Professional Documents

Culture Documents

Automated Cross-Docking System

Uploaded by

Tit NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automated Cross-Docking System

Uploaded by

Tit NguyenCopyright:

Available Formats

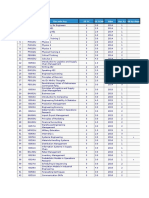

3.

DEPLOYMENT

3.1. Assigning:

Coding, mechanics, materials & decoration are main tasks of the project. For working efficiency,

members were assigned in three sub-groups: Coding, Mechanics work & Circuit, Materials & Decorating

as below.

Tasks

Coding

Mechanics work &

Circuit

Materials &

Decorating

Report

Members

Task Description

Write code for the system, including

servo motor, DC motor, etc.

Bien Thi Hai Van

Lam Khanh Trinh

Nguyen Lan Chi

Tran Thi Nhu Ha

Nguyen Vu Dai Thanh Cong

Bui Anh Dung

Ly Thuy Kieu Duyen

Nguyen Thanh Dan Nhi

Tran Thanh Hoang

Nguyen Thao My

Nguyen Thanh Dan Nhi

Ly Thuy Kieu Duyen

Build hardware

Build circuit

Purchase materials

Decorate the system

Make the report paper

Presentation

Bien Thi Hai Van

Present the system

Treasurer

Ly Thuy Kieu Duyen

Financial management

Table 1: Tasks assigning

3.2. Time schedule:

The Introduction to ISE/ Logistics and Supply Chain Management project is due in 10 weeks.

Therefore, it is scheduled and divided into 4 periods:

a. Period 1: 2 weeks. This period is for studying about cross docking (what it is, how it works and

why it is important in ISE field...). Training classes in coding and electrical; brainstorming ideas and

details sketching are also parts of this period.

b. Period 2: 6 weeks. This period is for hardware building, circuit building, and coding.

- Section 1: Building ball lifter (1 weeks)

- Section 2: Building storage (0.5 weeks)

- Section 3: Building parallel preparation racks (2 weeks) and marble pipes

Writing code and electrical assembly will be developed during each section.

c. Period 3: 1 week. This period is mainly for model testing and decoration.

d. Period 4: 1 week. This period is for preparing report & presentation.

3.3. Material Purchase:

There are 2 main kinds of materials for this project: Raw materials and Electrical equipment.

No.

Materials

Usage

Quantity

Foam sheets

Building container

Decorating

2 A0

Pipe coils

Building ball lifter

3x1m

Mica sheets

Decorating

Building storage

Building ball lifter

200cmx50cm

Wooden sticks

Building storage

Spray paint

Decorating

Wooden floor

Base

Nails

Connecting wooden materials

Fixed floor

Decal

Decorating

Marbles

Products

10

Water Pipes

Building ball lifter

11

Toy trucks

Inbound & outbound containers

8x1m

60

3x40cm

8

Table 1: Raw materials

No.

Electrical equipment

Quantity

DC motor

Servo Motor

25

Electrical wires

Breadboard

LCD

IR Sensor

Buzzer

Adaptor

Adruino

10

LED

Table 2: Electrical equipment

5. PROGRESS

5.1. Current Progress:

70% of materials have been bought, including:

2 A0 foam sheets.

Black mica sheets: 200x50cm.

White mica sheets: 200x50cm.

Wooden floor: 100x80cm.

8 wooden stick, 1m long.

8 toy trucks.

3 water pipes, 40cm long, 3cm.

3 pipes coils, 100cm long.

12 servo motors

Cords.

2 LCDs.

7 IR sensors.

Thus far, these are parts were done building:

Storage.

Ball lifter.

Wooden floor.

Coding (40%).

Inbound & outbound trucks.

This means the current progress is slower than expected.

5.2. Future plans: After determining the final model, there are things have to be done in order to

catch up with the schedule. The remaining tasks include:

Materials purchase.

Preparation racks & Pipes (3 weeks).

Supporting pillar (1 week)

Mechanics works.

Install electrical components.

Decorating.

Coding.

6. CONCLUSION

In conclusion, despite some difficulties at the beginning, things started to go into orbit. Our group hopes

that it will turn out as we expected.

7. REFERENCES

https://www.youtube.com/watch?v=5KY3hcbv7U8

http://logisticsvn.com/vn/

You might also like

- Sample Test: The Answer You Have Chosen On Your Answer SheetDocument10 pagesSample Test: The Answer You Have Chosen On Your Answer SheetTit NguyenNo ratings yet

- Production PlanningDocument14 pagesProduction PlanningTit NguyenNo ratings yet

- Optimize Warehouse Picking with Proper Storage and RoutingDocument9 pagesOptimize Warehouse Picking with Proper Storage and RoutingTit Nguyen0% (1)

- STT Mã môn học Tên môn học Số Tc Số Tchp Năm Học kỳ BB tự chọnDocument2 pagesSTT Mã môn học Tên môn học Số Tc Số Tchp Năm Học kỳ BB tự chọnTit NguyenNo ratings yet

- MADocument18 pagesMATit NguyenNo ratings yet

- Chapter 1 - Engineering EconomyDocument25 pagesChapter 1 - Engineering EconomyTit NguyenNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Granville 370 Ion Gauge Controller Manual 370119Document134 pagesGranville 370 Ion Gauge Controller Manual 370119johnsonlkNo ratings yet

- Delta Ia-Mds VFD Ms300 High Um en 20170306Document445 pagesDelta Ia-Mds VFD Ms300 High Um en 20170306ANKUR TRIPATHINo ratings yet

- Ag Cx350p.pj - En.ed - An.px (Dvqp1830za) eDocument201 pagesAg Cx350p.pj - En.ed - An.px (Dvqp1830za) eAlfonso RamiroNo ratings yet

- Rc-5bplus DiagramDocument21 pagesRc-5bplus Diagramluroguita-1No ratings yet

- ZWD-PAF Series: 100W To 440W Dual Output Power SuppliesDocument2 pagesZWD-PAF Series: 100W To 440W Dual Output Power SuppliesJOSEPH DIASNo ratings yet

- Module: Introduction To Solid State Physics and ElectronicsDocument7 pagesModule: Introduction To Solid State Physics and Electronicsnahom teferaNo ratings yet

- Hsdpa & Hsupa Challenges For UE Power Amplifier Design: Application NoteDocument50 pagesHsdpa & Hsupa Challenges For UE Power Amplifier Design: Application NoteRamarolahy Dadan'i EliaNo ratings yet

- 65° Quad Port Panel Antenna Enhanced Sidelobe SuppressionDocument2 pages65° Quad Port Panel Antenna Enhanced Sidelobe SuppressionDoc All TelecomNo ratings yet

- Fulltext01 PDFDocument17 pagesFulltext01 PDFShourya SONI (11C)No ratings yet

- Ovf20 Startup RoutineDocument14 pagesOvf20 Startup RoutineRaja DuraiNo ratings yet

- Universal Powerline Bus: X-10 To Upb Migration DocumentDocument25 pagesUniversal Powerline Bus: X-10 To Upb Migration DocumentCristopher PatricioNo ratings yet

- Interface Descriptioin JUMO DigiLineDocument52 pagesInterface Descriptioin JUMO DigiLineNatiqNo ratings yet

- FAN, 80X80X15, NMB, W Conn: REV Description Date ApprovalDocument1 pageFAN, 80X80X15, NMB, W Conn: REV Description Date Approvalhusam haiderNo ratings yet

- R7410210-Electrical Distribution SystemsDocument4 pagesR7410210-Electrical Distribution SystemssivabharathamurthyNo ratings yet

- Beginners Guide To Going SolarDocument18 pagesBeginners Guide To Going SolarRogelio AlvaradoNo ratings yet

- SDH BasicsDocument72 pagesSDH Basicsk_muange897No ratings yet

- Types of System Testing GuideDocument10 pagesTypes of System Testing GuidePatrick SerandonNo ratings yet

- My ModulesDocument273 pagesMy Modules1100% (1)

- NotesDocument176 pagesNoteskalyanNo ratings yet

- Btech Ec 3 Sem Fundamentals of Electronics Devices Eec 301 2018 19Document1 pageBtech Ec 3 Sem Fundamentals of Electronics Devices Eec 301 2018 19Vishesh Kumar SinghNo ratings yet

- Modutrol Motors Model Selection GuideDocument5 pagesModutrol Motors Model Selection GuidedanielNo ratings yet

- B Band FaultDocument3 pagesB Band FaultJay R SVNo ratings yet

- Amba Axi ProtocolDocument30 pagesAmba Axi Protocolanon_82531963No ratings yet

- Power Quality Issues in Microgrid and Its SolutionsDocument32 pagesPower Quality Issues in Microgrid and Its SolutionsDinu DasNo ratings yet

- 6G Wireless CommunicationDocument6 pages6G Wireless CommunicationMUHAMMAD BADAR ASHRAF RANANo ratings yet

- Fundamentals of Waves, Electricity, and MagnetismDocument3 pagesFundamentals of Waves, Electricity, and Magnetismkyla athea parillaNo ratings yet

- PM800 User GuideDocument122 pagesPM800 User Guidebobi156No ratings yet

- Ts Boost ConverterDocument6 pagesTs Boost Converterala houamNo ratings yet

- Multistage AmplifierDocument22 pagesMultistage AmplifierVijay AnandhNo ratings yet

- Input Filter Compensation For Switching Regulators by S S KelkarDocument371 pagesInput Filter Compensation For Switching Regulators by S S KelkarshrikrisNo ratings yet