Professional Documents

Culture Documents

Contoh TroubleShooting Record

Uploaded by

Jelski Hizkia IlatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Contoh TroubleShooting Record

Uploaded by

Jelski Hizkia IlatCopyright:

Available Formats

TSR

PT UNITED TRACTORS

TECHNICAL SERVICE REPORT

REPORT NO

CONTINUATION SHEET

H

MACHINE MODEL

0 0 7

ENGINE MODEL

1 2 V 1 6 0

5

/JHI/BKJ/2011

(No/Mech/Branch/Year)

MACHINE S / NO

5 6

ENGINE NO

2 4 7 1

SYMPTOM : REAR SUSPENSI RH LEAK

ANALYSYS : SETELAH DILAKUKAN DISASSEMBLY PADA REAR SUSPENSI RH, DITEMUKAN PACKING DALAM KEADAAN AUS, KEAUSAN INI DIKA

ADANYA GESEKAN ANTARA U-PACKING DENGAN ROD SYLINDER SUSPENSI SECARA TERUS MENERUS, SEHINGGA LAMA KELAMA

U-PACKING MENGALAMI KELELAHAN BAHAN DAN TIDAK MAMPU LAGI MENYEKAT PRESSURE OLI DI DALAM SUSPENSI, DAN AKH

TERJADI KEBOCORAN.

ACTION

: REPLACE REAR SUSPENSI RH

ATTACHED DRAWING PHOTOGRAPH

PACKING

WORN

TSR

DT 1052

PT. UNITED TRACTORS Tbk

EXCECUTED

INFORMATION ONLY

CONCEPT CLAIM NO

TECHNICAL SERVICE REPORT

DATE

REPORT NO

/JHI/BKJ/2011

06 October 2011

(Day - Month - Year )

(No/Branch/Product/Year

No/Mechanic/Branch /Year.

3 2 0 8

BRANCH

0 0 1

MACHINE MAKE

DOC. REF. NO;

DATE

Part

Technical

(Day-Month-Year )

Modification

CUSTOMER BUSSINESS

BATU KAJANG

KOMATSU

CUSTOMER NO

CUSTOMER NAME :

PT PAMA PERSADA NUSANTARA

MACHINE MODEL

1 5 0 0 7

ENGINE MODEL

S D A 1 2 V 1 6 0

H D

Genset Alternator

SMR/HRS

1 2 5 5 0

APPLICATION

2 0

SYMPTOM

MACHINE S/NO

3 0 0 5 6

ENGINE NO

3 1 7 2 4 7 1

MILEAGE

(PP) 20

OPT.ATTACH.NAME

ATTACHMENT MAKE

ATTACHMENT MODEL

ATTACHMENT NO

Optional

MODEL

SERIAL NO

- - - - - - - - - - - - - - - - - - TROUBLE DATE

CORRECTTED DATE

1 8 0 8 1 1

1 8 0 8 1 1

GROUND CONDITION

ENVIRONMENT

Std

3

MAKE

- - - - - - - - - - SMR/KM

DELIVERY DATE

0 5 0 2 0 9

WORKING CONDITION

MINING

COAL MINING

MACHINE LOCATION :

BATU KAJANG

UP HILL HAULING

3 1

SOIL

0 2

040C

REAR SUSPENSI RH LEAK

MAIN PART CAUSING THE PROBLEM ( PART NO )

5 8 1 - 5 0 - 1 1 2 9 0

FAILURE :

Worn (Aus )

Crack (Retak)

P A C K

Burn (Terbakar )

PART NAME

N G

COMPONENT

REAR SUSPENSION

Loose (Kendor )

Rusty (Karat)

Broken (Patah )

Others (Damage)

Dent (penyok

Short Circuit

Bend (Bengkok)

Scracth (Baret )

Pitting (Bopeng )

ANALYSIS : ( describe detail of failure,analysis the cause ,operating condition &ATTACHED PHOTOGRAQPHS 2 (Two ) Set and Figure Part Book 2 (Two)

SEE CONTINUATION SHEET ,PLEASE

Detail of REAR SUSPENSI LEAK BECAUSE U-PACKING OVER WORN

Failure

CAUSED :

YES NO

YES

MISOPERATION

BAD WELD

Missmaintenance

WEAK WELD

MISADJUSTMENT

POOR TORQUE

NO

MISSASEMBLY (SALAH PASANG )

FOREIGN MATERIAL ( BENDA ASING )

Fatique fracture (kelelahan bahan)

CORECTION MADE :

FINISH

Cause

0 7

action

11

0 7

TPC

NOT FINISH DUE TO :

P/N REPLACED

EL7969

*/PAY LOAD ( KG)

150,000

LUBRICANT

ENGINE

USED

MAKE

NO

MAN HOURS

REPLACE REAR SUSPENSI RH

YES

G NG

P/N INSTALLED

EL7969

*/MATERIAL CARRIAGE

SOIL

MAIN CLUTH/TC TRANSMISI

SWING MACH

PTO CASE

G NG

PART NAME

REAR SUSPENSI

*/MAX SPEED

40 KM/hours

B.GEAR DIFF

STEERING

GEAR BOX

QTY

1

WHY IS IT REPLACED

LEAK

*/AVERAGE SPEED

20 KM/hours

FINAL DRIVE/

CONE CRUSH

HYDRAULIC

BRAKE OIL

GREASE

PERTAMINA

PERTAMINA

PERTAMINA

MOBILE

PERTAMINA

MOBILE

PERTAMINA

PERTAMINA

ALBIDA

TYPE

EO

GO

GO

GO

HO

GO

HO

HO

LITHIUM

SAE NO

15W40

30

30

50

10

50

10

10

NLGI 2

CLASS

CF

CF

CF

CD

CD

CD

CD

CD

M.PURPOSE

NRP:

8 2 2 1 0 0 1 0

Mech

Level

MECHANIC NAME : JELSKI HIZKIA

SIGN :

ATTACHED PHOTO :

YES

NO

DOCUMENT TO :

SDH/SPV NAME :

G1A

SIGN

WO :

NOTE : (1)P/N REPLACED / INSTALLED

G=Genuine NG= Non Genuine

(2)*/ Forklift dan Truck

PMRQS

57175355

FAKTUR

KWITANSI

You might also like

- Failure Analysis Report DT2377 Engine DamperDocument14 pagesFailure Analysis Report DT2377 Engine DamperEng PLM ACPNo ratings yet

- 7 - Lakhs Bank EstimateDocument8 pages7 - Lakhs Bank Estimatevikram Bargur67% (3)

- Mosfet PDFDocument13 pagesMosfet PDFTad-electronics TadelectronicsNo ratings yet

- Engine Valves Production Summer PractiseDocument26 pagesEngine Valves Production Summer Practisestatica27100% (2)

- Pelajaran 1: Dasar-Dasar Engine DieselDocument73 pagesPelajaran 1: Dasar-Dasar Engine DieselRolly HasanNo ratings yet

- Fai GD755-5R Sn10001-UpDocument37 pagesFai GD755-5R Sn10001-UpJaybs GregorioNo ratings yet

- Oil Iso TablesDocument9 pagesOil Iso TablesSilvana Harrison100% (1)

- II. ENGINE DIESEL (Komponen Engine) PDFDocument34 pagesII. ENGINE DIESEL (Komponen Engine) PDFJoko SukarionoNo ratings yet

- Infor Mashup SDK Developers Guide Mashup SDKDocument51 pagesInfor Mashup SDK Developers Guide Mashup SDKGiovanni LeonardiNo ratings yet

- Master Form Standar PPM PC 2000-8Document3 pagesMaster Form Standar PPM PC 2000-8Burhan Mburine UdinNo ratings yet

- F 008am - Plta Pscs Pc1250 8Document6 pagesF 008am - Plta Pscs Pc1250 8TaufikNo ratings yet

- Contract of Lease-Water Refilling StationDocument4 pagesContract of Lease-Water Refilling StationEkeena Lim100% (1)

- 8 Step TroubleshootingDocument2 pages8 Step TroubleshootingEndri Asmoro Putro100% (1)

- TSR 007-Trk-Pmj-Terex 60-TR112 - T 8821378-Replace Ecm-Slamet Wahyu WDocument4 pagesTSR 007-Trk-Pmj-Terex 60-TR112 - T 8821378-Replace Ecm-Slamet Wahyu WFrigia IsudibyoNo ratings yet

- The 7 Basic Quality Tools: Michele CanoDocument60 pagesThe 7 Basic Quality Tools: Michele Canoeko4fxNo ratings yet

- Engine Performance AnalysisDocument214 pagesEngine Performance AnalysisDaniel Dale Ambo Sibarani100% (1)

- Management OVHDocument31 pagesManagement OVHRohmanNo ratings yet

- Heavy Equipment LubricationDocument52 pagesHeavy Equipment LubricationSawal Wal100% (2)

- Technical Trouble Handling FinalDocument8 pagesTechnical Trouble Handling FinalRohmanNo ratings yet

- Trakindo Lifting Jacking BlockingDocument80 pagesTrakindo Lifting Jacking BlockingVin YonisraNo ratings yet

- Periodic Preservice Inspection Sheet Kom PDFDocument2 pagesPeriodic Preservice Inspection Sheet Kom PDFEko FebriyantoNo ratings yet

- Bca Sheet MultiflowDocument55 pagesBca Sheet Multiflowbumatio latiNo ratings yet

- Preventive - Maintenance ZX350H-5GDocument27 pagesPreventive - Maintenance ZX350H-5GYoga SugiNo ratings yet

- Machine Control SystemDocument43 pagesMachine Control SystemanggieNo ratings yet

- Progress ReportDocument5 pagesProgress Reportapi-394364619No ratings yet

- Maintenance & Operation of Rotating MachineryDocument3 pagesMaintenance & Operation of Rotating MachineryElsayed AmerNo ratings yet

- Unit identification and component overviewDocument23 pagesUnit identification and component overviewHacker TampabNo ratings yet

- PM Clinic Dozers KomatsuDocument3 pagesPM Clinic Dozers Komatsujheison valencia100% (1)

- TA1 English - Generator SetDocument13 pagesTA1 English - Generator Setahmad adelNo ratings yet

- GEAR BOX 15.7TE27418 - 0977177015-TrungDocument63 pagesGEAR BOX 15.7TE27418 - 0977177015-TrungPeter TrungNo ratings yet

- What Is PID - TutorialDocument5 pagesWhat Is PID - Tutorialsocrates19582405No ratings yet

- HINO FM 1000 HR Service SheetDocument7 pagesHINO FM 1000 HR Service SheetYudi AriantoNo ratings yet

- Magnetic Plug InspectDocument1 pageMagnetic Plug InspectAbner VillanuevaNo ratings yet

- Taufik Hidayat Gultom PS3 D375Document26 pagesTaufik Hidayat Gultom PS3 D375Dava JrNo ratings yet

- Safety & Maintenance Checklist-Articulated TrucksDocument1 pageSafety & Maintenance Checklist-Articulated TruckskkmechNo ratings yet

- HarisDocument28 pagesHarisZen PNo ratings yet

- GROUP 1 NEDP BATCH 2 DOCUMENTDocument132 pagesGROUP 1 NEDP BATCH 2 DOCUMENTElsa Qorirotul Aini Susilo100% (1)

- Inspection Plug GuideDocument3 pagesInspection Plug GuideAbdul AzisNo ratings yet

- CV Henry Ronald TiyowDocument6 pagesCV Henry Ronald TiyowHenry R. TIYOWNo ratings yet

- Vania Karunia Heavy Equipment Maintenance RecordsDocument14 pagesVania Karunia Heavy Equipment Maintenance RecordsSuhendraNo ratings yet

- Bag 2.PREDICTIVE MAINTENANCE 1Document12 pagesBag 2.PREDICTIVE MAINTENANCE 1Bayu Prayoga Part IINo ratings yet

- List Item Autolube GracoDocument1 pageList Item Autolube Gracotantoh84No ratings yet

- Radcool 288: Safety Data SheetDocument6 pagesRadcool 288: Safety Data SheetHendri PriyantoNo ratings yet

- OJI - Improving Maintenance Process ReportDocument36 pagesOJI - Improving Maintenance Process Reportramadhan wibiNo ratings yet

- Qa-4 Assembling Work Sheet: Hour MeterDocument8 pagesQa-4 Assembling Work Sheet: Hour Meteredi Supriyono100% (1)

- Ppe When Working at HeightDocument2 pagesPpe When Working at Heightekoimamp100% (2)

- PM Clinic Excavator PDFDocument3 pagesPM Clinic Excavator PDFjheison valencia100% (1)

- SOS Sampling ReportDocument2 pagesSOS Sampling ReportAsaisan AsaisanNo ratings yet

- Cara Kerja Hoist Cylinder OhtDocument7 pagesCara Kerja Hoist Cylinder OhtIntan MhswrNo ratings yet

- Remove & Install RadiatorDocument4 pagesRemove & Install RadiatorIndah Widya PutriNo ratings yet

- GRACO Timer 220Document26 pagesGRACO Timer 220andraNo ratings yet

- Damper Hd785 7Document2 pagesDamper Hd785 7alan traderNo ratings yet

- 1 Product KnowledgeDocument5 pages1 Product Knowledgeyusfarlian prianggoNo ratings yet

- Kajian Efisiensi Bahan Bakar HD465 (Devi Diansyah R. Pratama - 10070112045)Document8 pagesKajian Efisiensi Bahan Bakar HD465 (Devi Diansyah R. Pratama - 10070112045)Devi RahmaditaNo ratings yet

- 777D Off Highway Truck: Service TrainingDocument10 pages777D Off Highway Truck: Service Trainingnilton acNo ratings yet

- Final Drive ChecklistDocument2 pagesFinal Drive Checklistkathir drayNo ratings yet

- Hd785-3 Electric OptionalDocument13 pagesHd785-3 Electric OptionalBima Dwi UtomoNo ratings yet

- Periodic Service 1000 Hours PC 200-8: Present By: Muh Arif Budiawan SyamDocument28 pagesPeriodic Service 1000 Hours PC 200-8: Present By: Muh Arif Budiawan SyamMuh Arief Budiawan Arief100% (1)

- Air Intake SystemDocument4 pagesAir Intake SystemGovea HeduNo ratings yet

- 2.a PM CLINIC Guideline HD785-7 Rev29112017Document20 pages2.a PM CLINIC Guideline HD785-7 Rev29112017Devid Waladan Sholehan100% (1)

- MONOGRADE VS MULTIGRADE ENGINE OILS: WHICH IS BETTERDocument3 pagesMONOGRADE VS MULTIGRADE ENGINE OILS: WHICH IS BETTERmdavilasNo ratings yet

- PC 1250 Elect ControlDocument43 pagesPC 1250 Elect ControlanggieNo ratings yet

- CAJA T12000 1102FT12345Document41 pagesCAJA T12000 1102FT12345bvaleriochucoNo ratings yet

- Failure Analysis Report GR3031 - Adjuster RH Blade BrokenDocument10 pagesFailure Analysis Report GR3031 - Adjuster RH Blade BrokenEng PLM ACPNo ratings yet

- Motor Grader EtrDocument15 pagesMotor Grader EtrMuhammad IchwanNo ratings yet

- Job Pending 6 Januari 2024 (Perdana - Loreh)Document18 pagesJob Pending 6 Januari 2024 (Perdana - Loreh)Reza SyailendraNo ratings yet

- Potential Land Suitability For TeaDocument26 pagesPotential Land Suitability For TeaGautam NatrajanNo ratings yet

- Ex 1-3 Without OutputDocument12 pagesEx 1-3 Without OutputKoushikNo ratings yet

- Machine Problem 6 Securing Cloud Services in The IoTDocument4 pagesMachine Problem 6 Securing Cloud Services in The IoTJohn Karlo KinkitoNo ratings yet

- Social Vulnerability Index Helps Emergency ManagementDocument24 pagesSocial Vulnerability Index Helps Emergency ManagementDeden IstiawanNo ratings yet

- BR18 Mechanical Engineering Robotics Semester VIDocument2 pagesBR18 Mechanical Engineering Robotics Semester VIPRAVEeNo ratings yet

- Igbt Irg 4p254sDocument9 pagesIgbt Irg 4p254sMilagros Mendieta VegaNo ratings yet

- Portfolio Corporate Communication AuditDocument8 pagesPortfolio Corporate Communication Auditapi-580088958No ratings yet

- Rochester MN Unified Development Code (Draft)Document442 pagesRochester MN Unified Development Code (Draft)randyNo ratings yet

- Memo in Motion For ContemptDocument118 pagesMemo in Motion For ContemptMark SternNo ratings yet

- AX CLI Ref v2 4 3-20100621Document718 pagesAX CLI Ref v2 4 3-20100621VisiGodNo ratings yet

- Bataan Peninsula State University - Balanga Campus: Certificate of RegistrationDocument1 pageBataan Peninsula State University - Balanga Campus: Certificate of RegistrationMichael PeraltaNo ratings yet

- Computer Application in Business NOTES PDFDocument78 pagesComputer Application in Business NOTES PDFGhulam Sarwar SoomroNo ratings yet

- Design of A Double Corbel Using CAST Per ACI 318-02 Appendix A, SI UnitDocument41 pagesDesign of A Double Corbel Using CAST Per ACI 318-02 Appendix A, SI Unityoga arkanNo ratings yet

- CCW Armored Composite OMNICABLEDocument2 pagesCCW Armored Composite OMNICABLELuis DGNo ratings yet

- Master List of Approved Vendors For Manufacture and Supply of Electrical ItemsDocument52 pagesMaster List of Approved Vendors For Manufacture and Supply of Electrical ItemsBhoopendraNo ratings yet

- KCC Strategic Plan 2020-2023Document103 pagesKCC Strategic Plan 2020-2023Kellogg Community CollegeNo ratings yet

- NSTP 1: Pre-AssessmentDocument3 pagesNSTP 1: Pre-AssessmentMaureen FloresNo ratings yet

- Whitmore EZ-Switch LubricantDocument1 pageWhitmore EZ-Switch LubricantDon HowardNo ratings yet

- F20-W21 - LP1 LP2 Instructions and Grading Rubric-STUDENT VersionDocument9 pagesF20-W21 - LP1 LP2 Instructions and Grading Rubric-STUDENT VersionjohnamenNo ratings yet

- How To Google Like A Pro-10 Tips For More Effective GooglingDocument10 pagesHow To Google Like A Pro-10 Tips For More Effective GooglingMinh Dang HoangNo ratings yet

- WebquestDocument3 pagesWebquestapi-501133650No ratings yet

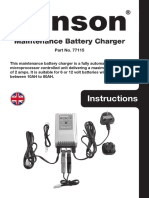

- 77115 Maintenance Battery ChargerDocument4 pages77115 Maintenance Battery ChargerClarence ClarNo ratings yet

- COA (Odoo Egypt)Document8 pagesCOA (Odoo Egypt)menams2010No ratings yet

- Railway Reservation System Er DiagramDocument4 pagesRailway Reservation System Er DiagramPenki Sarath67% (3)