Professional Documents

Culture Documents

Abstrak Annisa

Uploaded by

nisamawarrrCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abstrak Annisa

Uploaded by

nisamawarrrCopyright:

Available Formats

PENGARUH Na2SiO3 DAN NaOH SEBAGAI AKTIVATOR

FLY ASH TERHADAP SIFAT-SIFAT MORTAR GEOPOLIMER

Annisa Mawarni1*, Anis Saggaff2, dan Saloma3

1

Mahasiswa S-1 Teknik Sipil Universitas Sriwijaya

2

Professor Teknik Sipil Universitas Sriwijaya

3

Dosen Teknik Sipil Universitas Sriwijaya

*

Korespondensi penulis: annisakiran@gmail.com

Abstrak

Industri semen menyumbang sekitar 6% dari seluruh emisi CO2 yang diakibatkan oleh

manusia (McCaffrey, 2002). Oleh karena itu diperlukan upaya untuk menunjang mortar

berkelanjutan, salah satunya dengan cara mengganti material semen dengan material alternatif yaitu

fly ash. Fly ash sebagai bahan pengikat perlu ditambahkan aktivator alkali berupa Sodium Silikat

(Na2SiO3) atau Kalium Silikat (K2SiO3) dan Sodium Hidroksida (NaOH) atau Kalium Hidroksida

(KOH). Penelitian ini dilakukan di Laboratorium Bahan dan Beton Universitas Sriwijaya dengan

tujuan penelitian adalah untuk menganalisis pengaruh kadar larutan aktivator terhadap sifat-sifat

mortar geopolimer dan mengetahui besarnya kuat tekan yang dihasilkan. Variasi molaritas NaOH

yang digunakan 8, 12, 14, dan 16 M dengan rasio Na2SiO3/NaOH = 1,0. Rasio pasir/fly ash = 2,75

dan rasio aktivator/fly ash = 0,4. Benda uji berbentuk kubus ukuran 50 x 50 x 50 mm dilakukan

perawatan steam dengan suhu 60oC selama 48 jam. Hasil pengujian mortar segar menunjukkan

bahwa molaritas NaOH mempengaruhi slump flow dan setting time, semakin besar molaritas NaOH

maka semakin kecil nilai slump dan semakin cepat waktu ikat. Hasil pengujian berat jenis juga

menunjukkan bahwa semakin besar molaritas NaOH maka semakin besar berat jenis yang

dihasilkan. Hasil pengujian kuat tekan didapatkan bahwa kuat tekan maksimum dihasilkan oleh

mortar geopolimer 14M yaitu 10,06 MPa dan kuat tekan terendah dihasilkan oleh mortar

geopolimer 8M yaitu 3,95 MPa. Pengujian kuat tekan mortar geopolimer 16M menghasilkan kuat

tekan yang lebih rendah daripada mortar geopolimer 14M yaitu 9,16 MPa.

Kata kunci: mortar, mortar geopolimer, aktivator alkali, molaritas.

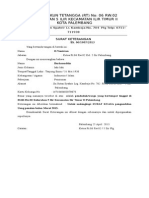

Indralaya,

November 2015

Dosen Pembimbing I,

Dosen Pembimbing II,

Prof. Dr. Ir. H. Anis Saggaff, MSCE.

Dr. Saloma, ST., MT.

NIP. 19621028 198903 1 002

NIP. 19761031 200212 2 001

Mengetahui/Menyetujui,

Ketua Jurusan Teknik Sipil,

Ir. Hj. Ika Juliantina, MS

NIP.19600701 198710 2 001

THE INFLUENCE OF Na2SiO3 AND NaOH TO THE CHARACTERISTIC

GEOPsOLYMER MORTAR WITH FLY ASH

Annisa Mawarni1*, Anis Saggaff2, dan Saloma3

1

Student of Civil Engineering Department, Faculty of Engineering, Sriwijaya University

Professor of Civil Engineering Department, Faculty of Engineering, Sriwijaya University

3

Lecturer of Civil Engineering Department, Faculty of Engineering, Sriwijaya University

*

Author correspondence: annisakiran@gmail.com

Abstract

The cement industry accounts for about 6% of all CO2 emissions caused by humans

(McCaffrey, 2002). Therefore, it is necessary to support sustained mortar, one of them by replacing

the cement material with alternative material is fly ash. Fly ash as a binder in alkaline activators

need to be added in the form of Sodium Silicate (Na2SiO3) or Potassium Silicate (K2SiO3) and

Sodium Hydroxide (NaOH) or Potassium Hydroxide (KOH). This research was conducted in the

Laboratory of Materials and Concrete Sriwijaya University which aims to analyze the effect of the

activator solution concentration on the properties of geopolymer mortar and to know the size of the

resulting compressive strength. The variation molarity of NaOH used 8, 12, 14, and 16 M with the

ratio Na2SiO3/NaOH = 1.0. The ratio of sand/fly ash ratio = 2.75 and activator/fly ash = 0.4. The

cube-shaped test specimen size 50 x 50 x 50 mm is made of steam curing at a temperature of 60 C

for 48 hours. The experimental results of the fresh mortar reported that NaOH molarity affect the

slump flow and setting time, higher concentration of NaOH produces the smaller value of slump

and the faster time of setting. The experimental of density results reported the increase of spesific

gravity when the NaOH molarity increased. The experimental results of the compressive strength

are showed that the maximum compressive strength of geopolymer mortar 14M is 10.06 MPa and

the lowest compressive strength produced by geopolymer mortar 8M is 3.95 MPa. Testing the

compressive strength of geopolymer mortar 16M produces compressive strength lower than 14M

geopolymer mortar is 9.16 MPa.

Keywords: mortar, geopolymer mortar , alkaline activator, molarity.

Indralaya, November

2015

Advisor I,

Advisor II,

Prof. Dr. Ir. H. Anis Saggaff, MSCE.

Dr. Saloma, ST., MT.

NIP. 19621028 198903 1 002

NIP. 19761031 200212 2 001

Head of Civil Engineering Department,

Ir. Hj. Ika Juliantina, MS

NIP.19600701 198710 2 001

You might also like

- 1.cover & Daftar IsiDocument4 pages1.cover & Daftar IsinisamawarrrNo ratings yet

- 8.lampiran G. Lain-Lain - FixDocument1 page8.lampiran G. Lain-Lain - FixnisamawarrrNo ratings yet

- SEMENTARADocument1 pageSEMENTARAnisamawarrrNo ratings yet

- Model Komputer SWMMDocument27 pagesModel Komputer SWMMRanoAdiyoso100% (3)

- CV Muhammad Rizky RamadhanDocument2 pagesCV Muhammad Rizky RamadhannisamawarrrNo ratings yet

- Pages From Prosiding Avoer 2011-22Document9 pagesPages From Prosiding Avoer 2011-22Arta K'dAekNo ratings yet

- Tutorial AutocadDocument22 pagesTutorial AutocadSepry Naldo0% (1)

- Tugas Peltim AnnisaDocument30 pagesTugas Peltim AnnisanisamawarrrNo ratings yet

- KD1 Bab1Document3 pagesKD1 Bab1-Hinata Caiianx Nara-No ratings yet

- Makalah Tugas KimiaDocument20 pagesMakalah Tugas KimianisamawarrrNo ratings yet

- Kertas FisdasDocument1 pageKertas FisdasnisamawarrrNo ratings yet

- Bab2 Struktur AtomDocument16 pagesBab2 Struktur Atomsanty_vanftowsNo ratings yet

- Kinetika KimiaDocument15 pagesKinetika KimiamurniatisariNo ratings yet

- Kebisingan PDFDocument19 pagesKebisingan PDFbundamegaNo ratings yet

- Bahan Kuliah Kalkulus I (Ibuk Awi)Document32 pagesBahan Kuliah Kalkulus I (Ibuk Awi)Olie Stiawan RandyNo ratings yet

- Bahan Kuliah Kalkulus I (Ibuk Awi)Document32 pagesBahan Kuliah Kalkulus I (Ibuk Awi)Olie Stiawan RandyNo ratings yet

- Biografi SenimanDocument11 pagesBiografi SenimannisamawarrrNo ratings yet

- Pages From Prosiding Avoer 2011-22Document9 pagesPages From Prosiding Avoer 2011-22Arta K'dAekNo ratings yet

- Presentasi 4 BDocument12 pagesPresentasi 4 BnisamawarrrNo ratings yet

- Contoh Soal Beda TinggiDocument13 pagesContoh Soal Beda TingginisamawarrrNo ratings yet

- Sustainable Development STRDocument22 pagesSustainable Development STRnisamawarrr0% (1)

- Sampul UnsriDocument1 pageSampul UnsrinisamawarrrNo ratings yet

- Surat RTDocument2 pagesSurat RTnisamawarrrNo ratings yet

- Struktur Organisasi PerusahaanDocument13 pagesStruktur Organisasi PerusahaanRickyi LieNo ratings yet

- Formulir Evaluasi Bangunan Sederhana PDFDocument2 pagesFormulir Evaluasi Bangunan Sederhana PDFnisamawarrrNo ratings yet