Professional Documents

Culture Documents

Calculation CEMA 5 - Parte4

Uploaded by

Angel AlvarezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation CEMA 5 - Parte4

Uploaded by

Angel AlvarezCopyright:

Available Formats

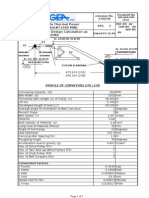

Example: Belt Conveyor Parameters

www.kmg.agh.edu.pl

Belt speed: 600 fpm

Belt width: 42 inches

Trough Angle: 35

5555 [ft3/hr] / 7524 [ft3/hr] = 74%

Idler spacing: 4.5 feet

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl

Department of Mining, Dressing and Transport Machines AGH

tel/fax +48126335162

The Selection of Idlers

www.kmg.agh.edu.pl

Idler life is determined by a combination of many factors, such as seals, bearings, shell thickness,

belt speed, lump size/material density, maintenance, environment, temperature, and the proper

CEMA series of idler to handle the maximum calculated idler load.

CEMA

CEMA

CEMA

CEMA

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl

B load rating based on minimum L10 of 30,000 hours at 500 rpm

C load rating based on minimum L10 of 30,000 hours at 500 rpm

D load rating based on minimum L10 of 60,000 hours at 500 rpm

E load rating based on minimum L10 of 60,000 hours at 500 rpm

Department of Mining, Dressing and Transport Machines AGH

tel/fax +48126335162

Step No. 1 Troughing Idler Series Selection

www.kmg.agh.edu.pl

Calculated Idler Load (lbs) = CIL = ((WB + (WM x K1)) x SI) + IML

Where:

WB = Belt weight (lbs/ft) use actual or estimate from Table 5-5

WM = Material weight (lbs/ft) = (Q x 2000) / (60 x Vee)

Q = Quantity of material conveyed (tons per hour)

Vee = Design belt speed (fpm)

SI = Spacing of idlers (ft)

Kl = Lump adjustment factor (see Table 5-6)

IML = Idler misalignment load (lbs) due to idler height deviation and

belt tension = (D x T) / (6 x SI)

Where:

D = Misalignment (in.)

T = Belt tension (lbs)

SI = Idler spacing (ft)

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl

Department of Mining, Dressing and Transport Machines AGH

tel/fax +48126335162

Step No. 1 Troughing Idler Series Selection

www.kmg.agh.edu.pl

WB = Belt weight (lbs/ft)

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl

Department of Mining, Dressing and Transport Machines AGH

tel/fax +48126335162

Step No. 1 Troughing Idler Series Selection

www.kmg.agh.edu.pl

Kl = Lump adjustment factor

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl

Department of Mining, Dressing and Transport Machines AGH

tel/fax +48126335162

You might also like

- Calculation CEMA 5 - Parte3Document5 pagesCalculation CEMA 5 - Parte3Angel AlvarezNo ratings yet

- Memoria de Calculo Cintas Transportadoras PDFDocument29 pagesMemoria de Calculo Cintas Transportadoras PDFluigimarloneNo ratings yet

- Belt ConveyorDocument11 pagesBelt Conveyormishra_1982No ratings yet

- Calculation CEMA 5 - Parte1Document5 pagesCalculation CEMA 5 - Parte1Angel AlvarezNo ratings yet

- Calculation CEMA 5 - Parte2Document5 pagesCalculation CEMA 5 - Parte2Angel AlvarezNo ratings yet

- Japan Pipe Belt Conveyor Sy...Document7 pagesJapan Pipe Belt Conveyor Sy...salkan_rahmanovic810No ratings yet

- MODERN PIPE CONVEYORS FOR COAL AND ASH TRANSPORTDocument12 pagesMODERN PIPE CONVEYORS FOR COAL AND ASH TRANSPORTIgor San Martín Peñaloza0% (1)

- Everything About Conveyor BeltsDocument30 pagesEverything About Conveyor BeltsJatin DarveNo ratings yet

- Belt Conveyor Take Up DesignDocument4 pagesBelt Conveyor Take Up DesignKroya HunNo ratings yet

- Beumer Overland Belt Conveyor enDocument16 pagesBeumer Overland Belt Conveyor enIgor San Martín PeñalozaNo ratings yet

- CEMA Standard 705-2004pvDocument5 pagesCEMA Standard 705-2004pvMateus Camargo0% (1)

- Cema 576Document9 pagesCema 576Edwin MariacaNo ratings yet

- Bucket Elevator ChainDocument4 pagesBucket Elevator Chainluisreng100% (1)

- Belt Conveying Vertical Curves and TransitionsDocument18 pagesBelt Conveying Vertical Curves and TransitionsFabio MiguelNo ratings yet

- Rex High Performance Chain Bucket Elevator ManualDocument170 pagesRex High Performance Chain Bucket Elevator ManualJohnNo ratings yet

- Manual Helix Delta t6Document309 pagesManual Helix Delta t6Ricardo Garay Reinoso100% (2)

- Sidewinder Manual (001-155)Document150 pagesSidewinder Manual (001-155)NighWolfNo ratings yet

- Belt ConveyorDocument3 pagesBelt ConveyorJawed AnsariNo ratings yet

- Tsubaki Conveyor Chains CatalogDocument60 pagesTsubaki Conveyor Chains Catalogditchche100% (2)

- Design Belt Conveyor Crushed LimestoneDocument13 pagesDesign Belt Conveyor Crushed LimestoneEyob AbabuNo ratings yet

- VFD Selection Guide for Screw FeedersDocument6 pagesVFD Selection Guide for Screw FeedersAndrea Fabiana Blaschi0% (1)

- CEMA8 5pgDocument5 pagesCEMA8 5pgkmats100% (2)

- Apron Feeder Power Calculations PDFDocument4 pagesApron Feeder Power Calculations PDFtuba25% (4)

- Conveyor BeltDocument2 pagesConveyor BeltSholhan AzizNo ratings yet

- Pressure-Resistant Gravimetric Coal Feeder CatalogueDocument10 pagesPressure-Resistant Gravimetric Coal Feeder CataloguesuparnabhoseNo ratings yet

- Final ThesisDocument59 pagesFinal ThesisBALRAM37710% (1)

- Pipe Conv Presentation ColourDocument25 pagesPipe Conv Presentation Colourgunduanil17No ratings yet

- Mato Belt Cleaner CatalogueDocument12 pagesMato Belt Cleaner Catalogueleeyod100% (1)

- L3271 F3Document223 pagesL3271 F3Jorge Rolando Alvarez Mendoza100% (6)

- Screw Conveyor Design Analysis MatlabDocument21 pagesScrew Conveyor Design Analysis Matlabavinash1987No ratings yet

- Belt Catalog #2 Bridge StoneDocument55 pagesBelt Catalog #2 Bridge Stonetinyfalse100% (3)

- Synergy Shuttle ConveyorDocument5 pagesSynergy Shuttle ConveyorTamal Tanu RoyNo ratings yet

- Discharge Screw Conveyors Design SelectionDocument5 pagesDischarge Screw Conveyors Design SelectionHadid100% (1)

- Conveyor ChainsDocument184 pagesConveyor ChainsAchinNo ratings yet

- BELT CONVEYOR COMPONENTSDocument38 pagesBELT CONVEYOR COMPONENTShidai100% (2)

- Belt Conveyor CalculationDocument8 pagesBelt Conveyor CalculationFarrahxviiiNo ratings yet

- 3100 CV 0001Document11 pages3100 CV 0001tranceinttNo ratings yet

- Chapter 4 belt capacities and speedsDocument1 pageChapter 4 belt capacities and speedsachmatNo ratings yet

- CEMC Screw Conveyor Manual 2.20Document107 pagesCEMC Screw Conveyor Manual 2.20Angel Alvarez100% (7)

- Pipe Conveyor Conveyors Pm-Check ListDocument5 pagesPipe Conveyor Conveyors Pm-Check Listgullipalli srinivasa raoNo ratings yet

- Belt Conveyor Pulley DesignDocument11 pagesBelt Conveyor Pulley Designthakur_raghab100% (1)

- Belt Conveyor Pulley Design - Why The FailuresDocument16 pagesBelt Conveyor Pulley Design - Why The FailuresenrimauryNo ratings yet

- OSHA Conveyor StandardsDocument49 pagesOSHA Conveyor Standardsmrkadu_61100% (1)

- Conveyor Belt Design Manual Contitech - EngDocument140 pagesConveyor Belt Design Manual Contitech - Engcanito73100% (12)

- Bucket ElevatorsDocument55 pagesBucket Elevatorsabosede2013100% (1)

- Conveyor Tension and Trajectory CalculationDocument8 pagesConveyor Tension and Trajectory CalculationGregory Nick Toledo Veliz50% (2)

- Konveyör Hesabı 7.24Document9 pagesKonveyör Hesabı 7.24Salih HasNo ratings yet

- PDF BeltConveyorsCalculationsCEMA5 EngDocument46 pagesPDF BeltConveyorsCalculationsCEMA5 EngfelramNo ratings yet

- Design (Imperial) 7.23Document9 pagesDesign (Imperial) 7.23ozgurturunc4No ratings yet

- Design (Imperial) 7.23Document9 pagesDesign (Imperial) 7.23Salih HasNo ratings yet

- ConveyDocument6 pagesConveyAbnetastroNo ratings yet

- Examples On Cycle TimeDocument44 pagesExamples On Cycle Timeabiodun0% (1)

- Project: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADocument7 pagesProject: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMASara Lopez100% (8)

- Conveyor Design CalcDocument6 pagesConveyor Design CalcGregory Nick Toledo VelizNo ratings yet

- Conveyor Design Summary ReportDocument53 pagesConveyor Design Summary ReportTotok ChemScoutNo ratings yet

- M 360 ContentDocument10 pagesM 360 ContentMonu SharmaNo ratings yet

- Project by Location: Girting Design ADocument10 pagesProject by Location: Girting Design AJurie_sk3608No ratings yet

- Main FileDocument9 pagesMain FileSyed Munawar AliNo ratings yet

- Access Scaffoding DesignDocument10 pagesAccess Scaffoding DesignSyed Munawar Ali100% (5)

- Technical Data A SWD SystemDocument4 pagesTechnical Data A SWD Systemintcosylva4167No ratings yet

- ArccostsDocument5 pagesArccostsAngel AlvarezNo ratings yet

- ArccostsDocument5 pagesArccostsAngel AlvarezNo ratings yet

- ArccostsDocument5 pagesArccostsAngel AlvarezNo ratings yet

- Calculation CEMA 5 - Parte10Document1 pageCalculation CEMA 5 - Parte10Angel AlvarezNo ratings yet

- Calculation CEMA 5 - Parte9Document5 pagesCalculation CEMA 5 - Parte9Angel AlvarezNo ratings yet

- Dimeco Catalogo Tecnico Parte1Document20 pagesDimeco Catalogo Tecnico Parte1Angel AlvarezNo ratings yet

- Calculation CEMA 5 - Parte10Document1 pageCalculation CEMA 5 - Parte10Angel AlvarezNo ratings yet

- CEMA B105.1 Welded Steel Conveyor Pulleys - Parte3Document3 pagesCEMA B105.1 Welded Steel Conveyor Pulleys - Parte3Angel AlvarezNo ratings yet

- CEMA B105.1 Welded Steel Conveyor Pulleys - Parte5Document3 pagesCEMA B105.1 Welded Steel Conveyor Pulleys - Parte5Angel Alvarez0% (1)

- CEMA B105.1 Welded Steel Conveyor Pulleys - Parte4Document3 pagesCEMA B105.1 Welded Steel Conveyor Pulleys - Parte4Angel AlvarezNo ratings yet

- CEMA B105.1 Welded Steel Conveyor Pulleys - Parte2Document3 pagesCEMA B105.1 Welded Steel Conveyor Pulleys - Parte2Angel AlvarezNo ratings yet

- CEMA B105.1 Welded Steel Conveyor Pulleys - Parte1Document3 pagesCEMA B105.1 Welded Steel Conveyor Pulleys - Parte1Angel AlvarezNo ratings yet

- Idler EngrDimDocument64 pagesIdler EngrDimOrlando MelipillanNo ratings yet

- Design of an above ground sulphuric acid storage tankDocument143 pagesDesign of an above ground sulphuric acid storage tankAngel Alvarez100% (6)

- Manufactura Ingenieria y Tecnologia-KalpakjianDocument596 pagesManufactura Ingenieria y Tecnologia-Kalpakjiandgeio1988No ratings yet

- Ba 1 3Document16 pagesBa 1 3Angel AlvarezNo ratings yet

- Vibrator Catalog Complete 003 T UpDocument48 pagesVibrator Catalog Complete 003 T UpAngel AlvarezNo ratings yet

- 52nd North Carolina Industrial Ventilation Conference Basics of Ventilation IIDocument11 pages52nd North Carolina Industrial Ventilation Conference Basics of Ventilation IIAngel AlvarezNo ratings yet

- Rotolok UK Rotary Valves AirlocksDocument6 pagesRotolok UK Rotary Valves AirlocksAngel AlvarezNo ratings yet

- This Book Is The Milk OkDocument121 pagesThis Book Is The Milk OkAngel Alvarez100% (1)

- Ba 1 3Document16 pagesBa 1 3Angel AlvarezNo ratings yet

- Basics of Dust Control - enDocument48 pagesBasics of Dust Control - enMuhammad RafiNo ratings yet

- 2013 Motor Catalog Toshiba PDFDocument228 pages2013 Motor Catalog Toshiba PDFrelicario25No ratings yet

- Pollution control equipment eliminators and scrubbersDocument6 pagesPollution control equipment eliminators and scrubbersAngel AlvarezNo ratings yet

- Simbolos Hidraulicos Din Iso 1219Document15 pagesSimbolos Hidraulicos Din Iso 1219Angel AlvarezNo ratings yet