Professional Documents

Culture Documents

RCTF Hot Tapping2

Uploaded by

muhammedemraanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCTF Hot Tapping2

Uploaded by

muhammedemraanCopyright:

Available Formats

Sequences of Hot Tapping Activities

Sequence

Activity No.

"Normal" Activity

SATIP

SAIC

Prepared by Onny

Inspection Level

Samsung Aramco

Report / Record

Standard/Code

NDE

Remarks

Material Receiving (Sticker (Spool-Branch for header)), Hot

Tap Valve, Gasket, Bolt, Reinforcing Pad, Plug)

SATIP-L-052-01

SAIC-L-2092

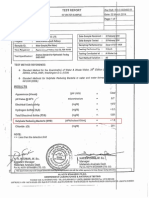

NDE REPORT

Radiography is required for sticker (pipe branch to flange) if

SAEP 311, PARA.

RT, MT

Sticker test Pressure is lower than piping system test Pressure

14.8.3

Pre-Installation Location Verification & NDE, Fitness for

Service Consideration, Acceptance of Exact Physical Location

and Sticker (Branch) Fit Up

SATIP-L-052-01

SAIC-L-2094

SATR-W-2006,

SAEP 311Appendix A1

SAEP 311, PARA.

5.4.3

UT

Sticker (Branch) Welding

Sticker (Branch) Visual Welding Inspection

SATIP-L-052-01

SAIC-W-2007

SATR-W-2007

MT / PT as applicable for Branch Connection

NDE REPORT

SAES-W-011

PARA. 17.5.3.1

MT/PT

Hot Tap Valve Installation (Flange Joint Inspection)

SATR-L-2001

Filling Test Fluid

Sticker (Branch) Pressure Testing

SATIP-L-052-01

SAIC-L-2095

SATR-A-2001 &

SATR-A-2001V

SAEP 311 PARA.

14.8

Hot Tap Valve "seat" Leak Testing

SATIP-L-052-01

SAIC-L-2095

SATR-A-2001 &

SATR-A-2001V

SAEP 311 PARA.

14.6.5

10

Hot Tap M/C Installation

11

+++ Final Hot Tap Assembly Pressure Testing

12

Release Test Fluid

13

Plug Installation (Fit Up)

14

Plug Installation (Welding)

15

Plug Installation (Visual Weld)

16

MT / PT as applicable (Plug & Reinforcing Pad - Header pipe)

17

Tapping Process

18

Inspect Cut Coupon

19

Gate Valve Full Close

To Isolated the running service

20

Hot Tap M/C Removal - End

By Approved subcont

21

Reinforcing Pad Installation (Fit Up)

22

Reinforcing Pad (Welding)

23

Reinforcing Pad (Visual Weld)

24

MT / PT as applicable (Plug & Reinforcing Pad - Header pipe)

SATIP-L-052-01/

SATIP-NDE-MPT- SAIC-MPT-2004

01

SATIP-L-052-01

SAIC-L-2014

Date UT readings taken, must be completed within 90 days of the

hot tap. As per SAEP 311 PARA. Appendix 2 - item 3.4

Gasket verification and bolt tightening

Normal Temperature = Water,

93 deg C to 290 deg C ==> Turbine Oil,

290 deg C to 310 deg C ==> Sillicone Fluid 200,

More Than 310 deg C Not Allowed

Header + Sticker

(The test pressure of the branch connection shall comply with

SAES-L-150 requirements and shall not exceed the maximum

pressure per Table-2 below Hot Connection Pressure Test

Formulas)

Header + Sticker + Hot Tap Valve

(The test pressure shall be the expected line pressure during hot

tapping plus 10%.)

SAEP 311 PARA.

14.3

By Approved subcont

SATIP-L-052-01

SAIC-L-2095

SATR-A-2001 &

SATR-A-2001V

SATIP-L-052-01

SAIC-W-2005

SATR-W-2006

SATIP-L-052-01

SAIC-W-2007

SATR-W-2007

NDE REPORT

SATIP-L-052-01/

SATIP-NDE-MPT- SAIC-MPT-2004

01

Header + Sticker + Hot Tap Valve (full open) + Hot Tap Machine

(The test pressure shall be the expected line pressure during hot

tapping plus 10%)

SAEP 311 PARA.

14.9

SAEP 311 PARA.

14.9.2

SAEP 311 PARA.

14.9.2

SAEP 311 PARA.

14.9.2

SAES-W-011

PARA. 17.5.3.2

MT/PT

By Approved subcont

SATIP-L-052-01

SAIC-L-2096

Check List

SATIP-L-052-01

SAIC-W-2005

SATR-W-2006

SATIP-L-052-01

SAIC-W-2007

SATR-W-2007

NDE REPORT

SATIP-L-052-01/

SATIP-NDE-MPT- SAIC-MPT-2004

01

SAES-W-011

PARA. 17.5.3.2

MT/PT

You might also like

- Piping Manifold - Scan Copy (A3 Size)Document4 pagesPiping Manifold - Scan Copy (A3 Size)muhammedemraanNo ratings yet

- Hempel's Epoxy Knifing Filler - DatasheetDocument2 pagesHempel's Epoxy Knifing Filler - Datasheetmuhammedemraan100% (2)

- 9404 For Drains Less Then 610 MM ClearanceDocument9 pages9404 For Drains Less Then 610 MM ClearancemuhammedemraanNo ratings yet

- UT Thickness Report - IMP For Tie-InDocument4 pagesUT Thickness Report - IMP For Tie-InmuhammedemraanNo ratings yet

- Dimensions of Structural SteelDocument4 pagesDimensions of Structural SteelmuhammedemraanNo ratings yet

- Method Statement For Indoor Auto BlastingDocument25 pagesMethod Statement For Indoor Auto BlastingmuhammedemraanNo ratings yet

- Old CertiDocument1 pageOld CertimuhammedemraanNo ratings yet

- PMI Check ValveDocument1 pagePMI Check ValvemuhammedemraanNo ratings yet

- NCR AG I 055 With Vendors ReplyDocument12 pagesNCR AG I 055 With Vendors ReplymuhammedemraanNo ratings yet

- Hempel's Epoxy Knifing Filler - DatasheetDocument2 pagesHempel's Epoxy Knifing Filler - Datasheetmuhammedemraan100% (2)

- Cross Reference of Astm Material Specifications Covering Cast and Equivalent Forged ValvesDocument1 pageCross Reference of Astm Material Specifications Covering Cast and Equivalent Forged ValvesmuhammedemraanNo ratings yet

- Saudi Council of Engineers MannulDocument22 pagesSaudi Council of Engineers MannulMohammed Irfan50% (2)

- Couplers and PlugsDocument8 pagesCouplers and PlugsmuhammedemraanNo ratings yet

- Piping Color Code Chart PDFDocument3 pagesPiping Color Code Chart PDFmuhammedemraan67% (6)

- Rfi FormDocument2 pagesRfi Formmuhammedemraan0% (1)

- Piping Color Code Chart PDFDocument3 pagesPiping Color Code Chart PDFmuhammedemraan67% (6)

- CSWIP 3.1 PracticalDocument4 pagesCSWIP 3.1 PracticalDevendran Marappan91% (11)

- Abrasive TypesDocument2 pagesAbrasive TypesmuhammedemraanNo ratings yet

- Galvanized FlangesDocument1 pageGalvanized FlangesmuhammedemraanNo ratings yet

- Cement Line PrecautionsDocument1 pageCement Line PrecautionsmuhammedemraanNo ratings yet

- Water AnalysisDocument1 pageWater AnalysismuhammedemraanNo ratings yet

- Rovver 900Document2 pagesRovver 900muhammedemraanNo ratings yet

- Rovver600 0805Document2 pagesRovver600 0805muhammedemraanNo ratings yet

- 455 Wrappingband CHZ 100 FCDocument2 pages455 Wrappingband CHZ 100 FCmuhammedemraanNo ratings yet

- 455 Wrappingband CHZ 100 FCDocument2 pages455 Wrappingband CHZ 100 FCmuhammedemraanNo ratings yet

- Fiberstrong Wavistrong Flange GuideDocument52 pagesFiberstrong Wavistrong Flange Guidemuhammedemraan100% (1)

- BlindFlangeThicknessCalc 20120108Document1 pageBlindFlangeThicknessCalc 20120108muhammedemraanNo ratings yet

- Weld DefectsDocument78 pagesWeld DefectsjobsjamesNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mathematics: Full Marks Zero Marks: 0 in All Other CasesDocument31 pagesMathematics: Full Marks Zero Marks: 0 in All Other CasesAbhishek KumarNo ratings yet

- Captain Marvel (DC Comics) : Shazam! Navigation SearchDocument34 pagesCaptain Marvel (DC Comics) : Shazam! Navigation SearchAce Orense Cupid Uranus Ace Sphinx Galzu Acetr444 son of Multiverses Chaos Gaeia Eros ACETR444No ratings yet

- Tests On Cement: IS: 4031 Part 4 1988 (Indian Standards)Document1 pageTests On Cement: IS: 4031 Part 4 1988 (Indian Standards)Lorna BacligNo ratings yet

- Serospin Operating Manual 20100407Document19 pagesSerospin Operating Manual 20100407Verdana50% (2)

- CH 01Document24 pagesCH 01Gabriel FlorêncioNo ratings yet

- PHD Call - TCD - Micha Ruhl - PHD Project Short DescriptionDocument2 pagesPHD Call - TCD - Micha Ruhl - PHD Project Short DescriptionabuzarNo ratings yet

- June 2023 BillingDocument10 pagesJune 2023 BillingEsther AkpanNo ratings yet

- Doctors Appointment - 4!14!17 Acid RefluxDocument11 pagesDoctors Appointment - 4!14!17 Acid RefluxRay Edwin Anderson IIINo ratings yet

- Sap MRP ConfigDocument23 pagesSap MRP Configsharadapurv100% (1)

- AbstractsDocument224 pagesAbstractsFrankmerced Emerzon Farfan HuancaNo ratings yet

- Assignment 1 Systems Analysis - EME5601Document7 pagesAssignment 1 Systems Analysis - EME5601Travis GrantNo ratings yet

- Therapeutic Drug Monitoring GuideDocument12 pagesTherapeutic Drug Monitoring GuidePromise NcubeNo ratings yet

- PV Elite ResultDocument18 pagesPV Elite ResultVeny MartianiNo ratings yet

- Sektion Installation Guide Fy21 Web ADocument16 pagesSektion Installation Guide Fy21 Web AmroliverridleyNo ratings yet

- Toxicology Compendium PDFDocument602 pagesToxicology Compendium PDFJUANNo ratings yet

- Yara Crop Nutrition For HorticultureDocument8 pagesYara Crop Nutrition For HorticultureadjieNo ratings yet

- Water Demand Fire Flow Calculation Hydraulic ModelingDocument110 pagesWater Demand Fire Flow Calculation Hydraulic ModelingArthur DeiparineNo ratings yet

- Connorized Classical CatalogDocument37 pagesConnorized Classical CatalogPablo Olea RodríguezNo ratings yet

- Kerr Injection WaxesDocument1 pageKerr Injection WaxesmarosnaxNo ratings yet

- RenderingDocument6 pagesRenderingJuno PajelNo ratings yet

- The Evolution of Order DiprotodontiaDocument35 pagesThe Evolution of Order DiprotodontiaMarianne Michelle Quiambao de la RosaNo ratings yet

- SynopsisDocument13 pagesSynopsisharivijay ranmaleNo ratings yet

- PLOTINUS: On Beauty (Essay On The Beautiful)Document12 pagesPLOTINUS: On Beauty (Essay On The Beautiful)Frederic LecutNo ratings yet

- Plant Seedling Classification Using CNNDocument12 pagesPlant Seedling Classification Using CNNYugal Joshi0% (1)

- BS en 10108-2004Document14 pagesBS en 10108-2004Martijn GrootNo ratings yet

- Fischer Carbene Complexes in Organic SynthesisDocument9 pagesFischer Carbene Complexes in Organic SynthesisNorah AltayyarNo ratings yet

- CHM4943 Wastewater TreatmentDocument7 pagesCHM4943 Wastewater TreatmentUsman GhaniNo ratings yet

- Data Sheet 2.07 Issue A: Water Flow Detector Model: WFDENDocument2 pagesData Sheet 2.07 Issue A: Water Flow Detector Model: WFDENOvidiu GavrilasNo ratings yet

- 1 5109354204116287644 PDFDocument336 pages1 5109354204116287644 PDFGerardoNo ratings yet