Professional Documents

Culture Documents

PWA Questionnaire JAN 2016

Uploaded by

loveson709Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PWA Questionnaire JAN 2016

Uploaded by

loveson709Copyright:

Available Formats

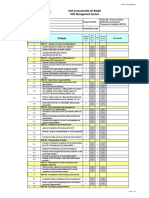

PWA SAFETY QUESTIONNAIRE

Description

YES

NO N/A

MANAGEMENT

Ref. to: (QCS: 11.1.1 + 11.2.1 + 11.2.3 + 11.2.4). (CDD / Fire Safety Handbook / Building Worksite Safety / 3 Page 35).

1:

OH&S plan submitted for approval Within 30 days of the award of the contract?

2:

OH&S organization chart available

3:

OH&S Policy displayed

4:

Regular meetings record

5:

Responsibilities defined

6:

Near Miss & Hazard reporting and follow up

7:

Provision for visitors

8:

Monitoring effectiveness implementation of OH&S program

9:

Generic Risk Assessment & Management

10:

Monitoring & Control Sub-contractor to comply with all existing rules & regulations?

11:

In general, contractor following the government rules & regulation.

Ref. to: (QCS: 11.1.1.8).

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

SAFETY STAFF

12:

OH&S Safety Staff CV submitted for approval within 30 days of the award of the contract?

13:

OH&S Officer available during all working hours

14:

OH&S Officer is exclusive for site & for H&S jobs

Ref. to: (QCS: 11.1.1 + 11.2.2 + 11.2.3). (Labor Law: Article 99).

YES

YES

YES

TRAINING

15:

Orientation / Site Induction

16: Tool Box Talk (TBT) daily documented

17: Task specific (Equipment Operators, Scaffolders, Riggers, Fire Watchers, Emergency Drill, etc

18:

Management

19:

Refresher courses

Ref. to: (QCS: 11.1.2 + 11.2.2 + 11.2.3). (Worker Rights Booklet 2009 Page 41 & 45). (CDD / Fire Safety Handbook

Safety / 3 Page 9 & 10).

YES

YES

YES

YES

YES

/ Building Worksite

WORK ENVIRONMENT

20

21

22

23

24

25

26

27

28

29

30

31

:

:

:

:

:

:

:

:

:

:

:

:

Ventilation

Removal of fumes and dust

Dust controls preventive measures

Noise levels (instrument available?)

Vibration

Lighting

General purpose for evening work

For a particular task around construction site

Absence of glare

Work area

Corridors

Exteriors

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

PWA SAFETY QUESTIONNAIRE

32 : >Ergonomics - layout of work area

33 : The disposal of surplus water and the accompanying growth of trees and the proliferation of insects and

rodents

34 : Does the site pose danger to the surrounding environment?

35 : Site office furniture

Ref. to: (QCS: 11.1.2) (Labor Law: Article 103,106 & 107).

YES

YES

NO

YES

WELFARE FACILITIES

36 : Clean toilets with exhaust fan

37 : Toilets & Sanitary in good condition

38 : Potable water provided

39 : Eating and resting areas

40 : Messing / Canteen facilities

41 : Washing facilities

42 : Regularly cleaned area

43 : Work clothes lockers and hanging areas

44 : Prevent the breeding of mosquitoes on the site

Ref. to: (QCS: 11.1.2.4 + 11.1.6 + 11.2.2 + 11.2.3). (Labor Law: Article 100,104,105 & 115).

YES

YES

YES

YES

YES

YES

YES

NO

N/A

FIRST AID AND MEDICAL

45 : Paramedics available & Names displayed according to number of workers

46 : Average Manpower Labor

47 : Accident reporting, records available &follow up

48 : Periodic medical examinations for workers and follow up

49 : Medical record book existing

50 : Paramedics Telephone numbers displayed

51 : Adequate first aid kits supplies & expiration dates (as per Hamad Medical Corporation Requirement

52 : Adequate first aid equipment

53 : Availability of stretcher / ambulance / Standby Vehicle

54 : Clean room with potable water supply.

55 : Doctor, Site Nurse & Site Clinic must be approved from Supreme Council of Health.

Ref. to: (Labor law: Article 100). (CDD / Fire Safety Handbook / Fire Safety Provisions For Construction Worksites

/ 2 Page 16).

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

EMERGENCY EQUIPMENT

56

57

58

59

60

61

62

63

64

:

:

:

:

:

:

:

:

:

Procedures

Assembly / Muster point

Conducted Emergency Drill Training every 6 month

Availability of Fire / Smoke / Gas detection mobile devices

Emergency contact telephone numbers / Communications

Breathing apparatus and / or respirators (if applicable)

Torches

Loud Hailer

Emergency lighting

YES

YES

YES

YES

YES

YES

YES

YES

YES

PWA SAFETY QUESTIONNAIRE

65 : Adequate and safe Emergency Exit / Doors are provided

66 : Escape routes, access ways to assembly points, extinguishers, hydrants and other firefighting equipment's

and first aid kits kept clear of obstruction at all times

Ref. to: (Labor Ministry Decision No. 20 of 2005). (CDD / Fire Safety Handbook / Fire Safety Provisions For

Construction Worksites / 2 Page 17).

YES

YES

HOUSEKEEPING AND TIDINESS

67 : Segregation of waste and scrap

68 :

Sufficient bins

69 : Waste and scrap regularly collected & removed from site

70 :

No buildup of flammable materials

71 :

Removal of combustibles

Ref. to: (Worker Rights Booklet 2009 Page 45). (CDD / Fire Safety Handbook / Fire Safety Provisions For

Construction Worksites / 2 Page 10). (CDD / Fire Safety Handbook / Building Worksite Safety / 3 Page 12).

YES

YES

YES

YES

YES

STORAGE-RACKS BINS SHELVES

72 : Aisles and walkways kept clear

73 :

Neat and orderly

74 : Not too high

75 :

Heavy items kept low

76 :

Sufficient space to access items

77 : Are chemicals, paints, flammable liquids and gas cylinders stored only in designated areas?

Ref. to: (QCS: 11.1.1.12).

YES

YES

YES

YES

YES

YES

SITE SECURITY AND ACCESS

78 : Adequate transportation between working site & accommodations

79 :

Security check correctly performed

80 : Guardhouse continuously manned

81 :

Round check register updated

82 :

Perimeter fence intact

83 :

Inspection of materials gate passes

84 :

Need for the existence of surveillance cameras inside the site

85 :

Need for security personnel within the site

Ref. to: (QCS: 11.1.2 + 11.2.3). (Labor Law: Article 101).

YES

YES

YES

YES

YES

YES

N/A

YES

PERSONAL PROTECTIVE EQUIPMENT

86

87

88

89

90

91

92

93

94

:

:

:

:

:

:

:

:

:

Coveralls

Eye protection

Head protection

Hand protection

Foot protection

Hearing Protection

Safety reflecting vests

Dust mask

Any other protection

YES

YES

YES

YES

YES

YES

YES

YES

YES

PWA SAFETY QUESTIONNAIRE

Ref. to: (Worker Rights Booklet 2009 Page 45).

SAFE WORK PRACTICES

95 : Avoid manual handling (Use mechanical handling equipment)

96 :

Not working alone

97 :

Cap (cover) for rebar / reinforcement steel

Ref. to: (QCS: 11.1.5.4 + 11.2.2 + 11.2.3). (CDD / Fire Safety Handbook / Building Worksite Safety / 3 Page 19).

YES

YES

YES

EXCAVATIONS

YES

98 :

Location of existing utilities confirmed

YES

99 :

Signs posted

YES

100 : Adequate hard barrier installed

YES

101 : Adequate warning tape & lighting

N/A

102 :

Bracing & Shoring provided (if applicable)

YES

103 :

1m spoil clearance from the excavated pit

N/A

104 :

Sloping maintained (if applicable)

YES

105 :

Correctly made ladders provided for access into excavation

YES

106 : Appropriate access provided (temporary bridges & footpaths)

Ref. to: (QCS: 11.1.1.4). (Worker Rights Booklet 2009 Page 46). (CDD / Fire Safety Handbook / Building Worksite Safety / 3 Page 10).

MECHANICAL

107 : Adequate guarding on machines

108 :

Inspected regularly with color code sticker & maintenance records

109 :

Grounding installed to equipment/machine

110 :

Unused machines electrically isolated

111 :

Emergency isolation switches

112 :

Safety devices

113 :

Heating equipment

Ref. to: (QCS: 11.1.5.3 + 11.2.2). (Worker Rights Booklet 2009 Page 46). (CDD / Fire Safety Handbook / Building

Worksite Safety / 3 Page 10).

YES

YES

YES

YES

YES

YES

YES

ELECTRICAL

114 :

115 :

116 :

117 :

118 :

119 :

120 :

121 :

Ref. to:

Insulation, cables, industrial plugs in good condition

Cables suspended using S hooks and lead stands

Inspected regularly with color code sticker

ELCB provided to site power boards

Qualified electrician hired to install (Name & Qualification)

Protection of fittings against external damage

Trailing leads used?

Ovens and furnaces in good condition?

(QCS: 11.1.3 + 11.2.3). (CDD / Fire Safety Handbook / Building Worksite Safety / 3 Page 19).

YES

YES

YES

YES

YES

YES

N/A

N/A

SCAFFOLDS AND LADDER

122 :

123 :

124 :

Certified scaffold supervisor and scaffolders

Scaffolds correctly erected

Scaffolds properly secured

YES

YES

YES

PWA SAFETY QUESTIONNAIRE

125 :

126 :

127 :

128 :

Ref. to:

Toe boards, guardrails (top & mid rail), handrails & access checked

Fully boarded platforms

Scaffolds correctly tagged

Materials in good condition

(QCS: 11.1.3 + 11.2.3). (CDD / Fire Safety Handbook / Building Worksite Safety / 3 Page 11, 12 & 19).

YES

YES

YES

YES

WORKING AT HEIGHT

129 :

Personnel working above 1.2 m using fall protection devices

130 :

Fall protection devices condition / Certificate

131 : Adequate safe access in place to working height elevations

132 :

Personnel properly trained in the selection and use of fall protection devices

133 : All loose material & tools at heights secured or removed

Ref. to: (QCS: 11.1.4 + 11.2.2 + 11.2.3).

YES

YES

YES

YES

YES

PLANT AND EQUIPMENT

YES

134 :

Qualifications of operators available

YES

135 : Available Qatar license for drivers / operators

YES

136 :

Banks man available

YES

137 :

Used as per its design (for intended purpose

YES

138 :

Vehicle and equipment condition

YES

139 :

Reverse alarm installed

YES

140 :

Flashing light installed

YES

141 :

Generators and welding machine in good condition?

YES

142 :

Compressors and water pumps in good condition?

NO

143 :

Oil / fuel leak causing environmentally pollution

Ref. to: (QCS: 11.1.4 + 11.2.3). (Worker Rights Booklet 2009 Page 45). (CDD / Fire Safety Handbook / Building Worksite Safety / 3 Page

19).

LIFTING OPERATIONS

144 : Available Qatar license/third party certificate for operators and certificate of training for banks men and YES

riggers

YES

145 :

Load capacity displayed

YES

146 :

Certification updated

YES

147 :

Condition of access and ground

YES

148 :

Lifting locations barrier off

YES

149 :

Outriggers/supports fully extended

YES

150 :

Hoist limiting device and SWL indicator working

Ref. to: (QCS: 11.1.4 + 11.2.3). (Worker Rights Booklet 2009 Page 45). (CDD / Fire Safety Handbook / Building Worksite Safety / 3 Page

19).

LIFTING GEAR

151

152

153

154

:

:

:

:

Ropes, Chains, Shackles etc. in good condition

Identity number and SWL displayed

Color-code system in place

Available 3rd party certificate for every lifting gear

YES

YES

YES

YES

PWA SAFETY QUESTIONNAIRE

155 :

Damaged lifting devices removed from the workplace

Ref. to: (QCS: 11.1.2.14).

YES

COMPRESSED GAS CYLINDERS

156 :

157 :

158 :

159 :

160 :

161 :

162 :

163 :

Ref. to:

Stored upright, valves protected

Regulators Gauges working; hoses inspected

Flashback arrestor fitted

Cylinders are securely tied or with trolley

Type of gas clearly marked on cylinders

Segregation of incompatible gases

Transported on appropriate trolley

Correct signage

(QCS: 11.1.1.10).

YES

YES

YES

YES

YES

YES

YES

YES

SAFETY OF THE PUBLIC (For Road Works)

164 : Approval from PWA, then from Traffic Dep. & Environmental ministry

165 :

International Warning signs

166 :

Warning yellow lights

167 : Adequate Barricades (to comply with Traffic law no. 19)

168 :

Railing

169 :

Pedestrians pathway signs & not interacted with work zone

170 : Adequate safe access to all properties

171 :

Night watchman available

172 : To provide road hump to reduce & control speed with approval from Traffic Department

Ref. to: (QCS: 11.1.8.2). (Labor Ministry Decision No. 20 of 2005).

YES

YES

YES

YES

YES

YES

YES

YES

YES

SAFETY SIGNAGE AND NOTICE BOARD

173 :

Clearly displayed

174 :

Shall be in Arabic, English & other languages

175 :

Clean and legible

176 :

Enough traffic diversion signboard?

177 : Adequate warning signs and guides are provided

178 :

Shall be fully illustrated and provide details of key safety procedures to be followed

Ref. to: (QCS: 11.2.2 + 11.2.3).

YES

YES

YES

YES

YES

YES

WORK PERMITS

179 :

Confined Space

180 :

Hot Work

181 :

Excavation

182 :

Scaffolding

183 :

Electrical Work

184 :

Work permit correctly issued and signed

185 : Ashghal s work permit enforced

Ref. to: (QCS: 11.1.7 + 11.2.2 + 11.2.3). (Fire Safety Handbook / Fire Safety Provisions For Construction Worksites

FIRE PROTECTION PREVENTION

YES

YES

YES

YES

YES

YES

YES

/ 2 Page 8).

PWA SAFETY QUESTIONNAIRE

186 :

Is the firefighting equipment which approved by Civil Defense available at working area?

YES

187 :

Welding and grinding at working area properly secured

YES

188 :

Firefighting equipment not obstructed

YES

189 :

Expiration date of firefighting equipment checked

YES

190 :

Monthly firefighting equipment visual inspected & recorded

YES

191 : Availability of Fire / Smoke / Gas detection system

YES

192 :

Alarm and Emergency Evacuation system

YES

193 : Are Alarms audible in all areas

YES

194 :

Minimum quantities of flammable material shall kept on site with full precautions required

YES

195 : Access for Fire Brigade cleared

Ref. to: (QCS: 11.1.2.3 + 11.2.2 + 11.2.3). (CDD / Fire Safety Handbook / Building Worksite Safety / 3 Page 15, 16, 17 & 18).

N/A

HAZARDOUS SUBSTANCES

196 : Toxic/ hazardous substance correctly tagged/ labeled and secured

197 : Adequate and Proper Storage provided

198 : Appropriate spill containment provided

199 :

Disposal Spill kit (location, appropriate, easy access)

200 :

Material Safety Data Sheet (MSDS) present & required training delivered to concerned employees

201 :

Class B fire extinguisher near by

202 :

Correct signage

203 :

Register of chemicals

204 :

Correct labeling

Ref. to: (QCS: 11.1.5.5). (CDD / Fire Safety Handbook / Building Worksite Safety / 3 Page 13 & 14).

YES

YES

YES

YES

YES

YES

YES

YES

YES

CONFINED SPACES

205

206

207

208

209

210

211

:

:

:

:

:

:

:

Gas detectors/monitors with rechargeable batteries and battery charger (2 No.)

Full body safety harnesses with lifelines and shackles (6 No.)

Lifting frame with fall arrest device (1 No.)

Constant flow escape breathing apparatus complete with storage cases (2 No.)

Automatic positive pressure self-contained breathing apparatus with storage case (1 No.)

To train employee for confined space activity & supervision monitoring

All equipment maintained & calibrated up to date with 3rd party certificate (record is available)

OTHER RELATED SAFETY ITEMS (COMMENTS/REMARKS)

YES

YES

YES

YES

YES

YES

YES

KEY PERFORANCE INDICATOR

212

213

214

215

:

:

:

:

No. of

No. of

No. of

No. of

Medical Treatment Cases

First Aid Cases

Near-Miss

Fatal Cases

Current

Month

0

13

2

0

Accumulating

Up to Date

02

197

18

0

PWA SAFETY QUESTIONNAIRE

216 : No. of RTA (Road Traffic Accidents)

217 : No. of Manpower (Average)

218 : No. of Direct Man-hours

596

14482

8

0

14482

8

0

1

0

1

10231

4

567

2847731

219 : No. of Hours Lost

220 : No. of Man-hours from Last Lost Time Accident

221

222

223

224

225

:

:

:

:

:

No. of Lost Time Accidents

No. of Safety Meeting

No. of Emergency Drill

No. of Audit

Kilometers Driven

297

1826712

1

26

13

16

2329766

**Note: *Number of accident in a year should be include

* No of Fatal Cases * No of Lost Time Accidents

Accumulative Accident Rate = (Accumulative) No. of Medical Treatment Cases + No. of Fatal Cases+ No. of RTA (Road Traffic

Accidents) + No. of Lost Time Accidents X 100,000 / No. of Manpower (Average):

Monthly Accident Rate = No. of Medical Treatment Cases + No. of Fatal Cases+ No. of RTA (Road Traffic Accidents) + No. of Lost

Time Accidents X 100,000 / No. of Manpower (Average):

Accumulative Frequency Rate Accident = (Accumulative) No. of Medical Treatment Cases + No. of Fatal Cases+ No. of RTA (Road

Traffic Accidents) + No. of Lost Time Accidents X 1000,000 / No. of Direct Man-hours:

Monthly Frequency Rate Accident = No. of Medical Treatment Cases + No. of Fatal Cases+ No. of RTA (Road Traffic Accidents) +

No. of Lost Time Accidents X 1000,000 / No. of Direct Man-hours:

You might also like

- HSE Formats (9508 - Part1)Document50 pagesHSE Formats (9508 - Part1)Paras Jani100% (1)

- 1.) Client OH&S Specification (Please Only Use The Relevant Sections)Document78 pages1.) Client OH&S Specification (Please Only Use The Relevant Sections)Fadley ValleyNo ratings yet

- Oisd 179Document27 pagesOisd 179Devashish SharmaNo ratings yet

- ADIS Question Paper - 2022 - 23108 - 01Document2 pagesADIS Question Paper - 2022 - 23108 - 01vikasNo ratings yet

- Samsung C&T - Registration Questionnaire For ContractorsDocument9 pagesSamsung C&T - Registration Questionnaire For ContractorsFandy RezitaNo ratings yet

- Mock Drill Observer Feedback Form Rev-01Document1 pageMock Drill Observer Feedback Form Rev-01Mohammad ArifNo ratings yet

- HSE Campaign 2013 / 2014 Launching Program Schedule Jurutama Sdn. BHD.: Maritime ProjectDocument1 pageHSE Campaign 2013 / 2014 Launching Program Schedule Jurutama Sdn. BHD.: Maritime ProjectMohd AdhaNo ratings yet

- Action Plan Jalalabad FinalDocument75 pagesAction Plan Jalalabad FinalLimra TravelsNo ratings yet

- Industrial Safety ManegmentDocument132 pagesIndustrial Safety ManegmentAdilsha shaikhNo ratings yet

- He0Alth, Safety and Environment Ola/Uber/Cab Drivers: Submitted byDocument22 pagesHe0Alth, Safety and Environment Ola/Uber/Cab Drivers: Submitted byRohan NandiNo ratings yet

- 10 2016 PDFDocument2 pages10 2016 PDFsurajNo ratings yet

- JTB-RJJ000-S0-PRC-900-00043 HSE Minimum Requirement PDFDocument24 pagesJTB-RJJ000-S0-PRC-900-00043 HSE Minimum Requirement PDFFarhan PutraNo ratings yet

- JP Jo Interview QuestionsDocument10 pagesJP Jo Interview QuestionsMuhammad MehboobNo ratings yet

- 100th HSJV Weekly Meeting Rev 8Document42 pages100th HSJV Weekly Meeting Rev 8Humpy DumpyNo ratings yet

- HSE Materials Stock InventoryDocument1 pageHSE Materials Stock InventorySreekumarNo ratings yet

- JHA For To Carryout Activities During Unloading of Product From Ship Rev00Document4 pagesJHA For To Carryout Activities During Unloading of Product From Ship Rev00Sreekumar100% (1)

- A List of Tested QuestionsDocument6 pagesA List of Tested QuestionsVijay Raj100% (1)

- Site Hse Inspection Report: SECB Supervision ProjectsDocument2 pagesSite Hse Inspection Report: SECB Supervision ProjectsRakesh SidhuNo ratings yet

- Frequently Asked Questions OnDocument15 pagesFrequently Asked Questions OnIIPHSNo ratings yet

- Adis Climum 201920Document16 pagesAdis Climum 201920EHS Plant6No ratings yet

- IGN 07 Working at Height and Working at Height Rescue PlanDocument75 pagesIGN 07 Working at Height and Working at Height Rescue Planin123No ratings yet

- MONTHLY REPORT S22 (iwk-PARA)Document12 pagesMONTHLY REPORT S22 (iwk-PARA)PDPPPJSM10822 Muhammad Aqil Asyraf bin M NazreNo ratings yet

- R U N G T A M I N e S L I M I T e DDocument16 pagesR U N G T A M I N e S L I M I T e DRAMODSNo ratings yet

- Vibration ProcedureDocument6 pagesVibration Procedurematam natarajNo ratings yet

- QHSE Coordinator QuestionnaireDocument1 pageQHSE Coordinator QuestionnaireSeaworks CompanyNo ratings yet

- Essentials of Houe and 5sDocument2 pagesEssentials of Houe and 5sRajesh Kumar SinghNo ratings yet

- Monthly HSE PerformanceReport REV2Document2 pagesMonthly HSE PerformanceReport REV2parthaNo ratings yet

- 0005 - 007 SAFETY RECOGNITION AND INCENTIVE PROGRAMS (SRIPs)Document5 pages0005 - 007 SAFETY RECOGNITION AND INCENTIVE PROGRAMS (SRIPs)baseet gazaliNo ratings yet

- OS 1.5 Pollution PreventionDocument9 pagesOS 1.5 Pollution PreventionclintNo ratings yet

- Job Hazard Analysis WorksheetDocument3 pagesJob Hazard Analysis WorksheetAbdul Hakam Mohamed YusofNo ratings yet

- 02 MAO Monthly Report Apr 20 PDFDocument80 pages02 MAO Monthly Report Apr 20 PDFjonesNo ratings yet

- Indexpro-Mpl-Prd-S-001-Hse Management Plan3Document21 pagesIndexpro-Mpl-Prd-S-001-Hse Management Plan3Edo-Abasi EkereNo ratings yet

- Tele HandlerDocument30 pagesTele HandlerArturNo ratings yet

- Construction Job Hazards Analysis: Hot TapDocument2 pagesConstruction Job Hazards Analysis: Hot TapMohammed MinhajNo ratings yet

- MOG-HSEQ-P-xxx Rev P1 PPE ManagementDocument47 pagesMOG-HSEQ-P-xxx Rev P1 PPE ManagementSamerNo ratings yet

- P6022MAB.000.51S.001a01 - FDH JV Site HSE Organization ChartDocument1 pageP6022MAB.000.51S.001a01 - FDH JV Site HSE Organization ChartbabjihanumanthuNo ratings yet

- Movile Plataform IncidentDocument34 pagesMovile Plataform IncidentAnonymous GfPSYi4nNo ratings yet

- Daily Site Report 07.aug.2021Document1 pageDaily Site Report 07.aug.2021engr.s.a.malik6424No ratings yet

- Monthly HSE Performance StatisticsDocument1 pageMonthly HSE Performance StatisticsRami KhedroNo ratings yet

- HSE Supervisors - Foreman Guide BookDocument12 pagesHSE Supervisors - Foreman Guide Bookmilyandi322No ratings yet

- Work Method Statement For Structure ErectionDocument12 pagesWork Method Statement For Structure ErectionMuhammad TeguhNo ratings yet

- Jha Atr, WHB, SD Field HydrotestingDocument3 pagesJha Atr, WHB, SD Field HydrotestingarunmirandaNo ratings yet

- HSE Evaluation CriteriaDocument2 pagesHSE Evaluation CriteriaChan RizkyNo ratings yet

- Risk Register: Hazards Identified Risk Control Measures Residual Risk by Whom L S R L S RDocument8 pagesRisk Register: Hazards Identified Risk Control Measures Residual Risk by Whom L S R L S Rzae nuddinNo ratings yet

- Selection Criteria For ContractorsDocument2 pagesSelection Criteria For ContractorsHonest Raj GanapathyNo ratings yet

- 01.WEEKLY REPORT 14 - 20 Mei 2021Document11 pages01.WEEKLY REPORT 14 - 20 Mei 2021reza fahleviNo ratings yet

- Indian Standard - Method For Computation of Frequency and Severity Rates For Industrial Injuries and Classification of Industrial AccidentsDocument29 pagesIndian Standard - Method For Computation of Frequency and Severity Rates For Industrial Injuries and Classification of Industrial AccidentsKunal JaiswalNo ratings yet

- 1.1 Buildings and FloorsDocument4 pages1.1 Buildings and FloorsMohamed Mouner100% (1)

- ESMPDocument21 pagesESMPdavid chisambaNo ratings yet

- Contractor Evaluation6Document18 pagesContractor Evaluation6inrsafety9742No ratings yet

- q11017 0100d Lps Sta Pk2 Ele MST 00010 c3 Gi and Flexible ConduitDocument77 pagesq11017 0100d Lps Sta Pk2 Ele MST 00010 c3 Gi and Flexible ConduitJobish ManikulathNo ratings yet

- Form Daily Site Diary and Progress ReportDocument1 pageForm Daily Site Diary and Progress ReportCécé Charles KoliéNo ratings yet

- Daily Observation ReportDocument1 pageDaily Observation ReportAnsar AliNo ratings yet

- MCQ-Question Paper With Answer Class Test I Academic Year 2020-21Document4 pagesMCQ-Question Paper With Answer Class Test I Academic Year 2020-21Anil WalkeNo ratings yet

- New Excavation Permit FormDocument5 pagesNew Excavation Permit FormMohammed ShifulNo ratings yet

- ADCE EHS Inspection FormDocument5 pagesADCE EHS Inspection Formyasser magdyNo ratings yet

- Observations Oct 2019Document38 pagesObservations Oct 2019mohammad samirNo ratings yet

- Night Work NotificationDocument1 pageNight Work NotificationSreekumarNo ratings yet

- CSHP Checklist 2011Document3 pagesCSHP Checklist 2011jey_dNo ratings yet

- CSHP Checklist 2011Document2 pagesCSHP Checklist 2011JenniferValle0% (1)

- App-16.2 - RISK ASSESSMENT For Construction of in Situ Foundation & Installation of Package Substation.Document15 pagesApp-16.2 - RISK ASSESSMENT For Construction of in Situ Foundation & Installation of Package Substation.loveson709100% (1)

- App-16.2 - Risk Assessment For Vermeer Axis WorksDocument13 pagesApp-16.2 - Risk Assessment For Vermeer Axis Worksloveson709No ratings yet

- App-16.2 - Risk Assessment For Traffic Signal SystemDocument13 pagesApp-16.2 - Risk Assessment For Traffic Signal Systemloveson709100% (2)

- App-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair RoadDocument15 pagesApp-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair Roadloveson709No ratings yet

- Emergency Rescue Plan For Operatives Working at HeightDocument9 pagesEmergency Rescue Plan For Operatives Working at Heightloveson709No ratings yet

- 3.1 SAMG-JV Emergency PreparednessResponse REV 00Document24 pages3.1 SAMG-JV Emergency PreparednessResponse REV 00loveson709100% (1)

- Near Miss Report: Complete This Form and Email It ToDocument1 pageNear Miss Report: Complete This Form and Email It Toloveson709No ratings yet

- INV Inv Ass Form TemplateDocument4 pagesINV Inv Ass Form Templateloveson70950% (2)

- Scaffold Erector Hiralal Mandal: PO Box 92986, Doha, Qatar Mob: 33428557Document2 pagesScaffold Erector Hiralal Mandal: PO Box 92986, Doha, Qatar Mob: 33428557loveson709No ratings yet

- 3.1 SAMG-JV Emergency PreparednessResponse REV 00Document24 pages3.1 SAMG-JV Emergency PreparednessResponse REV 00loveson709100% (1)

- Maintenance Log - TemplateDocument2 pagesMaintenance Log - Templateloveson709No ratings yet

- SCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift ProcedureDocument10 pagesSCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift Procedureloveson709100% (1)

- Emergency Rescue Plan For Operatives Working at HeightDocument9 pagesEmergency Rescue Plan For Operatives Working at Heightloveson709No ratings yet

- Assmt 1 Incident PhotosDocument3 pagesAssmt 1 Incident Photosloveson709No ratings yet

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- INV Action Plan TemplateDocument2 pagesINV Action Plan Templateloveson709No ratings yet

- 005 Ohs-Cop-Starrt & JhaDocument10 pages005 Ohs-Cop-Starrt & Jhaloveson709No ratings yet

- Assmt 1 TimelineDocument1 pageAssmt 1 Timelineloveson709No ratings yet

- Scaffold Erector Ram Sunar Yadav: PO Box 92986, Doha, Qatar Mob: 33428557Document2 pagesScaffold Erector Ram Sunar Yadav: PO Box 92986, Doha, Qatar Mob: 33428557loveson709No ratings yet

- RA082-C Grinding - ThornliebankDocument2 pagesRA082-C Grinding - Thornliebankloveson709No ratings yet

- N.Selvam:, BE (Mechanical)Document2 pagesN.Selvam:, BE (Mechanical)loveson709No ratings yet

- Yam Bahadur Budha CV PDFDocument2 pagesYam Bahadur Budha CV PDFloveson709No ratings yet

- Loveson Resume HSE ManagerDocument7 pagesLoveson Resume HSE Managerloveson709No ratings yet

- Epoxy COSHHDocument3 pagesEpoxy COSHHloveson709No ratings yet

- HSE Department Demobilization List: Trade May 2016Document1 pageHSE Department Demobilization List: Trade May 2016loveson709No ratings yet

- Po Ak-00076 - MR 534Document1 pagePo Ak-00076 - MR 534loveson709No ratings yet

- Loveson Glariyans: (Address, City, ST ZIP Code)Document2 pagesLoveson Glariyans: (Address, City, ST ZIP Code)loveson709No ratings yet

- PMC-FM-HSS-024 Near Miss ReportDocument1 pagePMC-FM-HSS-024 Near Miss Reportloveson709No ratings yet

- Board Reqd From AlkheesaDocument1 pageBoard Reqd From Alkheesaloveson709No ratings yet

- Impact of Technology On Our LivesDocument3 pagesImpact of Technology On Our LivesKim ErandioNo ratings yet

- McMurdo FastFind 220 PLB DatasheetDocument4 pagesMcMurdo FastFind 220 PLB DatasheetGiorgos PapadopoulosNo ratings yet

- Emc VNX MatrixDocument8 pagesEmc VNX Matrixpolivni0% (1)

- Model Questions and Answers Macro EconomicsDocument14 pagesModel Questions and Answers Macro EconomicsVrkNo ratings yet

- Pyrethroids April 11Document15 pagesPyrethroids April 11MadhumithaNo ratings yet

- Artikel 8 - (CURRICULUM EVALUATION)Document12 pagesArtikel 8 - (CURRICULUM EVALUATION)Kikit8No ratings yet

- Listening 3b Skills Test 1aDocument3 pagesListening 3b Skills Test 1aPticaSelicaNo ratings yet

- Frogs and ToadsDocument6 pagesFrogs and ToadsFaris AlarshaniNo ratings yet

- IELTS Materials ReadingDocument9 pagesIELTS Materials ReadingßläcklìsètèdTȜè0% (1)

- ABS CBN CorporationDocument16 pagesABS CBN CorporationAlyssa BeatriceNo ratings yet

- 11 My Immigration Story - Tan Le QuestionsDocument3 pages11 My Immigration Story - Tan Le QuestionsMallika Nand NairNo ratings yet

- Hunk (Aakc) - (Nov 2015)Document68 pagesHunk (Aakc) - (Nov 2015)Russell RiderNo ratings yet

- Nemo Outdoor 8.40 User Guide PDFDocument392 pagesNemo Outdoor 8.40 User Guide PDFXxbugmenotxXNo ratings yet

- Dry Docking QuotationDocument4 pagesDry Docking Quotationboen jayme100% (1)

- Exercise Chapter 4 This Is How You Do ItDocument10 pagesExercise Chapter 4 This Is How You Do ItAgustina WidiyantiNo ratings yet

- Power Factor Improvement SystemDocument25 pagesPower Factor Improvement SystemBijoy SahaNo ratings yet

- Angelic Spirit Work in The Hoodoo TraditionDocument6 pagesAngelic Spirit Work in The Hoodoo TraditionDaniel Sampaio100% (1)

- Cel2106 SCL Worksheet 6Document3 pagesCel2106 SCL Worksheet 6HarryJoy JackNo ratings yet

- CERADocument10 pagesCERAKeren Margarette AlcantaraNo ratings yet

- A Person On A Position of Air Traffic ControllerDocument7 pagesA Person On A Position of Air Traffic ControllerMUHAMMAD RAMZANNo ratings yet

- Sa Inc HCP English d10840Document64 pagesSa Inc HCP English d10840Ayu AfiantyNo ratings yet

- Argumentative EssayDocument7 pagesArgumentative EssayHoang Thi Huyen DieuNo ratings yet

- ScriptDocument12 pagesScriptWaleed Nadeem50% (2)

- New Life in Christ - Vol05 - Engl - Teacher GuideDocument29 pagesNew Life in Christ - Vol05 - Engl - Teacher GuideOliver Angus100% (1)

- Shower Tapware: For More Information and Detailed Specifications Please Refer To Our Website: WWW - Plumbline.co - NZDocument11 pagesShower Tapware: For More Information and Detailed Specifications Please Refer To Our Website: WWW - Plumbline.co - NZNoman KhanNo ratings yet

- List of ErpDocument2 pagesList of Erpnavyug vidyapeeth trust mahadNo ratings yet

- Vertical Transportation: Commercial, Hotel, Hospital, Etc)Document5 pagesVertical Transportation: Commercial, Hotel, Hospital, Etc)fdarchitectNo ratings yet

- Archaeology - October 2016 PDFDocument72 pagesArchaeology - October 2016 PDFOmer CetinkayaNo ratings yet

- Capital Structure UploadDocument17 pagesCapital Structure UploadLakshmi Harshitha mNo ratings yet

- Clay and Shale, Robert L VirtaDocument24 pagesClay and Shale, Robert L VirtaRifqi Brilyant AriefNo ratings yet