Professional Documents

Culture Documents

Valve Data Sheets

Uploaded by

zaldy1985Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valve Data Sheets

Uploaded by

zaldy1985Copyright:

Available Formats

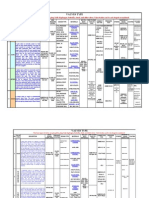

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag no.

: 51001

Location

: MUMBAI

Sheet No.

: 1 of 1

GATE VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 51001

PIPING CLASS

: A1A, A9A, A10A, A11A,

B1A

STANDARD

RATING

: 800

STANDARD

: API-602

MFGRS CAT/FIG

SIZE RANGE

: 0.5" TO 1.5"

ENDS

: SW 3000 TO B-16.11

RATING

ENDS

DESCRIPTION

CONSTRUCTION

BODY

MATERIAL

CONSTRUCTION

FORGED

ASTM A 105

BONNET

BOLTED

ASTM A 105

STEM

RISING

13% CR.STEEL (NO CASTING)

WEDGE DISC

SOLID

STELLITED

BODY SEAT RING

RENEWABLE

STELLITED

STEM PACKING

RENEWABLE WITH

VALVE OPEN ON

STREAM

GRAPHITED WITH SACRIFICIAL

CORR. INHIB.& INCONEL WIRE

REINFORCEMENT

HAND WHEEL

NON RISING

MALLEABLE IRON/CAST

ST/FAB.ST/DUCT. IRON

BONNET BOLTS

ASTM A193 GR B7

BONNET NUTS

ASTM A194 GR 2H

BONNET GASKET

SP WND SS316 - GRAPHITE

FILLER

SPECIAL SERVICE

CONDITION

MAX TEMP. 427 DEG. C.

BACK SEAT &

SHOULDER

INTEGRAL

OTHERS

O.S & Y.

HYDROSTATIC TEST

PRESSURE

BODY : 2975 PSIG.

TEST PRESSURE WITH

AIR

80 PSIG

MATERIAL

SEAT : 2175 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH JACOBS' SPEC, BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC IS ALLOWED.

TESTING SHALL BE AS PER API 598.

SHEET REV. NO.

DATE

SIGNATURE

&

SEAL

OF MANUFACTURER

19/04/2010

19/07/2010

21/12/2011

16/01/2012

51001

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag No.

: 51301

Location

: MUMBAI

Sheet No.

: 1 of 1

GATE VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 51301

PIPING CLASS

: A1A,A9A,A11A,J3A

STANDARD

RATING

: 150

STANDARD

: API-600

MFGRS CAT/FIG

ENDS

: FLGD TO B-16.5 /

B-16.47B RF/125AARH

RATING

ENDS

SIZE RANGE

: 2.0" TO 42.0"

DESCRIPTION

CONSTRUCTION

BODY

CAST

MATERIAL

CONSTRUCTION

MATERIAL

ASTM A 216 GR.WCB

BONNET

BOLTED

ASTM A 216 GR.WCB

STEM

RISING

13% CR.STEEL (NO CASTING)

WEDGE DISC

SOLID/FLEXIBLE

13% CR.STEEL FACING /

13% CR.STEEL

BODY SEAT RING

RENEWABLE/NON

RENEWABLE

13% CR.STEEL FACING /

13% CR.STEEL

STEM PACKING

RENEWABLE WITH

VALVE OPEN ON

STREAM

GRAPHITED WITH SACRIFICIAL

CORR. INHIB.& INCONEL WIRE

REINFORCEMENT

HAND WHEEL

NON RISING

MALLEABLE IRON/CAST

ST/FAB.ST/DUCT. IRON

BONNET BOLTS

ASTM A193 GR B7

BONNET NUTS

ASTM A194 GR 2H

BONNET GASKET

SP WND SS316-GRAPHITE

FILLER/CORRUGATED SOFT

IRON

REQUIREMENT OF

GEAR OPERATOR

14" NB & LARGER

SPECIAL SERVICE

CONDITION

MAX TEMP 427 DEG.C.

BACK SEAT & SHOULDER

13% CR STEEL

OTHERS

O.S & Y.

HYDROSTATIC TEST

PRESSURE

BODY : 450 PSIG

TEST PRESSURE WITH

AIR

80 PSIG

SEAT : 325 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC. IS ALLOWED.

SPACE PROVIDED FOR, WHEREVER BIDDER AGREES WITH JACOBS' SPEC., BIDDER SHALL INDICATE "AGREED".

4 TESTING SHALL BE AS PER API 598 FOR SIZES UPTO 24" AND AS PER BS 6755(PART-1) FOR SIZES 26" & ABOVE.

5 GATE VALVES OF SIZE 26" AND ABOVE SHALL BE IN ACCORDANCE WITH BS-1414 AND FLANGE ENDS SHALL

SIGNATURE

&

SEAL

OF MANUFACTURER

BE IN ACCORDANCE WITH ASME B16.47 SERIES B.

6 5% VALVE CASTINGS UPTO 24" AND 100% VALVE CASTINGS 26" AND ABOVE SHALL UNDERGO

RADIOGRAPHIC EXAMINATION.

SHEET REV. NO.

DATE

19/04/10

16/01/12

51301

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag No.

: 51401

Location

: MUMBAI

Sheet No.

: 1 of 1

GATE VALVE SPECIFICATION

TAG NO.

: 51401

PIPING CLASS

RATING

: 300

SIZE RANGE

: 2" TO 24"

DESCRIPTION

MANUF'S OFFER

: B1A

STANDARD

STANDARD

: API 600

MFGRS CAT/FIG

ENDS

: FLGD, B-16.5,

RF / 125 AARH

RATING

ENDS

CONSTRUCTION

MATERIAL

BODY

CAST

ASTM A 216 GR.WCB

BONNET

BOLTED

ASTM A 216 GR.WCB

STEM

RISING

13% CR. STEEL (NO CASTING)

WEDGE DISC

SOLID /FLEXIBLE

13% CR.STEEL FACING /

13% CR.STEEL

BODY SEAT RING

RENEWABLE / NON

RENEWABLE

13% CR.STEEL FACING /

13% CR.STEEL

STEM PACKING

RENEWABLE WITH

VALVE OPEN ON

STREAM.

GRAPHITED WITH SACRIFICIAL

CORR. INHIB. & INCONEL WIRE

REINFORCEMENT.

HAND WHEEL

NON RISING

MALLEABLE IRON / CAST ST /

FAB. ST / DUCT. IRON

BONNET BOLTS

ASTM A 193 GR.B7

BONNET NUTS

ASTM A 194 GR.2H

BONNET GASKET

SP WND SS316 -GRAPHITE FILLER

REQUIREMENT OF GEAR

OPERATOR

12" NB & LARGER

SPECIAL SERVICE

CONDITIONS

MAX TEMP. 427 DEG.C

BACK SEAT &

SHOULDER

13% CR. STEEL

OTHERS

O.S & Y.

HYDROSTATIC TEST

PRESSURE

BODY: 1125 PSIG.

TEST PRESSURE WITH

AIR

80 PSIG

CONSTRUCTION

MATERIAL

SEAT: 825 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR, WHEREVER BIDDER AGREES WITH JACOBS' SPEC., BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC. IS ALLOWED.

TESTING SHALL BE AS PER API 598.

SIGNATURE

&

SEAL

OF MANUFACTURER

10% VALVE CASTINGS UPTO 16" AND 100% VALVE CASTINGS 18" AND ABOVE SHALL UNDERGO

RADIOGRAPHIC EXAMINATION.

SHEET REV. NO.

DATE

19/04/10

16/01/12

51401

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag no.

: 52001

Location

: MUMBAI

Sheet No.

: 1 of 1

GLOBE VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 52001

PIPING CLASS

: A1A, A9A, A10A, A11A,

B1A

STANDARD

RATING

: 800

STANDARD

: BS-5352

MFGRS CAT/FIG

SIZE RANGE

: 0.5" TO 1.5"

ENDS

: SW 3000 TO B-16.11

RATING

ENDS

DESCRIPTION

CONSTRUCTION

BODY

MATERIAL

CONSTRUCTION

FORGED

ASTM A 105

BONNET

BOLTED

ASTM A 105

STEM

RISING

13% CR.STEEL (NO CASTING)

DISC

LOOSE PLUG TYPE

STELLITED

BODY SEAT RING

RENEWABLE/NON

RENEWABLE

STELLITED

STEM PACKING

RENEWABLE WITH

VALVE OPEN ON

STREAM

GRAPHITE WITH SACRIFICIAL

CORR. INHIBITOR & INCONEL

WIRE REINFORCEMENT.

HAND WHEEL

RISING

MALLEABLE IRON/CAST

ST/FAB.ST/DUCT. IRON

BONNET BOLTS

ASTM A193 GR B7

BONNET NUTS

ASTM A194 GR 2H

BONNET GASKET

SP WND SS316 -GRAPHITE

FILLER

OTHERS

MATERIAL

O.S & Y.

SPECIAL SERVICE

CONDITION

MAX TEMP. 427 DEG. C.

BACK SEAT &

SHOULDER

INTEGRAL

HYDROSTATIC TEST

PRESSURE

BODY : 2975 PSIG.

TEST PRESSURE WITH

AIR

80 PSIG

SEAT : 2175 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH JACOBS SPEC, BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS SPEC IS ALLOWED.

TESTING SHALL BE AS PER BS 6755 (PART-1).

SHEET REV. NO.

DATE

SIGNATURE

&

SEAL

OF MANUFACTURER

19/04/2010

19/07/2010

21/12/2011

16/01/2012

52001

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag No.

: 52301

Location

: MUMBAI

Sheet No.

: 1 of 1

GLOBE VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 52301

PIPING CLASS

: A1A, A9A, A10A, A11A,

J3A

STANDARD

RATING

: 150

STANDARD

: BS-1873

MFGRS CAT/FIG

ENDS

: FLGD TO B-16.5

RF/125AARH

RATING

ENDS

SIZE RANGE

: 2.0" TO 16.0"

DESCRIPTION

CONSTRUCTION

BODY

CAST

MATERIAL

CONSTRUCTION

BONNET

BOLTED

ASTM A 216 GR.WCB

STEM

RISING

13% CR.STEEL (NO CASTING)

DISC

LOOSE PLUG TYPE

13% CR.STEEL FACING /

13% CR.STEEL

BODY SEAT RING

RENEWABLE/NON

RENEWABLE

13% CR.STEEL FACING /

13% CR.STEEL

STEM PACKING

RENEWABLE WITH

VALVE OPEN ON

STREAM

GRAPHITED WITH SACRIFICIAL

CORR. INHIB.& INCONEL WIRE

REINFORCEMENT.

HAND WHEEL

RISING

MALLEABLE IRON/CAST

ST/FAB.ST/DUCT. IRON

BONNET BOLTS

ASTM A193 GR B7

BONNET NUTS

ASTM A194 GR 2H

BONNET GASKET

SP WND SS316-GRAPHITE

FILLER

REQUIREMENT OF

GEAR OPERATOR

8" NB & LARGER

OTHERS

MATERIAL

ASTM A 216 GR.WCB

O.S & Y.

SPECIAL SERVICE

CONDITION

MAX TEMP 427 DEG. C.

BACK SEAT &

SHOULDER

13% CR STEEL

HYDROSTATIC TEST

PRESSURE

BODY : 450 PSIG

TEST PRESSURE WITH

AIR

80 PSIG

SEAT : 325 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR, WHEREVER BIDDER AGREES WITH JACOBS' SPEC., BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC. IS ALLOWED.

TESTING SHALL BE AS PER BS 6755 (PART-1).

5% VALVE CASTINGS SHALL UNDERGO RADIOGRAPHIC EXAMINATION.

SHEET REV. NO.

DATE

SIGNATURE

&

SEAL

OF MANUFACTURER

19/04/2010

19/07/2010

21/12/2011

16/01/2012

52301

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag No.

: 52401

Location

: MUMBAI

Sheet No.

: 1 of 1

GLOBE VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 52401

PIPING CLASS

: B1A

STANDARD

RATING

: 300

STANDARD

: BS-1873

MFGRS CAT/FIG

SIZE RANGE

: 2" TO 12"

ENDS

: FLGD, B16.5,

RF / 125 AARH

RATING

ENDS

DESCRIPTION

CONSTRUCTION

MATERIAL

CONSTRUCTION

BODY

CAST

ASTM A 216 GR.WCB

BONNET

BOLTED

ASTM A 216 GR.WCB

STEM

RISING

13% CR. STEEL (NO CASTING)

DISC

LOOSE PLUG TYPE

13% CR.STEEL FACING /

13% CR.STEEL

BODY SEAT RING

RENEWABLE/NON

RENEWABLE

13% CR.STEEL FACING /

13% CR.STEEL

STEM PACKING

RENEWABLE WITH

VALVE OPEN ON

STREAM

GRAPHITED WITH SACRIFICIAL

CORR. INHIB. & INCONEL WIRE

REINFORCEMENT.

HAND WHEEL

RISING

MALLEABLE IRON / CAST ST /

FAB. ST / DUCT. IRON

BONNET BOLTS

ASTM A 193 GR.B7

BONNET NUTS

ASTM A 194 GR.2H

BONNET GASKET

SP WND SS316 - GRAPHITE

FILLER

REQUIREMENT OF GEAR

OPERATOR

8" NB & LARGER

OTHERS

MATERIAL

OS & Y

SPECIAL SERVICE

CONDITION

MAX TEMP. 427 DEG.C

BACK SEAT & SHOULDER

13% CR. STEEL

HYDROSTATIC TEST

PRESSURE

BODY: 1125 PSIG.

TEST PRESSURE WITH

AIR

80 PSIG

SEAT: 825 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC. IS ALLOWED.

TESTING SHALL BE AS PER 6755 (PART-1).

10% VALVE CASTINGS SHALL UNDERGO RADIOGRAPHIC EXAMINATION.

SPACE PROVIDED FOR, WHEREVER BIDDER AGREES WITH JACOBS' SPEC., BIDDER SHALL INDICATE "AGREED".

SHEET REV. NO.

DATE

19/04/2010

19/07/2010

21/12/2011

16/01/2012

SIGNATURE

&

SEAL

OF MANUFACTURER

52401

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag no.

: 53001

Location

: MUMBAI

Sheet No.

: 1 of 1

CHECK VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 53001

PIPING CLASS

: A1A, A9A, A10A, A11A,

B1A

STANDARD

RATING

: 800

STANDARD

: BS-5352

MFGRS CAT/FIG

SIZE RANGE

: 0.5" TO 1.5"

ENDS

: SW 3000 TO B-16.11

RATING

ENDS

DESCRIPTION

CONSTRUCTION

MATERIAL

BODY

FORGED

ASTM A 105

COVER

BOLTED

ASTM A 105

DISC/PISTON

CONSTRUCTION

MATERIAL

STELLITED

RENEWABLE/NON

RENEWABLE

BODY SEAT RING

STELLITED

DISC HINGE/HINGE

PIN

COVER STUD BOLT

ASTM A193 GR B7

COVER NUT

ASTM A194 GR 2H

COVER GASKET

SP WND SS316-GRAPHITE FILLER

TYPE

LIFT CHECK TYPE

OTHERS

SPECIAL SERVICE

CONDITION

MAX TEMP. 427 DEG. C.

WASHER,NUT,PIN

HYDROSTATIC TEST

PRESSURE

BODY : 2975 PSIG.

SEAT : 2175 PSIG

TEST PRESSURE WITH

AIR

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH JACOBS SPEC, BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS SPEC IS ALLOWED.

TESTING SHALL BE AS PER BS 6755 (PART-I).

VALVES SHALL BE OF STANDARD BORE DESIGN.

SHEET REV. NO.

DATE

19/07/2010

16/01/12

SIGNATURE

&

SEAL

OF MANUFACTURER

53001

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag No.

: 53301

Location

: MUMBAI

Sheet No.

: 1 of 1

CHECK VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 53301

PIPING CLASS

: A1A,A9A,A11A,B1A,J3A

STANDARD

RATING

: 150

STANDARD

: BS-1868

MFGRS CAT/FIG

ENDS

: FLGD TO B-16.5

RF/125AARH

RATING

ENDS

SIZE RANGE

: 2.0" TO 24.0"

DESCRIPTION

CONSTRUCTION

MATERIAL

BODY

CAST

ASTM A 216 GR.WCB

COVER

BOLTED

ASTM A 216 GR.WCB

CONSTRUCTION

MATERIAL

13% CR.STEEL FACING /

13% CR.STEEL

DISC

RENEWABLE/NON

RENEWABLE

BODY SEAT RING

13% CR.STEEL FACING /

13% CR.STEEL

DISC HINGE

13% CR STEEL/A216 GR

WCB/A515 GR 70

HINGE PIN

13% CR STEEL(NO CASTING)

COVER STUD BOLT

ASTM A193 GR B7

COVER NUT

ASTM A194 GR 2H

COVER GASKET

SP WND SS316-GRAPHITE

FILLER/ CORRUGATED SOFT

IRON

BY PASSES

TYPE

SWING CHECK TYPE

OTHERS

SPECIAL SERVICE

CONDITION

MAX TEMP 427 DEG. C.

WASHER,NUT,PIN

13% CR STEEL(NO

CASTING)/SS410/SS304

HYDROSTATIC TEST

PRESSURE

BODY : 450 PSIG

SEAT : 325 PSIG

TEST PRESSURE WITH

AIR

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR, WHEREVER BIDDER AGREES WITH JACOBS' SPEC., BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC. IS ALLOWED.

TESTING SHALL BE AS PER BS 6755 (PART-I).

5% VALVE CASTINGS SHALL UNDERGO RADIOGRAPHIC EXAMINATION.

SHEET REV. NO.

DATE

19/04/10

16/01/12

SIGNATURE

&

SEAL

OF MANUFACTURER

53301

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag no.

: 53401

Location

: MUMBAI

Sheet No.

: 1 of 1

CHECK VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 53401

PIPING CLASS

: B1A

STANDARD

RATING

: 300

STANDARD

: BS-1868

MFGRS CAT/FIG

ENDS

: FLGD, B 16.5,

RF / 125 AARH

RATING

ENDS

SIZE RANGE

: 2" TO 24"

DESCRIPTION

CONSTRUCTION

MATERIAL

BODY

CAST

ASTM A 216 GR.WCB

COVER

BOLTED

ASTM A 216 GR.WCB

CONSTRUCTION

MATERIAL

13% CR.STEEL FACING /

13% CR.STEEL

DISC

RENEWABLE /

NON RENEWABLE

BODY SEAT RING

13% CR.STEEL FACING /

13% CR.STEEL

DISC HINGE

13% CR. STEEL / ASTM A 216

GR.WCB / A515 GR.70

HINGE PIN

13% CR STEEL(NO CASTING)

COVER STUD BOLT

ASTM A193 GR.B7

COVER NUT

ASTM A 194 GR.2H

COVER GASKET

SP WND SS316-GRAPHITE FILLER

BY PASSES

TYPE

SWING CHECK TYPE

OTHERS

SPECIAL SERVICE

CONDITION

MAX TEMP. 427 DEG.C

WASHER, NUT, PIN

13% CR STEEL(NO

CASTING)/SS410/SS304

HYDROSTATIC TEST

PRESSURE

BODY: 1125 PSIG.

SEAT: 825 PSIG

TEST PRESSURE WITH

AIR

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH JACOBS' SPEC, BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC IS ALLOWED.

TESTING SHALL BE AS PER BS -6755 (PART-1).

5 20% VALVE CASTINGS UPTO 16" AND 100% VALVE CASTINGS 18" AND ABOVE SHALL UNDERGO

RADIOGRAPHIC EXAMINATION.

SHEET REV. NO.

DATE

19/07/2010

21/12/2011

16/01/2012

SIGNATURE

&

SEAL

OF MANUFACTURER

53401

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag no.

: 54301

Location

: MUMBAI

Sheet No.

: 1 of 1

BALL VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 54301

PIPING CLASS

: A1A, A9A, A10A, A11A

STANDARD

RATING

: 150

STANDARD

: BS-5351

MFGRS CAT/FIG

SIZE RANGE

: 0.5" TO 16.0"

ENDS

: FLGD TO B-16.5 RF/125AARH

RATING

ENDS

DESCRIPTION

CONSTRUCTION

MATERIAL

BODY

FORGED/CAST

ASTM A 105 / A 216GR.WCB

STEM

ANTI BLOWOUT

13% CR.STEEL/SS316; (NO CASTING)

BALL

SOLID

CONSTRUCTION

MATERIAL

13% CR.STEEL/SS304/SS316

RPTFE WITH SECONDARY METAL TO

METAL

BODY SEAT

GLAND

BOLTED/ RETAINED

BY NUT & WASHER

ASTM A105/13% CR STEEL/SS 316/SS 304

STEM SEAL

RENEWABLE WITH

VALVE OPEN ON

STREAM

GRAFOIL/PTFE V-RINGS +GRAFOIL

BODY SEAL

GRAFOIL/PTFE

BODY STUD

ASTM A193 GR.B7

BODY NUT

ASTM A194 GR 2H

OTHERS

REQUIREMENT OF

GEAR OPERATOR

6" NB & LARGER

SPECIAL SERVICE

CONDITION

MAX TEMP 204 DEG C.

SPRING

INCONEL X-750

HYDROSTATIC TEST

PRESSURE

BODY : 450 PSIG

TEST PRESSURE

WITH AIR

80 PSIG

SEAT : 325 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH JACOBS SPEC, BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS SPEC IS ALLOWED.

VALVES CAN ALSO BE SUPPLIED IN ACCORDANCE WITH API-6D. FOR API 6D VALVES,MIN BODY WALL

THICKNESS SHALL BE PER ASME B16.34.

SIGNATURE

&

SEAL

OF MANUFACTURER

ALL VALVES SHALL BE FIRE SAFE DESIGN.FIRE SAFE TEST SHALL BE AS PER API 607 IV EDITION/BS

6755(PART II) /API RP 6FA

TESTING SHALL BE AS PER BS 6755(PART 1)/API 6D.

FOR TRUNNION MOUNTED BALL,BODY SEAT SHALL BE SPRING LOADED.

ALL VALVES SHALL BE BIDIRECTIONAL.

FLOATING BALL VALVES SHALL BE PROVIDED WITH PRESSURE EQUALISATION SEATS TO RELIEVE THE

BODY-BONNET CAVITY PRESSURE TO THE UPSTREAM SIDE.

10

10 % VALVE CASTINGS SHALL UNDERGO RADIOGRAPHIC EXAMINATION.

11

BIDDER SHALL CERTIFY THE SUITABILITY OF VALVES FOR INTENDED SERVICE CONDITIONS.

12

BIDDER TO FURNISH SOFT SEAT DETAILS AND TYPE, GRADE & CLASS SELECTED FOR RPTFE FROM ASTM

D4745 WITH MANUFACTURER'S RECOMMENDATIONS LIKE PRESSURE-TEMPERATURE RATING CURVE/TABLE.

13

STEM SEAL/BODY SEAL MATERIALS SHALL BE PROVIDED WITH CORROSION INHIBITOR.

SHEET REV. NO.

DATE

0

19/07/2010

54301

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag no.

: 54401

Location

: MUMBAI

Sheet No.

: 1 of 1

BALL VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 54401

PIPING CLASS

: B1A

STANDARD

RATING

: 300

STANDARD

: BS - 5351

MFGRS CAT/FIG

ENDS

: FLGD, B - 16.5

RF / 125 AARH

RATING

ENDS

SIZE RANGE

: 0.5" TO 16"

DESCRIPTION

CONSTRUCTION

MATERIAL

BODY

FORGED / CAST

ASTM A 105 / ASTM A 216 GR.WCB

STEM

ANTI BLOWOUT

13% CR.STEEL/SS316; (NO CASTING)

BALL

SOLID

13% CR.STEEL/SS304/SS316

CONSTRUCTION

MATERIAL

RPTFE WITH SECONDARY METAL TO

METAL

BODY SEAT

GLAND

BOLTED /

RETAINED BY NUT &

WASHER

ASTM A105/13% CR STEEL/SS 316/SS 304

STEM SEAL

RENEWABLE WITH

VALVE OPEN ON

STREAM

GRAFOIL/PTFE V-RINGS + GRAFOIL

BODY SEAL

GRAFOIL/PTFE

BODY STUD

ASTM A 193 GR.B7

BODY NUT

ASTM A 194 GR.2H

OTHERS

REQUIREMENT OF GEAR

OPERATOR

6" NB & LARGER

SPECIAL SERVICE

CONDITIONS

MAX TEMP 204 DEG C.

SPRING

INCONEL X - 750

HYDROSTATIC TEST

PRESSURE

TEST PRESSURE WITH

AIR

BODY : 1125 PSIG

SEAT : 825 PSIG

80 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH JACOBS' SPEC, BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC IS ALLOWED.

VALVES CAN ALSO BE SUPPLIED IN ACCORDANCE WITH API-6D.

FOR API 6D VALVES, MIN BODY WALL THICKNESS SHALL BE AS PER ASME B16.34.

ALL VALVES SHALL BE FIRE SAFE DESIGN. FIRE SAFE TEST SHALL BE AS PER API 607 IV EDITION /

BS 6755 (PART II) / API RP 6FA.

TESTING SHALL BE AS PER BS 6755 (PART-I) / API 6D.

FOR TRUNNION MOUNTED BALL, BODY SEAT SHALL BE SPRING LOADED.

ALL VALVES SHALL BE BIDIRECTIONAL.

SIGNATURE

&

SEAL

OF MANUFACTURER

9 FLOATING BALL VALVES SHALL BE PROVIDED WITH PRESSURE EQUALISATION SEATS TO RELIEVE THE

BODY-BONNET CAVITY PRESSURE TO THE UPSTREAM SIDE.

10 20% VALVE CASTINGS SHALL UNDERGO RADIOGRAPHIC EXAMINATION.

11 BIDDER SHALL CERTIFY THE SUITABILITY OF VALVES FOR INTENDED SERVICE CONDITIONS.

12 BIDDER TO FURNISH SOFT SEAT DETAILS AND TYPE, GRADE & CLASS SELECTED FOR RPTFE FROM ASTM D4745

WITH MANUFACTURER'S RECOMMENDATIONS LIKE PRESSURE-TEMPERATURE RATING CURVE/TABLE.

13 STEM SEAL / BODY SEAL MATERIALS SHALL BE PROVIDED WITH CORROSION INHIBITOR.

14 10% VALVES IN EACH SIZE SHALL UNDERGO HYDROSTATIC TEST OF SEAT. SOFT SEAT SHALL BE REPLACED AFTER HYDROSTATIC TEST.

AFTER THIS ALL VALVES SHALL BE AIR TESTED.

SHEET REV. NO.

DATE

0

19/07/2010

54401

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag no.

: 55301

Location

: MUMBAI

Sheet No.

: 1 of 1

PLUG VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 55301

PIPING CLASS

: A1A, A9A, A10A, A11A

STANDARD

RATING

: 150

STANDARD

: BS-5353

MFGRS CAT/FIG

SIZE RANGE

: 0.5" TO 24.0"

ENDS

: FLGD TO B-16.5 RF/125AARH

RATING

ENDS

DESCRIPTION

CONSTRUCTION

MATERIAL

BODY

FORGED/CAST

ASTM A 105 / A 216GR.WCB

COVER

BOLTED

ASTM A 105/ASTM A 216 GR.WCB

PLUG

INVERTED, TAPER

ASTM A 105 / A 216GR.WCB, CASE

HARDENED & BONDED WITH LOW

FRICTION COATING

CONSTRUCTION

MATERIAL

ASTM A 105 / A 216GR.WCB, CASE

HARDENED & BONDED WITH LOW

FRICTION COATING

STEM

GLAND

BOLTED

ASTM A 105/A216 WCB

GLAND PACKING

RENEWABLE

GRAFOIL RINGS

LUBRICANT SCREW

WITH CHECK

VALVES

SS 410/A105

COVER BOLTS

ASTM A 193 GR. B7

COVER NUTS

ASTM A 194 GR. 2H

COVER GASKET

SP WND SS316-GRAPHITE FILLER

LUBRICATED,

PRESSURE BALANCED

OTHERS

REQUIREMENT OF

GEAR OPERATOR

8" NB & LARGER

SPECIAL SERVICE

CONDITION

HYDROCARBON, MAX. TEMP 250 DEG. C.

HYDROSTATIC TEST

PRESSURE

BODY : 450 PSIG

TEST PRESSURE

WITH AIR

80 PSIG

SEAT : 325 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH JACOBS SPEC, BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS SPEC IS ALLOWED.

PLUG VALVES IN ACCORDANCE WITH API-599 / API-6D ARE ALSO ACCEPTABLE.

FOR API 6D STD VALVE MIN. BODY WALL THICKNESS SHALL BE AS PER API 599/BS 5353.

6 TESTING SHALL BE AS PER BS 6755(PART-I)/API 598/API 6D

SIGNATURE

&

SEAL

OF MANUFACTURER

7 FOR WRENCH OPERATED VALVES, SEPARATE WRENCH REQUIRED FOR EACH VALVE.

8

VALVE POSITION INDICATOR SHALL BE PROVIDED.

VALVES SHALL BE FIRE-SAFE DESIGN AS PER BS-6755(PART-2) / API-607, 4TH EDITION/ API-6FA

10

VENDOR SHALL CONFIRM SUITABILITY OF LUBRICANT WITH RESPECT TO SERVICE AND SERVICE

CONDITIONS SPECIFIED.

11

BIDDER TO SUPPLY LUBRICANT FOR TWO YEARS OF NORMAL OPERATION.

12

10% VALVE CASTINGS SHALL UNDERGO RADIOGRAPIC EXAMINATION FOR SIZES UPTO 24".

13 UNLESS OTHERWISE SPECIFIED IN MR, VALVES SHALL BE SHORT PATTERN TYPE UPTO 12" AND VENTURI TYPE ABOVE 12" SIZE.

14 STEM INTEGRAL WITH PLUG IS ALSO ACCEPTABLE.

15 GLAND PACKING MATERIAL SHALL BE PROVIDED WITH CORROSION INHIBITOR.

SHEET REV. NO.

DATE

0

19/07/2010

55301

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag no.

: 55401

Location

: MUMBAI

Sheet No.

: 1 of 1

PLUG VALVE SPECIFICATION

: B1A

STANDARD

STANDARD

: BS - 5353

MFGRS CAT/FIG

ENDS

: FLGD,B - 16.5

RF / 125 AARH

RATING

ENDS

CONSTRUCTION

MATERIAL

TAG NO.

: 55401

PIPING CLASS

RATING

: 300

SIZE RANGE

: 0.5" TO 12"

DESCRIPTION

MANUF'S OFFER

BODY

FORGED / CAST

ASTM A 105 / ASTM A 216 GR.WCB

COVER

BOLTED

ASTM A 105 / ASTM A 216 GR.WCB

PLUG

INVERTED,TAPER

ASTM A 105 / A 216GR.WCB, CASE

HARDENED& BONDED WITH LOW

FRICTION COATING

CONSTRUCTION

MATERIAL

ASTM A 105 / A 216GR.WCB, CASE

HARDENED& BONDED WITH LOW

FRICTION COATING

STEM

GLAND

BOLTED

ASTM A 105 / ASTM A 216 GR.WCB

GLAND PACKING

RENEWABLE

GRAFOIL RINGS

LUBRICANT SCREW

WITH CHECK VALVES

SS 410/ A 105

COVER BOLTS

ASTM A 193 GR.B7

COVER NUTS

ASTM A 194 GR.2H

COVER GASKET

SP.WND. SS316L-GRAPHITE FILLER

LUBRICATED,PRESSURE

BALANCED

OTHERS

REQUIREMENT OF GEAR

OPERATOR

6" NB & LARGER

SPECIAL SERVICE

CONDITIONS

HYDROCARBON;MAX TEMP 250 DEG.C.

HYDROSTATIC TEST

PRESSURE

BODY : 1125 PSIG

TEST PRESSURE WITH

AIR

80 PSIG

SEAT : 825 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH JACOBS' SPEC, BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC IS ALLOWED.

PLUG VALVES IN ACCORADANCE WITH API-599 / API-6D ARE ALSO ACCETPTABLE.

FOR API 6D STD VALVES, MIN. BODY WALL THICKNESS SHALL BE AS PER API 599 / BS 5353.

TESTING SHALL BE AS PER BS 6755 (PART-I) / API 598 / API 6D.

FOR WRENCH OPERATED VALVES, SEPARATE WRENCH REQUIRED FOR EACH VALVE.

VALVE POSITION INDIACATOR SHALL BE PROVIDED.

VALVES SHALL BE FIRE-SAFE DESIGN AS PER BS 6755(PART-2)/API-607, 4TH EDITION/ API-6FA.

SIGNATURE

&

SEAL

OF MANUFACTURER

10 VENDOR SHALL CONFIRM SUITABILITY OF LUBRICANT WITH RESPECT TO SERVICE AND SERVICE CONDITIONS SPECIFIED .

11 BIDDER TO SUPPLY LUBRICANT FOR TWO YEARS OF NORMAL OPERATION.

12 STEM INTEGRAL WITH PLUG IS ALSO ACCEPTABLE.

13 20% VALVE CASTINGS SHALL UNDERGO RADIOGRAPHIC EXAMINATION.

14 UNLESS OTHERWISE SPECIFIED, VALVES SHALL BE SHORT PATTERN TYPE .

15 GLAND PACKING MATERIAL SHALL BE PROVIDED WITH CORROSION INHIBITOR.

SHEET REV. NO.

DATE

0

19/07/2010

55401

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag no.

: 56301

Location

: MUMBAI

Sheet No.

: 1 of 1

BUTTERFLY VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 56301

PIPING CLASS

: A1A, A10A

STANDARD

RATING

: 150

STANDARD

: BS - 5155

MFGRS CAT/FIG

SIZE RANGE

: 3" TO 24"

ENDS

: WAFL TO B-16.5 WAF/125AARH

RATING

ENDS

DESCRIPTION

CONSTRUCTION

MATERIAL

BODY

CAST

ASTM A 216 GR.WCB

DISC

CAST, TRIPLE

OFFSET

ASTM A 216 GR.WCB/ASTM A 351

GR.CF8M/ A351 GR.CF8/13% CR.STEEL

SHAFT

ANTI STATIC

17-4PH/A 479 XM19/13% CR.STEEL/

SS316/SS304(NO CASTING)

DISK SEAL

RPTFE

SHAFT BUSHING

PTFE/SS316

BODY SREWS / PIN

SS304/SS316

BODY SEATS

13% CR.STEEL/SS304/SS316/RPTFE(INBUILT)

SHAFT SEAL

PTFE+GRAFOIL/GRAFOIL

CLAMPING RINGS

(IF REQD.)

ASTM A 515 GR.70/SS316/SS304/13%

CR.STEEL

GASKET

SP.WND SS316+GRAFOIL FILLER

REQUIREMENT OF

GEAR OPERATOR

8" NB & LARGER

SPECIAL SERVICE

CONDITIONS

MAX TEMP 204 DEG C.

THRUST BEARING

SS 316

HYDROSTATIC TEST

PRESSURE

BODY : 450 PSIG

TEST PRESSURE WITH

AIR

80 PSIG

CONSTRUCTION

MATERIAL

SEAT : 325 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH VALVE SPEC, BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON VALVE SPEC IS ALLOWED.

4 VALVE CAN ALSO BE SUPPLIED IN ACCORDANCE WITH API 609, CATEGORY-B.

5 VALVE TESTING SHALL BE AS PER BS 5155/BS 6755(PART-I)/ API 598.

6 ALL VALVES SHALL BE FIRE SAFE DESIGN.FIRE SAFE TEST SHALL BE AS PER API 607/BS 6755(PART II) /API RP 6FA.

7

VALVES SHALL BE HIGH PERFORMANCE TYPE, TIGHT SHUT-OFF AND BI-DIRECTIONAL.

SIGNATURE

&

SEAL

OF MANUFACTURER

8 VALVE SHALL BE LUGGED WAFER TYPE(WAFL) AND VALVE ENDS TO SUIT B16.5 RF/125AARH.

9 FACE-TO-FACE DIMENSIONS SHALL BE AS PER WAFER SHORT/WAFER MEDIUM FOR BS-5155 VALVES AND AS

PER CATEGORY-B VALVES FOR API 609 VALVES.

10 5% VALVE CASTINGS SHALL UNDERGO RADIOGRAPHIC EXAMINATION.

11 DISC STRENGTH TEST SHALL BE CONDUCTED AS PER CODE.

12 VALVES SHALL BE SUITABLE FOR BOTH 'ON-OFF' AS WELL AS 'THROTTLING SERVICE' UNDER MAXIMUM DIFFERENTIAL PRESSURE FOR THE RATING

13 BOLTINGS FOR TAPPED HOLES IN BODY, IF ANY, SHALL BE SUPPLIED BY VENDOR IN MATERIAL ASTM A 193 GR.B7/A 194 GR.2H

14 VALVES SHALL BE PROVIDED WITH POSITION INDICATOR AND LOCKING DEVICE AT ANY POSITION.

15 CROSS-SECTIONAL DETAIL OF BODY SEAT/SEAL ARRANGEMENT SHALL BE SUBMITTED ALONG WITH THE OFFER

16 VENDOR SHALL SUBMIT VALVE DRAWING FOR APPROVAL

17 VALVE SHALL BE CERTIFIED SUITABLE FOR THE SERVICE AND SERVICE CONDITIONS SPECIFIED IN THE DATA SHEET FOR BUTTERFLY VALVES.

18 DISK SEALS SHALL BE PROVIDED FOR VALVES WITH METALLIC SEATS ONLY.

19 BIDDER TO FURNISH DISK SEAL/SOFT BODY SEAT DETAILS AND TYPE, GRADE & CLASS SELECTED FOR RPTFE FROM ASTM D4745 WITH

MANUFACTURER'S RECOMMENDATIONS LIKE PRESSURE-TEMPERATURE RATING CURVE/TABLE.

20 SHAFT SEAL MATERIAL(GRAFOIL) SHALL BE PROVIDED WITH CORROSION INHIBITOR.

SHEET REV. NO.

DATE

0

5/4/2010

56301

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag no.

: 56315

Location

: MUMBAI

Sheet No.

: 1 of 1

BUTTERFLY VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 56315

PIPING CLASS

: A1A, A10A

STANDARD

RATING

: 150

STANDARD

: BS - 5155

MFGRS CAT/FIG

SIZE RANGE

: 26" TO 48"

ENDS

: FLGD TO B-16.47 B RF/125AARH

RATING

ENDS

DESCRIPTION

CONSTRUCTION

MATERIAL

BODY

CAST

ASTM A 216 GR.WCB

DISC

CAST, TRIPLE

OFFSET

ASTM A 216 GR.WCB/ASTM A 351

GR.CF8M/ A351 GR.CF8/13% CR.STEEL

SHAFT

ANTI STATIC

17-4PH/A 479 XM19/13% CR.STEEL/

SS316/SS304(NO CASTING)

DISK SEAL

SS316/SS316+GRAPHITE

SHAFT BUSHING

PTFE/SS316

BODY SREWS / PIN

SS304/SS316

BODY SEATS

13% CR STEEL/SS304/SS316/STELLITED

SHAFT SEAL

PTFE+GRAFOIL/GRAFOIL

CLAMPING RINGS(IF

REQD.)

ASTM A 515 GR.70/SS316/SS304/13%

CR.STEEL

GASKET

SP.WND SS316+GRAFOIL FILLER

REQUIREMENT OF

GEAR OPERATOR

8" NB & LARGER

SPECIAL SERVICE

CONDITIONS

MAX TEMP 204 DEG C.

THRUST BEARING

SS 316

HYDROSTATIC TEST

PRESSURE

BODY : 450 PSIG

TEST PRESSURE WITH

AIR

80 PSIG

CONSTRUCTION

MATERIAL

SEAT : 325 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH JACOBS' SPEC, BIDDER SHALL INDICATE "AGREED".

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC IS ALLOWED.

4 VALVE TESTING SHALL BE AS PER BS 5155/BS 6755(PART-I).

SIGNATURE

&

SEAL

OF MANUFACTURER

5 ALL VALVES SHALL BE FIRE SAFE DESIGN.FIRE SAFE TEST SHALL BE AS PER API 607/BS 6755(PART II) /API RP 6FA.

6

VALVES SHALL BE HIGH PERFORMANCE TYPE, TIGHT SHUT-OFF AND BI-DIRECTIONAL.

7 VALVES SHALL BE DOUBLE FLANGED TYPE TO ASME B16.47B,RF/125AARH.

8 FACE-TO FACE DIMENSIONS SHALL BE AS PER BS 5155 SHORT PATTERN.

9 100% VALVE CASTINGS SHALL UNDERGO RADIOGRAPHIC EXAMINATION.

10 DISC STRENGTH TEST SHALL BE CONDUCTED AS PER CODE.

11 VALVES SHALL BE SUITABLE FOR BOTH 'ON-OFF' AS WELL AS 'THROTTLING SERVICE' UNDER MAXIMUM DIFFERENTIAL PRESSURE FOR THE RATING

12 BOLTINGS FOR TAPPED HOLES IN BODY, IF ANY, SHALL BE SUPPLIED BY VENDOR IN MATERIAL ASTM A 193 GR.B7/A 194 GR.2H

13 VALVES SHALL BE PROVIDED WITH POSITION INDICATOR AND LOCKING DEVICE AT ANY POSITION.

14 CROSS-SECTIONAL DETAIL OF BODY SEAT/SEAL ARRANGEMENT SHALL BE SUBMITTED ALONG WITH THE OFFER

15 VENDOR SHALL SUBMIT VALVE DRAWING FOR APPROVAL

16 VALVE SHALL BE CERTIFIED SUITABLE FOR THE SERVICE AND SERVICE CONDITIONS SPECIFIED IN THE DATA SHEET FOR BUTTERFLY VALVES.

17 SHAFT SEAL MATERIAL(GRAFOIL) SHALL BE PROVIDED WITH CORROSION INHIBITOR.

SHEET REV. NO.

DATE

0

19/07/2010

56315

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag No.

: 64001

Location

: MUMBAI

Sheet No.

: 1 of 1

PISTON VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 64001

PIPING CLASS

: A1A

STANDARD

RATING

: 800

STANDARD

: MNF' STD.

MFGRS CAT/FIG

SIZE RANGE

: 0.5" TO 1.5"

ENDS

: SW,3000#,B16.11

RATING

ENDS

DESCRIPTION

CONSTRUCTION

MATERIAL

BODY

FORGED

BONNET

BOLTED

ASTM A 105

STEM

RISING

13% CR. STEEL (NO CASTING)

MATERIAL

ASTM A 105

PISTON

13% CR. STEEL / 17% CR. STEEL /

SS304 / SS316

LANTERN BUSH/ SPACER

13% CR. STEEL

UPPER VALVE RING

RENEWABLE

REFER NOTE 5 BELOW

LOWER VALVE RING

RENEWABLE

REFER NOTE 5 BELOW

BELLEVILLE WASHER

50 CR. V4 / ASTM A240 GR. 302

HANDWHEEL

MALLEABLE IRON / CAST ST /

FAB. ST / DUCT. IRON

BONNET BOLTS

ASTM A 193 GR.B7

BONNET NUTS

ASTM A 194 GR.2H

OTHERS

CONSTRUCTION

NON-REGULATING

PISTON VALVE

STEAM/CONDENSATE; MAX. TEMP.

350C (AT 800# CLASS PRESSURE AS

PER API-602)

SPECIAL SERVICE

CONDITION

HYDROSTATIC TEST

PRESSURE

BODY: 2975 PSIG

TEST PRESSURE WITH

AIR

80 PSIG

SEAT: 2175 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC. IS ALLOWED.

TESTING SHALL BE AS PER IBR & BS - 6755 (PART-1) & LEAKAGE RATE SHALL BE CATEGORY 'A'.

VENDOR SHALL SPECIFY THE MATERIAL AND CERTIFY THE SUITABILITY OF MATERIAL SELECTED FOR SEALING

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH JACOBS' SPEC., BIDDER SHALL INDICATE "AGREED".

SIGNATURE

&

SEAL

OF MANUFACTURER

RINGS AND THE PARTS NOT MENTIONED IN THE SPECIFICATION SHEET FOR

A).

THE SERVICE AND PRESSURE - TEMP. CONDITIONS SPECIFIED.

B).

HIGH. TEMP. EXPERIENCED DURING WELDING OF SOCKET WELDED ENDS OF PIPE.

SHEET REV. NO.

DATE

0

19/07/2010

64001

VALVE MATERIAL SPECIFICATION

Client

: HINDUSTAN PETROLEUM CORP. LTD.

Project

: DHT

Tag No.

: 64301

Location

: MUMBAI

Sheet No.

: 1 of 1

PISTON VALVE SPECIFICATION

MANUF'S OFFER

TAG NO.

: 64301

PIPING CLASS

: A1A

STANDARD

RATING

: 150

STANDARD

: MNF' STD.

MFGRS CAT/FIG

SIZE RANGE

: 2" TO 8"

ENDS

: FLGD TO B 16.5

RF/125AARH

RATING

ENDS

DESCRIPTION

CONSTRUCTION

BODY

CAST

MATERIAL

BOLTED

ASTM A 216 GR.WCB

STEM

RISING

13% CR. STEEL (NO CASTING)

PISTON

13% CR. STEEL / 17% CR. STEEL /

SS304 / SS316

LANTERN BUSH/ SPACER

13% CR. STEEL

RENEWABLE

LOWER VALVE RING

RENEWABLE

MATERIAL

ASTM A 216 GR.WCB

BONNET

UPPER VALVE RING

CONSTRUCTION

REFER NOTE 5 BELOW

REFER NOTE 5 BELOW

BELLEVILLE WASHER

50 CR. V4 / ASTM A240 GR. 302

HANDWHEEL

MALLEABLE IRON / CAST ST /

FAB. ST / DUCT. IRON

BONNET BOLTS

ASTM A 193 GR.B7

BONNET NUTS

ASTM A 194 GR.2H

REQUIREMENT OF

RADIOGRAPHY

5% VALVE CASTINGS SHALL

UNDERGO RADIOGRAPHIC

EXAMINATION.

NON-REGULATING

PISTON VALVE

OTHERS

STEAM/CONDENSATE; MAX. TEMP.

350C (AT 150# CLASS PRESSURE AS

PER API-602)

SPECIAL SERVICE

CONDITION

HYDROSTATIC TEST

PRESSURE

BODY: 450 PSIG

TEST PRESSURE WITH

AIR

80 PSIG

SEAT: 325 PSIG

NOTES

1 THIS VALVE SPEC SHEET SHALL BE READ IN CONJUNCTION WITH TECHNICAL NOTES FOR VALVES.

2

BIDDER SHALL CLEARLY WRITE ALL / ANY DEVIATION AGAINST EACH PART/ MATERIAL OF VALVE IN THE

NO CUTTING / OVERWRITING BY BIDDER ON JACOBS' SPEC. IS ALLOWED.

TESTING SHALL BE AS PER IBR & BS - 6755 (PART-1) & LEAKAGE RATE SHALL BE CATEGORY 'A'.

VENDOR SHALL SPECIFY THE MATERIAL AND CERTIFY THE SUITABILITY OF MATERIAL SELECTED FOR SEALING

SPACE PROVIDED FOR. WHEREVER BIDDER AGREES WITH JACOBS' SPEC., BIDDER SHALL INDICATE "AGREED".

SIGNATURE

&

SEAL

OF MANUFACTURER

RINGS AND THE PARTS NOT MENTIONED IN THE SPECIFICATION SHEET FOR THE SERVICE AND PRESSURE - TEMP.

CONDITIONS SPECIFIED.

SHEET REV. NO.

DATE

0

19/07/2010

64301

You might also like

- 13.date Sheet For Gate ValveDocument2 pages13.date Sheet For Gate ValveMrinal Kanti BhaduriNo ratings yet

- 7a. Steel Pipeline FittingDocument37 pages7a. Steel Pipeline Fittingamaliabdulkader100% (1)

- Check ValveDocument1 pageCheck ValveRoshanKuckianNo ratings yet

- Technical Notes (General Specification) FOR Valves (Gate, Globe, Check, Ball, Plug, Needle, Butterfly & Piston Valves)Document30 pagesTechnical Notes (General Specification) FOR Valves (Gate, Globe, Check, Ball, Plug, Needle, Butterfly & Piston Valves)jayakumar100% (1)

- Ball Valve Data Sheet: Item Requirement NotesDocument1 pageBall Valve Data Sheet: Item Requirement NotesVivi OktaviantiNo ratings yet

- VDS (Valve Data Sheet)Document1 pageVDS (Valve Data Sheet)Shandi Hasnul Farizal0% (1)

- Rev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFDocument15 pagesRev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFNguyễnQuíTrọngNo ratings yet

- Manual Valves Datasheet. Rev 1Document7 pagesManual Valves Datasheet. Rev 1eke23No ratings yet

- Datasheet For Ball ValveDocument16 pagesDatasheet For Ball ValveDamu JankerboyNo ratings yet

- Valve DatasheetDocument9 pagesValve DatasheetArunkumarNo ratings yet

- Element Standard Manufacturing Method: Piping CommoditiesDocument8 pagesElement Standard Manufacturing Method: Piping CommoditiesKamalakannan AyyaduraiNo ratings yet

- P&Id Related: Sr. No. Check Points DoneDocument5 pagesP&Id Related: Sr. No. Check Points DoneSwapna Priya VattemNo ratings yet

- Valve DatasheetsDocument21 pagesValve DatasheetsArya Evan PerdanaNo ratings yet

- Datasheet For Gate ValveDocument2 pagesDatasheet For Gate ValveAlvin Smith67% (3)

- Pressure Test For Piping According To Asme B31.4Document13 pagesPressure Test For Piping According To Asme B31.4ahmed088394940% (1)

- Data Sheet For Globe ValveDocument4 pagesData Sheet For Globe ValveShaaban Noaman100% (1)

- Piping Material SpecificationDocument29 pagesPiping Material SpecificationSathiyaseelan Sakthi Shanmugam100% (2)

- Vector Techlok BrochureDocument34 pagesVector Techlok BrochureRobert Murray100% (2)

- Ball Valve Standard DesignDocument9 pagesBall Valve Standard DesignAbdullah Fahmi100% (1)

- Piping and Valve Specifications Rev. A PDFDocument28 pagesPiping and Valve Specifications Rev. A PDFYessine RebaiNo ratings yet

- PID Check ListDocument6 pagesPID Check ListArunachalam KaliyaperumalNo ratings yet

- Check List For Piping Material Take-OffDocument10 pagesCheck List For Piping Material Take-OffKyaw Kyaw AungNo ratings yet

- Control Valves Datasheet PDFDocument7 pagesControl Valves Datasheet PDFAlvin SmithNo ratings yet

- Material Requisition For Expansion Joint - Rev1Document4 pagesMaterial Requisition For Expansion Joint - Rev1altipatlarNo ratings yet

- Piping Wall Sizing and Thickness CalculationDocument16 pagesPiping Wall Sizing and Thickness CalculationAriNo ratings yet

- Piping Classes PDFDocument429 pagesPiping Classes PDFMichael Jordan100% (4)

- 500 SP PIP 018 Rev C (Check Valve)Document13 pages500 SP PIP 018 Rev C (Check Valve)anwar01No ratings yet

- Check List - Basic Engineering Package (BEP) Information Input/ ReviewDocument4 pagesCheck List - Basic Engineering Package (BEP) Information Input/ ReviewssgentisNo ratings yet

- Piping Material Specification Rev CDocument44 pagesPiping Material Specification Rev Cmengelito almonte100% (4)

- API 602 Forged Steel Gate, Globe & Check Valves (Vel-Sfv-Web) PDFDocument22 pagesAPI 602 Forged Steel Gate, Globe & Check Valves (Vel-Sfv-Web) PDFThomasFrenchNo ratings yet

- PMS PDFDocument215 pagesPMS PDFAlvin Smith100% (4)

- 6 44 0005 Rev5 PDFDocument439 pages6 44 0005 Rev5 PDFprasadNo ratings yet

- Piping Material SpecificationDocument36 pagesPiping Material Specificationravirawat15100% (2)

- Safety Relief Valve DatasheetDocument1 pageSafety Relief Valve Datasheetalmandhari330% (1)

- ASTM Grades in PipingDocument1 pageASTM Grades in PipingRajkumar ANo ratings yet

- BD100IX0012 - B1 TR For Multiphase FlowMeterDocument29 pagesBD100IX0012 - B1 TR For Multiphase FlowMetervamcodong100% (1)

- Pressure RELIEF VALVE DATA SHEETDocument4 pagesPressure RELIEF VALVE DATA SHEETAlvin SmithNo ratings yet

- Checklist For Piping Model and Equipment LayoutDocument1 pageChecklist For Piping Model and Equipment LayoutJorge Santos RomeroNo ratings yet

- P&ID of CCPDocument74 pagesP&ID of CCPNguyễnTrường80% (10)

- Piping SpecificationDocument77 pagesPiping SpecificationVignesh Panchabakesan67% (3)

- FS 2004D Rev.08Document26 pagesFS 2004D Rev.08Shakeel AhmedNo ratings yet

- Pressure Safety Valve DatasheetDocument1 pagePressure Safety Valve DatasheetAlvin Smith100% (5)

- Basic Type of ValvesDocument2 pagesBasic Type of ValvesbharathaninNo ratings yet

- P&ID Legend SymbolsDocument21 pagesP&ID Legend SymbolsVidhyananthan RamasamyNo ratings yet

- Valve SheetDocument23 pagesValve SheetAris KancilNo ratings yet

- Control ValvesDocument38 pagesControl ValvesSridhar GudapatiNo ratings yet

- Data Sheet Pressure Relief ValveDocument10 pagesData Sheet Pressure Relief ValveAnonymous UArnIExNo ratings yet

- Valve Data Sheet: BCXS302TDocument1 pageValve Data Sheet: BCXS302TRoo FaNo ratings yet

- Valve Material SpecsDocument112 pagesValve Material Specsjoseph.maquez24No ratings yet

- Piping ClassDocument881 pagesPiping ClassAvr Chandana100% (1)

- DatasheetDocument17 pagesDatasheetHimawan Sigit NugrohoNo ratings yet

- Equipment & Piping Progress ReportDocument2 pagesEquipment & Piping Progress Reportjayson_581669935100% (1)

- PipingDocument7 pagesPipingfarhanyazdaniNo ratings yet

- Technical Notes and Specifications Part CDocument29 pagesTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- PMS-V32-Ball Valves - FlangedDocument2 pagesPMS-V32-Ball Valves - FlangedMB Azharudeen100% (1)

- 1113 DWSDWSDDocument53 pages1113 DWSDWSDenjoygurujiNo ratings yet

- Valve Procurement SpecsDocument39 pagesValve Procurement Specsjoseph.maquez24100% (2)

- Hoja A-E0 Valves Specifications Size TAG Description: Gestión de Proyectos de InfraestructuraDocument1 pageHoja A-E0 Valves Specifications Size TAG Description: Gestión de Proyectos de InfraestructuraJOHNNY ROMERONo ratings yet

- Eil Piping Material SpecDocument48 pagesEil Piping Material Specnisargkedar60% (10)

- VB71 ValveDocument1 pageVB71 Valvescribd_thakurNo ratings yet

- ASPE Pool PDFDocument29 pagesASPE Pool PDFHany RifaatNo ratings yet

- Rectangular DuctsDocument23 pagesRectangular Ductszaldy1985100% (1)

- Basics of Fire Sprinkler Design KSDocument21 pagesBasics of Fire Sprinkler Design KSzaldy1985100% (1)

- Thermal WheelDocument32 pagesThermal Wheelzaldy1985No ratings yet

- Radiant Time SeriesDocument7 pagesRadiant Time Serieszaldy1985No ratings yet

- Inertial Filters: Delivering Specialised Engineering SolutionsDocument2 pagesInertial Filters: Delivering Specialised Engineering Solutionszaldy1985No ratings yet

- Basic Pump Station DesignDocument24 pagesBasic Pump Station Designzaldy1985No ratings yet

- Aeration Tank Plan DrawingDocument1 pageAeration Tank Plan Drawingzaldy1985No ratings yet

- Caesar II BrochureDocument3 pagesCaesar II Brochurezaldy1985No ratings yet

- Fastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Document3 pagesFastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Paul OnionsNo ratings yet

- Analysis of The Relationships Between Causes of Delay in Construction Projects in BangladeshDocument10 pagesAnalysis of The Relationships Between Causes of Delay in Construction Projects in Bangladeshtm7No ratings yet

- Graduation Project: (Strengthening Methods of Reinforced Concrete Columns)Document17 pagesGraduation Project: (Strengthening Methods of Reinforced Concrete Columns)Bashdar AzadNo ratings yet

- Wall Gain Load in Cold StorageDocument10 pagesWall Gain Load in Cold StorageTinay Padayao TigueNo ratings yet

- Lecture-Trenches GEN IDocument20 pagesLecture-Trenches GEN IjashndeepNo ratings yet

- 2.1) Control Cable 2.5mm SQ and 2.0 MM Screen Cable Are Being Connected Between Engine Panel and New Syn Control PanelDocument16 pages2.1) Control Cable 2.5mm SQ and 2.0 MM Screen Cable Are Being Connected Between Engine Panel and New Syn Control PanelRizky Wahyudha PutraNo ratings yet

- p400 BoltedDocument24 pagesp400 BoltedCIMARTEC TECNICOSNo ratings yet

- Fire Fighting Design and BasicsDocument22 pagesFire Fighting Design and Basicsmahesh86% (7)

- Technical Manual LU 8047 TMDocument6 pagesTechnical Manual LU 8047 TMArif ZuhairiNo ratings yet

- CPD 2023 Brochure v6Document43 pagesCPD 2023 Brochure v6Raja ShekarNo ratings yet

- 9812/0010 B4-6-1 Dipper (Stick) Extradig, 14'Document4 pages9812/0010 B4-6-1 Dipper (Stick) Extradig, 14'Виталий РогожинскийNo ratings yet

- Indian Highways: SEPTEMBER, 2020Document52 pagesIndian Highways: SEPTEMBER, 2020anitaramolaNo ratings yet

- It'S Built.: Trust Isn'T BoughtDocument33 pagesIt'S Built.: Trust Isn'T BoughtBogasi Q.No ratings yet

- 0901d196808e5f7c PDF Preview MediumDocument2 pages0901d196808e5f7c PDF Preview MediumSanjanNo ratings yet

- Civil Design Help Foundation For Machines PDFDocument4 pagesCivil Design Help Foundation For Machines PDFSheissNo ratings yet

- PR 1 Series Pressure Regulator Repair Kits 23297bDocument2 pagesPR 1 Series Pressure Regulator Repair Kits 23297bJames JansonNo ratings yet

- Ilovepdf Merged AllDocument47 pagesIlovepdf Merged AllAkash VakkayilNo ratings yet

- SBS Waterproofing ITP & ChecklistDocument27 pagesSBS Waterproofing ITP & Checklistlike saddamNo ratings yet

- Case StudyDocument69 pagesCase StudyBhadrecha AbhishekNo ratings yet

- Ahmedabad M CDocument47 pagesAhmedabad M CdhavanmehtaNo ratings yet

- Datasheet Polystone P CubX ENDocument1 pageDatasheet Polystone P CubX ENjavierNo ratings yet

- Architectural Record - Outubro 2014Document236 pagesArchitectural Record - Outubro 2014James WilsonNo ratings yet

- CHAPTER 2 p6-10Document144 pagesCHAPTER 2 p6-10Kirk Gwapo SilvaNo ratings yet

- IBR Book - FileDocument74 pagesIBR Book - FileSakthi VelNo ratings yet

- Project Completion ReportDocument363 pagesProject Completion ReportTony SinambelaNo ratings yet

- BILLS OF QUANTITIES STRUCTURE AND FINISHING H4 Anglais PDFDocument37 pagesBILLS OF QUANTITIES STRUCTURE AND FINISHING H4 Anglais PDFMohamed NashNo ratings yet

- K Ey Points To Be Checked in Architecture and Structural DrawingDocument12 pagesK Ey Points To Be Checked in Architecture and Structural DrawingSrinivasan RanganathanNo ratings yet

- 3-6 Stress Analysis, Sub Parkash, Fluor PDFDocument24 pages3-6 Stress Analysis, Sub Parkash, Fluor PDFMarlon TurnerNo ratings yet

- Iron AlloysDocument6 pagesIron AlloysHieu NguyenNo ratings yet

- Cont HSE Alignment Kickoff Meeting F0228Document2 pagesCont HSE Alignment Kickoff Meeting F0228NAGARJUNA75% (4)