.7 (Continued) : 7.3.12 Stainless SteelsumairNo ratings yet

- Stainless Steel ClassificationDocument5 pagesStainless Steel Classificationyatin888No ratings yet

- A330 PylonsDocument21 pagesA330 Pylonsosamoz100% (2)

- Ajp Module-2Document75 pagesAjp Module-2Naveen S BasandiNo ratings yet

- Chapter 8Document5 pagesChapter 8Eisha MalikNo ratings yet

- Unit 4-2-NonferrousDocument32 pagesUnit 4-2-NonferrousNisha JaiswalNo ratings yet

- Mechanical Design For Pressure VesselDocument26 pagesMechanical Design For Pressure VesselibicengNo ratings yet

- Material of ConstructionDocument43 pagesMaterial of ConstructionMohammed.abudi1996No ratings yet

- Duplex 2209 Weld Overlay by ESSC Process: Er. Manoj Kumar, Dr. Abhishek KambojDocument7 pagesDuplex 2209 Weld Overlay by ESSC Process: Er. Manoj Kumar, Dr. Abhishek KambojAyyappanSubramanianNo ratings yet

- 5.1 Nonferrous Metals & AlloysDocument28 pages5.1 Nonferrous Metals & Alloysjayvee allineraNo ratings yet

- Quiz WeldingDocument3 pagesQuiz WeldingnafNo ratings yet

- Ferrous and Non-Ferrous MetalsDocument43 pagesFerrous and Non-Ferrous MetalsSuzette MacalinaoNo ratings yet

- Unit-V Engineering MaterialsDocument47 pagesUnit-V Engineering MaterialsUdin DzonoNo ratings yet

- Heat Resistant CeramicsDocument26 pagesHeat Resistant Ceramicsivy_oforiNo ratings yet

- Nitric Acid StorageDocument7 pagesNitric Acid StorageEr Bali PandhareNo ratings yet

- Weldability: Introduction and Factor Affecting ItDocument15 pagesWeldability: Introduction and Factor Affecting ItAnant Ajithkumar100% (2)

- A Simple Method For A Protective Coating On StainlDocument18 pagesA Simple Method For A Protective Coating On StainlKrishnan DeviNo ratings yet

- Report Stainless SteelDocument6 pagesReport Stainless SteelAhmed ShokryNo ratings yet

- Hydrogen in Material SelectionDocument4 pagesHydrogen in Material SelectionAsad Bin Ala Qatari0% (1)

- Alloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureDocument2 pagesAlloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureBharathi SrinivasanNo ratings yet

- Lesson Title: Types of MetalsDocument8 pagesLesson Title: Types of MetalsEric LamNo ratings yet

- Heat TreatmentDocument4 pagesHeat TreatmentAshish BoraNo ratings yet

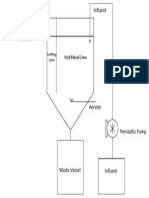

- Bioenv ApparatusDocument1 pageBioenv ApparatushellopianoNo ratings yet

- Bioenv ApparatusDocument1 pageBioenv ApparatushellopianoNo ratings yet

- A Comparative Study On Predictions of VLE of Biodiesel SystemsDocument6 pagesA Comparative Study On Predictions of VLE of Biodiesel SystemsMario Ricardo Urdaneta ParraNo ratings yet

- KSB-Elite - Performance CurvesDocument37 pagesKSB-Elite - Performance Curveswoodywheel50% (2)

- Bioenv ApparatusDocument1 pageBioenv ApparatushellopianoNo ratings yet

- Bioenv ApparatusDocument1 pageBioenv ApparatushellopianoNo ratings yet

- There Are No FactsDocument1 pageThere Are No FactshellopianoNo ratings yet

- Stuff For ChromatographyDocument1 pageStuff For ChromatographyhellopianoNo ratings yet

- Conversions For ChemistryDocument2 pagesConversions For ChemistryhellopianoNo ratings yet

- Stuff For ChromatographyDocument1 pageStuff For ChromatographyhellopianoNo ratings yet

- Filippo Marchetti: Fascination For Voice and Piano (Fascinação)Document5 pagesFilippo Marchetti: Fascination For Voice and Piano (Fascinação)hellopianoNo ratings yet

- Week 1 5 WordsDocument4 pagesWeek 1 5 WordshellopianoNo ratings yet

- Conversions For ChemistryDocument2 pagesConversions For ChemistryhellopianoNo ratings yet

- Addition of HCLDocument1 pageAddition of HCLhellopianoNo ratings yet

- Addition of HCLDocument1 pageAddition of HCLhellopianoNo ratings yet

- Addition of HCLDocument1 pageAddition of HCLhellopianoNo ratings yet

- How To Practice SpellingDocument1 pageHow To Practice SpellinghellopianoNo ratings yet

- This Coupon Allows You To Go To The TOILET During ClassDocument4 pagesThis Coupon Allows You To Go To The TOILET During ClasshellopianoNo ratings yet

- Addition of HCLDocument1 pageAddition of HCLhellopianoNo ratings yet

- PlaylistDocument7 pagesPlaylisthellopianoNo ratings yet

- PlaylistDocument7 pagesPlaylisthellopianoNo ratings yet