Professional Documents

Culture Documents

ALCATEL ONE TOUCH 6012 L2 Repair Document V1.0

Uploaded by

Enne BrujaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ALCATEL ONE TOUCH 6012 L2 Repair Document V1.0

Uploaded by

Enne BrujaCopyright:

Available Formats

L2E Repair Document

TCT

Mobile Limited

California

ONE TOUCH 6012

Note: this manual is non-contractual and TCT Mobile Limited can modify it without prior notice on

the characteristics of described equipments.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

1/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

TCT

L2E Repair Document

1.0

2013-12-3

Draft creation

Zhangdi

Rev.

Date

Modification description

Prepared By

Checked By

Rev.

1.0

Mobile Limited

Approved By

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

2/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

Content

1 Level 2 repair process .............................................................................................. 4

2 Warranty Check and Visual Inspection ................................................................... 5

2.1 Warranty confirmation of L1..................................................................................... 5

2.2 Visual mechanical check .......................................................................................... 5

2.3 Pretest ........................................................................................................................ 6

3 Software download ................................................................................................... 9

3.1 Equipments requested when download: ................................................................. 9

3.2 SW download process .............................................................................................. 9

4 Disassembly and assembly ONE TOUCH 6012E .................................................. 13

4.1 ESD Safety ................................................................................................................ 13

4.2 Disassembly tool ...................................................................................................... 13

4.3 Disassembly process ............................................................................................. 13

4.4 Reassembly Process .............................................................................................. 20

4.5 Disassembly process evaluation ........................................................................... 20

5 Disassembly Complete ........................................................................................... 21

6 Level 2 repair ........................................................................................................... 24

7 PCBA exchange....................................................................................................... 35

8 Other component exchange ................................................................................... 36

9 Final test .................................................................................................................. 36

9.1 Function Test ............................................................................................................ 36

9.2 Measurement ............................................................................................................ 37

APPENDIX 1 Packaging Requirements ........................................................................ 37

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

3/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

TCT

L2E Repair Document

Mobile Limited

1 Level 2 repair process

Start

Visual Inspection

Warranty Check

Pretest & Failure confirm

Back up user data

SW Upgrade

OK

Function test

NG

Disassembly

L2 Repair

PCBA Replace

NG

Retest

OK

Reassembly

Retest

NG

OK

Restore User Information

Record in BIG

End

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

4/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

2 Warranty Check and Visual Inspection

2.1 Warranty confirmation of L1

Humidity sticker: Liquid detection on humidity sticker.

2.2 Visual mechanical check

Mechanical warranties check items:

1)

Corrosion

2)

Corrosion on the USB connector, SIM connector, and other metal surfaces

Hole (diameter > 1mm)

Holes on any surface, including the front casing, furnished frame, battery cover, touch Lens,

keypad

3)

Bump

Bumps (diameter > 1mm) on any surface, including front casing, decorate frame, battery

cover, touch Lens, keypad, etc.

4)

Scratch

Scratches (length > 3mm) on any surface, including the front casing, decorate frame, battery

cover, touch Lens, keypad, etc.

5)

Distortion

6)

Bend, twisted or crushed on the h/s, cover/casing or connectors, etc.

Broken

7)

Touch broken, casing/cover broken, etc.

Dropped

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

5/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

8)

TCT

Mobile Limited

Keypad tear off, touch lens, connectors dropped, etc.

Gap

9)

External physical damage relating to abnormal use, like front case and frame opened

Others

Damage caused by disassembly ,wrong part assembly, loss of components

Use in abnormal environment like high temperature causing plastic melts

2.3 Pretest

1)

Check that the SIM card is set correctly.

2)

Power on the cell phone.

3)

If the cell phone cant power on, visually check the condition of the battery connector. Replace it if

necessary (refer to paragraph 3.3 for battery test).

4)

If the cell phone asks to input NCK code, which means it is SIM locked, and can only be worked with

dedicated SIM card. Use the correct SIM card.

5)

Enter the phone code if necessary.

6)

If power on, test step by step with the auto test code:

Press *#2886# in dial screen and select Auto to start the auto test, then you will see the interface

displaying the version. Press Pass to continue.

If one of the test failed, it will ask you Restart?, press YES to restart the auto test from the first one

and NO to exit the auto test, while NEXT to continue the auto test.

TRACABILITY Test

I. You can get some information such as IMEI, CU, BT, WIFI, etc

II. Press Pass to continue.

TP

I. Please draw the yellow data according to instructions and it will show TEST RESULT:

OK!

II. Press PASS to continue.

LCD MIRE/BLACK/GREYCHART/WHITE

I. You will see the LCD color changes if it functions well.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

6/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

II. Press Pass to continue.

LCD BackLight Level

I. The screen backlight will be flashing if it functions well.

II. Press Pass to continue.

KEYPAD.

I. Press the key displayed on the screen. The key on the screen will disappear when

you press it if it functions well.

II. Press Pass to continue.

Flash LED Light Test.

I. The light near the camera will flashing.

II. Press Pass to continue.

CAMERA IMG

Press Pass to continue if the camera functions well.

CAMERA IMG FRONT

Press Pass to continue if front camera functions well.

CAMERA LED

I. Camera LED will be turned on if functions well.

II. Press Pass to continue.

CHARGER LED

I. CHARGER LED will be turned on if functions well.

II. Press Pass to continue.

RECEIVE/SPEAKER/MIC/MIC2

I. You will hear the melody if it functions well.

II. Press Pass to continue.

HEADSET/FM

I.

Insert the headset and you will hear FM if functions well.

II. Press "Pass" to continue.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

7/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

III. Remove headset according the instruction and it will say Headset tested if it functions

well.

IV. Press Pass to continue.

USB

I. Insert USB cable and the phone will detect Charger: OK USB: OK if it functions well.

II. Remove USB cable according to the instruction and then press "Pass" to continue.

VIBRATOR

I. You can feel the phones vibrating if it functions well.

II. Press Pass to continue.

G-SENSOR

I. Screen will display put the handset up and towards up, follow this prompt screen will

display left arrow, right arrow, up arrow, down arrow and face down arrow. Put the

phone to the positions according to the arrows direction. It will say all positions

checked if functions well.

II. Press Pass to continue.

LIGHT SENSOR/PROXIMITY

I. It will say Proximity Sensor detected, put the phone near your skin and then move away

from your skin. values such as near->far:2 will be shown if functions well;

II. Press Pass to continue.

SIM

I. Insert the SIM card and the phone will detect it if it functions well.

II. Press Pass to continue

MEMORY CARD

I. Insert the Memory card and the phone will detect it if it functions well.

II. Press Pass to continue.

BT

I. The phone will running the BT and show the BT address on screen.

II. Press "Pass" to continue.

WIFI

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

8/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

TCT

L2E Repair Document

Mobile Limited

I. The phone will running the WIFI and search available network.

II. Press "Pass" to continue.

GPS

I. The phone will running the GPS and search satellite.

II. Press "Pass" to continue.

BATTERY TEMP

I. Battery temperature will be displayed on the screen.

II. Press Pass to continue.

CALL

I. You will hear a voice prompt which introduces some emergency call numbers if functions

well;

II. Press Pass to continue.

3 Software download

It is authorized to download software for the handset which needs to be updated. This downloading

tool is called SW upgrade tool. Handset Software can be downloaded from TS website via it. Thus

internet access is necessary.

TS Website: https://css.tclmobile.cn/.

3.1 Equipments requested when download:

A handset with full charged battery;

PC with windows system;

A USB cable.

3.2 SW download process

The upgrade process is as below:

. Open Sugar MTK_SP 1.4.0 (you can get the latest version from TS website: https://css.tclmobile.cn/).

Then input User name and Password and log on. Sugar MTK_SP login window looks like follow picture.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

9/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

. Select Com port which created by your installed cable, and select the product models ONE TOUCH

6012.You can check handset information (just like the current and available software version, IMEI,

PTM, CU ref etc.) on the server immediately by checking Get Version button:

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

10/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

. Click Upgrade .

. Select com port and click Upgrade, the upgrade process will auto running.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

11/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

V. Upgrade finished and it will spend about 40 minutes(It depends on network speed).

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

12/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

TCT

L2E Repair Document

Mobile Limited

4 Disassembly and assembly ONE TOUCH 6012E

4.1 ESD Safety

Please wear static loop or static glove

4.2 Disassembly tool

You may use the following tools during the disassembly and reassembly procedure:

Plastic Flake

Tweezers

Screwdriver

Hot wind gun

Soldering iron

4.3 Disassembly process

The steps of disassembly ONE TOUCH 6012E are as below.

Step 1: Unpack the SD cover, take off the screw by screw driver.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

13/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

Step 2Separate the furnished frame from furnished front casing by using plastic flake.

Step 3: Take off the 8 screws from main board and antenna support.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

14/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

Step 4: Disconnect the connections as below picture shows.

Step 5: Remove the antenna support from sub PCBA, then remove the speaker from antenna support.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

15/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

Step 6: Tearing the paster above the battery, then remove the battery by paster.

WARNING OF BATTERY: Potential for fire or burning. Do not puncture, crush, or

heat the battery. Strictly avoid using sharp tool to pry up battery.

Fire extinguisher is needed for emergency.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

16/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

DO NOT re-use the battery after battery disassembly.

NOTE:

NO need to disassemble the battery except below 2 circumstances

1) Battery defected;

2) Furnished front casing exchange;

Step 7: Disconnect the 3 connections as below:

Step8: Remove the PCBA and main FPC

Step 9: Remove the power key FPC , volume key FPC and vibrator (TemperatureLead-free

technology 330

10

time2~3

seconds)

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

17/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

Step 10: Remove the receiver from front casing.

Step 11: Remove the sub PCBA from front casing.

Step 12 :Seperate LCD and touch panel from furnished front casing by hot wind gun.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

18/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

1). Please use hot wind gun to heat up LCD and touch panel around the four edges (Temperature: 100, Air

Level: 3, Height:5-10mm, Time:<60s)

2).Use plastic flake to pry the LCD and touch panel starting from top- left corner of the touch lens; be

careful not to damage the touch lens FPC.

Change another TP adhesive

when you reassemble the

LCD+ touch panel.

Step 14: Disassembly complete.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

19/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

Disassembly Notice:

Put all the spare parts on right position (dont let all spare parts mixed and put on the clean place to avoid

vitiated or stained for each spare part) after disassembly. When taking apart of LCD module, take care not

to dirty or damage it.

4.4 Reassembly Process

Please make reference to the disassembly process for assembly reverse an order of the disassembly

steps.

Attention: Insert main FPC and assembly main PCBA with furnished keypad casing, lock the main FPC

connector to PCBA connector, and then place the volume key, Assembly the furnished frame. Note the

orientations of the main FPC.

4.5 Disassembly process evaluation

We list the ONE TOUCH 6012E parts disassembly time, technique levels and disassembly methods as

below, for technique levels, Class 1 signifies easy to disassembly, Class 2 signifies normal to disassembly

and Class 3 signifies hard to disassembly.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

20/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

TCT

L2E Repair Document

Spare part

Furnished Main

Down Casing

8 screws

Time for

disassembly

Jigs for

disassembly

Difficulty

Class

60s

Plastic Flake

Class 3

80s

screwdriver

Class 1

Main PCBA

20s

Plastic Flake

Class 1

Volume key

3S

Tweezers

Class 1

Speaker

Main Camera

PS FPC

volume keypad

FPC

Power key FPC

3s

5s

3s

Receiver

Tweezers

Plastic flake

Tweezers

Mobile Limited

Remark

Class 1

Class 1

Class 1

15s

Soldering iron

Class 2

15S

Soldering iron

Class 2

3s

Tweezers

Class 1

vibrator

10s

Soldering iron

Class 2

RF cable

5s

Tweezers

Class 1

Sub PCBA

10s

Plastic flake

Class 1

LCD+ touch panel

300s

Hot wind gun

Plastic Flake

Class 3

Camera connector

60s

Hot wind gun

Tweezers

Class 3

BTB connector

socket

60s

Hot wind gun Tweezers

Class3

Earphone connect

100s

Hot wind gun Tweezers

Class3

USB connector

60s

Hot wind gun Tweezers

Class3

Antenna springs

120s

Hot wind gun Tweezers

Class3

SIM card connector

120s

Hot wind gun

Tweezers

Class 3

T flash connector

120s

Hot wind gun

Tweezers

Class 3

Battery connector

40s

Hot wind gun

Tweezers

Class3

Be careful for

LCD and touch

FPC damage

The connector

is easy to be

damaged

The connector is

easy to be

damaged

The connector is

easy to be

damaged

The connector is

easy to be

damaged

The connector

is easy to be

damaged

The connector

is easy to be

damaged

The connector

is easy to be

damaged

Disassembly Complete

Explored view

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

21/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

Below table lists ONE TOUCH 6012E L2 spare parts for example. Regarding more spare part list you

could also refer to: https://css.tclmobile.cn/.

Item Name

Partnumber

SWAP PCBA

Quantit Description

y

F-B17U3C2PH1 1

,,Tiger X,,,CU:6012E-2*C2PH1,

Furnished front casing

BCA17U0A11C0

,Furnished front casing,California,Black painting,NO l

Furnished Main Down CasBCC17U2C14C0

2SIM,Furnished Main Down Casing,California 2SIM,PC+10%

10

LCD+touch panel

AUC430T101C1

LCD+,LCD + Touch Panel,16.7M,4.3",480854,TFT-IPS,Wide

11

receiver

AWB1206S05C1

,Receiver,6122.32mm,121+-3dB,10 mW,spring,With Mayle

12

speaker

AWA1318S02C1

,Speaker,Rectangular,13182.9 mm,90.5+-2.5dB,500 mW,spr

13

Cylindrical Vibrator

AVA0408L07C1

,Vibrator motor,cylindrical,4L8.0mm(12.9),DC3.0V,6

14

Camera

ASA5001058C1

,Camera,CMOS,5M,AF,8.58.54.9mm,FPC+BTB,MIPI,OV56

15

SideKey FPC

SBF17U00031A

FPC,SideKey FPC,California,A Version,2 Layers,N/A,With G

16

PS FPC

SBF17U00041A

FPC,PS FPC,California,A Version,2 Layers,N/A,Without Glue

17

SENSOR rubber

BNJ17U0000C0

SENSOR ,SENSOR rubber,California,rubber,,

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

22/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

18

CAMERA rubber

BNJ17U0001C0

CAMERA ,CAMERA rubber,California,rubber,,

19

Main MIC rubber

BNJ17U0002C0

,Main MIC rubber,California,rubber,,

20

sub pcba mylar

BPC17U0002C0

,sub pcba mylar,California,7.76.9T0.05,

21

TP IC adhesive

BPA17U0006C0

TP IC ,TP IC adhesive,California,Tesa 68547,

22

Screw

BMA1425263C1

,Screw,PM(Machine),1.4*0.3*2.5,Flat Head,2.6*0.5,+ type,+1

23

Screw

BMA1025181C3

,Screw,PM(Machine),PM 1.0XL2.5X0.25P,Flat Head,D1.8XT0.5,+

24

RF cablewire

ARM0000038C1

RF ,RF cablewire,N/A,0 PINs,0 mm,D2.4XL65.5 mm,W/O POST+

25

LI-Polymer Battery

CAC1700001C1

,LI-Polymer Battery,N/A,1700 mAh,3.8 V,4.35 V,Alca

26

Metal Sheet

BMG17U0000C0

,Metal Sheet,California,SUS 304,0.2MM,LAIMU

27

main antenna

BBC17U1A10C1

,MAIN ANTENNA,California,US,LDS,balck,,speed

28

Sub MIC rubber

BNJ17U0003C0

,Sub MIC rubber,California,rubber,

29

main MIC mesh

BNF17U0000C0

MIC,main MIC mesh,California,200 ,T0.1,

30

Furnished Sub PCBA

SBH17U10000E

,Furnished Sub PCBA,California,US,BAH17U000EC1,N/A,TCT

31

MIC

AWC3729M06C1

,MIC,MEMS,3.762.951.1mm,-42+/-3dB,SMT,N/A,MA-BFA423-

32

BTB Connector(Socket) ARC0240013C1

(),BTB Connector(Socket),OVER PCB,24.0 PINs,0.

33

Coaxial Cable Socket

ARF0030001C1

(),Coaxial Cable Socket,Over PCB,3.0 PINs,N/A,

34

RF switch

ARF0060003C1

RF,RF switch,Over PCB,6.0 PINs,2.32 mm,2.52.5H1.5mm,

35

MicroUSB-B Connector ARH0050040C1

MicroUSB-B,MicroUSB-B Connector,Cut PCB,5 PINs,0.65 mm,5

36

Antenna spring

BMF32E0000C0

,Antenna spring,Martell,,3.45*1.2*H1.66,,W/O post,W/O

37

Power FPC

SBF17U00021B

FPC,Power FPC,California,B Version,2 Layers,N/A,With G

38

Main FPC

SBF17U00011B

FPC,Main FPC,California,B Version,2 Layers,N/A,With Glue,70.

39

Camera module

ASA0300001C2

,Camera module,CMOS,0.3M,FF,3.24x2.8xH2.74mm,SMT 20p

40

FPC Connector

ARA0250003C1

FPC,FPC Connector,Over PCB,25.0 PINs,0.30 mm,9.03.5H

41

BTB Connector(Socket) ARC0100002C1

(),BTB Connector(Socket),OVER PCB,10.0 PINs,0.

42

Audio Jack

ARG0040008C1

,Audio Jack,Cut PCB,4 PINs,D3.5 mm,12.54x8.7xH4.4 mm,W

43

SIM Card Connector

ARD0080005C1

SIM,SIM Card Connector,Push-Push,8 PINs,0.6 mm,16.35x1

44

coaxial cable connect-soc ARM0020009C1

,coaxial cable connect-socket,Over PCB,2 PINs,

45

RF Connector

ARF0020001C1

RF,RF Connector,Over PCB,2 PINs,0 mm,1.8*1.8*0.85 mm,W/O

46

WTB connector

ARM0060002C1

,WTB connector,Over PCB,6 PINs,1.2 mm,9x4.35xH1.2

47

Antenna spring

ARM0010025C1

,Antenna spring,Over PCB,1 PINs,N/A,3.5x1.1xWH1.5,W/O

48

PCBA LABLE

CPG0000048C0

,PCBA LABLE,Rav4,N/A,10.008.00 mm,N/A,With Glue,N/A,

49

Mylar battery

BPC17U0005C0

,Mylar battery,California,,0.05T,

50

Mylar USB

BPC17U0007C0

USB,Mylar USB,California,,0.05T,

51

Receiver DECO

BDA17U0V10C0

,Receiver DECO,California,with adhesive,Light

52

TP G2M adhesive

BPA17U0000C0

G2M,TP G2M adhesive,California,YT7720F,T0.2,

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

23/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

TCT

L2E Repair Document

Mobile Limited

6 Level 2 repair

This chapter describes the Level 2 repair that can be done without any diagnostic equipment.

Problem description

Charging

Action And Solution

Bad

1.Check voltage of the battery: if 0V,

or

charge some minutes and check the

No Charge

charge indicator;

2.Check the battery contact, change the

battery connector if broken;

3.Check the charge plug on B cover,

change it if necessary;

Switch on with

Can t Switch on

battery power

1.Check voltage of the battery;

2.Check the battery contact, change the

battery connector if broken;

3.Check the power on key;

4.Check BTB connector socket pin

Main display

Vibrator

Missing line or column; no

Check Connection flex (FPC

display; bad or no LCD

cable),change it if necessary;

backlight

Replace display module if necessary;

The vibrator does not work

Check the contact on the PCBA (dirty or

oxidized), replace the vibrator if

necessary;

Network Problem

No emission or No reception

Check the antenna contactor on the B

cover;

Check the contact on the PCBA (dirty or

oxidized);

TF card

No communication between

Check the TF connector on the PCBA;

the phone and the TF card

Camera

Camera doesn't work

Check camera module

Check also camera socket broken or

not

Audio

Bad or no emission (TX

Check microphone, replace it if

audio from mobile);

necessary;

Check the contact on the PCBA (dirty or

Bad or no reception (RX

oxidized)

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

24/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

TCT

L2E Repair Document

Mobile Limited

audio on mobile);

Check loud speaker, replace it if

Hands-free problem;

necessary;

Key beep and melody

Check the contact on the PCBA (dirty or

problem

oxidized)

In case the Level 2 repair cant solve the problem, or the PCBA is damaged, exchange the PCBA.

7. L2 Enhance repair

Before performing the following troubleshooting operations, please make sure the software of the device is

in good condition and restored to default settings.

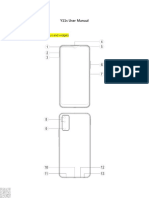

7.1 Position of L2 enhance components on main PCBA and sub PCBA

>Main PCBA (Side A):

>Main PCBA (Side B)

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

25/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

Sub PCBA (side A)

Sub PCBA (side B)

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

26/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

7.2 Trouble shooting for common failures

NOTE:

1) Because the main PCBA will become damp after long time storage, please use oven to bake the main

, Tim e:

PCBA firstly if it has been stored for more than 7days (oven temperature: 105

it may cause the PCBA blister easily when you heat part of the PCBA by using hot wind gun.

2) Interchange method means using a new component to test the function in order to verify whether the

old component is defected.

3) Please use hot wind gun to reweld or disassemble/assemble the component mentioned afterwards.

(hot wind gun temperature: 330, Air Level: 2~3, Height: around 10mm, Time: less than 60s)

4) Before rewelding or disassembling/assembling the component, DO remember to paste high

temperature adhesive tape on the components which are close to it, in order to avoid damaging of

these components.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

27/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

7.2.1 LCD display failure

Reassemble LCD

Reweld or replace

CON1201

Change LCD

Check whether the connection

between LCD and CON1201

FPC connector is good

Check whetherCON1201is normal

C h e c k w h e t h e r LCD i s

normalinterchange

method

Replace PCBA

7.2.2 Power on failure

Power on failure

C h e c k w h e t h e r power key

FPC is normal

Reweld or replace power

key FPC

Replace PCBA

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

28/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

7.2.3 TP function failure

Reassemble TP

Check whether the connection

between TP and CON1202 is

good

Change TP

Reweld or replace

CON1202

Check whether TP is normal

interchange method

Check whether CON1202 is

normal

Replace PCBA

7.2.4 Voice transmitting failure

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

29/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

N

Reassemble SUB PCBA

Reweld or replace

CON701CON101

Replace MIC101 main MIC

Mobile Limited

Check whether the connection

between CON701 and

CON101 is good

TCT

C h e c k

w h e t h e r

CON701CON101 is normal

Check whether MIC 101 is normal

Replace PCBA

7.2.5 No Ringing

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

30/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

Main

Mobile Limited

Replace Main Antspeaker

C h e c k w h e t h e r

Antspeaker is normal

TCT

Reassemble or replace

SUB PCBA

Reweld or replace

CON701CON101

Check whether the connection

between main FPC and

CON701CON701 is good

C h e c k

w h e t h e r

CON701CON101 is normal

Replace PCBA

7.2.6 p-sensor function failure

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

31/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

TCT

L2E Repair Document

C h e c k w h e t h e r P-sensor

rubber is normal

Reassemble or replace

P-sensor rubber

Mobile Limited

Check whether the connection

b e t w e e n p-sensor F P C a n d

J2101 is good

Reassemble p-sensor FPC

Reweld or replace J2101

Check whether J2101 is normal

Replace PCBA

7.2.7 SIM card is not recognized

Reassemble SIM card

Reweld or replace

CON1901

Check whether the SIM card is

well inserted

Check whether CON1901 is

normal

Replace PCBA

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

32/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

TCT

L2E Repair Document

Mobile Limited

7.2.8 main camera function failure

Reassemble main camera

Reweld or replace J1301

Replace main camera

Check whether the connection

b e t w e e n m a i n camera a n d

J1301 is good

Check whether J1301 is normal

Check whether main camera is

normal (Interchange method)

Replace PCBA

7.2.9 charging failure

Check whether charging

indicator displays OK

Check whether USB

CON102 is normal

Reweld or replace

USB CON102

Reweld or replace

CON701CON101

C h e c k w h e t h e r battery i s

normalInterchange method,

no need to disassemble the

old battery)

Replace battery

Check whether the

connection between SUB

P C B A

a n d

C O N 7 0 1 C O N 1 01 i s

good

Replace PCBA

7.2.10 USB is not recognized

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

33/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

N

R e w e l d o r r e p l a c e USB

CON102

Reassemble or replace

SUB PCBA

Reweld or replace

CON701,CON101

Mobile Limited

Check whether USB

CON102 is normal

TCT

Check whether the connection

between CON701 and

CON101 is good

Check whether CON701 and CON101

is normal

Replace PCBA

7.2.11 no signal

Reweld or replace TP150/

TP151/TP152

Reassemble or replace

RF coaxial cable

Reweld or replace J601/CON603 RF

coaxial cable connector

Check whether TP150/TP151/

TP152 is normal

Check whether RF coaxial

cable is assembled well

Check whether J601/CON603 RF

coaxial cable connector is normal

Replace PCBA

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

34/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

7.3 Trouble shooting for common failures

California ONE TOUCH 6012 L2E spare part list

8 PCBA exchange

If Level 2 repair does not solve the failure, it is mandatory to change the PCBA and follow the process as

below.

1)

Collect the PCBA (without accessories, LCD and camera), with microphone and vibrator.

2)

Get a new PCBA from the swap stock. Reuse those accessories to assemble the mobile.

3)

Fill in the record sticker with IMEI number, fault code, short code, Hardware Technical Level and

software version.

4)

Send the NG PCBA with record sticker back to L3 repair center with the recommended packaging

method,

Note: packaging method please refer item 12. Packaging requirement.

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

35/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

9 Other component exchange

The other components exchange such as

1)

LCD + touch panel

2)

USB connector

3)

FPC connector

4)

Receiver

5)

Speaker

6)

Main Camera

7)

Sub camera

8)

Main FPC

9)

Volume keypad FPC

10) Power key FPC

11) Other related mechanical components

Please follow the detail steps 4.3 (Disassembly and assembly process).

But need to be very careful to handle the components with related special tool or jig (especially replacing

new components)

It is better to handle it with plastic tools (plastic tweezers and wedge etc.).

Besides operator must wear anti-static gloves, fingertips or wear static loop during the whole process of

components exchange.

10 Final test

9.1 Function Test

During the function test, the following items must be checked and validated.

1)

Cosmetic aspect of the handset,

2)

The Software Technical sticker state on the Board

3)

Switch on the handset

4)

Default welcome message

5)

Press *#2886# on the idle screen to start the auto test

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

36/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

9.2 Measurement

APPENDIX 1 Packaging Requirements

Appearance Requirements of PCBA

The failure code label, commercial label, custom label and network code should be stuck onto

PCBA

The repair PCBA and custom label should be matched (see appendix one for the detailed

information)

PCBA of Flip Phone

Network

code

Custom

label

Commercial

label

Failure

code label

put commercial label and network code on

Put failure code label and custom label on

one side

other side

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

37/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

Network

code

PCBA of Bar Phone

Custom

label

Commercial

code

Failure

code label

Put commercial label and custom label on

At the same time put network code

PCBA

label and failure code label

PCBA Packing Requirements

After packing with anti-vibration bag, the commercial label on PCBA should be

easy recognized;

Custom

label is

easy to

see

Inner packing is anti-static bag

Outer packing is anti-vibration bag

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

38/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

L2E Repair Document

TCT

Mobile Limited

Put commercial label on anti-vibration bag

Packing Requirements

i.

Please pay attention to the following points when different models put into one box

ii.

Stick up the same models with tapes

iii.

Mark the model, quantity and specification of custom label on tape

iv.

The packing box for PCBA should have marking sticker and well sealed by the tape

v.

with TCL logo

vi.

Finally put all the packing boxes into packing cases strong enough and post to HK.

Model

Quantity

Specification

Stick up the same models with tapes

Mark the model, quantity and specification of

custom label on tape

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

39/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

TCT

L2E Repair Document

The packing box for PCBA should have

marking sticker and well sealed by the tape

with TCL logo

Mobile Limited

Put all the packing boxes into packing cases

strong enough and post to HK

Once the PCBA are damaged or cannot be repaired or delayed in custom because of unqualified

packing, the shipping side will take the responsibility.

If you have any question or problem, please feel free to contact us

(tct_gcc_techSupport@tcl.com) .

Thanks for your cooperation.

TCT Mobile Limited

Global Customer Service TS Dept.

Dec.3th, 2013

Rev.

1.0

Page

ONE TOUCH 6012 Level 2 Enhance Repair Document

40/40

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

You might also like

- Samsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneFrom EverandSamsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneNo ratings yet

- OnePlus One User Manual: Guide to Help Unleash Your Smartphone Device!From EverandOnePlus One User Manual: Guide to Help Unleash Your Smartphone Device!No ratings yet

- ALCATEL ONE TOUCH 6030 X D A N L2 Repair Document V1.3Document46 pagesALCATEL ONE TOUCH 6030 X D A N L2 Repair Document V1.3Enne BrujaNo ratings yet

- Sony Ericsson J20i Hazel Test Instructions v1Document18 pagesSony Ericsson J20i Hazel Test Instructions v1Kamil Pieńkosz100% (1)

- 5600 User ManualDocument34 pages5600 User Manualmadhu2079No ratings yet

- W508 - Test Instruction SVCMDocument16 pagesW508 - Test Instruction SVCMJose GarciaNo ratings yet

- Service ManualDocument52 pagesService ManualAFAG200181No ratings yet

- Samsung Att I907Document23 pagesSamsung Att I907jonnyguga261No ratings yet

- HC300M User ManualDocument11 pagesHC300M User Manualgme komunikacijeNo ratings yet

- Alcatel One Touch 4010 - OT4011 L2 Service ManualDocument22 pagesAlcatel One Touch 4010 - OT4011 L2 Service ManualEdgar Jose Aranguibel MorilloNo ratings yet

- Test Instruction, MechanicalDocument12 pagesTest Instruction, MechanicalMas NoNo ratings yet

- MT Pro Product Manual en V1.1 July 2022 1Document15 pagesMT Pro Product Manual en V1.1 July 2022 1Renato Ogeda E SouzaNo ratings yet

- User Manual: Please Refer To This Manual Before Using The ProductDocument8 pagesUser Manual: Please Refer To This Manual Before Using The ProductPERENo ratings yet

- At T Mobility DeviceDocument26 pagesAt T Mobility DeviceJuan MendozaNo ratings yet

- En-Hytera PNC360S PoC Radio Quick Reference Guide V1.0.00Document5 pagesEn-Hytera PNC360S PoC Radio Quick Reference Guide V1.0.00Ru LIUNo ratings yet

- In Dash Navi & Infotainment System With Bluetooth: Service ManualDocument70 pagesIn Dash Navi & Infotainment System With Bluetooth: Service ManualMonete FlorinNo ratings yet

- FOR CAMIRAZTE MF 86 3G CCTV CameraDocument10 pagesFOR CAMIRAZTE MF 86 3G CCTV CameraSameh FayedNo ratings yet

- lt60h Gnss Data Controller ManualDocument16 pageslt60h Gnss Data Controller ManualvandongcbdNo ratings yet

- MAXIMUM Inspection Camera 57-4548-0 ManualDocument1 pageMAXIMUM Inspection Camera 57-4548-0 ManualGordonWinnow0% (2)

- User Manual en UsDocument41 pagesUser Manual en Usyemy76No ratings yet

- Alcatel One Touch-992D L2 Service ManualDocument33 pagesAlcatel One Touch-992D L2 Service ManualEdgar Jose Aranguibel MorilloNo ratings yet

- Infrared Wild Camera User's Manual WCT-8020WDocument13 pagesInfrared Wild Camera User's Manual WCT-8020WrobertNo ratings yet

- Manual CKDZ - Procesador VideoDocument29 pagesManual CKDZ - Procesador VideoJaime OneyNo ratings yet

- Owner Manual Lenovo - s930Document6 pagesOwner Manual Lenovo - s930Zulkhairi AbidinNo ratings yet

- Android C200 ManualDocument20 pagesAndroid C200 ManualAlexey DrakunovNo ratings yet

- OT995 - OT996 - OT4301 - OTA10 L2 Service ManualDocument25 pagesOT995 - OT996 - OT4301 - OTA10 L2 Service ManualkaukauNo ratings yet

- User Manual: Touch MonitorDocument19 pagesUser Manual: Touch MonitorLaocyberspace MITNo ratings yet

- Datasheet Huawei x103Document24 pagesDatasheet Huawei x103Cantun BernaNo ratings yet

- Manual Vivo Y11sDocument17 pagesManual Vivo Y11sa6No ratings yet

- Lenovo A316i: Quick Start Guide v1.0Document6 pagesLenovo A316i: Quick Start Guide v1.0Z3R037No ratings yet

- KONNWEI KW650 - BedienungsanleitungDocument13 pagesKONNWEI KW650 - BedienungsanleitungHaraldNo ratings yet

- Horno MaurerDocument26 pagesHorno MaurerAngel Huarcaya HuamaliNo ratings yet

- DocumentDispatch Test Instruction 004Document22 pagesDocumentDispatch Test Instruction 004Cassiano Sponton PintoNo ratings yet

- TCM005 User ManualDocument14 pagesTCM005 User ManualRafael zacarias colinaNo ratings yet

- Qb102 User Manual - Jt808 ProtocolDocument5 pagesQb102 User Manual - Jt808 ProtocolAurélio FariaNo ratings yet

- CP960-Teams Edition: Quick Start Guide (V15.20)Document8 pagesCP960-Teams Edition: Quick Start Guide (V15.20)Juan Saint ClairNo ratings yet

- MA300 User Manual V1.1 PDFDocument46 pagesMA300 User Manual V1.1 PDFEmmanuel RebelsounHdzNo ratings yet

- English TEW-421PC 423PI (C1) PDFDocument11 pagesEnglish TEW-421PC 423PI (C1) PDFMaxNo ratings yet

- Codigos VAG InterDocument15 pagesCodigos VAG InterMaría Martz De GarcíaNo ratings yet

- Gsmart Classic User ManualDocument38 pagesGsmart Classic User ManualVeljko RabrenovicNo ratings yet

- At T Mobility Device Unlock Code InstructionsDocument24 pagesAt T Mobility Device Unlock Code InstructionskarinakarusNo ratings yet

- GPS Watch TV680 User Manual PDFDocument14 pagesGPS Watch TV680 User Manual PDFshowstoppernavNo ratings yet

- Enginnering Manual Yale SmartHome Alarm SeriesDocument38 pagesEnginnering Manual Yale SmartHome Alarm SeriesGuilherme MonteiroNo ratings yet

- Lenovo K900: Quick Start GuideDocument14 pagesLenovo K900: Quick Start GuideDwi SagittaNo ratings yet

- ManualDocument9 pagesManualekseucjbgyzubudnnzNo ratings yet

- SB9011D User Manual v1.0Document21 pagesSB9011D User Manual v1.0LucasZarauzaNo ratings yet

- Sony Xperia M Test Instructions Mechanical - 1277-1359 - Rev2Document25 pagesSony Xperia M Test Instructions Mechanical - 1277-1359 - Rev2kanojesumitNo ratings yet

- T630/T630B User Guide: Screw S Sim Cover Nano Sim Sim SlotDocument17 pagesT630/T630B User Guide: Screw S Sim Cover Nano Sim Sim SlotDaniel ParNo ratings yet

- Ms80 User ManualDocument73 pagesMs80 User ManualAlejandro MorardNo ratings yet

- Wireless Programmable Mouse: Package Contents (Attachment)Document25 pagesWireless Programmable Mouse: Package Contents (Attachment)Customer ServiceNo ratings yet

- Install 9inch Touch Screen Tutorial Raspberry PiDocument17 pagesInstall 9inch Touch Screen Tutorial Raspberry PiJohn BahamonNo ratings yet

- Iclock880 User ManualDocument154 pagesIclock880 User ManualNarciso Benjamin Salinas Garcia100% (1)

- Anviz M3 T5 T5Pro UserManual V1.1 ENDocument21 pagesAnviz M3 T5 T5Pro UserManual V1.1 ENjcbello1No ratings yet

- 201.TK109 GPS Watch Tracker User ManualDocument19 pages201.TK109 GPS Watch Tracker User Manualel hackNo ratings yet

- Portable Gas Leak Detector: Operation ManualDocument12 pagesPortable Gas Leak Detector: Operation Manualcharly36No ratings yet

- Walton Primo EF6 User ManualDocument8 pagesWalton Primo EF6 User Manualxawef46116No ratings yet

- GSmart F240 PDFDocument16 pagesGSmart F240 PDFAnonymous k2NqMoNo ratings yet

- User Manual I8 KeyboardDocument1 pageUser Manual I8 Keyboardajaibhatnagar83% (6)

- ca34b0592a1966a3cb9fc14674003749Document87 pagesca34b0592a1966a3cb9fc14674003749voin154No ratings yet

- What Andon Truely is in Lean Manufacturing?: Toyota Production System ConceptsFrom EverandWhat Andon Truely is in Lean Manufacturing?: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- First - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeDocument2 pagesFirst - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeyoyoyoNo ratings yet

- GCP Vol 2 PDF (2022 Edition)Document548 pagesGCP Vol 2 PDF (2022 Edition)Sergio AlvaradoNo ratings yet

- Project ProposalDocument4 pagesProject Proposaljiaclaire2998100% (1)

- CRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEADocument21 pagesCRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEAcristian colceriu100% (2)

- EngHub How To Break HabitsDocument13 pagesEngHub How To Break HabitsViktoria NovikovaNo ratings yet

- Chapter 2.3.3 History of Visual Arts Modernism Post ModernismDocument17 pagesChapter 2.3.3 History of Visual Arts Modernism Post ModernismKim Ashley SarmientoNo ratings yet

- ABI TM 13 16 SL - EngDocument1 pageABI TM 13 16 SL - EngJuan Carlos Benitez MartinezNo ratings yet

- Verniers Micrometers and Measurement Uncertainty and Digital2Document30 pagesVerniers Micrometers and Measurement Uncertainty and Digital2Raymond ScottNo ratings yet

- Introduction To HDLDocument28 pagesIntroduction To HDLBack UpNo ratings yet

- FINAL BÁO-CÁO-THỰC-TẬP.editedDocument38 pagesFINAL BÁO-CÁO-THỰC-TẬP.editedngocthaongothi4No ratings yet

- Introducing The Thinkcentre M70A. A Desktop You DefineDocument3 pagesIntroducing The Thinkcentre M70A. A Desktop You DefineSiti RohayatiNo ratings yet

- Etextbook PDF For Pharmacology Connections To Nursing Practice 3rd EditionDocument61 pagesEtextbook PDF For Pharmacology Connections To Nursing Practice 3rd Editionkarla.woodruff22798% (45)

- Term Paper Inorganic PolymersDocument24 pagesTerm Paper Inorganic PolymersCasey Karua0% (1)

- Bgrim 1q2022Document56 pagesBgrim 1q2022Dianne SabadoNo ratings yet

- UFO Yukon Spring 2010Document8 pagesUFO Yukon Spring 2010Joy SimsNo ratings yet

- Lancru hzj105 DieselDocument2 pagesLancru hzj105 DieselMuhammad MasdukiNo ratings yet

- Lesson 1: Composition: Parts of An EggDocument22 pagesLesson 1: Composition: Parts of An Eggjohn michael pagalaNo ratings yet

- Measurement and Scaling Techniques1Document42 pagesMeasurement and Scaling Techniques1Ankush ChaudharyNo ratings yet

- LEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Document4 pagesLEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Cindy PNo ratings yet

- Chapter 20 AP QuestionsDocument6 pagesChapter 20 AP QuestionsflorenciashuraNo ratings yet

- KMKT Pra PSPM ANS SCHEMEDocument16 pagesKMKT Pra PSPM ANS SCHEMEElda AldaNo ratings yet

- 4B - Urp - Shavya's FarmDocument22 pages4B - Urp - Shavya's FarmSnehansh KishoreNo ratings yet

- Algorithms For Automatic Modulation Recognition of Communication Signals-Asoke K, Nandi, E.E AzzouzDocument6 pagesAlgorithms For Automatic Modulation Recognition of Communication Signals-Asoke K, Nandi, E.E AzzouzGONGNo ratings yet

- Marion Nicoll: Life & Work by Catharine MastinDocument147 pagesMarion Nicoll: Life & Work by Catharine MastinArt Canada InstituteNo ratings yet

- Healthymagination at Ge Healthcare SystemsDocument5 pagesHealthymagination at Ge Healthcare SystemsPrashant Pratap Singh100% (1)

- Lalit Resume-2023-LatestDocument2 pagesLalit Resume-2023-LatestDrew LadlowNo ratings yet

- Ahmad Syihabudin: BiodataDocument2 pagesAhmad Syihabudin: BiodatabhjjqrgrwmNo ratings yet

- Aribah Ahmed CertificateDocument2 pagesAribah Ahmed CertificateBahadur AliNo ratings yet

- CTS2 HMU Indonesia - Training - 09103016Document45 pagesCTS2 HMU Indonesia - Training - 09103016Resort1.7 Mri100% (1)

- 21 Tara Mantra-Wps OfficeDocument25 pages21 Tara Mantra-Wps OfficeAlteo FallaNo ratings yet