Professional Documents

Culture Documents

Applied Thermodynamics (Turbine)

Uploaded by

haqjmi0 ratings0% found this document useful (0 votes)

6 views9 pagesApplied Thermodynamics(Turbine)

Original Title

Applied Thermodynamics(Turbine)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentApplied Thermodynamics(Turbine)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views9 pagesApplied Thermodynamics (Turbine)

Uploaded by

haqjmiApplied Thermodynamics(Turbine)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

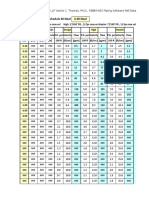

Ody Sinn ow ate

ie

L

|

idee UC alge Na ee eect

* Oho a Spee Wc pa ghs o

see 1 Pov %

pvt wile a uy he

WSO m~]s ate a hivectim WHI Cate

on Mh 16° & fe emir Velowts. SIR

Gomes eal (We mous ue WK an absoeier

ua

: v Cin Nelo b

ee pe ee

a

Yo

Deve vp. Wer Came Sb

a Veber ky 4, Sou wy anda (ie

Day cee bed, a

Vehor kg 4 loo “ys mM Bhiveetin, oe Wo? uate

Hive q Bled node. Dae bla, ave

Se nine UE Power ark Powe Gt Bak Belin

Bess Pover = 429-34 Gw Bovty

Dh mene chime? of UE blk ons 2 eee

Wheel y (oS an anh wb Spee ao “4 Sega

*h VOQtren 4

Come mut eg (er 8 pe. wile

2 “be og & 20%

av *

_ - arch UE bog

So's Conttictone 3 Uo ge Bebe Me

o Rower apd dy he

Ww

&3

ee re 4, We vo | Ym. Wn Sead waety b OF

be

A RN Tree When,

FAER gh & (So ay Ww “Oo

Avr Pree 2 YotroSten ye 767 7

Pave Gees > SPS lew -

Ab a Shope weecGin evkinn WW mean bees

Delteune LE blue. cat ange mH fe be i a

ta ogy —

h Lo’. Ms, weir Spek & Sev pm. Aes pe

Rag WK pereen Ge promene Lepraw

Sey OK ter Spent Wee te 5 sig

be

wun at VE loos Wow eek Speed, thd oni y

Vee ete Ye DL 5 7 cenit dre

a An oY

Reaction Turbine

A reaction turbine, therefore, is one that is constructed of rows of fixed and rows of

moving blades. The fixed blades act as nozzles. The moving blades move as a result of,

the impulse of steam received (caused by change in momentum) and also as a result of

expansion and acceleration of the steam relative to them. In other words, they also act

as nozzles. The enthalpy drop per stage of one row fixed and one row moving blades is

divided among them, often equally. Thus a blade with a 50 percent degree of reaction,

or a 50 percent reaction stage, is one in which half the enthalpy drop of the stage occurs

in the fixed blades and half in the moving blades. The pressure drops will not be equal,

however. They are greater for the fixed blades and greater for the high-pressure than

the low-pressure stages.

The moving blades of a reaction turbine are easily distinguishable from those of an

impulse turbine in that they are not symmetrical and, because they act partly as nozzles,

have a shape similar to that of the fixed blades, although curved in the opposite

direction. The schematic pressure line (Fig. 24.2) shows that pressure continuously

drops through all rows of blades, fixed and moving. The absolute steam velocity

changes within each stage as shown and repeats from stage to stage. Figure 24.3

shows a typical velocity diagram for the reaction stage.

PRESSURE

ING VELOCITY

is

|e-sack PRESSURE

Figure 24.2 Three stages of reaction turbine indicating pressure and velocity

distribution

Pressure and enthalpy drop both in the fixed blade or stator and in the moving blade

or Rotor

Enthaipy drop in Rotor

Degree of Reaction = 2#thaly drop in Stage

Arin

R

(24.3)

7 Ty hy (24.3)

Avery widely used design has half degree of reaction or 50% reaction and this is known

as Parson's Turbine. This consists of symmetrical stator and rotor blades.

Flxed Blade

Figure 24.3 The velocity diagram of reaction blading

The velocity triangles are symmetrical and we have

Cpa) Olga

Ha. YnaVa

Energy input per stage (unit mass flow per second)

vA

2

a (24.4)

2

2

woos

2 =

B= (i -U? + 2HU cosem)/2 (24.5)

From the inlet velocity triangle we have,

2a

v2 -U? - 2% cosa

Work done (for unit mass flow per second) ~ 7 = Une

= U(QH cosy -U)

Therefore, the Blade efficiency

2K; cose -U)

=e

i —U? + WU cosy

Reaction Turbine,

®

Put

Qp(2eosey - P)

We =>

=p? + 2pcosey

dt 26

For the maximum efficiency 4° and we get

(1p? + 2pcosay) (4cos cy ~ 49}

= 2p(2o0s ay =p}(-2p+ 2cosexy) =O

from which finally it yields

U

vw-(t)

(24.6)

(24.7)

(25.1)

(25.2)

(25.3)

Figure 25.1 Velocity diagram for maximum efficiency

Absolute velocity of the outlet at this stage is axial (see figure 25.1). In this case, the

energy transfer

E =U y =U (25.4)

‘Me Imarimum can be found out by putting the value of P= °° in the expression for

blade efficiency

(25.5)

(Mp dimgratse = 0087 C4 (25.6)

js greater in reaction turbine. Energy input per stage is less, so there are more

number of stages.

Stage Effici

ncy and Reheat factor

The Thermodynamic effect on the turbine efficiency can be best understood by

considering a number of stages between two stages 1 and 2 as shown in Figure 25.2

Enthalpy

Entropy »

Figure 25.2 Different stage of a steam turbine

‘The total expansion is divided into four stages of the same efficiency "'s) and pressure

ratio.

Ra Se

pase tes (25.7)

RR RF d

‘The overall efficiency of expansion is ‘lo. The actual work during the expansion from 1 to

2is

Wa=1¥

_ Wa _actuél enthalpy drop (1-2)

No = (2:

o W isontrepie heat rop (1-2) ee)

Curnulative enthalpy drop (isentropic)

Reheat factor (R.)= He*ireple enthalpy drop Coverall)

+ Akg + Bly, + Aft

a Fee lee Pe (25.9)

Aa

REF is 1.03 to 1.04

ifs remains same for all the-stages or "s is the mean stage efficiency.

Alyy _ Sly _ Altys

Ea eae 28

bee cara nie (25.10)

Alyy + My + Altyg + Bh

MS = Rha FAs + Mpg + Dep (25.11)

on, 1A Blige + Mize + MteD

actual enthalpy drop

Stamalative enthalpy drop (seniropi

We can see:

ng = 15 XRF (25.12)

This makes the overall efficiency of the turbine greater than the individual stage

efficiency.

The effect depicted by Eqn (25.12) is due to the thermodynamic effect called "reheat’

This does not imply any heat transfer to the stages from outside. It is merely the

reappearance of stage losses an increased enthalpy during the constant pressure

heating (or reheating) processes AX, BY, CZ and D2.

Exercise Problems (for Steam Turbines)

Q1, The adiabatic enthalpy drop in a given stage of a multi-stage impulse turbine is 22.1

KJikg of steam. The nozzle outlet angle is '®°> and the efficiency of the nozzle, defined

as the ratio of the actual gain of kinetic energy in the nozzle to adiabatic heat drop, is

92%. The mean diameter of the blades is 1473.2 mm and the revolution per minutes is

1500, Given that the carry over factor ° is 0.88, and that the blades are equiangular (the

blade velocity coefficient is 0.87). Calculate the steam velocity at the outlet from nozzles,

blade angles, and gross stage efficiency.

Q2. The following particulars relate to a two row velocity compounded impulse wheel

which forms a first stage of a combination turbine.

Steam velocity at nozzle outlet = §79.12m/s

Mean blade velocity = 115.82m/s

Nozzle outlet angle = 16°

Outlet angle first row of moving blades = 12”

Outlet angle fixed guide blades = 22°

Outlet angle, second row of moving blades = 36°

‘Steam flow rate = 2.4 kg/s

‘The ratio of the relative velocity at outlet to that at inlet is °-84 for all blades. Determine

for each row of moving blades the following

+ The velocity of whirl

+ The tangential thrust on blades

+ The axial thrust on the blades

+ The power developed

What is the efficiency of the wheel as a whole?

Q3. A velocity compounded impulse wheel has two rows of moving blades with a mean

diameter of 714.2 ram. The speed of rotation is 3000rpm, the nozzle angle is 16° and

the estimated steam velocity at the nozzle outlet is 554.73m/s. The mass flow rate of the

steam passing through the blades is 5.07 kg/s.

Assuming that the energy loss in each row of blades (moving and fixed) is 24% of the

kinetic energy of the steam entering the blades and referred to as the relative velocity,

and that the outlet angles of the blades are:

(1) first row of moving blades 18°,

(2) intermediate guide blade 22°,

2

(3) second row of moving blades is 38” | draw the diagram of relative velocities and

derive the following

+ Blade inlet angles,

+ Power developed in each row of blades

+ Efficiency of the wheel as a whole

Q4. The following particulars refer to a stage of an impulse-reaction turbine.

Outlet angle of fixed blades = 20°

Outlet angle of moving blades = 20°

Radial height of fixed blades =100mm

Radial height of moving blades =100mm

Mean blade velocity = 138m/s

Ratio of blade speed to steam speed = 0.625

3

Specific volume of steam at fixed blade outlet =1.235 " /E

31 by

Specific volume of steam at moving blade outlet =1.305 "7 /#z

Calculation the degree of reaction, the adiabatic heat drop in pair of blade rings, and the

gross stage efficiency, given the following coefficients which may be assumed to be the

same in Both fixed and moving blades : "im = 09, =0:86

Q5. Steam flows into the nozzles of a turbine stage from the blades of preceding stage

with a velocity of 100m/s and issues from the nozzles with a velocity of 325 m/s at angle

‘of 20° to the wheel plane. Calculate the gross stage efficiency for the following data:

Mean blade velocity=180m/s

Expansion efficiency for nozzles and blades = 0.9

Carry over factor for nozzles and blades = 0.9

Degree of reaction = 0.26

Blade outlet angle = 28°

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Wall Thickness Calculation-2Document1 pageWall Thickness Calculation-2haqjmiNo ratings yet

- Pipe Sizing Data.Document50 pagesPipe Sizing Data.haqjmiNo ratings yet

- Em - 1110 2 3006 PDFDocument118 pagesEm - 1110 2 3006 PDFhaqjmiNo ratings yet

- Resume DataDocument1 pageResume DatahaqjmiNo ratings yet

- Technical Specifications - Cable LayingDocument48 pagesTechnical Specifications - Cable LayingShkelzen GoxhajNo ratings yet

- Call Out FormatDocument10 pagesCall Out FormathaqjmiNo ratings yet

- Country - CurrencyDocument1 pageCountry - CurrencyhaqjmiNo ratings yet

- Introduction To SolidWorksDocument235 pagesIntroduction To SolidWorksMario Castro-Cedeno93% (30)

- Piping SpecificationDocument2,163 pagesPiping Specificationhaqjmi0% (1)

- SmartPlant InstructionsDocument5 pagesSmartPlant InstructionsrolwinNo ratings yet

- Job Application Form: Page 1 of 3 Staff-In-ConfidenceDocument3 pagesJob Application Form: Page 1 of 3 Staff-In-Confidencehaqjmi100% (1)

- Piping DataDocument365 pagesPiping Datahaqjmi100% (1)

- AXENMS0045Document72 pagesAXENMS0045shareyhouNo ratings yet

- SP3D Shortcut KeysDocument4 pagesSP3D Shortcut KeysManish SharmaNo ratings yet

- Erection Testing and CommissioningDocument70 pagesErection Testing and CommissioninghaqjmiNo ratings yet

- SP3D Shortcut KeysDocument13 pagesSP3D Shortcut Keyshaqjmi0% (1)

- Chapter 9 - Forced ConvectionDocument98 pagesChapter 9 - Forced ConvectionhaqjmiNo ratings yet

- sp3d Spec20Document20 pagessp3d Spec20haqjmi100% (1)

- Troughed - Design Guidelines and StandardsDocument6 pagesTroughed - Design Guidelines and StandardshaqjmiNo ratings yet

- Chapter 13 RadiationDocument78 pagesChapter 13 RadiationhaqjmiNo ratings yet

- SP3D Drawings Training ExercisesDocument135 pagesSP3D Drawings Training Exercisessamueloluwaseyi68No ratings yet

- Design of SwitchyardDocument107 pagesDesign of SwitchyardPritamNo ratings yet

- 3.1 Selection of Turbine and Governing System PDFDocument72 pages3.1 Selection of Turbine and Governing System PDFtanujaayer100% (1)

- Troughed - Design Guidelines and StandardsDocument6 pagesTroughed - Design Guidelines and StandardshaqjmiNo ratings yet

- Mechanical Engineer Cover LetterDocument0 pagesMechanical Engineer Cover Lettersalic2013No ratings yet

- Erection Testing and CommissioningDocument70 pagesErection Testing and CommissioninghaqjmiNo ratings yet

- Belt Conveyor DesignDocument11 pagesBelt Conveyor Designhaqjmi50% (2)

- How To Install SmartPlant 3D (Step-By-step Guide)Document3 pagesHow To Install SmartPlant 3D (Step-By-step Guide)haqjmiNo ratings yet

- Power Electronics TextDocument460 pagesPower Electronics TextSindhu BijjalNo ratings yet

- Mechanical Engg ProjectDocument45 pagesMechanical Engg ProjecthaqjmiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)