Professional Documents

Culture Documents

gx160 Honda

Uploaded by

matt1985200967%(3)67% found this document useful (3 votes)

7K views1 pageCYLINDER HEAD valve GUIDE (2) VALVE SPRING (2) INTAKE VALVE PUSH ROD (2) REASSEMBLY: Check both ends for wear, and check the rod for straightness. DO not remove the VALVE SPRING retainers while the CYLINDER HEAD is installed, or the valves will drop into the cylinder.

Original Description:

Original Title

gx160 honda

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCYLINDER HEAD valve GUIDE (2) VALVE SPRING (2) INTAKE VALVE PUSH ROD (2) REASSEMBLY: Check both ends for wear, and check the rod for straightness. DO not remove the VALVE SPRING retainers while the CYLINDER HEAD is installed, or the valves will drop into the cylinder.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

67%(3)67% found this document useful (3 votes)

7K views1 pagegx160 Honda

Uploaded by

matt19852009CYLINDER HEAD valve GUIDE (2) VALVE SPRING (2) INTAKE VALVE PUSH ROD (2) REASSEMBLY: Check both ends for wear, and check the rod for straightness. DO not remove the VALVE SPRING retainers while the CYLINDER HEAD is installed, or the valves will drop into the cylinder.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

GX120 ·GX160 ·GX200 Engine Assembly Information

PISTON CYLINDER HEAD/VALVES

GX120/GX160: VALVE SPRING RETAINER EXHAUST VALVE

PISTON RING MARKING

DISASSEMBLY: REASSEMBLY:

REASSEMBLY: Push down and slide the retainer to the side, so the valve ・Before installation, remove carbon deposits

TOP RING (CHROME FACED)

· Install all rings with the markings facing upward. stem slips through the hole at the side of the retainer. and inspect the valve.

· Be sure that the top and second rings are not interchanged. SECOND RING (BLACK FACED) REASSEMBLY: ・Do not interchange with the intake valve.

· Check that the rings rotate smoothly after installation. The exhaust valve retainer has a larger center recess than VALVE HEAD DIAMETER

· Space the piston ring end gaps 120 degrees apart, and OIL RING (COMBINATION RINGS)

the intake valve retainer so it can accept the valve rotator. GX120: IN: 22 mm (0.87 in)

do not align the gaps with the piston pin bore. PISTON PISTON PIN CLIP NOTICE: EX: 19 mm (0.75 in)

· Space the oil ring side rail end gaps at least 10 mm (0.4 in) REASSEMBLY: Do not remove the valve spring retainers while the cylinder GX160: IN: 25 mm (0.98 in)

apart. Coat the oil ring with oil after assembly. Install by setting one end of the clip in

PISTON PIN head is installed, or the valves will drop into the cylinder. EX: 24 mm (0.94 in)

the piston groove, holding the other

end with long-nosed pliers, and CYLINDER HEAD

TOP RING VALVE ROTATOR (Exhaust valve only)

CONNECTING rotating the clip in. VALVE GUIDE (2)

(CHROME FACED) NOTICE:

ROD Do not align the end gap of the clip

SECOND RING If the valve rotator is not installed, the VALVE SPRING (2) INTAKE VALVE

REASSEMBLY: Install the with the cutout in the piston pin bore.

(BLACK FACED) exhaust valve may drop into the cylinder PUSH ROD (2)

connecting rod with the CLIP

when starting the engine. REASSEMBLY:

OIL RING long end toward the

triangle-marked side of Check both ends for wear,

(COMBINATION RINGS) ROCKER ARM PIVOT (2)

CUT-OUT and check the rod for

the piston.

ROCKER ARM straightness.

PIVOT LOCK NUT (2) Be sure the rod ends are

10 N·m (1.0 kgf·m, 7 lbf·ft) firmly seated in the lifters.

CRANKCASE COVER/CRANKSHAFT/PISTON

PISTON ROCKER ARM PIVOT BOLT (2) 24 N·m (2.4 kgf·m, 17 lbf·ft)

VALVE LIFTER CAMSHAFT

REASSEMBLY: ROCKER ARM (2)

REASSEMBLY: REASSEMBLY:

Install with the GX200: Refer to the above for information not shown below.

Install the lifters ・With the crankshaft in place, align the REASSEMBLY:

triangle mark Before installing, check for wear on the surfaces which contact VALVE STEM SEAL (Intake valve only)

immediately before timing punch mark on the cam gear with

toward the the pivot bolt, the push rod, and the rocker arm pivot.

installing the camshaft. the punch mark on the crankshaft gear. Replace with a new one

pushrod hole. ・Before installing, inspect for worn and when reassembling.

TRIANGLE MARK weakened springs and check that the

decompressor weight moves smoothly. INTAKE VALVE

PUSH ROD HOLE

REASSEMBLY:

OIL SEAL 22 x 35 x 6 mm (GX120) · Do not interchange with the exhaust valve.

25 x 41 x 6 mm Valve head diameter: Intake: 25 mm (0.98 in) Exhaust: 24 mm (0.94 in)

(GX160/GX200) · Be careful not to damage the valve stem seal when installing.

GOVERNOR DRIVE

GEAR PUNCH MARKS

PUNCH MARKS CYLINDER HEAD GOVERNOR

CRANKCASE

6 x 28 (GX120)

COVER 8 x 55 (4) (GX120), 8 x 60 (4) (GX160/GX200)

12 N·m (1.2 kgf·m, 9 lbf·ft) GOVERNOR WEIGHT GOVERNOR SLIDER WASHER

GASKET 24 N·m (2.4 kgf·m, 17 lbf·ft)

8 x 32 (GX160/GX200) GASKET REASSEMBLY: Be sure REASSEMBLY:

GREAS Do not reuse. REMOVAL/INSTALLATION: WASHER (2)

24 N·m (2.4 kgf·m, 17 lbf·ft) Do not reuse. to install the governor Install inside

Loosen and tighten the weight before installing

OIL SEAL the case.

bolts in a crisscross pattern the crankshaft.

CRANKCASE 22 x 41 x 6 mm (GX120) in 2-3 steps.

25 x 41 x 6 mm (GX160/GX200) LOCK PIN

CLIP GOVERNOR REASSEMBLY:

OIL DRAIN

REASSEMBLY: ARM SHAFT The lock pin must be

BOLT

Insert firmly installed with the

18 N·m

into the shaft straight side of the pin

(1.8 kgf·m,

groove. against the groove in

13 lbf·ft)

BALL the shaft.

DRAIN BOLT WASHER BEARING DOWEL PINS

6 x 12 (2)

Replace. TIMING GEAR CYLINDER BARREL 10 mm NUT

CONNECTING ROD BOLT CYLINDER HEAD

12 N·m (1.2 kgf·m, 9 lbf·ft) CRANKSHAFT REMOVAL/INSTALLATION: Green ( To side plate)

CONNECTING ROD CAP REASSEMBLY: · Before installation, remove any carbon deposits

OIL LEVEL SWITCH

REASSEMBLY: from the combustion chamber and inspect the Yellow ( To engine switch) O-RING

Push in until the bearing touches GREAS

Install with the oil dipper toward the camshaft and the the crankcase. Be careful not to valve seats.

· Measure the cylinder compression after reassembly. REASSEMBLY: Install firmly in the groove.

ribs on the cap and connecting rod are aligned. damage the oil seal. CRANKCASE COVER

See the shop manual for additional information. © Honda Motor Co., Ltd. 2009

You might also like

- GX120 160 200 UT2 English PDFDocument61 pagesGX120 160 200 UT2 English PDFRazielboy Kain100% (1)

- Honda Gx120 Gx160Document45 pagesHonda Gx120 Gx160Miguel OrtizNo ratings yet

- GX200 Engine Carb DiagramDocument1 pageGX200 Engine Carb Diagramflex78No ratings yet

- Honda GX120G 160G 200 PDFDocument1 pageHonda GX120G 160G 200 PDFClejeanu MihaelaNo ratings yet

- Owner's Manual Kohler CH25-CH730 enDocument20 pagesOwner's Manual Kohler CH25-CH730 enBruno MarianoNo ratings yet

- ZAMA Carburetor ServiceDocument5 pagesZAMA Carburetor ServiceJEF GRAY100% (1)

- 1970-1973 Ski-Doo Technical ManualDocument88 pages1970-1973 Ski-Doo Technical ManualRotax_KidNo ratings yet

- Walbro & Tillotson CarburetorsDocument12 pagesWalbro & Tillotson CarburetorsjeillingNo ratings yet

- Honda GC160, GC190, GS190 Service ManualDocument86 pagesHonda GC160, GC190, GS190 Service Manualcfi2834657100% (3)

- Engine Tools 03Document74 pagesEngine Tools 03abduallah muhammadNo ratings yet

- Gx160 Parts ManualDocument11 pagesGx160 Parts Manualabelmonte_geotecniaNo ratings yet

- 2065 01 fd680vDocument162 pages2065 01 fd680vSteve MarshNo ratings yet

- Zama 2011 Service ManualDocument170 pagesZama 2011 Service ManualHans Hansen100% (1)

- GX Service ManualDocument26 pagesGX Service Manualyamyrules100% (1)

- Honda TRX 200 OwnersDocument78 pagesHonda TRX 200 Ownersfourjaxson100% (1)

- Heavy Duty E Ngine&: Instruction B Ook and Parts ListDocument44 pagesHeavy Duty E Ngine&: Instruction B Ook and Parts ListRich SchneiderNo ratings yet

- 2005 Skidoo Operator's ManualDocument283 pages2005 Skidoo Operator's ManualMary Annie0% (2)

- Top End Install GY6Document28 pagesTop End Install GY6a10526268100% (3)

- Zama Carburetor Tech Guide, 2 CycleDocument16 pagesZama Carburetor Tech Guide, 2 Cyclejteam100% (4)

- Gx160ut1, RT1, Ut2, RT214Z4M603 PDFDocument167 pagesGx160ut1, RT1, Ut2, RT214Z4M603 PDFLupin GonzalezNo ratings yet

- Kubota GR2020G - GR2120 - GR2120AU Lawn and Garden Tractor Operators ManualDocument100 pagesKubota GR2020G - GR2120 - GR2120AU Lawn and Garden Tractor Operators ManualСвятослав ВороновNo ratings yet

- HusqvarnaDocument50 pagesHusqvarnanikolaos12a100% (1)

- Ford 6.9 and 7.3 IDI Diesel Stall After Starting Troubleshooting HelpDocument2 pagesFord 6.9 and 7.3 IDI Diesel Stall After Starting Troubleshooting Helpcrawdoogie100% (1)

- Honda Goldwing gl1100 1980 To 1982 Honda Parts Manual PDFDocument195 pagesHonda Goldwing gl1100 1980 To 1982 Honda Parts Manual PDFnuno araujoNo ratings yet

- Fuel Injection Pump - Install - Type 2 Engines and 7BJ EnginesDocument4 pagesFuel Injection Pump - Install - Type 2 Engines and 7BJ EnginesDaniel AndradeNo ratings yet

- Troubleshooting and RepairDocument12 pagesTroubleshooting and Repairsorintatar100% (1)

- Ym 155 DDocument159 pagesYm 155 DFranciscoJavierChamizoMartinNo ratings yet

- Whitfield Traditions Pellet Stove ManualDocument40 pagesWhitfield Traditions Pellet Stove ManualMr. MorganNo ratings yet

- Husqvarna 136Document7 pagesHusqvarna 136Paul CristeaNo ratings yet

- Service Manual for 150cc Product 6150/7150/200 Series /TITLEDocument82 pagesService Manual for 150cc Product 6150/7150/200 Series /TITLEbgarvosNo ratings yet

- SDW225SS Rev 2 ManualDocument146 pagesSDW225SS Rev 2 ManualZeck0% (1)

- Ford 601 & 801 Series Tractors - Owner's Manual - 1957Document68 pagesFord 601 & 801 Series Tractors - Owner's Manual - 1957Francisco Javier MoraNo ratings yet

- Ms660 Parts ListDocument46 pagesMs660 Parts ListVladut MariusNo ratings yet

- KZ750 Carb GuideDocument15 pagesKZ750 Carb GuideMats MehisNo ratings yet

- Gy6 Big Bore Kit and Top End Rebuild GuideDocument28 pagesGy6 Big Bore Kit and Top End Rebuild GuideDodea Nicu100% (1)

- Kohler CH26 Service ManualDocument218 pagesKohler CH26 Service Manualjaken202100% (2)

- MSD PowersportsDocument72 pagesMSD PowersportsMaria Andrews0% (1)

- Preview Only: 2.4L and 3.0L Diesel EnginesDocument5 pagesPreview Only: 2.4L and 3.0L Diesel Enginesjim50% (2)

- Kohler Comand PRO CV940 - CV1000 Service ManualDocument72 pagesKohler Comand PRO CV940 - CV1000 Service Manualabduallah muhammadNo ratings yet

- Briggs & Stratton Vanguard Twin Cylinder OHV Liquid Cooled PDFDocument85 pagesBriggs & Stratton Vanguard Twin Cylinder OHV Liquid Cooled PDFJabin Hayward100% (1)

- Bobcat 225 MillerDocument80 pagesBobcat 225 MillerAngel Alberto Franco KukNo ratings yet

- King Quad 700 Tips 101 Ver 1.2Document36 pagesKing Quad 700 Tips 101 Ver 1.2Andy House100% (1)

- Vstar 1100jettingDocument14 pagesVstar 1100jettingCarlos Niebla100% (2)

- Carbu Rad orDocument3 pagesCarbu Rad orDaniel Hernandez MendietaNo ratings yet

- Combat Heavy Equipment TheftDocument36 pagesCombat Heavy Equipment TheftLU YONo ratings yet

- Honda Gx160 5.5 HP Quick RefDocument2 pagesHonda Gx160 5.5 HP Quick RefNivedanSahayNo ratings yet

- Kohler CH20-servicemanualDocument218 pagesKohler CH20-servicemanualLuis Eduardo Corzo Enriquez100% (1)

- Stihl 211 Chainsaw ManualDocument60 pagesStihl 211 Chainsaw ManualwaltoiNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualFrom EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualRating: 4.5 out of 5 stars4.5/5 (2)

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- New Hemi Engine Swaps: How to Swap 5.7L, 6.1L, 6.4L & Hellcat Engines into Almost Anything: How to Swap 5.7L, 6.1L, 6.4L & Hellcat Engines into Almost AnythingFrom EverandNew Hemi Engine Swaps: How to Swap 5.7L, 6.1L, 6.4L & Hellcat Engines into Almost Anything: How to Swap 5.7L, 6.1L, 6.4L & Hellcat Engines into Almost AnythingNo ratings yet

- Hemi Under Glass: Bob Riggle and His Wheel-Standing Mopars: Bob Riggle and His Wheel-Standing MoparsFrom EverandHemi Under Glass: Bob Riggle and His Wheel-Standing Mopars: Bob Riggle and His Wheel-Standing MoparsNo ratings yet

- Donny's Unauthorized Technical Guide to Harley Davidson 1936 to Present: Volume Ii: Performancing the Twin CamFrom EverandDonny's Unauthorized Technical Guide to Harley Davidson 1936 to Present: Volume Ii: Performancing the Twin CamNo ratings yet

- Weight Calcs U Uu JJDocument1 pageWeight Calcs U Uu JJjasekanNo ratings yet

- WSM - Maintenance Instruction Part - 1 Truk - en PDFDocument120 pagesWSM - Maintenance Instruction Part - 1 Truk - en PDFDul AdulNo ratings yet

- Imarest Article1Document2 pagesImarest Article1Satyabrat GaanNo ratings yet

- Gear Group (Front) - Remove: Desarmado y ArmadoDocument3 pagesGear Group (Front) - Remove: Desarmado y ArmadoJulio MezaNo ratings yet

- Pre Training AssignmentDocument38 pagesPre Training AssignmentBdje doeNo ratings yet

- June2023 INCAL DVD CoverLetter Rev2Document4 pagesJune2023 INCAL DVD CoverLetter Rev2АслагNo ratings yet

- Bearings & Deflections - 1Document41 pagesBearings & Deflections - 1Glen MacNo ratings yet

- BBPP MPV BMTI/Automotive Reskilling & Upskilling 2020Document10 pagesBBPP MPV BMTI/Automotive Reskilling & Upskilling 2020KaiZen PuTra MiddleNo ratings yet

- Variable Valve Timing and Lifting Technologies in Different Automobiles CompaniesDocument5 pagesVariable Valve Timing and Lifting Technologies in Different Automobiles CompaniesAwais AnwarNo ratings yet

- Weber Carb Buyers GuideDocument2 pagesWeber Carb Buyers Guideclaudio_sorianoNo ratings yet

- TECH-COM 2004-3 NEF EngineDocument44 pagesTECH-COM 2004-3 NEF EngineDmytro PichkurNo ratings yet

- MF 3854 WDDocument96 pagesMF 3854 WDRizwanAli100% (1)

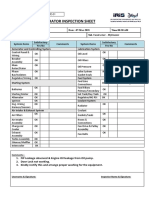

- Generator inspection sheet JE-01Document2 pagesGenerator inspection sheet JE-01rohit tiwariNo ratings yet

- Amal Concentric HintsDocument8 pagesAmal Concentric HintsJohn NeweyNo ratings yet

- Upgrading of Camshaft: Improved Performance For Old WÄRTSILÄ Vasa 32 Diesel EnginesDocument2 pagesUpgrading of Camshaft: Improved Performance For Old WÄRTSILÄ Vasa 32 Diesel EnginesAlexanderNo ratings yet

- Isuzu c240pkjDocument7 pagesIsuzu c240pkjPGAstockNo ratings yet

- PMM WordDocument3 pagesPMM WordShrey R DhanawadkarNo ratings yet

- Weber CarburettorsDocument81 pagesWeber Carburettorsyiannisplymouth100% (2)

- 1990 2004.yamaha - Yfm350x.warrior - Factory.service - ManualDocument3 pages1990 2004.yamaha - Yfm350x.warrior - Factory.service - ManualBobbi Jo Bach-Oachs50% (2)

- Catalog E90320si S2000Document121 pagesCatalog E90320si S2000blancohccNo ratings yet

- Reciprocating Compressors IMPDocument21 pagesReciprocating Compressors IMPrutujaNo ratings yet

- Honda GD1250 Diesel Engine SpecsDocument4 pagesHonda GD1250 Diesel Engine SpecsWidi PrasetyoNo ratings yet

- Energy Conversion and Management: Baowei Fan, Jianfeng Pan, Wenming Yang, Yangxian Liu, Stephen Bani, Wei ChenDocument13 pagesEnergy Conversion and Management: Baowei Fan, Jianfeng Pan, Wenming Yang, Yangxian Liu, Stephen Bani, Wei ChenÖmer Faruk AkçilNo ratings yet

- 2015 N13 Engine Diagnostic ManualDocument2,583 pages2015 N13 Engine Diagnostic ManualJonathan Luiz PolezaNo ratings yet

- X - Lubricación en Motores PequeñosDocument39 pagesX - Lubricación en Motores PequeñosRay Cepeda MenaNo ratings yet

- DTC Diagnostic Trouble Code GuideDocument13 pagesDTC Diagnostic Trouble Code GuideantonioNo ratings yet

- En (STI) (Diag) Engine (Diagnostics)Document386 pagesEn (STI) (Diag) Engine (Diagnostics)George IordacheNo ratings yet

- 7 Overhaul Protocol COP 1240 1640 1840 2540 LR-ForMDocument2 pages7 Overhaul Protocol COP 1240 1640 1840 2540 LR-ForMChachou MohamedNo ratings yet

- RPM RWHP RWTQ FWHP FWTQ FW Ve Green Field Yellow Runner CFM Intake CFM Piston SpeedDocument31 pagesRPM RWHP RWTQ FWHP FWTQ FW Ve Green Field Yellow Runner CFM Intake CFM Piston SpeedSmoking Wheels100% (7)

- Gas Gas 125 Racing 2013-PartsDocument72 pagesGas Gas 125 Racing 2013-Partsnissim halfonNo ratings yet