Professional Documents

Culture Documents

Bus Bar Calculation - Requirement

Uploaded by

srigirisetty208Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bus Bar Calculation - Requirement

Uploaded by

srigirisetty208Copyright:

Available Formats

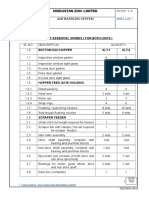

INDAL CHART

Dimension of Al.

Bus bar

Total Cross Section Per Phase ( sq. mm)

AC Current at an ambient of 35 deg & rise Correctio

50 deg.

n Factor

Derated current considering correction

factor as .667

Width

(mm)

Thickness

(mm)

25.4

6.35

161.29

322.58

483.87

645.16

355

705

970

1100

0.667

236.785

470.235

646.99

733.7

38.1

6.35

241.94

483.87

725.81

967.74

520

1020

1350

1535

0.667

346.84

680.34

900.45

1023.845

50.8

6.35

322.58

645.16

967.74

1290.32

670

1290

1705

1940

0.667

446.89

860.43

1137.235

1293.98

63.5

6.35

403.23

806.45

1209.68

1612.90

810

1510

2000

2260

0.667

540.27

1007.17

1334

1507.42

76.2

6.35

483.87

967.74

1451.61

1935.48

960

1740

2310

2620

0.667

640.32

1160.58

1540.77

1747.54

101.6

6.35

645.16

1290.32

1935.48

2580.64

1235

2140

2800

3200

0.667

823.745

1427.38

1867.6

2134.4

127

6.35

806.45

1612.90

2419.35

3225.80

1505

2510

3240

3700

0.667

2161.08

2467.9

152.4

6.35

967.74

1935.48

2903.22

3870.96

1780

2860

3680

4240

0.667

1187.26

1907.62

2454.56

2828.08

50.8

9.53

484.12

968.25

1452.37

1936.50

830

1500

1970

2260

0.667

553.61

1000.5

1313.99

1507.42

76.2

9.53

726.19

1452.37

2178.56

2904.74

1180

2050

2660

3030

0.667

787.06

1367.35

1774.22

2021.01

101.6

9.53

968.25

1936.50

2904.74

3872.99

1495

2480

3150

3560

0.667

997.165

1654.16

2101.05

2374.52

127

9.53

1210.31

2420.62

3630.93

4841.24

1860

2930

3660

4200

0.667

1240.62

1954.31

2441.22

2801.4

152.4

9.53

1452.37

2904.74

4357.12

5809.49

2120

3340

4080

4680

0.667

1414.04

2227.78

2721.36

3121.56

203.2

9.53

1936.50

3872.99

5809.49

7745.98

2750

4150

4900

5740

0.667

1834.25

2768.05

3268.3

3828.58

76.2

12.7

967.74

1935.48

2903.22

3870.96

1355

2240

2830

3240

0.667

903.785

1494.08

1887.61

2161.08

101.6

12.7

1290.32

2580.64

3870.96

5161.28

1740

2720

3360

3900

0.667

1160.58

1814.24

2241.12

2601.3

127

12.7

1612.90

3225.80

4838.70

6451.60

2080

3120

3900

4550

0.667

1387.36

2081.04

2601.3

3034.85

152.4

12.7

1935.48

3870.96

5806.44

7741.92

2420

3500

4400

5100

0.667

1614.14

2334.5

2934.8

3401.7

203.2

12.7

2580.64

5161.28

7741.92

10322.56

3060

4450

5300

6150

0.667

2041.02

2968.15

3535.1

4102.05

254

12.7

3225.80

6451.60

9677.40

12903.20

3640

5000

6000

6850

0.667

2427.88

3335

4002

4568.95

No. of bars

No. of bars

0.667

No. of bars

1003.835 1674.17

CALCULATION OF ALUMINIUM dropper for 800A

PARAMETERS

Feeder Rating

800 A

Size of Aluminium Bus Bar considered

2x50x10 mm2

i.e. Runs/Phase

2 mm

Width

50 mm

Thickness

10 mm

Current rating as per INDAL Aluminium ( E91)=0.97*EIE M

grade current

1455 A

Design Ambient Temperature

50 C

Rise in Temperature allowed

40 oC

Final Temperature Permitted

Size of Bus Bar enclosure

i.e. Height

Depth

Fault current (for 1 sec)

Duration of Fault

Grade of Al. dropper

A.

for EIE-M grade (Amp)

90

175 x 800

175

800

50000

C

sq.mm

mm

mm

A

o

1 s

E91-E

MINIMUM CONDUCTOR SIZE

Formula

to determine the minimum size of conductor for any fault level:

t = (k/100) x ( Isc/A)2 x (1+ 20 . ) x t

( Ref: Industrial Power Engineering and Application Handbook, Page 865)

t= temperature rise above operating temp. in deg. C

100 oC

(190-90)oC

95 oC

(185-90)oC

Isc= symmetrical fault current in r.m.s in Amps.

A= cross sectional area of conductor in mm 2

20= temperature coefficient of resistence at 20 deg C/deg C

0.00403 for pure Aluminium

0.00363 for Aluminium alloy

0.00393 for pure copper

= operating temperature of the conductor at which the fault occurs

k=

1.166 for aluminium

0.52 for copper

t= duration of fault in seconds

Aluminium starts softening at a temperature of around 180-200 deg.As a rule of thumb for

Al conductor,on a fault a safe temperature rise of 100 deg above the allowable end temperature

of 90 deg of the conductor during normal condition has been considered & taken as the basis

to determine the minimum size of the conductor

Final temp. allowed for busbar after short circuit is 190 deg C

By putting all values in the above equation

1500

100 = (1.166/100) ( 50000/A)2 (1+ 0.00363 x 90) x 1

A=

630.26 sq.mm

for pure Al.

621.88 sq.mm

for Al alloy

646.63 sq.mm

638.03 sq.mm

( final temp 190 i.e. 90+100)

( final temp 190 i.e. 90+100)

for pure Al.

for Al alloy

( final temp 185 i.e. 90+95)

( final temp 185 i.e. 90+95)

B.

THERMAL RATING

I.

DERATING FACTOR ON ACCOUNT OF HIGHER AMBIENT

TEMPERATURE

Design Ambient Temperature

50 oC

Rise in Temperature allowed

40 oC

Derating Factor k1 :

0.88

( Ref: Industrial Power Engineering and Application Handbook, Page 870,871)

II.

DERATING DUE TO ENCLOSURE

Cross sectional area of busbar

cross sectional area of enclosure

= No. of Phase x (Cross Section per Phase) x 100

cross sectional area of enclosure

= 300000

140000

As per table 5(enclosed) of INDAL paper on INDAL Al. Bus Bar,

the derating factor, k2 :

if ratio is less than 5%

0.75

2.1428571429

III. DERATING DUE TO PROXIMITY EFFECT

Busbar rating is lower than 1600A

So,the derating due to proximity effect will be , k3 :

( Ref: Industrial Power Engineering and Application Handbook, Page 887)

IV.

DERATING DUE TO BUSBAR MATERIAL

Grade :

Electrolytic gr. Al.(D50SWP)

Derating Factor , k4 :

V.

0.95

i.e. E91-E

( INDAL ALLOY)

TOTAL DERATING FACTOR

Total derating = derating due to ambient x derating due to enclosure x derating due

to proximity effect x derating due to busbar material

= k1 x k2 x k3 x k4

0.627

So, the cross section of dropper required for 630 A out going ACB shall cary 630A after

considering all derating factors = (Combined derating factor) x ( Current from Indal Data Sheet)

=(k1 x k2 x k3 x k4) x ( Current from Indal Data Sheet)

912.285

So,the busbar size choosen from Indal sheet shall be capable of

carrying

912.285 A

CALCULATION OF ALUMINIUM dropper for 1000/1250A

PARAMETERS

Feeder Rating

1000/1250

Size of Aluminium Bus Bar considered

3x50x10 mm2

i.e. Runs/Phase

3 mm

Width

50 mm

Thickness

10 mm

Current rating as per INDAL Aluminium ( E91)=0.97*EIE M

grade current

1998.2 A

Design Ambient Temperature

50 C

Rise in Temperature allowed

40 oC

Final Temperature Permitted

Size of Bus Bar enclosure

i.e. Height

Depth

Fault current (for 1 sec)

Duration of Fault

Grade of Al. dropper

A.

for EIE-M grade (A)

90

175 x 800

175

800

50000

C

sq.mm

mm

mm

A

o

1 s

E91-E

MINIMUM CONDUCTOR SIZE

Formula

to determine the minimum size of conductor for any fault level:

t = (k/100) x ( Isc/A)2 x (1+ 20 . ) x t

( Ref: Industrial Power Engineering and Application Handbook, Page 865)

t= temperature rise above operating temp. in deg. C

100 oC

(190-90)oC

95 oC

(185-90)oC

Isc= symmetrical fault current in r.m.s in Amps.

A= cross sectional area of conductor in mm 2

20= temperature coefficient of resistence at 20 deg C/deg C

0.00403 for pure Aluminium

0.00363 for Aluminium alloy

0.00393 for pure copper

= operating temperature of the conductor at which the fault occurs

k=

1.166 for aluminium

0.52 for copper

t= duration of fault in seconds

Aluminium starts softening at a temperature of around 180-200 deg.As a rule of thumb for

Al conductor,on a fault a safe temperature rise of 100 deg above the allowable end temperature

of 90 deg of the conductor during normal condition has been considered & taken as the basis

to determine the minimum size of the conductor

Final temp. allowed for busbar after short circuit is 190 deg C

By putting all values in the above equation

2060

100 = (1.166/100) ( 50000/A)2 (1+ 0.00363 x 90) x 1

A=

630.26 sq.mm

for pure Al.

621.88 sq.mm

for Al alloy

646.63 sq.mm

638.03 sq.mm

( final temp 190 i.e. 90+100)

( final temp 190 i.e. 90+100)

for pure Al.

for Al alloy

( final temp 185 i.e. 90+95)

( final temp 185 i.e. 90+95)

B.

THERMAL RATING

I.

DERATING FACTOR ON ACCOUNT OF HIGHER AMBIENT

TEMPERATURE

Design Ambient Temperature

50 oC

Rise in Temperature allowed

40 oC

Derating Factor k1 :

0.88

( Ref: Industrial Power Engineering and Application Handbook, Page 870,871)

II.

DERATING DUE TO ENCLOSURE

Cross sectional area of busbar

cross sectional area of enclosure

= No. of Phase x (Cross Section per Phase) x 100

cross sectional area of enclosure

= 450000

140000

As per table 5(enclosed) of INDAL paper on INDAL Al. Bus Bar,

the derating factor, k2 :

if ratio is less than 5%

0.75

3.2142857143

III. DERATING DUE TO PROXIMITY EFFECT

Busbar rating is lower than 1600A

So,the derating due to proximity effect will be , k3 :

( Ref: Industrial Power Engineering and Application Handbook, Page 887)

IV.

DERATING DUE TO BUSBAR MATERIAL

Grade :

Electrolytic gr. Al.(D50SWP)

Derating Factor , k4 :

V.

0.95

i.e. E91-E

( INDAL ALLOY)

TOTAL DERATING FACTOR

Total derating = derating due to ambient x derating due to enclosure x derating due

to proximity effect x derating due to busbar material

= k1 x k2 x k3 x k4

0.627

So, the cross section of dropper required for 630 A out going ACB shall cary 630A after

considering all derating factors = (Combined derating factor) x ( Current from Indal Data Sheet)

=(k1 x k2 x k3 x k4) x ( Current from Indal Data Sheet)

1252.8714

So,the busbar size choosen from Indal sheet shall be capable of

carrying

1252.8714 A

CALCULATION OF ALUMINIUM dropper for 1250/1600A

PARAMETERS

Feeder Rating

1250/1600

Size of Aluminium Bus Bar considered

4x50x10 mm2

i.e. Runs/Phase

4 mm

Width

50 mm

Thickness

10 mm

Current rating as per INDAL Aluminium ( E91)=0.97*EIE M

grade current

2429.85 A

Design Ambient Temperature

50 C

Rise in Temperature allowed

40 oC

Final Temperature Permitted

Size of Bus Bar enclosure

i.e. Height

Depth

Fault current (for 1 sec)

Duration of Fault

Grade of Al. dropper

A.

for EIE-M grade (A)

90

175 x 800

175

800

50000

C

sq.mm

mm

mm

A

o

1 s

E91-E

MINIMUM CONDUCTOR SIZE

Formula

to determine the minimum size of conductor for any fault level:

t = (k/100) x ( Isc/A)2 x (1+ 20 . ) x t

( Ref: Industrial Power Engineering and Application Handbook, Page 865)

t= temperature rise above operating temp. in deg. C

100 oC

(190-90)oC

95 oC

(185-90)oC

Isc= symmetrical fault current in r.m.s in Amps.

A= cross sectional area of conductor in mm 2

20= temperature coefficient of resistence at 20 deg C/deg C

0.00403 for pure Aluminium

0.00363 for Aluminium alloy

0.00393 for pure copper

= operating temperature of the conductor at which the fault occurs

k=

1.166 for aluminium

0.52 for copper

t= duration of fault in seconds

Aluminium starts softening at a temperature of around 180-200 deg.As a rule of thumb for

Al conductor,on a fault a safe temperature rise of 100 deg above the allowable end temperature

of 90 deg of the conductor during normal condition has been considered & taken as the basis

to determine the minimum size of the conductor

Final temp. allowed for busbar after short circuit is 190 deg C

By putting all values in the above equation

2505

100 = (1.166/100) ( 50000/A)2 (1+ 0.00363 x 90) x 1

A=

630.26 sq.mm

for pure Al.

621.88 sq.mm

for Al alloy

646.63 sq.mm

638.03 sq.mm

( final temp 190 i.e. 90+100)

( final temp 190 i.e. 90+100)

for pure Al.

for Al alloy

( final temp 185 i.e. 90+95)

( final temp 185 i.e. 90+95)

B.

THERMAL RATING

I.

DERATING FACTOR ON ACCOUNT OF HIGHER AMBIENT

TEMPERATURE

Design Ambient Temperature

50 oC

Rise in Temperature allowed

40 oC

Derating Factor k1 :

0.88

( Ref: Industrial Power Engineering and Application Handbook, Page 870,871)

II.

DERATING DUE TO ENCLOSURE

Cross sectional area of busbar

cross sectional area of enclosure

= No. of Phase x (Cross Section per Phase) x 100

cross sectional area of enclosure

= 600000

140000

As per table 5(enclosed) of INDAL paper on INDAL Al. Bus Bar,

the derating factor, k2 :

if ratio is less than 5%

0.75

4.2857142857

III. DERATING DUE TO PROXIMITY EFFECT

Busbar rating is lower than 1600A

So,the derating due to proximity effect will be , k3 :

( Ref: Industrial Power Engineering and Application Handbook, Page 887)

IV.

DERATING DUE TO BUSBAR MATERIAL

Grade :

Electrolytic gr. Al.(D50SWP)

Derating Factor , k4 :

V.

0.95

i.e. E91-E

( INDAL ALLOY)

TOTAL DERATING FACTOR

Total derating = derating due to ambient x derating due to enclosure x derating due

to proximity effect x derating due to busbar material

= k1 x k2 x k3 x k4

0.627

So, the cross section of dropper required for 630 A out going ACB shall cary 630A after

considering all derating factors = (Combined derating factor) x ( Current from Indal Data Sheet)

=(k1 x k2 x k3 x k4) x ( Current from Indal Data Sheet)

1523.51595

So,the busbar size choosen from Indal sheet shall be capable of

carrying

1523.51595 A

CALCULATION OF ALUMINIUM BUS LINK for 800A

PARAMETERS

Feeder Rating

800 A

Size of Aluminium Bus Bar considered

2x76.2x6.35 mm2

i.e. Runs/Phase

2 mm

Width

76.2 mm

Thickness

6.35 mm

Current rating as per INDAL Aluminium ( E91)=0.97*EIE M

grade current

1740 A

Design Ambient Temperature

50 oC

Rise in Temperature allowed

40 oC

Final Temperature Permitted

Size of Bus Bar enclosure

i.e. Height

Depth

Fault current (for 1 sec)

Duration of Fault

Grade of Al. dropper

A.

90

175 x 800

175

800

50000

C

sq.mm

mm

mm

A

o

1 s

E91-E

MINIMUM CONDUCTOR SIZE

Formula

to determine the minimum size of conductor for any fault level:

t = (k/100) x ( Isc/A)2 x (1+ 20 . ) x t

( Ref: Industrial Power Engineering and Application Handbook, Page 865)

t= temperature rise above operating temp. in deg. C

100 oC

(190-90)oC

95 oC

(185-90)oC

Isc= symmetrical fault current in r.m.s in Amps.

A= cross sectional area of conductor in mm 2

20= temperature coefficient of resistence at 20 deg C/deg C

0.00403 for pure Aluminium

0.00363 for Aluminium alloy

0.00393 for pure copper

= operating temperature of the conductor at which the fault occurs

k=

1.166 for aluminium

0.52 for copper

t= duration of fault in seconds

Aluminium starts softening at a temperature of around 180-200 deg.As a rule of thumb for

Al conductor,on a fault a safe temperature rise of 100 deg above the allowable end temperature

of 90 deg of the conductor during normal condition has been considered & taken as the basis

to determine the minimum size of the conductor

Final temp. allowed for busbar after short circuit is 190 deg C

By putting all values in the above equation

100 = (1.166/100) ( 50000/A)2 (1+ 0.00363 x 90) x 1

A=

630.26 sq.mm

for pure Al.

621.88 sq.mm

for Al alloy

646.63 sq.mm

638.03 sq.mm

( final temp 190 i.e. 90+100)

( final temp 190 i.e. 90+100)

for pure Al.

for Al alloy

( final temp 185 i.e. 90+95)

( final temp 185 i.e. 90+95)

B.

THERMAL RATING

I.

DERATING FACTOR ON ACCOUNT OF HIGHER AMBIENT

TEMPERATURE

Design Ambient Temperature

50 oC

Rise in Temperature allowed

40 oC

Derating Factor k1 :

0.88

( Ref: Industrial Power Engineering and Application Handbook, Page 870,871)

II.

DERATING DUE TO ENCLOSURE

Cross sectional area of busbar

cross sectional area of enclosure

= No. of Phase x (Cross Section per Phase) x 100

cross sectional area of enclosure

= 290322

140000

As per table 5(enclosed) of INDAL paper on INDAL Al. Bus Bar,

the derating factor, k2 :

if ratio is less than 5%

0.75

2.0737285714

III. DERATING DUE TO PROXIMITY EFFECT

Busbar rating is lower than 1600A

So,the derating due to proximity effect will be , k3 :

( Ref: Industrial Power Engineering and Application Handbook, Page 887)

IV.

DERATING DUE TO BUSBAR MATERIAL

Grade :

Electrolytic gr. Al.(D50SWP)

Derating Factor , k4 :

V.

0.95

i.e. E91-E

( INDAL ALLOY)

TOTAL DERATING FACTOR

Total derating = derating due to ambient x derating due to enclosure x derating due

to proximity effect x derating due to busbar material

= k1 x k2 x k3 x k4

0.627

So, the cross section of dropper required for 630 A out going ACB shall cary 630A after

considering all derating factors = (Combined derating factor) x ( Current from Indal Data Sheet)

=(k1 x k2 x k3 x k4) x ( Current from Indal Data Sheet)

1090.98

So,the busbar size choosen from Indal sheet shall be capable of

carrying

1090.98 A

CALCULATION OF ALUMINIUM BUS LINK f for 1000/1250A

PARAMETERS

Feeder Rating

1000/1250

Size of Aluminium Bus Bar considered

3x76.2x6.35 mm2

i.e. Runs/Phase

3 mm

Width

76.2 mm

Thickness

6.35 mm

Current rating as per INDAL Aluminium ( E91)=0.97*EIE M

grade current

2310 A

Design Ambient Temperature

50 oC

Rise in Temperature allowed

40 oC

Final Temperature Permitted

Size of Bus Bar enclosure

i.e. Height

Depth

Fault current (for 1 sec)

Duration of Fault

Grade of Al. dropper

A.

90

175 x 800

175

800

50000

C

sq.mm

mm

mm

A

o

1 s

E91-E

MINIMUM CONDUCTOR SIZE

Formula

to determine the minimum size of conductor for any fault level:

t = (k/100) x ( Isc/A)2 x (1+ 20 . ) x t

( Ref: Industrial Power Engineering and Application Handbook, Page 865)

t= temperature rise above operating temp. in deg. C

100 oC

(190-90)oC

95 oC

(185-90)oC

Isc= symmetrical fault current in r.m.s in Amps.

A= cross sectional area of conductor in mm 2

20= temperature coefficient of resistence at 20 deg C/deg C

0.00403 for pure Aluminium

0.00363 for Aluminium alloy

0.00393 for pure copper

= operating temperature of the conductor at which the fault occurs

k=

1.166 for aluminium

0.52 for copper

t= duration of fault in seconds

Aluminium starts softening at a temperature of around 180-200 deg.As a rule of thumb for

Al conductor,on a fault a safe temperature rise of 100 deg above the allowable end temperature

of 90 deg of the conductor during normal condition has been considered & taken as the basis

to determine the minimum size of the conductor

Final temp. allowed for busbar after short circuit is 190 deg C

By putting all values in the above equation

100 = (1.166/100) ( 50000/A)2 (1+ 0.00363 x 90) x 1

A=

630.26 sq.mm

for pure Al.

621.88 sq.mm

for Al alloy

646.63 sq.mm

638.03 sq.mm

( final temp 190 i.e. 90+100)

( final temp 190 i.e. 90+100)

for pure Al.

for Al alloy

( final temp 185 i.e. 90+95)

( final temp 185 i.e. 90+95)

B.

THERMAL RATING

I.

DERATING FACTOR ON ACCOUNT OF HIGHER AMBIENT

TEMPERATURE

Design Ambient Temperature

50 oC

Rise in Temperature allowed

40 oC

Derating Factor k1 :

0.88

( Ref: Industrial Power Engineering and Application Handbook, Page 870,871)

II.

DERATING DUE TO ENCLOSURE

Cross sectional area of busbar

cross sectional area of enclosure

= No. of Phase x (Cross Section per Phase) x 100

cross sectional area of enclosure

= 435483

140000

As per table 5(enclosed) of INDAL paper on INDAL Al. Bus Bar,

the derating factor, k2 :

if ratio is less than 5%

0.75

3.1105928571

III. DERATING DUE TO PROXIMITY EFFECT

Busbar rating is lower than 1600A

So,the derating due to proximity effect will be , k3 :

( Ref: Industrial Power Engineering and Application Handbook, Page 887)

IV.

DERATING DUE TO BUSBAR MATERIAL

Grade :

Electrolytic gr. Al.(D50SWP)

Derating Factor , k4 :

V.

0.95

i.e. E91-E

( INDAL ALLOY)

TOTAL DERATING FACTOR

Total derating = derating due to ambient x derating due to enclosure x derating due

to proximity effect x derating due to busbar material

= k1 x k2 x k3 x k4

0.627

So, the cross section of dropper required for 630 A out going ACB shall cary 630A after

considering all derating factors = (Combined derating factor) x ( Current from Indal Data Sheet)

=(k1 x k2 x k3 x k4) x ( Current from Indal Data Sheet)

1448.37

So,the busbar size choosen from Indal sheet shall be capable of

carrying

1448.37 A

CALCULATION OF ALUMINIUM BUS LINK for 1250/1600A

PARAMETERS

Feeder Rating

1250/1600

Size of Aluminium Bus Bar considered

4x76.2x6.35 mm2

i.e. Runs/Phase

4 mm

Width

76.2 mm

Thickness

6.35 mm

Current rating as per INDAL Aluminium ( E91)=0.97*EIE M

grade current

2620 A

Design Ambient Temperature

50 oC

Rise in Temperature allowed

40 oC

Final Temperature Permitted

Size of Bus Bar enclosure

i.e. Height

Depth

Fault current (for 1 sec)

Duration of Fault

Grade of Al. dropper

A.

90

175 x 800

175

800

50000

C

sq.mm

mm

mm

A

o

1 s

E91-E

MINIMUM CONDUCTOR SIZE

Formula

to determine the minimum size of conductor for any fault level:

t = (k/100) x ( Isc/A)2 x (1+ 20 . ) x t

( Ref: Industrial Power Engineering and Application Handbook, Page 865)

t= temperature rise above operating temp. in deg. C

100 oC

(190-90)oC

95 oC

(185-90)oC

Isc= symmetrical fault current in r.m.s in Amps.

A= cross sectional area of conductor in mm 2

20= temperature coefficient of resistence at 20 deg C/deg C

0.00403 for pure Aluminium

0.00363 for Aluminium alloy

0.00393 for pure copper

= operating temperature of the conductor at which the fault occurs

k=

1.166 for aluminium

0.52 for copper

t= duration of fault in seconds

Aluminium starts softening at a temperature of around 180-200 deg.As a rule of thumb for

Al conductor,on a fault a safe temperature rise of 100 deg above the allowable end temperature

of 90 deg of the conductor during normal condition has been considered & taken as the basis

to determine the minimum size of the conductor

Final temp. allowed for busbar after short circuit is 190 deg C

By putting all values in the above equation

100 = (1.166/100) ( 50000/A)2 (1+ 0.00363 x 90) x 1

A=

630.26 sq.mm

for pure Al.

621.88 sq.mm

for Al alloy

646.63 sq.mm

638.03 sq.mm

( final temp 190 i.e. 90+100)

( final temp 190 i.e. 90+100)

for pure Al.

for Al alloy

( final temp 185 i.e. 90+95)

( final temp 185 i.e. 90+95)

B.

THERMAL RATING

I.

DERATING FACTOR ON ACCOUNT OF HIGHER AMBIENT

TEMPERATURE

Design Ambient Temperature

50 oC

Rise in Temperature allowed

40 oC

Derating Factor k1 :

0.88

( Ref: Industrial Power Engineering and Application Handbook, Page 870,871)

II.

DERATING DUE TO ENCLOSURE

Cross sectional area of busbar

cross sectional area of enclosure

= No. of Phase x (Cross Section per Phase) x 100

cross sectional area of enclosure

= 580644

140000

As per table 5(enclosed) of INDAL paper on INDAL Al. Bus Bar,

the derating factor, k2 :

if ratio is less than 5%

0.75

4.1474571429

III. DERATING DUE TO PROXIMITY EFFECT

Busbar rating is lower than 1600A

So,the derating due to proximity effect will be , k3 :

( Ref: Industrial Power Engineering and Application Handbook, Page 887)

IV.

DERATING DUE TO BUSBAR MATERIAL

Grade :

Electrolytic gr. Al.(D50SWP)

Derating Factor , k4 :

V.

0.95

i.e. E91-E

( INDAL ALLOY)

TOTAL DERATING FACTOR

Total derating = derating due to ambient x derating due to enclosure x derating due

to proximity effect x derating due to busbar material

= k1 x k2 x k3 x k4

0.627

So, the cross section of dropper required for 630 A out going ACB shall cary 630A after

considering all derating factors = (Combined derating factor) x ( Current from Indal Data Sheet)

=(k1 x k2 x k3 x k4) x ( Current from Indal Data Sheet)

1642.74

So,the busbar size choosen from Indal sheet shall be capable of

carrying

1642.74 A

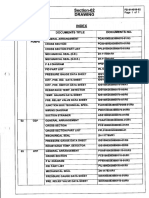

Operating temperature 90 deg C

Ambient temp

Permissible Bar temp rise

C

35

40

45

50

C

55

50

45

40

Derating Factor

1.05

1

0.945

0.88

55

60

35

30

0.815

0.75

Operating temperature 85 deg C

Ambient temp

Permissible Bar temp rise

C

30

35

40

45

50

55

C

55

50

45

40

35

30

Derating Factor

1.05

1

0.945

0.88

0.815

0.75

Derating Factor due to material

Electrolytic Grade i.e. E91-E

0.94

Derating Factor due to Proximity Effect

Busbar rating is lower than 1600A

0.95

Derating Factor due to enclosure

Enclosure

1.Outdoor

2.Indoor where the enclosure

itself is in a well ventillated

room

2.Indoor where the enclosure

itself is in a poorly ventillated

room & room temp is high

Ratio

<1%

5%

10%

Derating Factor

0.95

0.9

0.85

<1%

5%

10%

<1%

5%

0.85

0.75

0.65

0.65

0.6

10%

0.5

You might also like

- Panel Busbar Sizing Calculations - Thomas and RataDocument4 pagesPanel Busbar Sizing Calculations - Thomas and Ratakapil100% (12)

- Motion ReportDocument2 pagesMotion Reportmikeb-erau100% (2)

- BusBar Short Circuit CalculationDocument3 pagesBusBar Short Circuit Calculationbhaskarinvu79% (19)

- 3200A Busduct Busbar Calculation PDFDocument4 pages3200A Busduct Busbar Calculation PDFPramod B.Wankhade100% (7)

- 11kV CT CalculationDocument38 pages11kV CT Calculationjm.mankavil6230100% (9)

- Busbar Sizing For 50ka For 1 SecDocument1 pageBusbar Sizing For 50ka For 1 SecAnagha Deb100% (6)

- Bus Bar Design Calculations For Busduct MarsDocument8 pagesBus Bar Design Calculations For Busduct MarsKamesh1977No ratings yet

- Busbar Sizing CalculationDocument1 pageBusbar Sizing CalculationJanardhanan Palani100% (3)

- HT Cable Sizing CalculationDocument3 pagesHT Cable Sizing CalculationBalamurugan Arumugam100% (1)

- Fault level calculation using base MVA methodDocument2 pagesFault level calculation using base MVA methodTreesa Archnana100% (3)

- Bus Duct Calculations For 4000A Rated CurrentDocument4 pagesBus Duct Calculations For 4000A Rated CurrentGnanavel GNo ratings yet

- CT calculations for 33kV Switchgear for ADWEA contract no G1408Document31 pagesCT calculations for 33kV Switchgear for ADWEA contract no G1408jm.mankavil6230100% (2)

- Busbar Calculation For Current Carrying Capacity 1000 A With 50 X 12 CuDocument1 pageBusbar Calculation For Current Carrying Capacity 1000 A With 50 X 12 Cudipak_eee8291% (22)

- ECSDocument58 pagesECSPradeesh Vijayan (v.prathi)No ratings yet

- Usn LM2500 Asme Paper GT2010-22811 61410 JalDocument7 pagesUsn LM2500 Asme Paper GT2010-22811 61410 Jalferrerick0% (1)

- Lg938l - Operation & Maintenance ManualDocument114 pagesLg938l - Operation & Maintenance ManualMuhammad Nadim MakhlufNo ratings yet

- Parameters: Calculation For Al Bus Bar Suitable For 50ka Fault LevelDocument1 pageParameters: Calculation For Al Bus Bar Suitable For 50ka Fault Levelanand_girgaonkarNo ratings yet

- Bus Bar Sizing Calculation for 3200A Main PanelDocument9 pagesBus Bar Sizing Calculation for 3200A Main PanelsbpathiNo ratings yet

- MCC Bus Bar Sizing CalculationDocument12 pagesMCC Bus Bar Sizing Calculationerkamlakar223480% (5)

- Busbar Calulation For 2000a Copper BusbarsDocument3 pagesBusbar Calulation For 2000a Copper Busbarsbalaallied100% (5)

- Busbar CalculationDocument8 pagesBusbar Calculationdsilvasaucedo100% (4)

- Client: - M/ P C H P - L - ProjectDocument5 pagesClient: - M/ P C H P - L - Projectgirishprabhu19840% (1)

- 630A MCC BUSBAR SIZING CALCULATIONDocument42 pages630A MCC BUSBAR SIZING CALCULATIONAnonymous OKkHA0NzNo ratings yet

- Alumimium Bus Bar Calculation 4000ADocument5 pagesAlumimium Bus Bar Calculation 4000ATjsampathkumar Kumar67% (6)

- E7-60 SAND PLANT busbar sizing reportDocument4 pagesE7-60 SAND PLANT busbar sizing reportRahul Bhattacharyya100% (1)

- 17july10 WDC Busbar SizingDocument8 pages17july10 WDC Busbar Sizingtceterex100% (1)

- Busbar calculation for 1500kVA distribution feeder pillarDocument2 pagesBusbar calculation for 1500kVA distribution feeder pillarSAI0% (1)

- Aluminium Busbar Sizing Software OutputDocument3 pagesAluminium Busbar Sizing Software Outputkapil100% (4)

- Bus Bar SizingDocument16 pagesBus Bar Sizingusamaanfield100% (1)

- kV 5000A LT BUSDUCT CALCULATIONSDocument5 pageskV 5000A LT BUSDUCT CALCULATIONSNatarajan Ramakrishnan50% (2)

- Revised-13.8kV Cable Sizing Calc-Arar 03.03.2005Document10 pagesRevised-13.8kV Cable Sizing Calc-Arar 03.03.2005srigirisetty208No ratings yet

- DSLP CalculationDocument7 pagesDSLP Calculationravi shankar100% (1)

- Selection and Sizing of APFC PanelDocument21 pagesSelection and Sizing of APFC PanelpvpavanNo ratings yet

- MV Capacitor CalculationDocument1 pageMV Capacitor CalculationPramod B.WankhadeNo ratings yet

- Typical HT and LT Power Cable Sizing PDFDocument26 pagesTypical HT and LT Power Cable Sizing PDF1382ace100% (2)

- Bus Bar CalculationDocument20 pagesBus Bar CalculationAnirban Sen100% (2)

- Ieee 80 Tiuch and Step Volt - Full CalcDocument22 pagesIeee 80 Tiuch and Step Volt - Full CalcVasu Iyer100% (1)

- Busbar Sizing CalculationDocument13 pagesBusbar Sizing CalculationPower Solution100% (2)

- Panel Design and Calculate Bus Bar SizeDocument14 pagesPanel Design and Calculate Bus Bar SizeThirumal100% (1)

- Voltage Drop For 11KV CableDocument1 pageVoltage Drop For 11KV CableMohamed Anwar0% (1)

- MV CAPACITOR SIZING CALCULATION FOR KARAIKAL PORT PROJECTDocument3 pagesMV CAPACITOR SIZING CALCULATION FOR KARAIKAL PORT PROJECTRaja ShannmugamNo ratings yet

- CT & PT Calculations-480V Swgr-ArarDocument9 pagesCT & PT Calculations-480V Swgr-Ararsrigirisetty208No ratings yet

- Transformer Sizing CalculationDocument2 pagesTransformer Sizing CalculationAvishek Chowdhury100% (2)

- Calculate Bus Bar SizeDocument22 pagesCalculate Bus Bar Sizevjvijay88No ratings yet

- Bus Cal - 2500aDocument11 pagesBus Cal - 2500aPCE PROJECTS PVT. LTD.No ratings yet

- Below Ground & Above Ground Earthing CalculationDocument8 pagesBelow Ground & Above Ground Earthing CalculationPramod B.Wankhade0% (1)

- Design of Grade SlabDocument7 pagesDesign of Grade SlabMUTHUKKUMARAM100% (1)

- Technical Data Sheet for Isolated Phase BusductDocument7 pagesTechnical Data Sheet for Isolated Phase Busductsuleman247No ratings yet

- 33KV Earthmat 1designDocument204 pages33KV Earthmat 1designVelavan AnnamalaiNo ratings yet

- Station Grounding CalculationDocument7 pagesStation Grounding CalculationhamgaiNo ratings yet

- MR758Document7 pagesMR758Bruno NascimentoNo ratings yet

- Bus BarsDocument36 pagesBus Barstceterex100% (1)

- Air Conditioning Calculation - R0Document28 pagesAir Conditioning Calculation - R0harikrishnanpd3327No ratings yet

- 33KV Earthmat 1designDocument176 pages33KV Earthmat 1designVelavan AnnamalaiNo ratings yet

- Design Procedure Block Diagram Earthing CalculationDocument17 pagesDesign Procedure Block Diagram Earthing CalculationMauricio Cesar Molina ArtetaNo ratings yet

- Miter B1 ADocument55 pagesMiter B1 AFarid TataNo ratings yet

- Calculating cable sizes, fault currents and power factor correctionDocument12 pagesCalculating cable sizes, fault currents and power factor correctionVs PkdNo ratings yet

- Earthing Calculations for 110KV SwitchyardDocument8 pagesEarthing Calculations for 110KV SwitchyardGarmangh GersNo ratings yet

- Earthing Design Calculation: Project: Document No. DateDocument9 pagesEarthing Design Calculation: Project: Document No. Dateboopathy1705100% (1)

- Everything You Need to Know About High Speed Square Body FusesDocument73 pagesEverything You Need to Know About High Speed Square Body FusescocacolapepsiNo ratings yet

- Design Cal IndoramaDocument13 pagesDesign Cal IndoramaKUNALJAYNo ratings yet

- Voltage Drop CalculationDocument4 pagesVoltage Drop CalculationSreekanth RaveendranNo ratings yet

- Fatigue of Materials Solved Problems UnlockedDocument20 pagesFatigue of Materials Solved Problems UnlockedMAT-LIONNo ratings yet

- NB O&M Brochure 01sept2020Document10 pagesNB O&M Brochure 01sept2020srigirisetty208No ratings yet

- 5C1. Coal Ash Generation Process and Application FieldsDocument2 pages5C1. Coal Ash Generation Process and Application Fieldssrigirisetty208No ratings yet

- 330MW Shrinagar Project Technical Data SheetDocument4 pages330MW Shrinagar Project Technical Data Sheetsrigirisetty208No ratings yet

- 4.11 - Bypass Channel - Automatic GateDocument1 page4.11 - Bypass Channel - Automatic Gatesrigirisetty208No ratings yet

- Boiler Tube Failures Due To Improper CommissioningDocument21 pagesBoiler Tube Failures Due To Improper CommissioningDhandapani ManoharanNo ratings yet

- 330MW Shrinagar Hydroelectric Project Penstock Intake DataDocument2 pages330MW Shrinagar Hydroelectric Project Penstock Intake Datasrigirisetty208No ratings yet

- Care and Maintenance of CFB Boilers Refractory FailureDocument6 pagesCare and Maintenance of CFB Boilers Refractory FailureAnonymous a19X9GHZNo ratings yet

- Arar 33kV Cable Sizing ReportDocument9 pagesArar 33kV Cable Sizing Reportsrigirisetty208No ratings yet

- Fire Detection and Alarm System Design Basis DocumentDocument12 pagesFire Detection and Alarm System Design Basis Documentsrigirisetty208No ratings yet

- 4.19 - Instrumentation and ControlDocument2 pages4.19 - Instrumentation and Controlsrigirisetty208No ratings yet

- 330MW Shrinagar Project Technical Data SheetDocument4 pages330MW Shrinagar Project Technical Data Sheetsrigirisetty208No ratings yet

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistDocument3 pages4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208No ratings yet

- 4.2 - Dam and Spillway - Radial Gates and Hydraulic HoistDocument3 pages4.2 - Dam and Spillway - Radial Gates and Hydraulic Hoistsrigirisetty208No ratings yet

- 4.13 - Penstock Intake - Trashrack and Cleaning MachineDocument2 pages4.13 - Penstock Intake - Trashrack and Cleaning Machinesrigirisetty208No ratings yet

- HZL Ahs EssentialsparesDocument8 pagesHZL Ahs Essentialsparessrigirisetty208No ratings yet

- 4.5 - Dam and Spillway - ElevatorDocument2 pages4.5 - Dam and Spillway - Elevatorsrigirisetty208No ratings yet

- HZL Chs EssentialsparesDocument6 pagesHZL Chs Essentialsparessrigirisetty208No ratings yet

- 4.17 - Powerhouse - Powerhouse CraneDocument3 pages4.17 - Powerhouse - Powerhouse Cranesrigirisetty208No ratings yet

- HZL Crane EssentialsparesDocument2 pagesHZL Crane Essentialsparessrigirisetty208No ratings yet

- SCH 3A.17 Q.a.assessmentDocument1 pageSCH 3A.17 Q.a.assessmentsrigirisetty208No ratings yet

- Quality Assurance Plan for 2x150 MW Coal Power PlantDocument1 pageQuality Assurance Plan for 2x150 MW Coal Power Plantsrigirisetty208No ratings yet

- 150 MW Coal Fired Power Plant Construction Equipment ListDocument2 pages150 MW Coal Fired Power Plant Construction Equipment Listsrigirisetty208No ratings yet

- SCH 3A.12 Special Tools &tacklesDocument3 pagesSCH 3A.12 Special Tools &tacklessrigirisetty208No ratings yet

- SCH 3A.9 Places of Mfg.Document1 pageSCH 3A.9 Places of Mfg.srigirisetty208No ratings yet

- BFP Drawings PDFDocument42 pagesBFP Drawings PDFsrigirisetty208No ratings yet

- Guaranteed DataDocument2 pagesGuaranteed Datasrigirisetty208No ratings yet

- SCH 3A.11 SparesDocument3 pagesSCH 3A.11 Sparessrigirisetty208No ratings yet

- Sch-3A 14-Perfor GuartDocument5 pagesSch-3A 14-Perfor Guartsrigirisetty208No ratings yet

- BFP DrawingsDocument42 pagesBFP Drawingssrigirisetty208No ratings yet

- Equipment Supply by BidderDocument6 pagesEquipment Supply by Biddersrigirisetty208100% (2)

- 3.17. Creep EquationsDocument10 pages3.17. Creep Equationsruchit solankiNo ratings yet

- Control Fixed Bed ReactorsDocument4 pagesControl Fixed Bed ReactorsAddison JuttieNo ratings yet

- Crompton Greaves LimitedDocument3 pagesCrompton Greaves LimitedNitish SinghNo ratings yet

- Nichrome60 Wire Data SheetDocument2 pagesNichrome60 Wire Data SheetvvingtsabtaNo ratings yet

- CFS50 motor feedback installation instructionsDocument1 pageCFS50 motor feedback installation instructionsJavier AlzateNo ratings yet

- Guidelines For Planning Childcare Centers & Playground DesignDocument15 pagesGuidelines For Planning Childcare Centers & Playground Design105auco100% (1)

- Service Menu - SamyGODocument5 pagesService Menu - SamyGOVenkatesh SubramanyaNo ratings yet

- Michelson Interferometer Na Lamp-1Document11 pagesMichelson Interferometer Na Lamp-1SOHINI KAYALNo ratings yet

- Strength of Pressure Vessels With Ellipsoidal HeadsDocument8 pagesStrength of Pressure Vessels With Ellipsoidal Headsنصرالدين ادريسNo ratings yet

- Lesson 7: Cylinders: Basic Hydraulic SystemsDocument12 pagesLesson 7: Cylinders: Basic Hydraulic Systemsoscar el carevergaNo ratings yet

- 2009 Energy Storage-U.S. Department of EnergyDocument380 pages2009 Energy Storage-U.S. Department of EnergydiwhiteNo ratings yet

- XZX ZX ZXDocument4 pagesXZX ZX ZXWong VoonyeeNo ratings yet

- Deventer04 MACDocument201 pagesDeventer04 MACFrancisco Solano Reyes EspinozaNo ratings yet

- RCC BEAM DESIGN AND SERVICEABILITYDocument15 pagesRCC BEAM DESIGN AND SERVICEABILITYprashmceNo ratings yet

- CAD1 AssignmentDocument11 pagesCAD1 AssignmentJohn2jNo ratings yet

- P1 Conservation and Dissipation of Energy Student Book AnswersDocument11 pagesP1 Conservation and Dissipation of Energy Student Book AnswersjoeNo ratings yet

- Microsoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbaDocument14 pagesMicrosoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbashubhamformeNo ratings yet

- EZ-THUMP™ Series: Portable Fault Location SystemsDocument2 pagesEZ-THUMP™ Series: Portable Fault Location Systemsriyad abdulhafeedNo ratings yet

- Classification of FluidDocument29 pagesClassification of FluidAbdur RehmanNo ratings yet

- Product Design Recommended Reading ListDocument3 pagesProduct Design Recommended Reading ListSai Prasath100% (1)

- Smart Access 1105Document12 pagesSmart Access 1105Gerson Freire De Amorim FilhoNo ratings yet

- For Steel Cage Lapping by Using U-ClipDocument4 pagesFor Steel Cage Lapping by Using U-Cliptin aungtunNo ratings yet

- Advanced Data Structures and ImplementationDocument56 pagesAdvanced Data Structures and ImplementationSyam Prasad Reddy BattulaNo ratings yet

- Modeling of The Effective Thermal Conductivity and Diffusivity of A Packed Bed With Stagnant FluidDocument9 pagesModeling of The Effective Thermal Conductivity and Diffusivity of A Packed Bed With Stagnant Fluidbasura12345No ratings yet

- NIKI V4 Infusion Pump Service ManualDocument54 pagesNIKI V4 Infusion Pump Service ManualIgor Simonelli BermudesNo ratings yet

- BPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDocument1 pageBPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDeepak DayalNo ratings yet

- Application of PLC and SCADA in Auto-Control Systems For Silo Grain HandlingDocument4 pagesApplication of PLC and SCADA in Auto-Control Systems For Silo Grain Handlingshahid_scribdNo ratings yet