Professional Documents

Culture Documents

2 Piles Cap Design bs8110

Uploaded by

Faizal ImranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 Piles Cap Design bs8110

Uploaded by

Faizal ImranCopyright:

Available Formats

Project

Job no.

Calcs for

Start page no./Revision

1

Calcs by

Calcs date

Checked by

Checked date

Approved by

Approved date

13/5/2015

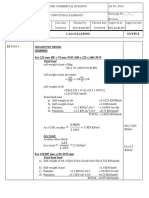

RC PILE CAP DESIGN (BS8110:PART1:1997)

TEDDS calculation version 2.0.07

Loaded width - x

2 Pile Cap, height h

s

e

ex

b

P1

P2

L

Pile Cap Design Truss Method

Design Input - 2 Piles - With Eccentricity

Number of piles;

N=2

ULS axial load;

Fuls = 361.0 kN

Characteristic axial load;

Fchar = 246.0 kN

Pile diameter;

= 150 mm

Pile spacing;

s = 450 mm

Eccentricity from centroid of pile cap;

ex = 75 mm

The characteristic load in pile, 1 is;

Fchar_pile_1 = Fchar (s/2 - ex)/s = 82.0 kN

The characteristic load in pile, 2 is;

Fchar_pile_2 = Fchar (s/2 + ex)/s = 164.0 kN

Pile cap overhang ;

e = 200 mm

Overall length of pile cap;

L = s + + 2 e = 1000 mm

Overall width of pile cap;

b = + 2 e = 550 mm

Overall height of pile cap;

h = 800 mm

Dimension of loaded area;

x = 300 mm; (parallel to pile cap)

Cover

Concrete grade;

fcu = 25.0 N/mm2

Nominal cover;

cnom = 50 mm

Tension bar diameter;

Dt = 16 mm

Link bar diameter;

Ldia = 12 mm

Depth to tension steel;

d = h cnom - Ldia - Dt/2 = 730 mm

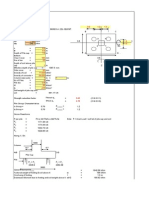

Pile Cap Forces

Maximum compression within pile cap;

Fc = max(Fc1, Fc2) = 245.7 kN

Maximum tension within pile cap;

Ft = max(Ft1, Ft2) = 49.5 kN

Tension In One Truss Member

Characteristic strength of reinforcement;

fy = 460 N/mm2

Partial safety factor for strength of steel;

ms = 1.15

Required area of reinforcement;

As_req = Ft /(1/ms fy) =124 mm2

Provided area of reinforcement;

As_prov = Ast = 804 mm2

Project

Job no.

Calcs for

Start page no./Revision

2

Calcs by

Calcs date

Checked by

Checked date

Approved by

Approved date

13/5/2015

Pt = (1/ms fy) As_prov = 321.7 kN

Tension in truss member;

PASS Tension

Cl. 3.11.4.2

Max / Min Areas Of Reinforcement

Minimum area of tension steel;

Ast_min = kt Ac = 572 mm2

Maximum area of tension steel;

Ast_max = 4 % Ac = 17600 mm2

Area of tension steel provided OK

Cl. 3.12.6 & Table 3.25

Shear

Applied shear stress

Shear force pile 1;

V1 = Fuls_pile_1 = 120.3 kN

Shear force pile 2;

V2 = Fuls_pile_2 = 240.7 kN

Width of pile cap shear plane;

bv = min( b, 3 ) = 450 mm

Shear stress pile 1;

v1 = V1/(bv d) = 0.37 N/mm2

Shear stress pile 2;

v2 = V2/(bv d) = 0.73 N/mm2

Allowable shear stress;

vallowable = min ((0.8 N1/2/mm) (fcu ), 5 N/mm2 ) = 4.00 N/mm2

Shear stress - OK

Cl. 3.4.5.2

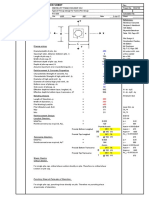

Design concrete shear strength

Determine concrete shear strengths on the sections at distance / 5 inside face of each pile:

Cl. 3.11.4.3 & fig. 3.23

Shear stress - BS8110-1:1997 Table 3.8;

vc_25 = 0.79 r1/3 max(0.67, (400 mm/d)1/4) 1.0 N/mm2 / 1.25 = 0.34 N/mm2

Enhanced shear stress - Cl. 3.4.5.8 & fig. 3.5;

vc = vc_25 ( min(fcu, 40 N/mm2 )/25 N/mm2 )1/3 = 0.34 N/mm2

av_1 = min(2 d, max(s/2 + ex - /2 + /5- x/2, 0.1 mm)) = 105 mm

av_2 = min(2 d, max(s/2 - ex - /2 + /5- x/2, 0.1 mm)) = 0 mm

Concrete shear strength - Case 1;

vc_enh_1 = min( vallowable , 2 d vc / av_1 ) = 4.00 N/mm2

Concrete shear strength - Case 2;

vc_enh_2 = min( vallowable , 2 d vc / av_2 ) = 4.00 N/mm2

Concrete shear strength - OK, no links reqd. for case 1

Concrete shear strength - OK, no links reqd. for case 2

Table 3.16

Note: If no links are provided, the bond strengths for PLAIN bars must be used in calculations for anchorage and lap

lengths.

Cl. 3.12.8.3

Clear Distance Between Bars In Tension (Cl 3.12.11.2.4)

Bar spacing;

spacingbars = max( 0mm, (b- 2 (cadopt + Ldia) - Dt)/(Lnt - 1) - Dt) = 121 mm

Maximum allowable spacing;

spacingmax = min((47000 N/mm)/fs, 300 mm) = 300 mm

Minimum allowable spacing;

spacingmin = hagg + 5 mm = 25 mm

Bar spacing OK

Clear Distance Between Face Of Beam And Tension Bars (Cl 3.12.11.2.5)

Distance to face of beam;

Distedge = cadopt + Ldia + Dt/2 = 70 mm

Design service stress in reinforcement;

fs = 2 fy As_req /(3 As_prov b) = 47.1 N/mm2

Max allowable clear spacing;

Spacingmax = min((47000 N/mm)/fs, 300 mm) = 300 mm

Max distance to face of beam;

Distmax = Spacingmax /2 = 150 mm

Max distance to beam edge check - OK

Project

Job no.

Calcs for

Start page no./Revision

3

Calcs by

Calcs date

Checked by

Checked date

Approved by

Approved date

13/5/2015

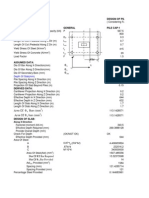

Anchorage Of Tension Steel

Anchorage factor;

factor =44

Type of lap length;

lap_type ="tens_lap"

Type of reinforcement;

reft_type = "def2_fy500"

Minimum radius;

rbar = 32 mm

Minimum end projection;

Pbar = 130 mm

Minimum anchorage length or lap length reqd;

Ltable 3.27 = factor Dt = 704 mm

Check anchorage length to cl. 3.12.9.4 (b);

Lcl. 3.12.9.4 = 12 Dt + d/2 = 557 mm

Required minimum effective anchorage length;

La = max(Ltable 3.27, Lcl. 3.12.9.4) = 704 mm

Deflection Check (Cl 3.4.6)

Redistribution ratio;

b = 1.0

Design service stress in tension reinforcement;

fs = 2 fy As_req /(3 As_prov b) = 47.1 N/mm2

Modification for tension reinforcement;

factortens = min( 2, 0.55 + (477 N/mm2 - fs)/(120 (0.9 N/mm2 + Ft /(bd )))) = 2.000

Modified span to depth ratio;

modfspan_depth = factortens basicspan_depth = 40.0

Span of pile cap for deflection check;

Ls = 1000 mm

Actual span to depth ratio;

actualspan_depth = Ls /d = 1.37

PASS - Deflection

You might also like

- Design of Concrete Stump With Axial Load and Minimum MomentDocument4 pagesDesign of Concrete Stump With Axial Load and Minimum MomentIbrahim A.L100% (1)

- Design of Sleeper Pedestal Reinforcement in CulvertDocument2 pagesDesign of Sleeper Pedestal Reinforcement in Culvertmunishant10% (1)

- RC Beam Design To EC2Document3 pagesRC Beam Design To EC2suman_civilNo ratings yet

- Column Wall DesignDocument42 pagesColumn Wall DesignCivilax.comNo ratings yet

- Hollow Pot Design WorksheetDocument7 pagesHollow Pot Design Worksheetpatrick chegeNo ratings yet

- RC Beam Design Calculation SheetDocument3 pagesRC Beam Design Calculation Sheetikanyu79100% (1)

- Crack Width CalculationDocument8 pagesCrack Width CalculationSM ConsultantsNo ratings yet

- Job Pile Design-450 (R1)Document3 pagesJob Pile Design-450 (R1)Kyle Foreman100% (1)

- Design of Pile CapDocument120 pagesDesign of Pile Capcivilaskar100% (3)

- Pile Cap For 4 PilesDocument4 pagesPile Cap For 4 Pileshemantkle2u100% (2)

- RC Beam Design (BS8110)Document2 pagesRC Beam Design (BS8110)Parthiban ArivazhaganNo ratings yet

- Hilti Rebar Calculation PDFDocument5 pagesHilti Rebar Calculation PDFEn JoyNo ratings yet

- Manual Beam DesignDocument14 pagesManual Beam DesignRonald Kaaku50% (2)

- Wall DesignDocument13 pagesWall DesignAnantPawarNo ratings yet

- Staad Pro DFF, DJ1 and DJ2Document10 pagesStaad Pro DFF, DJ1 and DJ2syed AffanNo ratings yet

- Surcharge CalculatorDocument7 pagesSurcharge CalculatorJunnoKaiserNo ratings yet

- Base Slab Design - RampDocument6 pagesBase Slab Design - RampSuresh Mahalingam100% (1)

- Design of Parapet Wall up to 3.45m CushionDocument5 pagesDesign of Parapet Wall up to 3.45m Cushionsrikanth2vangaraNo ratings yet

- Reference Calculations Output: N/A Project CalculationDocument2 pagesReference Calculations Output: N/A Project CalculationRyan De LeonNo ratings yet

- Strip Footing 3 Columns Bsi 8110 - 2Document11 pagesStrip Footing 3 Columns Bsi 8110 - 2Magdy Bakry100% (2)

- Moment Connection Beam Column Is Bs Section For Is800Document27 pagesMoment Connection Beam Column Is Bs Section For Is800Ramesh SelvarajNo ratings yet

- Pile CAP Design Example + 2 PilesDocument3 pagesPile CAP Design Example + 2 PilesTharanga Pradeep100% (1)

- Ground Anchor DesignDocument4 pagesGround Anchor DesignVardhanNo ratings yet

- Sachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Document5 pagesSachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Costas SachpazisNo ratings yet

- Raft Foundation DesignDocument6 pagesRaft Foundation DesignstructuralengNo ratings yet

- Timber Roof Beam 1Document4 pagesTimber Roof Beam 1John SmithNo ratings yet

- Pile Cap DesignDocument35 pagesPile Cap Designعصام السامرائي100% (2)

- Pile Cap DesignDocument5 pagesPile Cap Designসন্দীপ চন্দ্র100% (1)

- Calculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLDocument3 pagesCalculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLV.m. RajanNo ratings yet

- Pedestal DesignDocument18 pagesPedestal DesignAnand.5No ratings yet

- Pad Footing Analysis & Design (BS8110)Document6 pagesPad Footing Analysis & Design (BS8110)Maqsood100% (1)

- Anchored Sheet Pile WallDocument10 pagesAnchored Sheet Pile Wall12151973No ratings yet

- 2 - FLDS 385 Chapter 2 Principles of HydraulicsDocument47 pages2 - FLDS 385 Chapter 2 Principles of HydraulicsAvneet MultaniNo ratings yet

- Design For Torsion (Beams BS 8110)Document3 pagesDesign For Torsion (Beams BS 8110)dhanya1995100% (1)

- Design of Pad & Chimney FoundationDocument26 pagesDesign of Pad & Chimney FoundationTulsi LakhaniNo ratings yet

- Pile Cap Design - ColumnsDocument6 pagesPile Cap Design - ColumnsSadatcharaMoorthi N100% (1)

- RIV ACI 2-Pile CapDocument12 pagesRIV ACI 2-Pile CapMitra RampersadNo ratings yet

- EC2 Continuous Beam DesignDocument14 pagesEC2 Continuous Beam Designikanyu79No ratings yet

- Crack Width CheckDocument2 pagesCrack Width CheckJitendra SinghNo ratings yet

- RC CURVED BEAM DESIGN WITH UNIFORM AND POINT LOADSDocument8 pagesRC CURVED BEAM DESIGN WITH UNIFORM AND POINT LOADSkeat_leong_yeeNo ratings yet

- Column Design Calculation PDFDocument2 pagesColumn Design Calculation PDFSamantha0% (1)

- Column to Girder Connection CalculationDocument15 pagesColumn to Girder Connection CalculationNitesh SinghNo ratings yet

- Pile Cap Design Calculations With CSI SAFEDocument7 pagesPile Cap Design Calculations With CSI SAFEMiguel J.No ratings yet

- Crack WidthDocument5 pagesCrack WidthchanakyaNo ratings yet

- Reinforced Concrete Pile Cap Design CalculationsDocument14 pagesReinforced Concrete Pile Cap Design CalculationsHoihogo Hoi100% (1)

- RC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Document5 pagesRC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Natasha WyneNo ratings yet

- Design of Pile Cap Excel SheetDocument4 pagesDesign of Pile Cap Excel SheetKaushal Raut100% (1)

- EC2 Beam DesignDocument4 pagesEC2 Beam Designikanyu79No ratings yet

- Design for Pile Cap Calculation SheetDocument3 pagesDesign for Pile Cap Calculation Sheetbhaskardharani50% (2)

- Pile Cap Design (4-Piles)Document4 pagesPile Cap Design (4-Piles)Uttam Kumar GhoshNo ratings yet

- Input Data Materials: Double Pile CapDocument10 pagesInput Data Materials: Double Pile CapBilal Al-MuhtasebNo ratings yet

- Calculation of Pile Bearing CapacityDocument3 pagesCalculation of Pile Bearing Capacityhayder1974No ratings yet

- Pile Cap 2019Document22 pagesPile Cap 2019Saeed ShubairNo ratings yet

- JPPJ Calcs for Raft Foundation DesignDocument1 pageJPPJ Calcs for Raft Foundation DesignHimura_100% (1)

- Pile Cap DesignDocument4 pagesPile Cap DesignMohamed RifdyNo ratings yet

- Design of Rectangular Footing Col at Edge - 3Document27 pagesDesign of Rectangular Footing Col at Edge - 3Glenn SarneNo ratings yet

- Pad Footing Analysis and Design (Bs8110-1:1997)Document6 pagesPad Footing Analysis and Design (Bs8110-1:1997)ikanyu79No ratings yet

- Section A-A: Wall Cheq'D PlateDocument1 pageSection A-A: Wall Cheq'D PlateAL BASTAKI CONTRACTING L.L.C.50% (2)

- Load Combination For Steel Design Per BS en 1990 EditionDocument2 pagesLoad Combination For Steel Design Per BS en 1990 EditionAsaru Deen100% (1)

- Chequered Plate PlatformDocument3 pagesChequered Plate PlatformFilip RisteskiNo ratings yet

- RC MEMBER DESIGN CALCULATIONSDocument3 pagesRC MEMBER DESIGN CALCULATIONS郑 凯伦 Tey Kai LoonNo ratings yet

- Model For Record Report PROBLEM 1Document3 pagesModel For Record Report PROBLEM 1Siddhartha Harsha OmmiNo ratings yet

- Amd07 Him JourDocument9 pagesAmd07 Him JourNagarjun SinghNo ratings yet

- Chapter Ii - Fluid StaticsDocument72 pagesChapter Ii - Fluid StaticszetseatberhanuNo ratings yet

- Stress Analysis of Rectangular BracketDocument28 pagesStress Analysis of Rectangular BracketArun prakashNo ratings yet

- ANSYS CFX-Solver Theory GuideDocument372 pagesANSYS CFX-Solver Theory GuideBhaskar NandiNo ratings yet

- Chapter 2Document28 pagesChapter 2Siti Hajar Mohd PodziNo ratings yet

- Clarkson Strength of Materials Formula SheetDocument1 pageClarkson Strength of Materials Formula SheetMadi SilalahiNo ratings yet

- Chapter 7-Work, Energy UpdatedDocument43 pagesChapter 7-Work, Energy UpdatedNoor BlNo ratings yet

- Katrine PHD ThesisDocument207 pagesKatrine PHD ThesiszewhiteNo ratings yet

- Mark Scheme 29 Oct 2021Document5 pagesMark Scheme 29 Oct 2021Physics ProjectNo ratings yet

- Strain Rosette Analysis BeamDocument7 pagesStrain Rosette Analysis Beammuhammad haroonNo ratings yet

- HeatTransferModuleUsersGuide PDFDocument580 pagesHeatTransferModuleUsersGuide PDFjmiscNo ratings yet

- Convert MefsDocument3 pagesConvert MefssaghfadNo ratings yet

- Topic 1 (Introduction and Friction) Part 1Document21 pagesTopic 1 (Introduction and Friction) Part 1Brix DavidNo ratings yet

- Vdocuments - MX - cvg3109 Lab Vane Shear Test 2014 PDFDocument9 pagesVdocuments - MX - cvg3109 Lab Vane Shear Test 2014 PDFجابر عباس صكرNo ratings yet

- Sheet No.2 (Simple Stress)Document3 pagesSheet No.2 (Simple Stress)elhalawanyh46No ratings yet

- Forms of EnergyDocument15 pagesForms of EnergyTrajce StojanovNo ratings yet

- Tarea 19 - Metodo API Rp11lDocument12 pagesTarea 19 - Metodo API Rp11lMelo GutiérrezNo ratings yet

- Friction and constrained motion problems from JEE Main objective questionsDocument24 pagesFriction and constrained motion problems from JEE Main objective questionsShuvanshu GuptaNo ratings yet

- Physics Chapter 5 Test A - Work, Energy, PowerDocument4 pagesPhysics Chapter 5 Test A - Work, Energy, PowerCamdrn WrightNo ratings yet

- Digital Assignment-2 Fall Semester 2020-2021Document2 pagesDigital Assignment-2 Fall Semester 2020-2021ermiasNo ratings yet

- Statistical Molecular Thermodynamics: Christopher J. CramerDocument7 pagesStatistical Molecular Thermodynamics: Christopher J. CramerLuciano Sánchez AramburuNo ratings yet

- Soda Can AnalysisDocument21 pagesSoda Can AnalysisYashwant RaoNo ratings yet

- Numerical Analysis of Erosion and Its Induced Vibration Proposal Rakish Samman PrithiviDocument23 pagesNumerical Analysis of Erosion and Its Induced Vibration Proposal Rakish Samman PrithiviSamman Singh PradhanNo ratings yet

- Compressibility RubberDocument11 pagesCompressibility Rubber2007rlwjdtnNo ratings yet

- Chapter-04-Applications-Thermodynamics-Earth 4744 0 PDFDocument43 pagesChapter-04-Applications-Thermodynamics-Earth 4744 0 PDFJou IndrajatiNo ratings yet

- Open Channel Flow AnalysisDocument29 pagesOpen Channel Flow AnalysisMD. TANVIR ANJUM JIMNo ratings yet

- Unit 3 One Marks QuestionsDocument6 pagesUnit 3 One Marks QuestionsRahulNo ratings yet

- Bulaqi 2015Document7 pagesBulaqi 2015Padmini ReddyNo ratings yet