Professional Documents

Culture Documents

Leaching of Copper

Uploaded by

Mduduzi Magiva MahlanguOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leaching of Copper

Uploaded by

Mduduzi Magiva MahlanguCopyright:

Available Formats

s

am

e

pl

e

g

a

SHORT COURSE

A-Z of Copper Ore

Leaching

Melbourne, Australia

www.altamet.com.au

Sa

e

pl

e

g

a

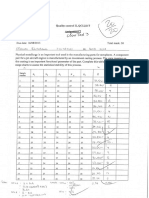

Table 2 Composition of Some Copper Oxide Minerals

MINERAL

COMPOSITION

%Cu

SG

AZURITE

2Cu2CO3.Cu(OH)2

55.3

3.7

MALACHITE

CuCO3.Cu(OH)2

57.6

3.6-4.1

CHRYSOCOLLA

CuSiO3.2H2O

36.1

2-2.4

TENORITE

CuO

79.7

6.5

CUPRITE

Cu2O

88.8

6.1

DIOPTASE

CuSiO3.H2O

40.3

3.2

BROCHANTITE

CuSO4.3Cu(OH)2

56.2

4.0

ATACAMITE

CuCl2.3Cu(OH)2

59.5

3.8

PSEUDO MALACHITE

Cu5(PO4)2(OH)4.H2O

53.5

4.3

NATIVE COPPER

Cu

100

8.96

Notes:

1. A basic knowledge of the solubilities of copper minerals, and the reaction chemistry involved, lays the

foundation for the evaluation of ores for leaching.

2. A basic knowledge of the behaviour of gangue minerals in contact with the lixiviant is another key in

assessing ores for leaching.

3. CO2 can benefit bio-leaching of sulphide minerals and mixed oxide/sulphide ores, as it promotes bacterial

growth. On the debit side, release of CO2 can hinder solution percolation in heap leaching, and is a

potential hazard particularly in agitated and vat leaching plants due to accumulation in enclosed and low

lying areas.

4. High silica in the leach solution can cause leach solution clarification problems and phase disengagement

and crud problems in associated solvent extraction facilities.

5. The presence of chloride in the leach solution above about 1 g/L can render 316 stainless steel unsuitable

for use in equipment, and result in the need to use more expensive alloys. High chloride can also result in

the need for additional equipment in SX to keep it out of the associated EW.

A-Z of Copper Ore Leaching

Sa

e

pl

e

g

a

FIG. 9 SEPON FLOWSHEET (Sepon Hydromet, S. Keokhounsy, T. Moore and M. Liu, ALTA Copper

2006)

A-Z of Copper Ore Leaching

34

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 2015b Mat271b Exa MemoDocument9 pages2015b Mat271b Exa MemoMduduzi Magiva Mahlangu100% (1)

- MAT351T WR2 2014A MemoDocument3 pagesMAT351T WR2 2014A MemoMduduzi Magiva MahlanguNo ratings yet

- Spark Plasma Sintering - FundamentalsDocument44 pagesSpark Plasma Sintering - FundamentalsUstaoğlu EmreNo ratings yet

- The Low Temperature Warning SignDocument9 pagesThe Low Temperature Warning SignMduduzi Magiva MahlanguNo ratings yet

- 2016B Exam: Differential Equations, Calculus & AlgebraDocument10 pages2016B Exam: Differential Equations, Calculus & AlgebraMduduzi Magiva MahlanguNo ratings yet

- Resistive Matching DesignDocument17 pagesResistive Matching DesignMduduzi Magiva MahlanguNo ratings yet

- Retsch Mills-Balls PM400 ManualDocument60 pagesRetsch Mills-Balls PM400 ManualMduduzi Magiva MahlanguNo ratings yet

- 2016 S2 NUA301T Semister Test 1 MemoDocument6 pages2016 S2 NUA301T Semister Test 1 MemoMduduzi Magiva MahlanguNo ratings yet

- 2017A - MAT271B Supplementary MemoDocument11 pages2017A - MAT271B Supplementary MemoMduduzi Magiva MahlanguNo ratings yet

- Principles of Blast CleaningDocument39 pagesPrinciples of Blast CleaningMduduzi Magiva MahlanguNo ratings yet

- BEE ConferenceDocument1 pageBEE ConferenceMduduzi Magiva MahlanguNo ratings yet

- 2017A Exam C: MAT271B / MAT271T / ITT10BT / MAT251F / MATH600 MEMODocument10 pages2017A Exam C: MAT271B / MAT271T / ITT10BT / MAT251F / MATH600 MEMOMduduzi Magiva MahlanguNo ratings yet

- ThickenersDocument1 pageThickenersMduduzi Magiva MahlanguNo ratings yet

- 2013 QCL221T Class Test3+memoDocument2 pages2013 QCL221T Class Test3+memoMduduzi Magiva MahlanguNo ratings yet

- RFC321T Practical Manual 2016 FinalDocument22 pagesRFC321T Practical Manual 2016 FinalMduduzi Magiva MahlanguNo ratings yet

- TutorialDocument62 pagesTutorialMduduzi Magiva MahlanguNo ratings yet

- 2013 QCL221T Class Test2+memoDocument2 pages2013 QCL221T Class Test2+memoMduduzi Magiva MahlanguNo ratings yet

- P1 - Practical ReportDocument9 pagesP1 - Practical ReportMduduzi Magiva MahlanguNo ratings yet

- Concrete BrickDocument1 pageConcrete BrickMduduzi Magiva MahlanguNo ratings yet

- Assignment 03Document2 pagesAssignment 03Mduduzi Magiva MahlanguNo ratings yet

- TDA 301T - 2015-10 - Thermodynamic Properties Real SubstancesDocument146 pagesTDA 301T - 2015-10 - Thermodynamic Properties Real SubstancesMduduzi Magiva Mahlangu100% (1)

- Differentiation TechniquesDocument20 pagesDifferentiation TechniquesMduduzi Magiva MahlanguNo ratings yet

- Corrosion To Be ContinuedDocument4 pagesCorrosion To Be ContinuedMduduzi Magiva MahlanguNo ratings yet

- MAT351T WR3 2014A MemoDocument6 pagesMAT351T WR3 2014A MemoMduduzi Magiva MahlanguNo ratings yet

- Physical Properties of Pure MethanolDocument1 pagePhysical Properties of Pure MethanolSJ ChuaNo ratings yet

- CalcII IntegrationStrategyDocument9 pagesCalcII IntegrationStrategyMduduzi Magiva MahlanguNo ratings yet

- ConsentDocument3 pagesConsentMduduzi Magiva MahlanguNo ratings yet

- Mechanics, Electricity, Magnetism & More Physics FormulasDocument1 pageMechanics, Electricity, Magnetism & More Physics FormulasMduduzi Magiva MahlanguNo ratings yet

- MAT351T Formula SheetDocument2 pagesMAT351T Formula SheetMduduzi Magiva MahlanguNo ratings yet